High-strength anti-corrosion aluminum/magnesium dissimilar alloy connector containing middle layer and preparing method of connector

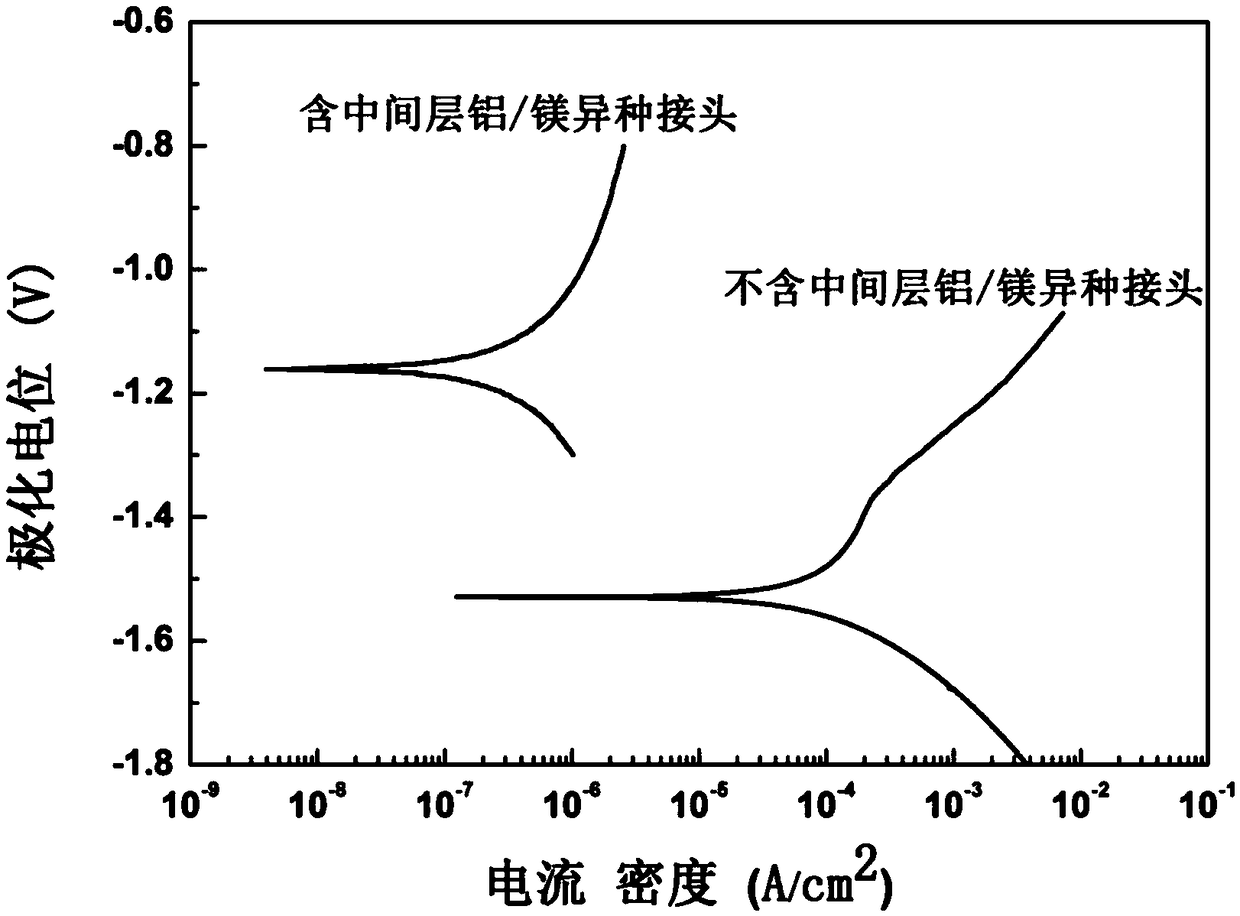

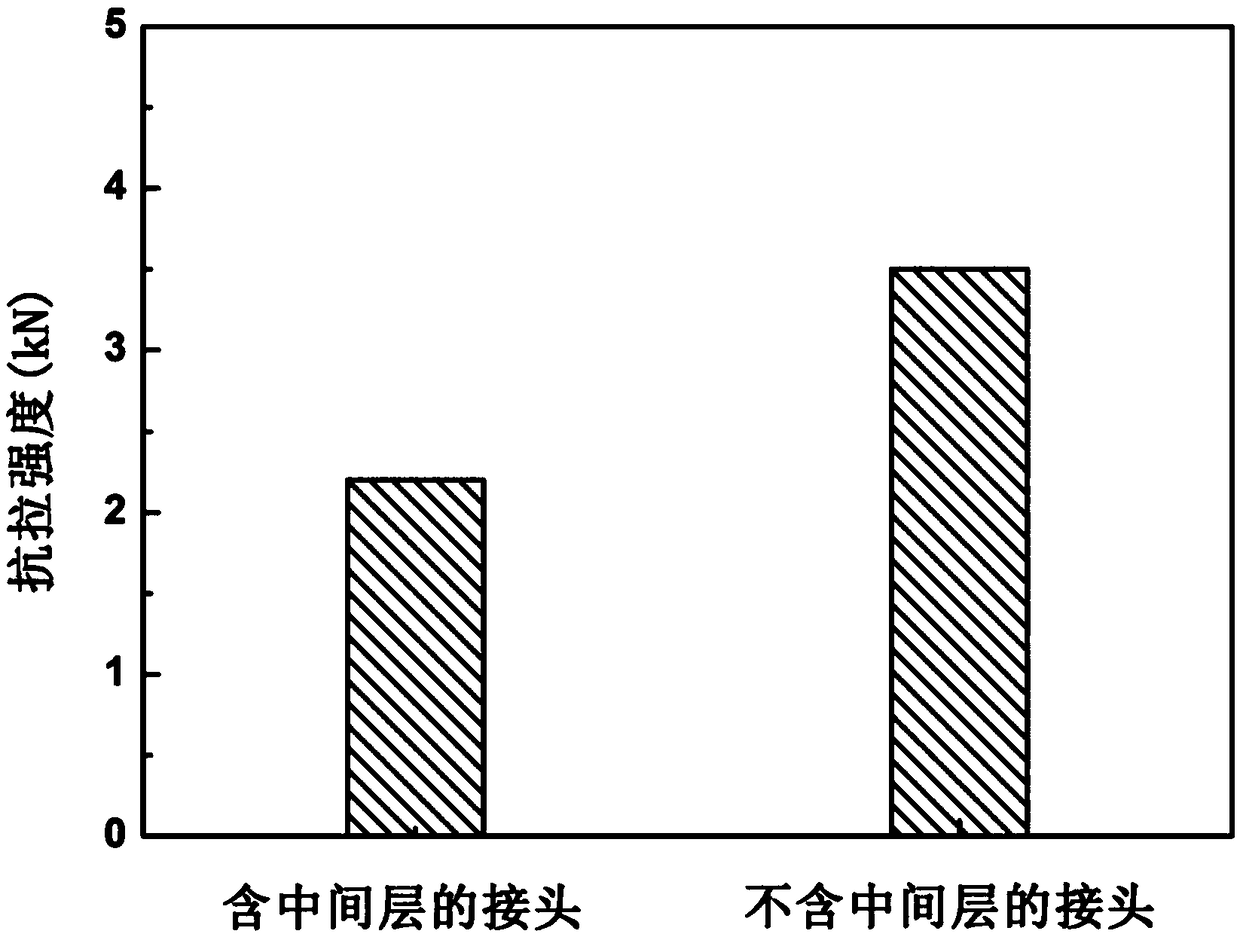

An intermediate layer and magnesium alloy technology, applied in welding equipment, metal processing equipment, coating, etc., can solve the problems of poor corrosion performance and low strength, and achieve the effect of improving corrosion resistance, increasing tensile strength, and inhibiting compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a high-strength corrosion-resistant aluminum / magnesium dissimilar alloy joint for a multi-material vehicle body in the present invention, the specific implementation of this preparation method has the following steps:

[0031] The first step: plate surface pretreatment

[0032] The surface of the aluminum alloy sheet and magnesium alloy sheet to be welded is pretreated, and polished on 500#, 1000#, 1500#, 2000# and 2500# water sandpaper in sequence to remove surface scale and impurities, and then use 0.25μm particle size diamond The abrasive paste is mechanically polished, followed by chemical polishing with 2% hydrochloric acid alcohol solution to remove surface polishing marks, and finally ultrasonically cleaned in acetone and alcohol for 20 minutes, and dried with cold air.

[0033] The second step: Co-Cr intermediate layer preparation

[0034] (A) Put the magnesium alloy sheet with the surface pretreatment in the first step into the ion impla...

Embodiment 1

[0041] The first step: plate surface pretreatment

[0042] Perform surface pretreatment on the 5052 aluminum alloy plate and ZK60 magnesium alloy plate to be welded, and polish them on 500#, 1000#, 1500#, 2000# and 2500# water sandpaper in turn to remove surface scale and impurities, and then use 0.25μm grain Diamond grinding paste was used for mechanical polishing, followed by chemical polishing with 2% volume fraction hydrochloric acid alcohol solution to remove surface polishing marks, and finally ultrasonic cleaning in acetone and alcohol for 20 minutes, and cold air drying.

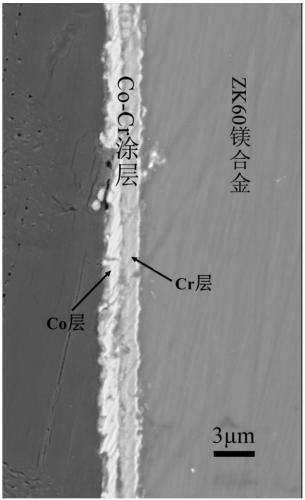

[0043] The second step: Co-Cr intermediate layer preparation

[0044] (A) Put the ZK60 magnesium alloy plate with the surface pretreatment in the first step into the ion implantation deposition composite coating machine for chromium ion implantation deposition, using pure chromium (99.99%) as the cathode target, in a vacuum of 1 × 10 -4 Pa start arc, ion implantation dose 5×10 15 ions / cm 2 , injec...

Embodiment 2

[0056] The first step: plate surface pretreatment

[0057] The surface of the 6061 aluminum alloy sheet and the AZ31B magnesium alloy sheet to be welded are pretreated, and polished on 500#, 1000#, 1500#, 2000# and 2500# water sandpaper in sequence to remove surface scale and impurities, and then use 0.25μm grain Diamond grinding paste was used for mechanical polishing, followed by chemical polishing with 2% volume fraction hydrochloric acid alcohol solution to remove surface polishing marks, and finally ultrasonic cleaning in acetone and alcohol for 20 minutes, and cold air drying.

[0058] The second step: Co-Cr intermediate layer preparation

[0059] (A) Put the AZ31B magnesium alloy sheet with the surface pretreatment in the first step into the ion implantation deposition composite coating machine for chromium ion implantation deposition, using pure chromium as the cathode target, in a vacuum of 1×10 -4 Pa start arc, ion implantation dose 1×10 16 ions / cm 2 , injection v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com