Silicone oil removing water base detergent

An oil-water-based, cleaning agent technology, applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of difficult cleaning, inapplicability, excessive silicone oil content, etc., to improve synergy, Improves wetting, improves penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

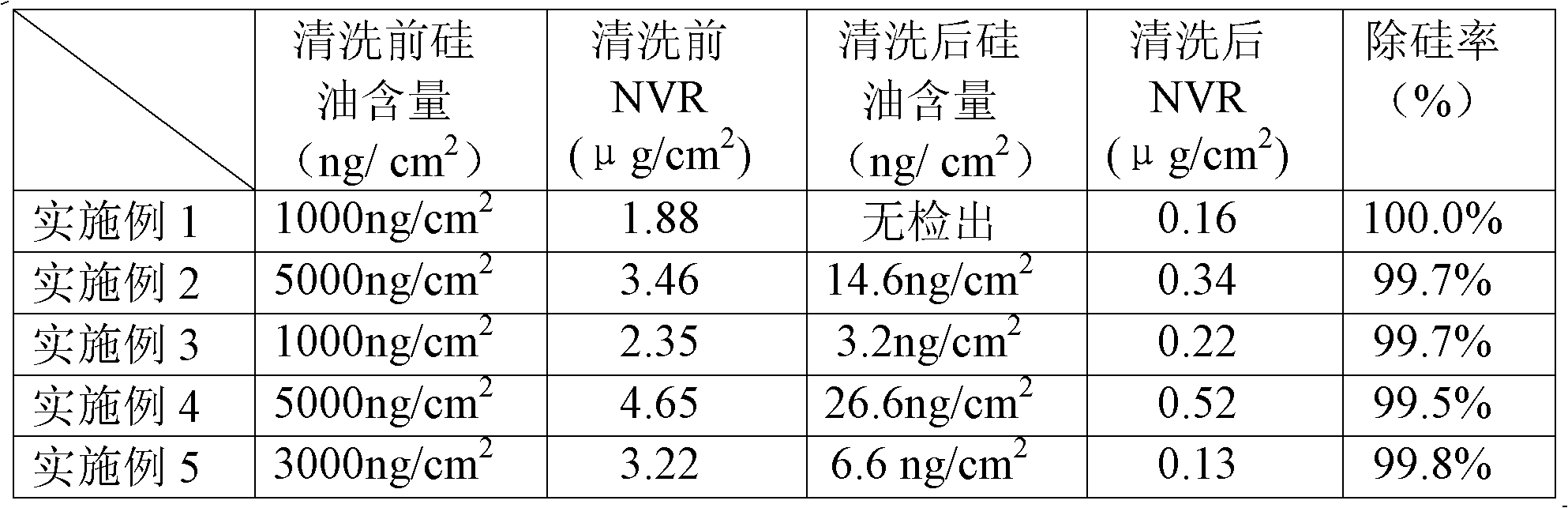

Examples

Embodiment 1

[0028] Example 1, a water-based cleaning agent for removing silicone oil, including octylphenol polyoxyethylene ether OP-7 [i.e. C 8 h 17 C 6 h 4 O(CH 2 CH 2 O) 7 H], OP-10[ie C8H 17 C 6 h 4 O(CH 2 CH 2 O) 10 H], sorbitan monolaurate span-20, sorbitan monolaurate span-40, ethylene glycol methyl ether, ethylene glycol dimethyl ether CH 3 O(C 2 h 4 O) 1 CH 3 , adding the above-mentioned raw materials into a mixed solution prepared in deionized water. Wherein the weight percentage of each component in the mixed solution is: OP-7 [namely C 8 h 17 C 6 h 4 O(CH 2 CH 2 O) 7 H]0.05%, OP-10[namely C8H 17 C 6 h 4 O(CH 2 CH 2 O) 10 H] 0.05%, (HLB=12.8 of OP); sorbitan monolaurate span-20 is 0.01%, sorbitan monolaurate span-40 is 0.04% (span HLB=8.2) ; Ethylene glycol methyl ether 1.0%; Ethylene glycol dimethyl ether CH 3 O(C 2 h 4 O) 1 CH 3 (n=1) 0.01%. The configured water-based cleaning agent HLB=11.3.

[0029] The silicon content is 1000ng / cm 2 Put...

Embodiment 2

[0030] Example 2, a water-based cleaning agent for removing silicone oil, including octylphenol polyoxyethylene ether OP-10 [that is, C8H 17 C 6 h 4 O(CH 2 CH 2 O) 10 H], Sorbitan monopalmitate span-40, Ethylene glycol ether, Polyethylene glycol dimethyl ether CH 3 O(C 2 h 4 O) 3 CH 3 (n=3), adding the above-mentioned raw materials into a mixed solution prepared in deionized water. Wherein the weight percentage of each component in the mixed solution is: OP-10 [namely C 8 h 17 C 6 h 4 O(CH 2 CH 2 O) 10 H] 0.01% (its HLB=14.0), sorbitan monopalmitate span-40 is 0.01% (its HLB=8.6), ethylene glycol ether 1%, polyethylene glycol dimethyl ether CH 3 O(C 2 h 4 O) 3 CH 3 (n=3) 0.1%, the configured water-based cleaning agent HLB=11.6. The silicon content is 5000ng / cm 2 Put the polyester fiber knitted fabric into the cleaning agent, after it is completely wet, wash it at 60°C for 30 minutes, take it out and dry it at 105°C for 30 minutes, and measure the silicone...

Embodiment 3

[0031] Example 3, a water-based cleaning agent for removing silicone oil, including octylphenol polyoxyethylene ether OP-7 [i.e. C 8 h 17 C 6 h 4 O(CH 2 CH 2 O) 7 H], sorbitan monolaurate span-20, butyl glycol ether, CH 3 O(C 2 h 4 O) 1 CH 3 (n=1), CH 3 O(C 2 h 4 O) 2 CH 3 (n=2), CH 3 O(C 2 h 4 O) 3 CH 3 (n=3), adding the above-mentioned raw materials into a mixed solution prepared in deionized water. Wherein the weight percentage of each component in the mixed solution is: OP-7 [namely C 8 h 17 C 6 h 4 O(CH 2 CH 2 O) 7 H] 0.5% (its HLB=11.5), sorbitan monolaurate span-20 is 0.01% (its HLB=6.7), butyl glycol ether 0.1%, CH 3 O(C 2 h 4 O) 1 CH 3 (n=1)0.25%, CH 3 O(C 2 h 4 O) 2 CH 3 (n=2)0.15%, CH 3 O(C 2 h 4 O) 3 CH 3 (n = 3) 0.1%, the water-based cleaning agent configured, HLB = 11.0, the silicon content is 1000ng / cm 2 Put the polyester fiber knitted fabric into the cleaning agent, after it is completely wet, wash it at 60°C for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com