Oil membrane bearing oil composition and preparation method thereof

An oil film bearing and oil composition technology, applied in the field of bearing oil, can solve the problems of high price, complex oil system, poor antibacterial effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

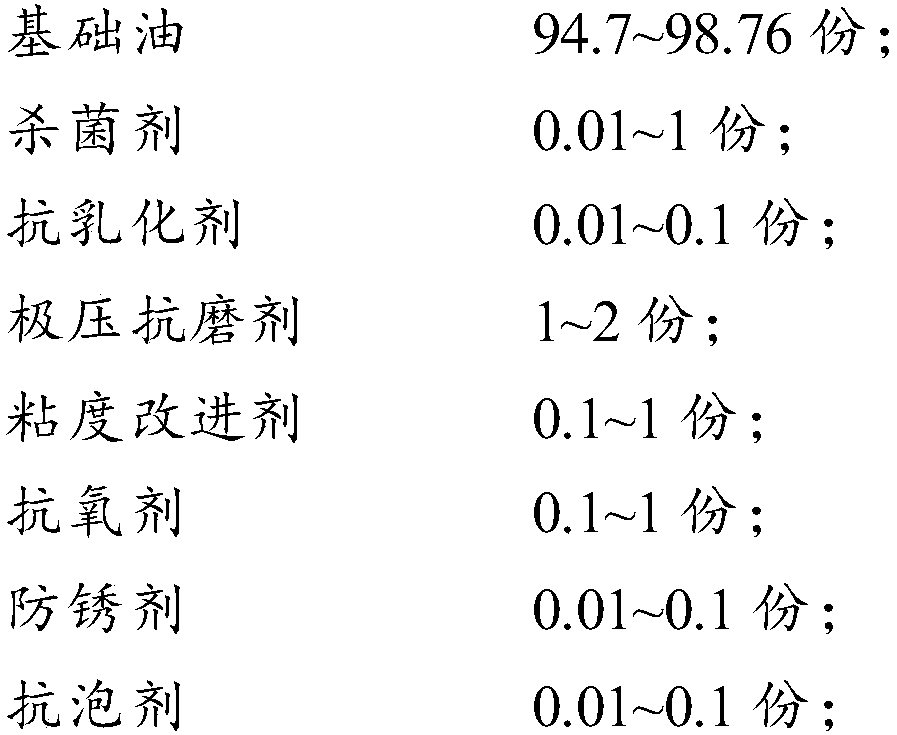

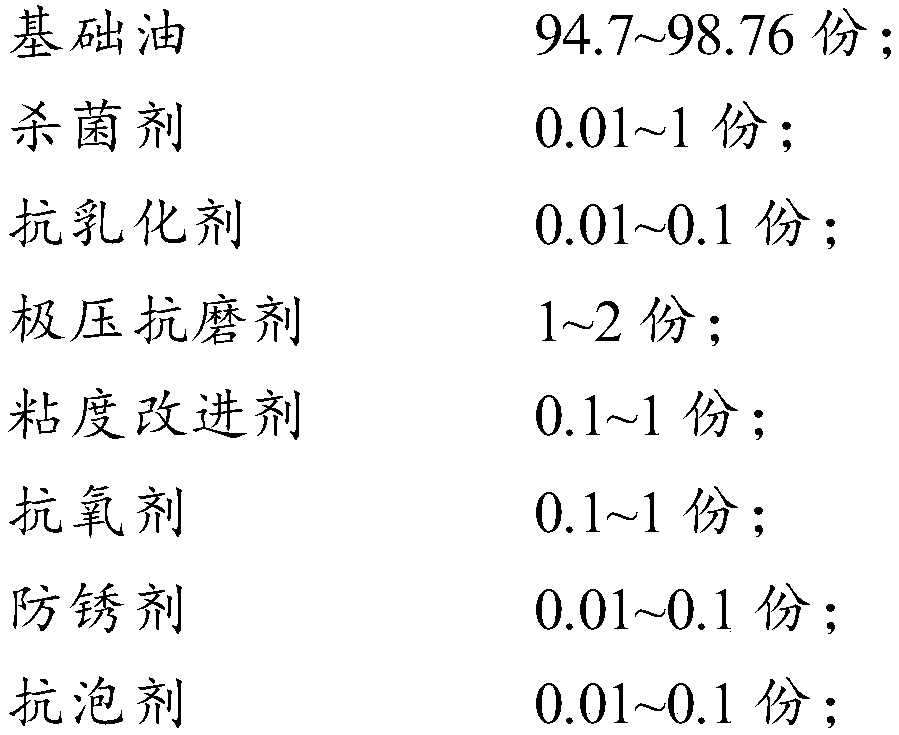

Method used

Image

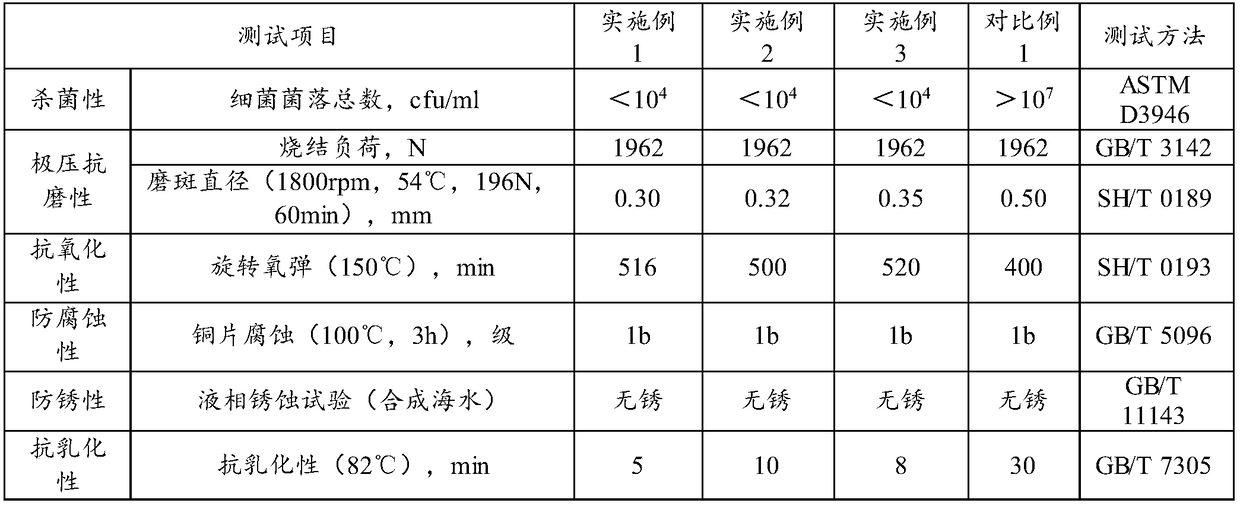

Examples

preparation example Construction

[0048] The present invention also provides a method for preparing the oil film bearing oil composition described in the above technical solution, comprising:

[0049] After the base oil is heated and dehydrated, the temperature is lowered to 60-80° C., a viscosity improver, a bactericide, an antioxidant, an extreme pressure anti-wear agent, an anti-emulsifier and an anti-rust agent are added and mixed evenly to obtain an oil film bearing oil composition.

[0050] Wherein, the types, dosages and sources of base oils, viscosity modifiers, bactericides, antioxidants, extreme pressure antiwear agents, anti-emulsifiers and antirust agents are all consistent with those described in the above technical solutions, and will not be repeated here. A repeat. The heating temperature is preferably 110-130°C, more preferably 120°C. After rising to the target temperature, it is preferably kept for 1 hour.

Embodiment 1

[0053] Raw materials: 10 parts of base oil HVIⅠ150, 87.23 parts of base oil HVIⅠ650, 0.1 part of fungicide N-octadecyl-γ-diquaternary ammonium salt, 1.5 parts of extreme pressure and antiwear agent T306, 10.05 parts of anti-emulsifier T100, Rust agent T746 0.1 part, viscosity improver T801 0.5 part, antifoaming agent T921 0.02 part, antioxidant T531 0.5 part.

[0054] Preparation: Heat up the base oil to 120°C to remove water, then cool down to 70°C, add other raw materials and mix well to obtain oil film bearing oil.

Embodiment 2

[0056] Raw materials: 76.2 parts of base oil HVIⅠ750, 20 parts of base oil HVI II 4, 1 part of fungicide isothiazolinone, 0.1 part of extreme pressure and antiwear agent triphenyl thiophosphate, 0.1 part of anti-emulsifier ethylene glycol ester, 0.05 part of rust agent sodium sebacate, 0.6 part of viscosity improver T803A, 0.05 part of antifoaming agent T911, 1 part of antioxidant dinonyl diphenylamine.

[0057] Preparation: Heat up the base oil to 120°C to remove water, then cool down to 70°C, add other raw materials and mix well to obtain oil film bearing oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com