Water distributor and production process thereof

A production process and water separator technology, which is applied in the direction of branch pipelines, pipes, pipes/pipe joints/fittings, etc., can solve problems such as poor bonding between main pipes and branch pipes, poor anti-corrosion and anti-rust performance of products, and poor product aesthetics , to achieve the effect of improving aesthetics and sealing performance, improving sealing and aesthetics, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

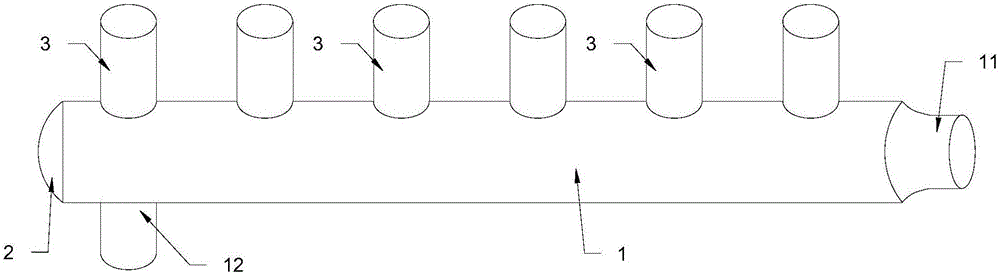

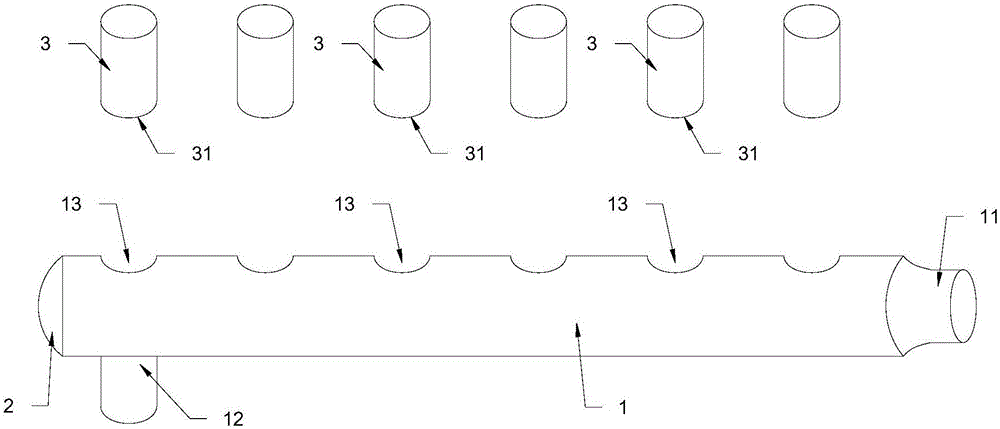

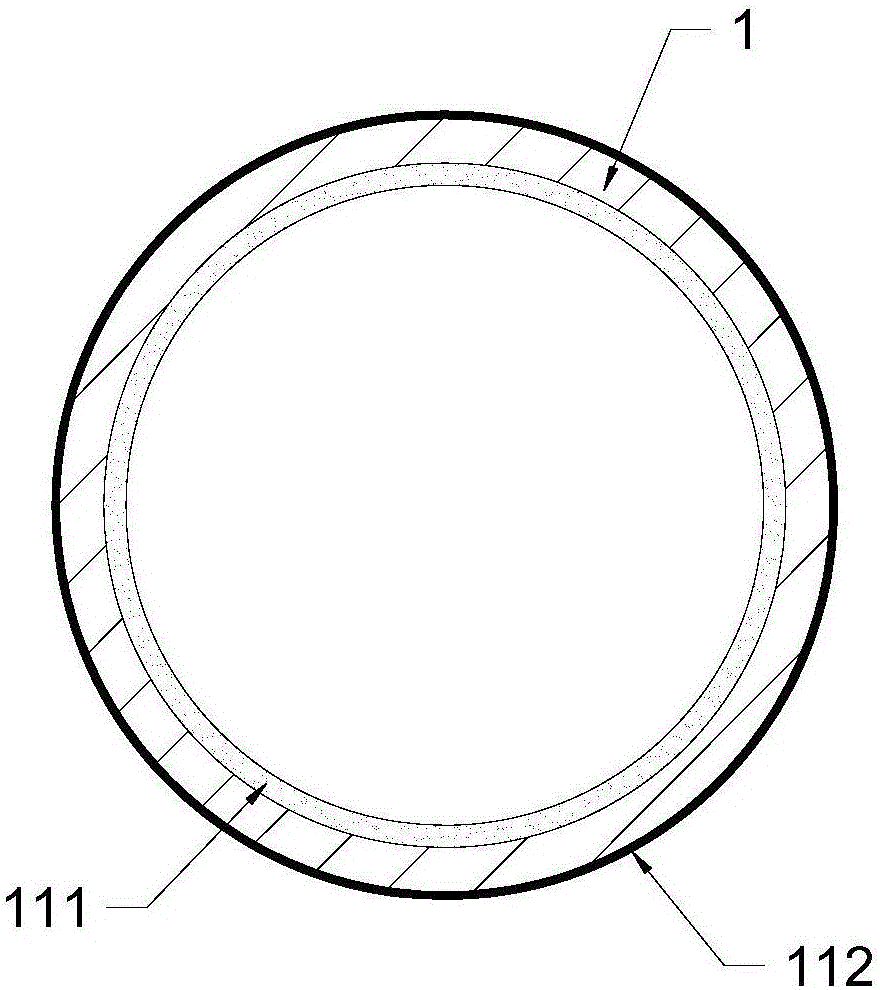

[0033] This embodiment provides a water separator, such as figure 1 with figure 2 As shown, it includes a main pipe and several branch pipes respectively connected with the main pipe. One end of the main pipe is the water inlet end, and the other end is provided with a head. The water inlet end has been shrinked. The inner diameter is reduced by 30 to 40%, that is, the inner diameter of the water inlet at the left end of the main pipe is 60 to 70% of the inner diameter of the main part of the central part of the main pipe.

[0034] In the water separator provided in this embodiment, the water inlet end of the main pipe is shrinked, and the inner diameter of the water inlet end is smaller than the inner diameter of the main part of the main pipe except the water inlet end. Under the same flow rate, the inner diameter of the main part in the middle of the main pipe is larger. The internal water flow velocity is lower than the water flow velocity inside the water inlet end, the...

Embodiment 2

[0041] The present embodiment provides a kind of water trap (particularly the water trap shown in embodiment 1) production process, comprises the following steps:

[0042] S1. Use a CNC pipe cutting machine to cut carbon steel seamless steel pipes as the main pipe blank, use the left end of the main pipe blank as the water inlet end and perform necking treatment. During the necking treatment, the inner diameter of the water inlet end is reduced to 60~ of the original diameter. 70%;

[0043] S2. Use punching equipment to punch out several arc holes in sequence on the upper surface of the side wall of the main pipe blank to obtain the main pipe;

[0044] S3, using a CNC pipe cutting machine to cut a carbon steel seamless steel pipe as a branch pipe blank, and using an arc punching machine to punch one end of the branch pipe blank out of the arc recess corresponding to the arc hole on the S2 main pipe to obtain a branch pipe;

[0045] S4. Weld the arc concave ends of several bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com