Aluminum oxide reinforced copper base composite material and preparation method thereof

A copper-based composite material and alumina technology, which is applied in the field of copper-based composite materials, alumina-reinforced copper-based composite materials and their preparation, can solve the problems such as the inability to fully exert the reinforcing effect of ceramic alumina, poor wetting and dispersibility, etc. To achieve excellent enhancement and promotion effect, good dispersion uniformity, and the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Al 2 o 3 particle surface modification

[0071] Will Al 2 o 3 Particles were added to 2g / L sodium lauryl sulfate aqueous solution, ultrasonically dispersed for 30min, in which Al 2 o 3 The ratio of the weight of the particles to the volume of the sodium lauryl sulfate aqueous solution is 0.1g:40ml; after standing for 24 hours, filter, take the filter residue and dry it in vacuum at 80°C for 24 hours to obtain the surface-modified Al 2 o 3 particles.

[0072] By comparing the surface modified Al 2 o 3 Particles with Al without surface modification 2 o 3 Morphological characteristics of the particles, it was found that the surface-modified Al 2 o 3 The surface of the particles is smooth, the impurity content is less, and the dispersion is better.

[0073] Al mentioned in the following examples 2 o 3 The particles refer to the Al particles obtained after surface modification by the above method. 2 o 3 particles.

Embodiment 2

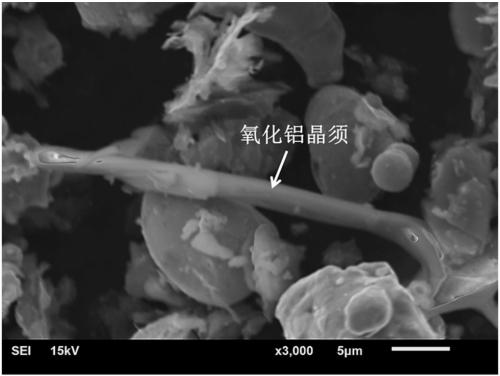

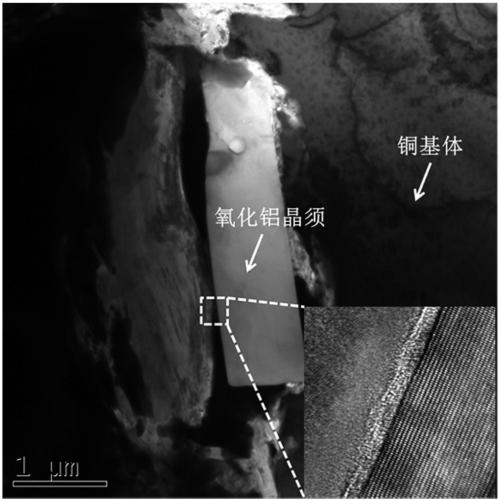

[0075] al 2 o 3 Whisker Surface Modification

[0076] Will Al 2 o 3 Whiskers were added to 2g / L sodium lauryl sulfate aqueous solution, ultrasonically dispersed for 30min, in which Al 2 o 3 The ratio of the weight of the whiskers to the volume of the sodium lauryl sulfate aqueous solution is 0.1g:40ml; after standing for 24 hours, filter, take the filter residue and dry it in vacuum at 80°C for 24 hours to obtain the surface-modified Al 2 o 3 whiskers.

[0077] By comparing the surface modified Al 2 o 3 Whiskers and Al without surface modification 2 o 3 Morphological characteristics of whiskers, found Al without surface modification 2 o 3 Whiskers are mainly in the form of flocculation, uneven dispersion, and more impurities attached to the surface; the surface-modified Al 2 o 3 Whiskers have smooth surface, less impurity content and better dispersion.

[0078] Al mentioned in the following examples 2 o 3 Whiskers refer to the Al alloys obtained after surfa...

Embodiment 3

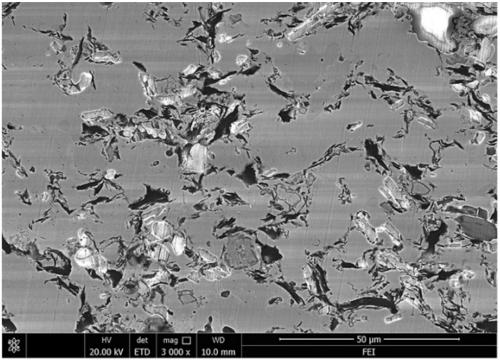

[0080] Copper Matrix Composite

[0081] (1) get the Al of surface modification treatment in embodiment 1 2 o 3 Particles; (2) in parts by weight, 3.5 parts of surface-modified Al 2 o 3 Particles, 6.5 parts of graphite powder, 1.5 parts of Ti 3 SiC 2 Powder, 5 parts of nickel powder, 5 parts of iron powder, 4.7 parts of tin powder, 3 parts of bismuth powder, 0.5 part of zirconia powder, 0.3 part of lanthanum powder and 70 parts of copper powder are mixed by ball milling at a speed of 350 rpm. The ball milling time is 120min; (3) The composite powder is vacuum hot-pressed and sintered at a temperature of 900°C, the pressure is 20MPa, and the heat preservation and pressure holding time is 2h; (4) The obtained block material is subjected to hot isostatic pressing for 2h, The hot isostatic pressing sintering temperature is 900°C, the pressure is 100MPa, and the aluminum oxide reinforced copper matrix composite material is obtained by rapid cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com