Titanium and titanium alloy surface anodic oxidation coloring method

An anodizing and titanium alloy technology, applied in the field of metal surface treatment, can solve the problems of single coloring effect, long production time, complicated process, etc., and achieve the effect of simplifying anodizing process, improving efficiency and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

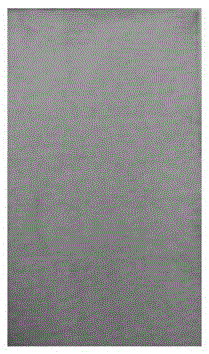

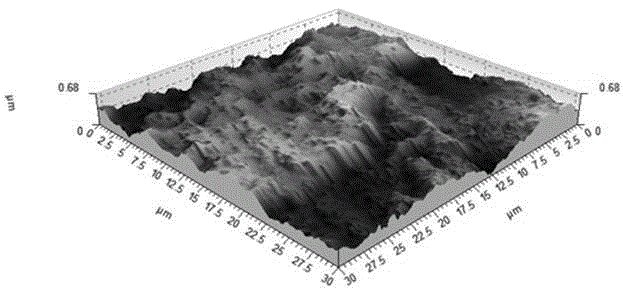

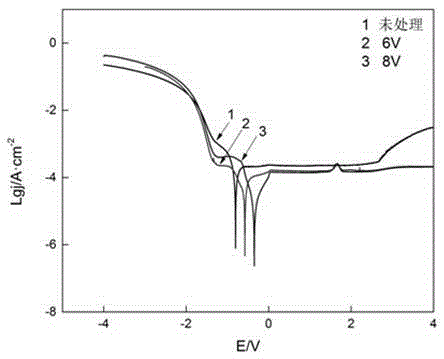

Image

Examples

Embodiment 1

[0024] This implementation provides a method for anodizing and coloring titanium surfaces, which specifically includes the following steps:

[0025] (1) At room temperature, place industrially pure titanium with a size of 10mm×10mm×0.2mm in acetone and ethanol solutions for ultrasonic vibration, take it out after 20 minutes of treatment, and then wash it with deionized water for later use.

[0026] (2) Add 2mL of hydrofluoric acid and 16mL of concentrated nitric acid in sequence to 200mL of deionized water to prepare an electrolytic polishing solution; put the pure titanium sheet after degreasing treatment into the electrolytic polishing solution, use the titanium sheet as the cathode, graphite The plate is an anode, the distance between cathode and anode is 10cm, the area ratio of cathode and anode is 1:2, the voltage is adjusted to 10V, and it is taken out after energizing treatment for 1min; the pure titanium after electropolishing is washed with deionized water successively...

Embodiment 2

[0030] This implementation provides a method for anodizing and coloring titanium surfaces, which specifically includes the following steps:

[0031] (1) Place the rectangular TC4 plate sample in acetone and ethanol solutions for ultrasonic vibration, take it out after 20 minutes of treatment, and then wash it with deionized water for later use.

[0032] (2) Add 6mL of hydrofluoric acid and 12mL of concentrated nitric acid to 200mL of deionized water in turn to prepare an electrolytic polishing solution; put the degreased titanium sheet into the electrolytic polishing solution, use the titanium sheet as the cathode, and graphite plate It is used as an anode, the area ratio of cathode and anode is 1:3, the distance between electrodes is 2cm, the voltage is adjusted to 3V, and it is taken out after 10 minutes of electrification treatment; the samples after electropolishing treatment are washed with deionized water successively, and then ultrasonicated in ethanol solution Wash for...

Embodiment 3

[0036] This implementation provides a method for anodizing and coloring titanium surfaces, which specifically includes the following steps:

[0037] (1) Place the TC4 titanium plate sample successively in acetone and ethanol solutions for ultrasonic vibration, take it out after 20 minutes of treatment, and then wash it with deionized water for later use.

[0038] (2) Add 4mL of hydrofluoric acid and 14mL of concentrated nitric acid to 200mL of deionized water in turn to prepare an electrolytic polishing solution; put the degreased titanium sheet into the electrolytic polishing solution, use the titanium sheet as the cathode, and graphite plate As an anode, the area ratio of cathode and anode is 1:2.5, the distance between them is 5cm, the voltage is adjusted to 5V, and it is taken out after 8 minutes of electrification treatment; the pure titanium after electropolishing treatment is cleaned with deionized water successively, and then ultrasonically cleaned in ethanol solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com