Rustproof corrosion inhibitor and preparation method and application thereof

A technology of corrosion inhibitor and defoamer, which is applied in the field of antirust and corrosion inhibitor and its preparation, can solve the problems that water-based antirust agent cannot fully meet the needs of the market, the hazards of environmental operators, and the unsatisfactory water solubility. Achieve good anti-rust and anti-corrosion effect, less harm to the environment and human body, good anti-corrosion performance and anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] In a second aspect, this embodiment provides a method for preparing the above-mentioned antirust and corrosion inhibitor, comprising the following steps:

[0071] (a) First heat the mixture of phytic acid, water, acrylamide, glutamic acid, sodium benzoate, triethanolamine, ethanolamine, disodium hydrogen phosphate, sodium molybdate, complexing agent and film-forming agent to 50-60°C ;

[0072] (b) Add defoamer again, continue heating to 85-90°C, keep warm for 2-3 hours, let cool, and obtain the rust-proof and corrosion-inhibitor.

[0073] In an optional embodiment, in step (a), a pH stabilizer is also added.

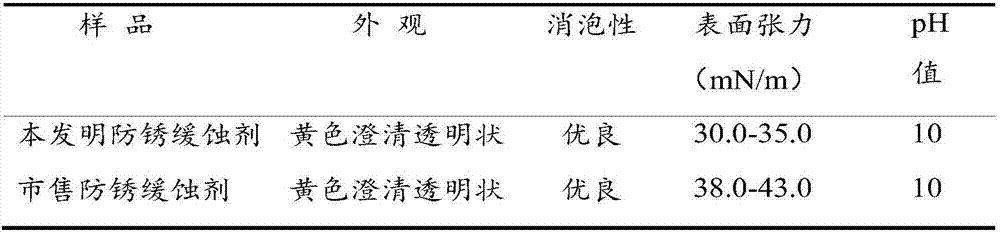

[0074] The preparation method of the anti-rust and corrosion inhibitor of the present invention has simple process and convenient operation, no special preparation equipment is required in the whole preparation process, and the product obtained by the method has good stability and is not prone to phenomena such as delamination and precipitation. And excellent ru...

Embodiment 1

[0084] An antirust and corrosion inhibitor, mainly prepared from the following raw materials in parts by weight:

[0085] 1 part of phytic acid, 60 parts of water, 0.1 part of acrylamide, 0.05 part of glutamic acid, 1 part of sodium benzoate, 5 parts of triethanolamine, 1 part of ethanolamine, 0.1 part of disodium hydrogen phosphate, 5 parts of sodium molybdate, disodium EDTA 0.2 part, 0.5 part of horse-propylene copolymer, 0.1 part of polydimethylsiloxane, and an appropriate amount of sodium hydroxide, so that the pH value of the antirust and corrosion inhibitor = 10.

Embodiment 2

[0087] An antirust and corrosion inhibitor, mainly prepared from the following raw materials in parts by weight:

[0088] 10 parts of phytic acid, 85 parts of water, 1 part of acrylamide, 0.3 parts of glutamic acid, 5 parts of sodium benzoate, 15 parts of triethanolamine, 5 parts of ethanolamine, 1 part of disodium hydrogen phosphate, 15 parts of sodium molybdate, disodium EDTA 2 parts, 3 parts of horse-propylene copolymer, 1 part of polydimethylsiloxane, and an appropriate amount of sodium hydroxide, so that the pH value of the antirust and corrosion inhibitor = 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com