Metal vacuum warming plate and manufacturing method for same

A technology of vacuum insulation board and production method, which is applied in the directions of heat preservation, climate change adaptation, insulation improvement, etc. It can solve the problems of single wall decoration method, inability to form special-shaped boards, and sticking and degumming around, so as to achieve excellent airtightness and improve Excellent rigidity, anti-corrosion and anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

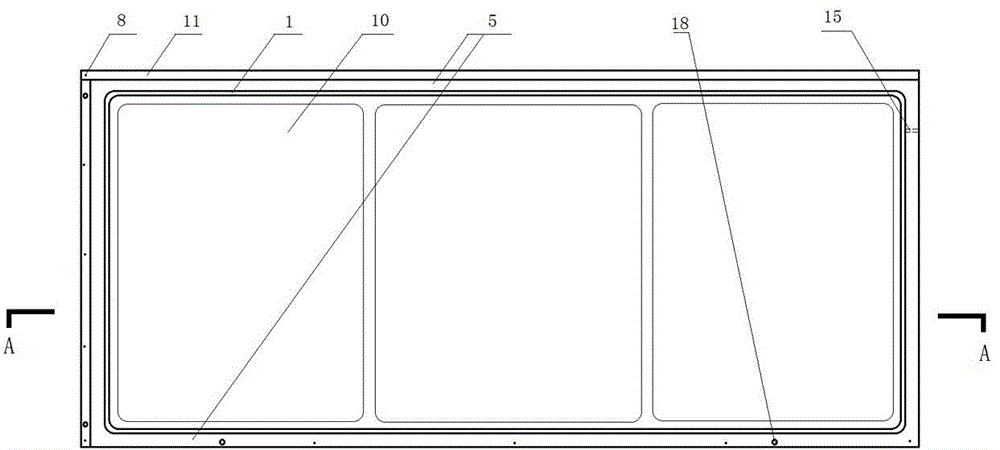

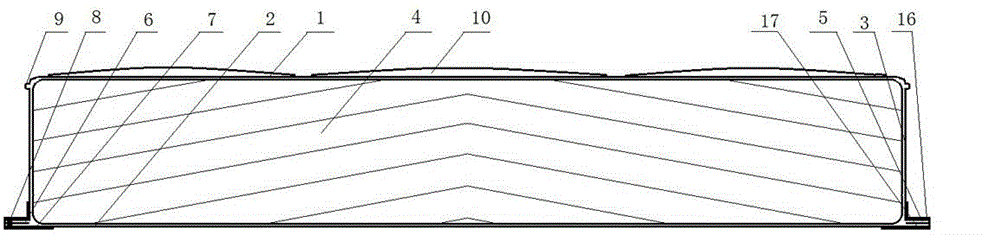

[0033] Such as figure 1 , 2 As shown, the metal vacuum insulation panel provided by the present invention is composed of a support core 4, an upper metal plate 1 and a lower metal plate 2, and the sealing edge 16 of the upper metal plate 1 and the sealing edge 17 of the lower metal plate 2 are sealed and fitted to form Vacuum chamber, the cavity wall of the vacuum chamber is provided with a vacuum hole 15, and a metal or its alloy airtight strip 6 is arranged between the sealing edge 16 of the upper metal plate 1 and the sealing edge 17 of the lower metal plate 2, and the airtight strip 6 is a melting point Metal or its alloy materials at 90°C-385°C, such as tin and its alloys, lead and its alloys, or low-temperature zinc alloys, etc., after the sealing strip 6 is heated or ultrasonically treated, it will be in contact with the sealing edge 16 and the bottom of the upper metal plate 1. The sealing edge 17 of the metal plate 2 is bonded together to form an integral seal.

[...

Embodiment 2

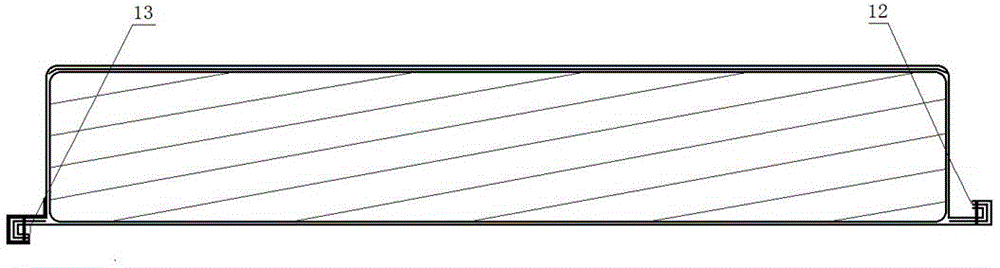

[0036] Such as image 3 As shown, in the metal vacuum insulation panel provided by the present invention, one side of the sealing edge is provided with an outward flange 12 with a gap left, and the other side of the sealed edge is inward with a flange 13 with a gap left, and the flange 12 and The flanging 13 is corresponding, and during installation, the flanging 13 is buckled in the flanging 12, and other structures are the same as the first embodiment.

Embodiment 3

[0038] Such as Figure 4 As shown, the outer surface of the metal vacuum insulation board provided by the present invention is provided with a decorative protective layer 14, and the decorative protective layer 14 is buckled on the anti-seepage convex strip 9, or fixed to the melting airtight edge 5 or the flange 11, 12, all the other structures are with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com