A kind of aluminum nitride ceramic copper-clad substrate and preparation method thereof

A technology of aluminum nitride ceramics and copper clad substrates, applied in the field of aluminum nitride ceramic metallization, can solve the problems of the surface aluminum oxide film is not dense, the gas cannot be discharged, the contact area between the copper layer and the ceramic layer becomes smaller, etc. Strength boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] According to the second aspect of the present disclosure, the preparation method may further include a pretreatment process before step S1, and the pretreatment process includes: the aluminum nitride ceramic substrate may be subjected to ultrasonic cleaning, alkaline solution cleaning, alcohol cleaning, Wash and dry. Ultrasonic cleaning can be carried out in medium water, the alkaline solution can be sodium hydroxide solution, and the acidic solution can be sulfuric acid solution. The condition of described pretreatment can be: deionized water ultrasonic cleaning time is 2-10min, the concentration of the NaOH solution used when alkaline solution cleaning is 5-20% by weight, cleaning time is 5-60min, the concentration of alcohol is 30-95% by volume, the cleaning time is 5-60min, and the drying can be dried with hot air at a temperature of 30-70°C.

[0063] According to the second aspect of the present disclosure, the magnetron sputtering in step S1 includes vacuuming, a...

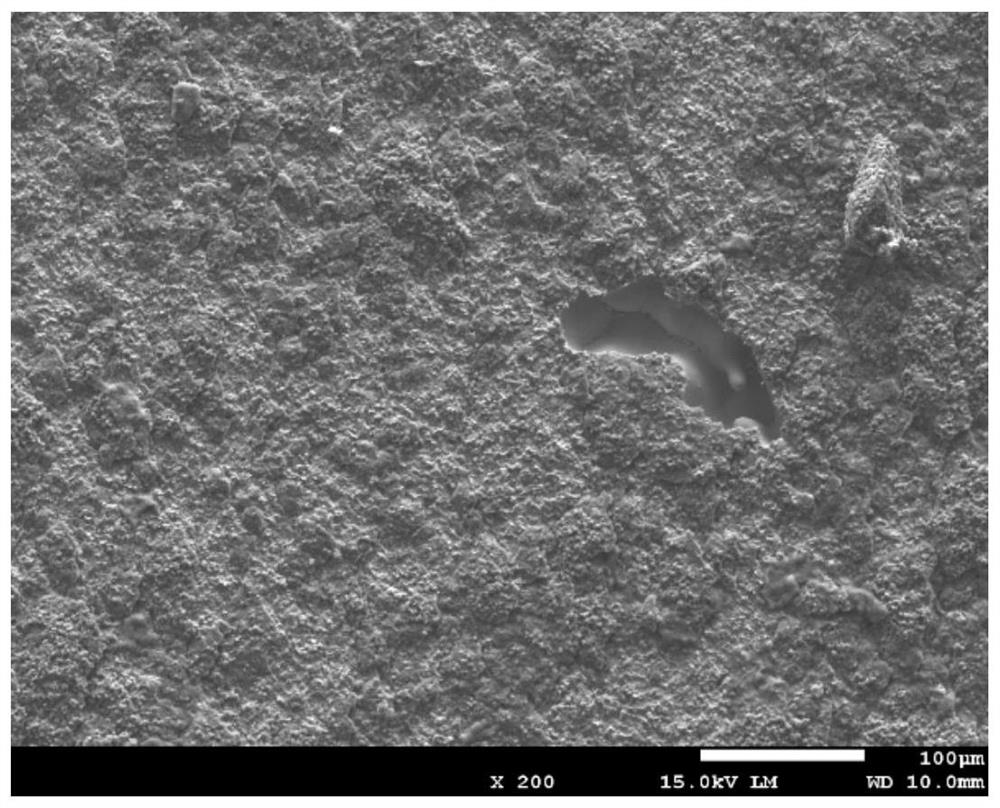

Embodiment 1

[0074] In this embodiment, the target plated on the surface of the aluminum nitride ceramic is silicon dioxide; the thickness of the aluminum nitride ceramic substrate used is 0.63mm, the surface roughness Ra is 0.4μm, the thickness of the copper foil is 0.3mm, and the SiO 2 The coating thickness is 0.2 μm.

[0075] The production process is as follows: ①The pretreatment process of the aluminum nitride ceramic substrate: first use deionized water to ultrasonically clean for 3 minutes, then wash with 10% by weight NaOH solution for 10 minutes, and then use 95% by volume of industrial alcohol to clean for 10 minutes, and finally Rinse with deionized water and dry with hot air at 50°C; ②Put the pretreated aluminum nitride ceramic substrate in the coating equipment to coat SiO 2 , the coating time is 100min (according to experience, the deposition rate of the target is 2nm / min); The oxygen content is 90% by volume, the gas flow rate is 2.0L / min, the temperature is raised to 1300°...

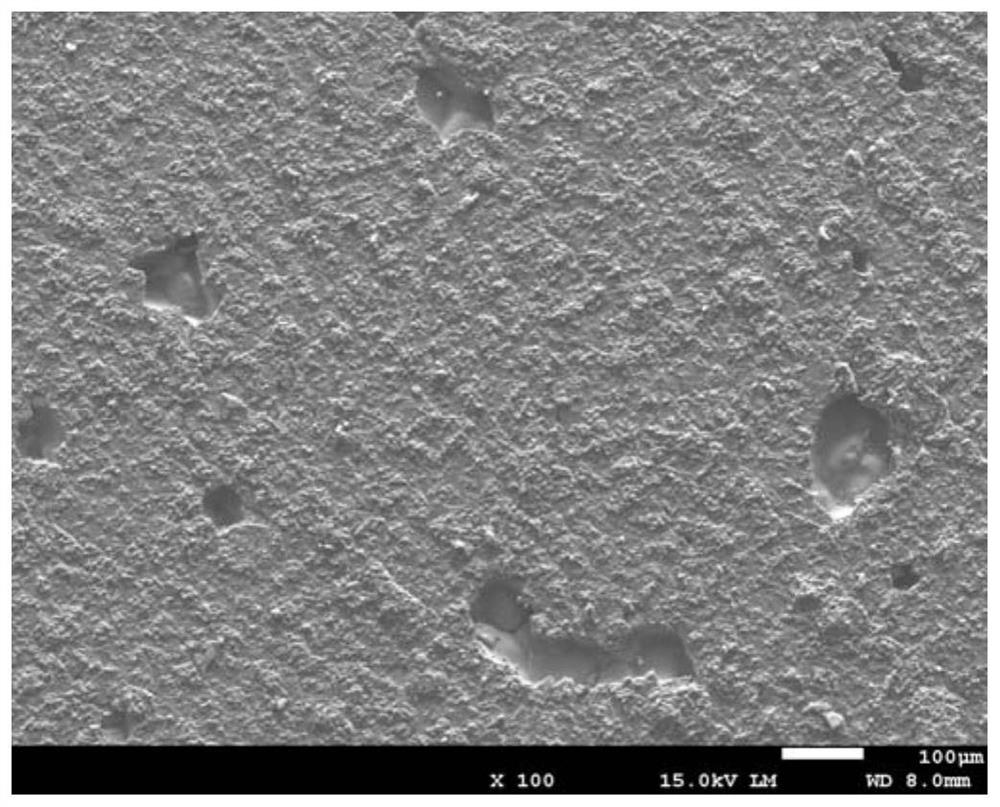

Embodiment 2

[0077] The difference from Example 1 is that the target material coated on the surface of aluminum nitride ceramics in this example is zirconia.

[0078] The thickness of the aluminum nitride ceramic substrate used is 0.63mm, the surface roughness Ra is 0.4μm, the thickness of the copper foil is 0.3mm, ZrO 2 The coating thickness is 0.2 μm.

[0079] The production process is as follows: ①The pretreatment process of the aluminum nitride ceramic substrate: first use deionized water to ultrasonically clean for 3 minutes, then use 10% by weight NaOH solution to clean for 10 minutes, then use 95% by volume industrial alcohol to clean for 10 minutes, and finally use Rinse with deionized water and dry with hot air at 50°C; ②Place the pretreated aluminum nitride ceramic substrate in the coating equipment to coat ZrO 2 , the coating time is 100min (according to experience, the deposition rate of the target is 2nm / min); The oxygen content is 90% by volume, the gas flow rate is 2.0L / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com