Synthetic compressor lubricating oil composition and production method thereof

A technology for compressor oil and composition, applied in the directions of lubricating composition, petroleum industry, etc., can solve the problems of poor oil oxidation stability, easy formation of carbon deposits, difficult to satisfy air compressors, etc., and achieves low carbon deposition tendency and no three wastes. The effect of emission, good anti-corrosion and anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of liquid A: take a 40 ℃ viscosity of 32mm 2 / s polyalphaolefin (PAO) base oil 88kg.

[0030] Prepare liquid B: take 10kg of diester, 0.60kg of zinc dialkylthiocarbamate, 0.3kg of alkylated diphenylamine antioxidant, 0.4kg of sodium petroleum sulfonate, 0.1kg of thiadiazole derivative, and 0.1kg of thiophosphoric acid tris 0.60kg of phenyl ester, 0.03kg of condensate of amine and ethylene oxide, 0.006kg of methyl silicone oil composite antifoaming agent, put the above raw materials into the mixing kettle, stir at 60-70°C for 1 hour, and obtain 12.036kg of liquid B to be prepared use.

[0031] Then add the prepared liquid A and liquid B into the mixing tank and mix, keep the temperature at 60-65°C and stir for 1.5 hours, cool and stand for 12 hours, take samples for testing, and filter to obtain the finished product.

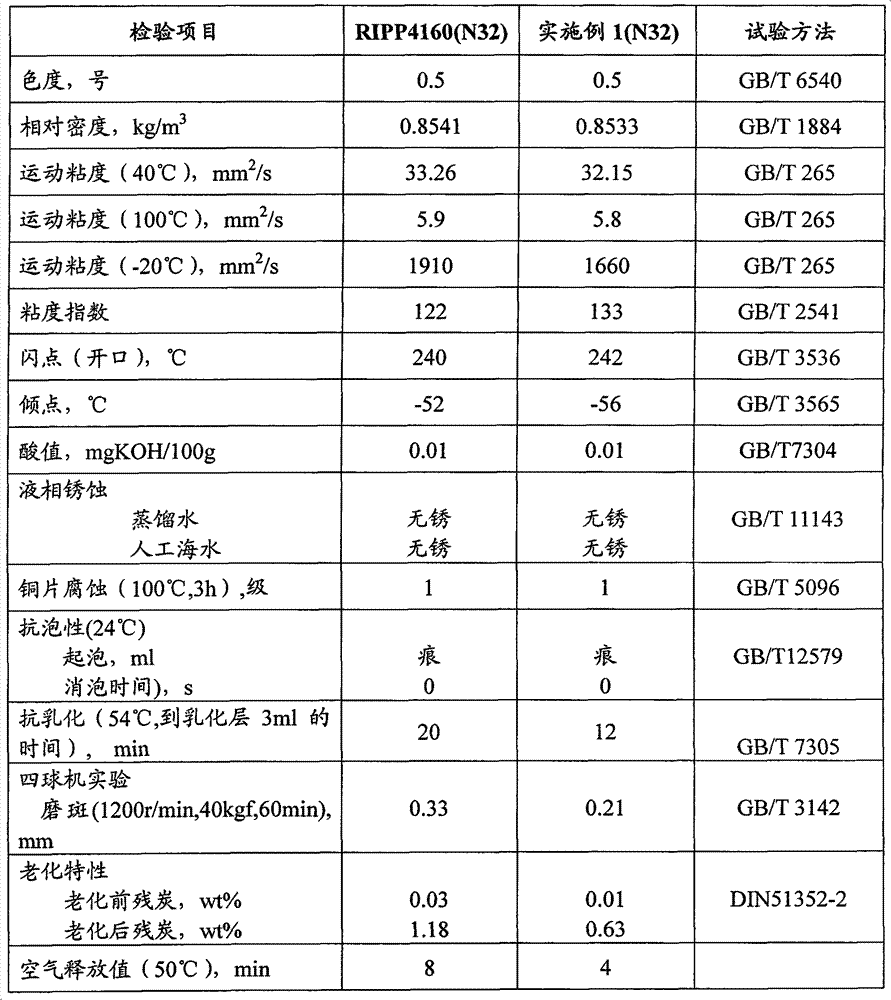

[0032] The technical parameters of the synthetic compressor lubricating oil of the present invention thus obtained are listed in the followi...

Embodiment 2

[0035] Preparation of liquid A: choose one with a viscosity of 100mm at 40°C 2 90kg of polyalphaolefin (PAO) base oil per s is ready for use.

[0036] Prepare liquid B: take 10.0kg of diester, 0.8kg of zinc dialkylthiocarbamate, 0.3kg of alkylated diphenylamine antioxidant, 0.5kg of alkenyl succinic acid, 0.2kg of benzotriazole derivative, dioxane 0.7kg of molybdenum dithiocarbamate, 0.03kg of amine and ethylene oxide condensate, 0.005kg of methyl silicone oil composite antifoaming agent, add the above raw materials into the blending kettle, and stir at 60-70°C for 1 hour to obtain 12.535kg of liquid B is ready for use.

[0037] Mix 87.5kg of liquid A and 12.535kg of liquid B into the blending kettle, keep the temperature at 60-65°C and stir for 1.5 hours, cool and stand for 12 hours, take samples for testing, and filter to obtain the finished product.

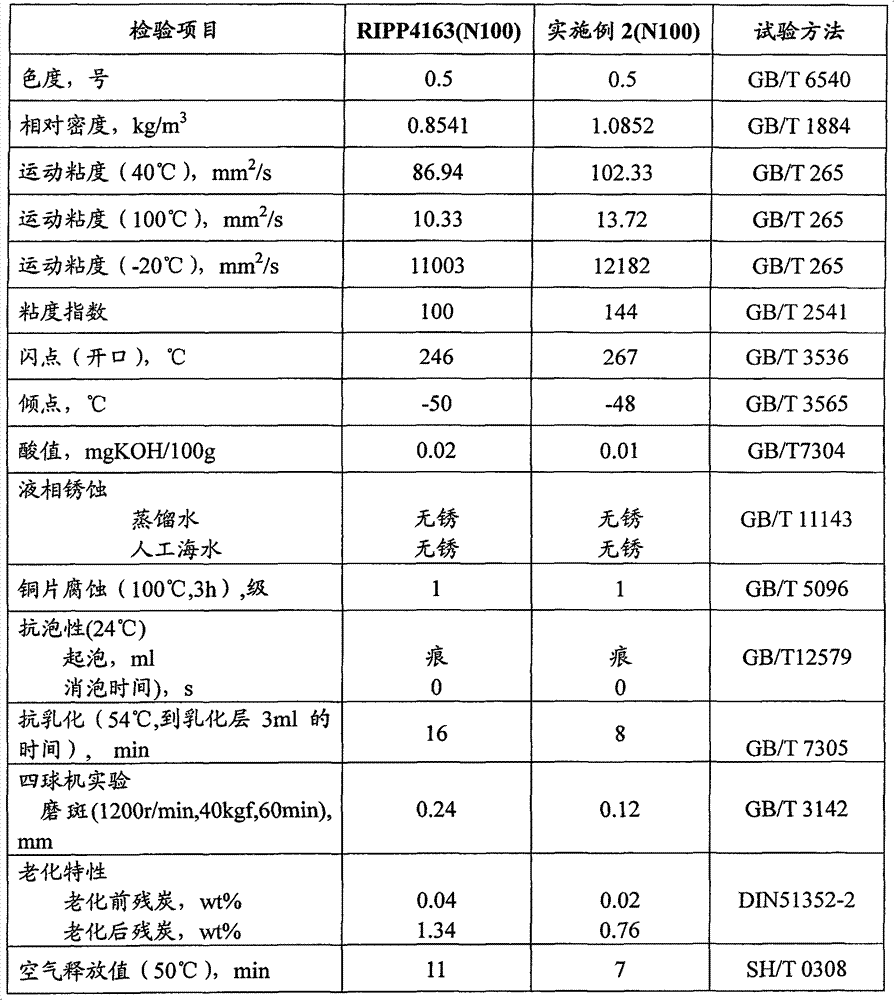

[0038] The parameter list is as follows:

[0039]

[0040] In order to facilitate follow-up investigation and analysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com