Method for activating winding wire of motor and coil with winding wire

A coil wire and motor technology, applied in the manufacture of motor generators, transformer/inductor coils/windings/connections, coils, etc., can solve problems such as difficult-to-impregnate resin adhesion, and achieve the effect of reducing activation costs and maintaining takt time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

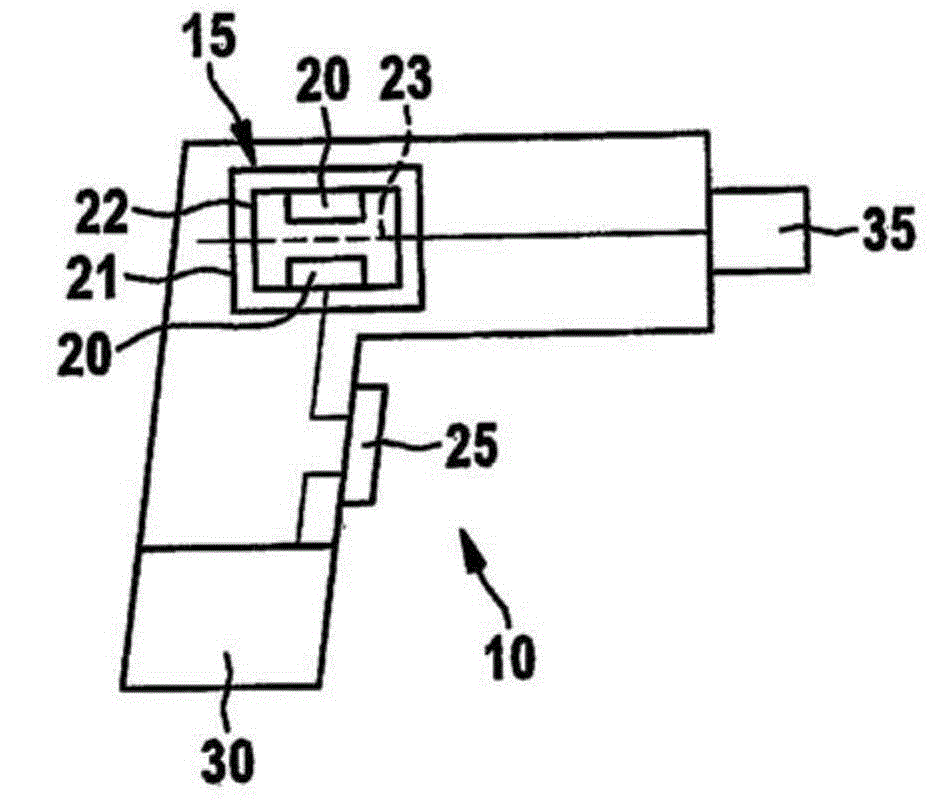

[0030] figure 1 A schematic illustration of a hand power tool 10 with an electric motor 15 is shown. In this embodiment, hand-held power tool 10 is designed as a drill. The electric motor 15 includes a stator 21 and a rotor 22 with a plurality of coils 20 . It goes without saying that the coil 20 can additionally or alternatively also be arranged in the stator 21 . In this case, the rotor 22 is arranged rotatably about an axis of rotation 23 . The coil 20 is connected to a battery pack 30 through an operation switch 25 . In this case, a control device (not shown) can additionally be provided in order to convert or adjust the signal of the operating switch 25 in order to control the electric motor 15 depending on the configuration of the electric motor 15 . The electric motor 15 is used in the hand power tool 10 to drive and rotate a chuck 35 . For this purpose, the electric motor 15 is coupled to the drill chuck 35 .

[0031] It goes without saying that the electric moto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com