Proton exchange membrane fuel cell stack activation method

A fuel cell stack and proton exchange membrane technology, applied in fuel cells, electrochemical generators, circuits, etc., can solve the problems of reduced membrane electrode activity, increased cost, uneven voltage distribution, etc., to reduce activation time and reduce activation cost , the effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

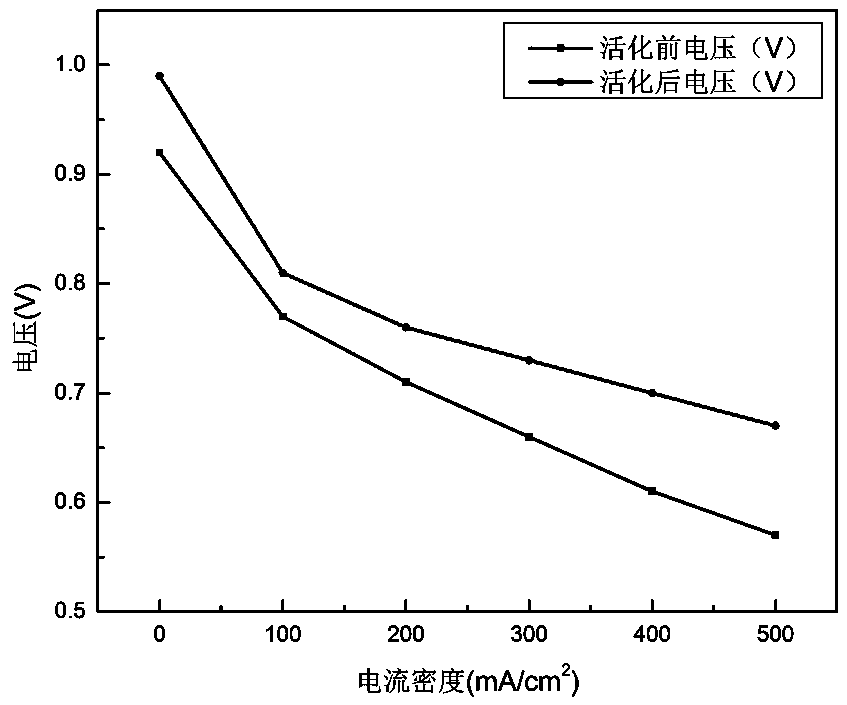

Embodiment 1

[0037] Embodiment 1 of the present invention provides a method for activating a proton exchange membrane fuel cell stack, comprising the following steps:

[0038] Step one, check the airtightness of the proton exchange membrane fuel cell stack;

[0039] Step 2: Introduce hydrogen into the anode of the single-piece proton exchange membrane fuel cell stack, and the hydrogen flow rate is 5000 mlmin -1 , the hydrogen pressure is 4 Kpa, the cathode is fed with low-flow air, the electronic load is adjusted to constant voltage mode, and the voltage of the proton exchange membrane fuel cell stack is gradually reduced in the single-chip 0.5V mode until the single-chip voltage is close to 0.2V, and Keep for 5 minutes;

[0040] Step 3, after turning off the electronic load, air-cool the proton exchange membrane fuel cell stack;

[0041] Step 4, repeat steps 2 and 3 5 times, then turn off the electronic load, and the anode stops air intake;

[0042] Step 5: Introduce hot water at 60°C ...

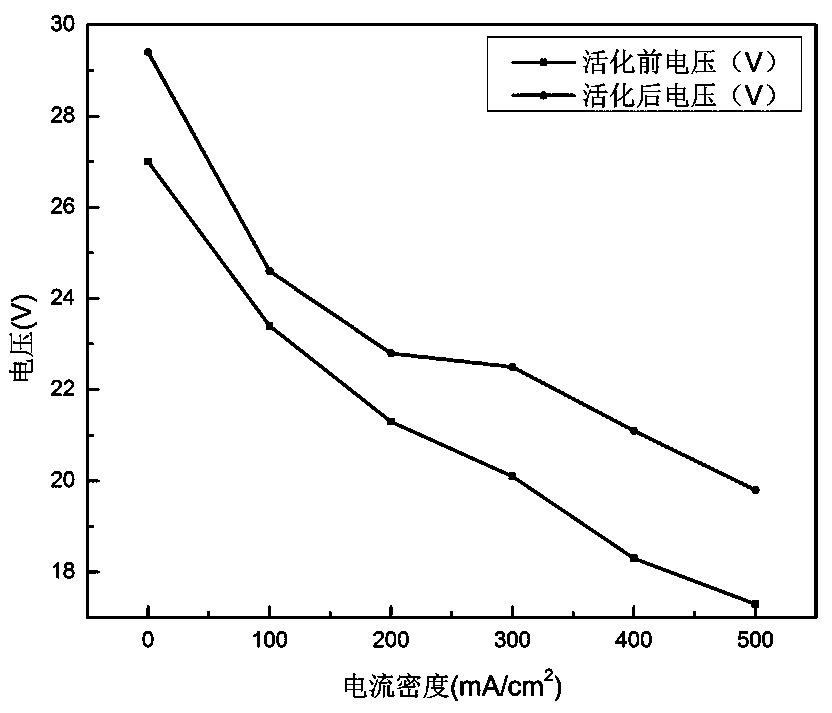

Embodiment 2

[0045] Embodiment 2 of the present invention provides a method for activating a proton exchange membrane fuel cell stack, comprising the following steps:

[0046] Step one, check the airtightness of the proton exchange membrane fuel cell stack;

[0047] Step 2: Introduce hydrogen into the anodes of 30 proton exchange membrane fuel cell stacks, and the hydrogen flow rate is 5000 mlmin -1 , the hydrogen pressure is 30 Kpa, the cathode is fed with low-flow air, the electronic load is adjusted to constant voltage mode, and the voltage of the proton exchange membrane fuel cell stack is gradually reduced in the single-chip 0.5V mode until the single-chip voltage is close to 0.2V, and Hold for 8 minutes;

[0048] Step 3, after turning off the electronic load, air-cool the proton exchange membrane fuel cell stack;

[0049] Step 4, repeat steps 2 and 3 5 times, then turn off the electronic load, and the anode stops air intake;

[0050] Step 5: Introduce hot water at 60°C at the anod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com