Lubricating oil composition for industrial robot speed reducer

A lubricating oil composition and technology for industrial robots, applied in the field of lubricating oil, can solve problems such as blank formulation of special oil for robots, and achieve excellent wear resistance and thermal oxidation stability, good economic and social benefits, and production costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

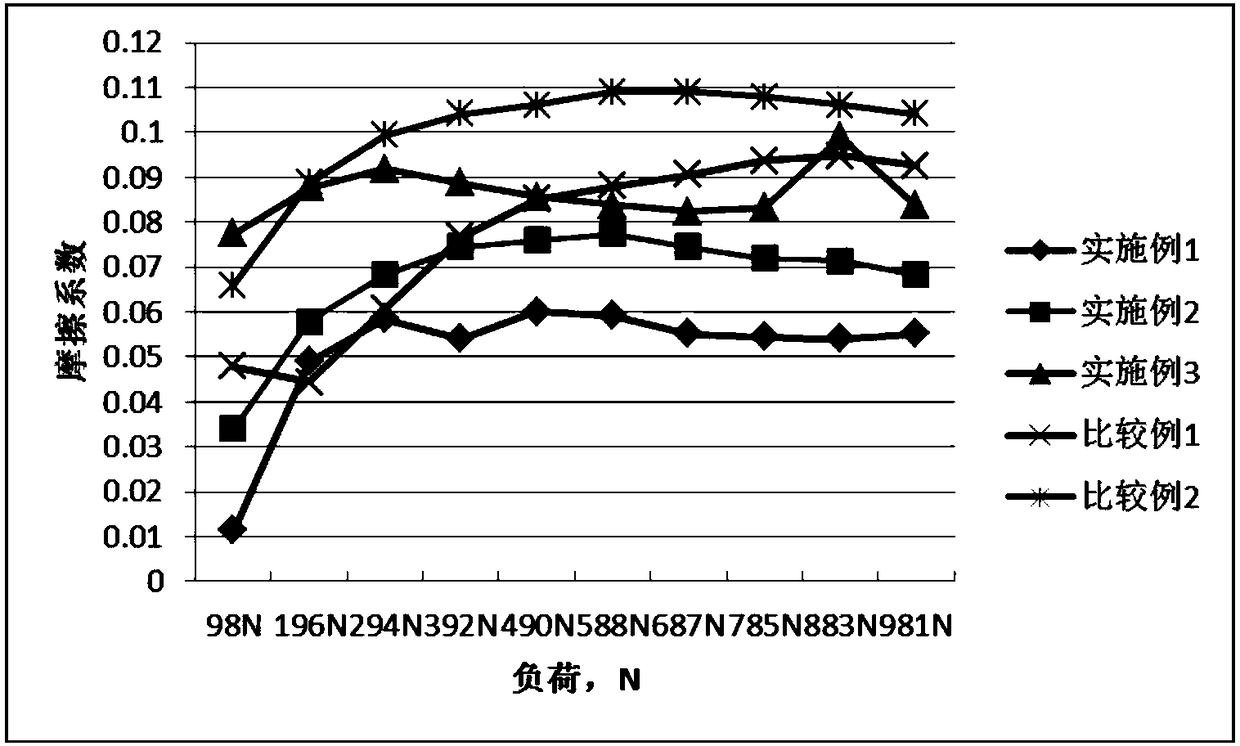

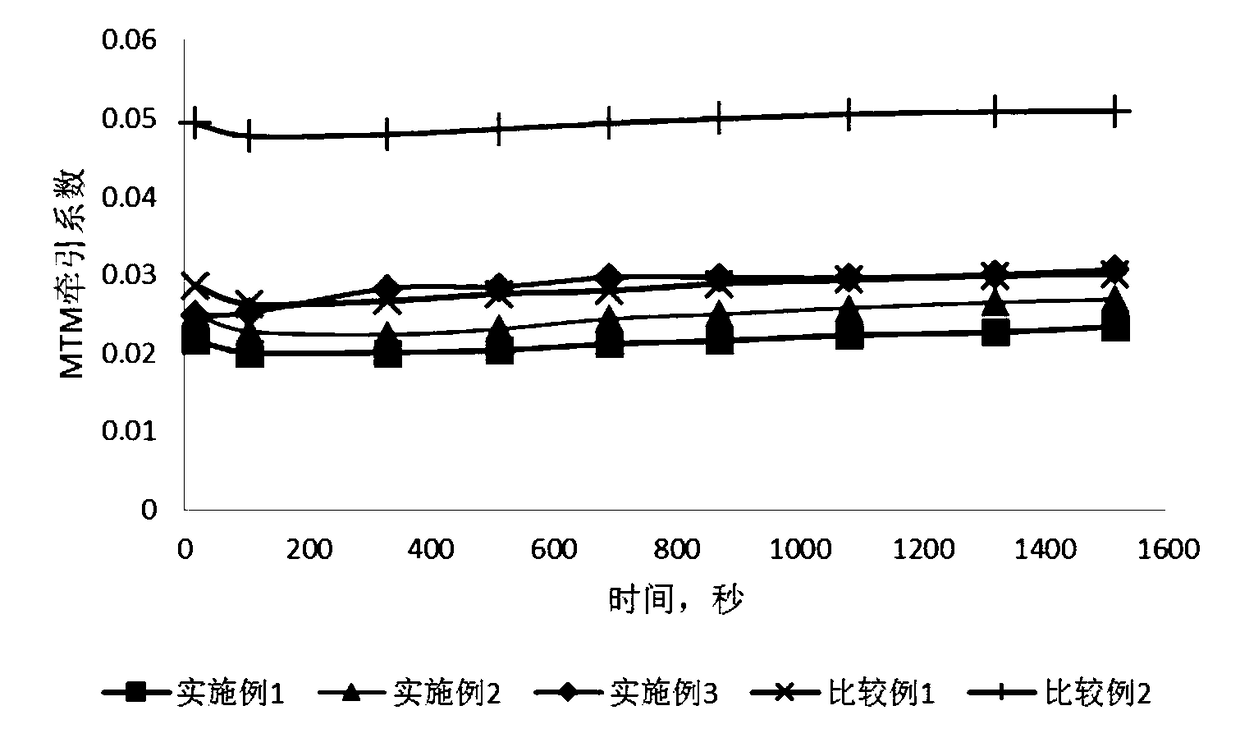

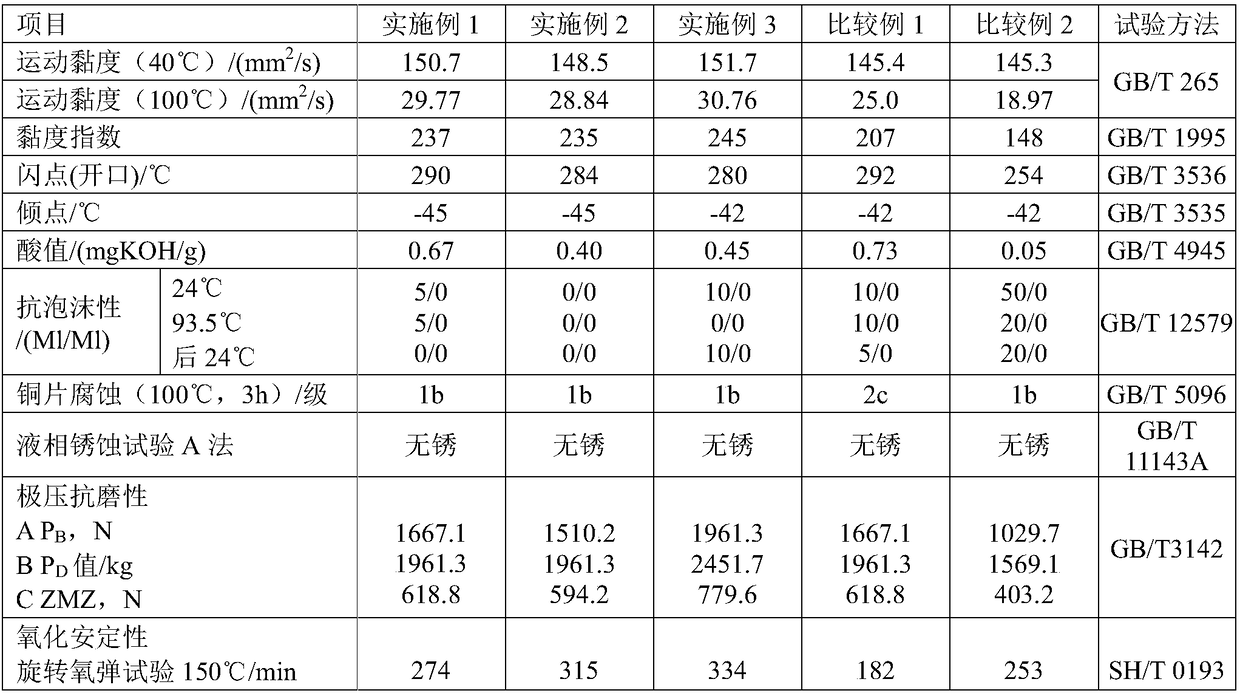

Embodiment 1

[0049] Lubricating oil composition, it comprises: the water-soluble polyalkylene glycol base oil (component A) that contains 60% EO unit of 93.58wt%; The isotridecyl adipate (component B) of 5.0wt% ); 0.50wt% tricresyl phosphate and 0.1wt% diisooctyl phosphate stearylamine salt (component C); 0.02wt% benzotriazole dioctylamine formaldehyde condensate (component D); 0.20wt % isopropyl isooctyl phosphate dodecylamine salt (component E); 0.40 wt% of 2,6-di-tert-butyl-p-cresol and 0.20 wt% of dialkyldiphenylamine (component F); 20 μg / g silicone antifoam (component G). The sum of the above components is 100%wt%.

Embodiment 2

[0051] Lubricating oil composition, it comprises: the water-soluble polyalkylene glycol base oil (component A) that contains 50% EO unit of 93.58wt%; The saturated pentaerythritol ester of 5.0wt% (component B); 0.30wt% Tricresyl phosphate and 0.3 wt% isopropyltriaryl phosphate (component C); 0.02 wt% benzotriazole dioctylamine formaldehyde condensate (component D); 0.20 wt% dodecenylsuccinic acid Half ester (component E); 0.40 wt% of 2,6-di-tert-butyl-p-cresol and 0.20 wt% of dialkyldiphenylamine (component F); 20 μg / g silicone antifoam (component points G). The sum of the above components is 100%wt%.

Embodiment 3

[0053] A lubricating oil composition comprising: 93.68 wt% of water-soluble polyalkylene glycol base oil (component A) containing 60% EO units; 5.0 wt% of trimethylolpropane octadecanoate (component B); 0.30 wt% tricresyl phosphate and 0.2 wt% 2,5-dimercaptothiadiazole phosphite amine salt (component C); 0.02 wt% benzotriazole dioctylamine formaldehyde condensate (component Part D); 0.10wt% acyl sarcosine and 0.10wt% imidazole (component E); 0.40wt% 2,6-di-tert-butyl-p-cresol and 0.20wt% dialkyldiphenylamine (component F); 20 μg / g silicone antifoam (component G). The sum of the above components is 100%wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com