Preparation and carbonization method of needle-punched pre-oxidative fiber prefabricated part

A technology of pre-oxidized yarn and prefabricated body, which is applied in textiles and papermaking, heating/cooling fabrics, fabric surface trimming, etc. It can solve the problems of high cost, poor z-direction performance of charcoal discs, broken needles, etc., and achieve stable material performance, Good friction and wear performance, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

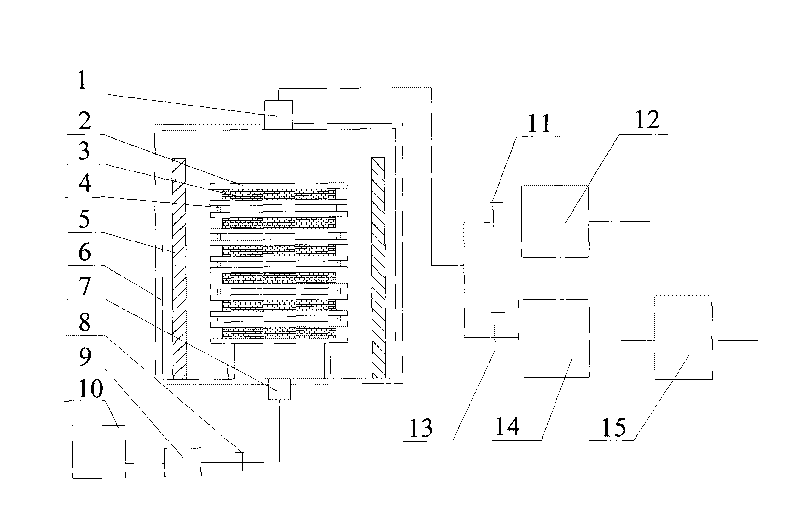

[0026] See figure 1 , the present invention is implemented in the carbonization furnace equipment.

[0027] The present invention is a method for preparing and carbonizing an acupuncture pre-oxidized silk prefabricated body. The specific steps of the method are as follows:

[0028] The prefabricated body was prepared by using 12k pre-oxidized wire from Dalian Xingke Carbon Fiber Co., Ltd.

[0029] Step 1: Preparation of the preform. Select the long pre-oxygenated yarn to lay the weft-free cloth, and the chopped pre-oxygenated yarn to lay the mesh tire, one layer of the weft-free cloth and one layer of the mesh tire are stacked, and the two adjacent layers of the weft-free cloth form an angle of 90°, and then layer by layer Acupuncture to make pre-oxygenated silk quasi-three-dimensional prefabricated body.

[0030] Step 2: Carbonization of the prefabricated body. Fix the prefabricated body with a graphite plate 2, put it into the carbonization furnace, close the gas valves ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com