Corrosion-resistant water-borne coating and preparation method thereof

A water-based coating, corrosion-resistant technology, applied in the field of coatings, to achieve the effect of low surface tension, good anti-corrosion and anti-rust performance, and long anti-corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

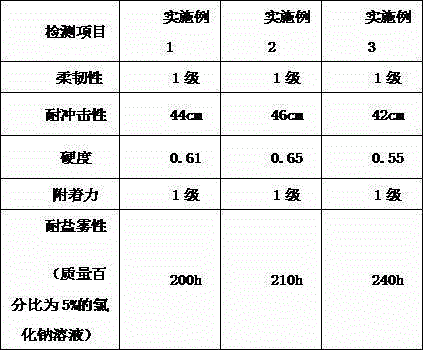

Examples

Embodiment 1

[0034] A kind of corrosion-resistant water-based paint and its preparation method provided in this embodiment, the components of the corrosion-resistant water-based paint are calculated in parts by weight: acrylic resin: 40 parts, bisphenol A epoxy resin: 20 parts, methyl silanol Potassium: 5 parts, magnesium stearate: 7 parts, epoxy modified silicone resin: 10 parts, silicon carbide: 8 parts, titanium dioxide: 12 parts, deionized water: 20 parts, water: 35 parts, alkyd Resin: 5 parts, talcum powder: 15 parts, propylene glycol methyl ether: 3 parts; wherein: titanium dioxide is purified titanium dioxide, and the purification method of titanium dioxide is as follows:

[0035] First dehydrate the organic solvent with 13X molecular sieve for 10 days for later use;

[0036] Add titanium dioxide, organic solvent, catalyst and capture agent into a 350mm three-neck flask, stir at room temperature for 30min, then let stand for 3h, then use a suction filtration device consisting of...

Embodiment 2

[0043] A kind of corrosion-resistant water-based paint and its preparation method provided by the present embodiment, the components of the corrosion-resistant water-based paint are calculated in parts by weight: acrylic resin: 45 parts, bisphenol A epoxy resin: 23 parts, methyl silanol Potassium: 8 parts, magnesium stearate: 9 parts, epoxy modified silicone resin: 15 parts, silicon carbide: 12 parts, titanium dioxide: 15 parts, deionized water: 30 parts, water: 40 parts, alkyd Resin: 8 parts, talcum powder: 18 parts, propylene glycol methyl ether: 4 parts; wherein: titanium dioxide is purified titanium dioxide, and the purification method of titanium dioxide is as follows:

[0044] Dehydrate the organic solvent with 13X molecular sieve for 12 days for later use;

[0045] Add titanium dioxide, organic solvent, catalyst and capture agent to a 350mm three-neck flask, stir at room temperature for 50min, then let stand for 4h, then use a suction filtration device consisting of...

Embodiment 3

[0052] A kind of corrosion-resistant water-based paint and its preparation method provided by the present embodiment, the components of the corrosion-resistant water-based paint are calculated in parts by weight: acrylic resin: 42 parts, bisphenol A epoxy resin: 22 parts, methyl silanol Potassium: 7 parts, magnesium stearate: 8 parts, epoxy modified silicone resin: 12 parts, silicon carbide: 10 parts, titanium dioxide: 13 parts, deionized water: 25 parts, water: 38 parts, alkyd Resin: 7 parts, talcum powder: 16 parts, propylene glycol methyl ether: 4 parts; wherein: titanium dioxide is purified titanium dioxide, and the purification method of titanium dioxide is as follows:

[0053] Dehydrate the organic solvent with 13X molecular sieve for 11 days for later use;

[0054] Add titanium dioxide, organic solvent, catalyst and capture agent to a 350mm three-neck flask, stir at room temperature for 40min, then let stand for 3.5h, then use circulating water test vacuum pump, Buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com