Method for improving corrosion resisting performance of palladium film on surface of stainless steel and palladium film

A stainless steel and corrosion-resistant technology, which is applied to a method and a palladium film layer to improve the corrosion resistance of the palladium film layer on the surface of the stainless steel, can solve problems such as economic loss in industrial production, equipment damage, stainless steel corrosion, etc., and achieves improved corrosion resistance, The effect of improving corrosion resistance and self-corrosion potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will combine figure 1 The method for improving the corrosion resistance of the palladium film layer on the stainless steel surface and the palladium film layer of the present invention are further described in detail.

[0013] In a preferred embodiment of the present invention, the process flow of plating a palladium film on the surface of stainless steel is: inspection before electroplating → organic solvent degreasing → chemical degreasing → hot water washing → pure water washing → activation → pure water washing → electroplating → cold water washing → pure Water washing → drying → heat treatment → packaging.

[0014] 1) Organic solvent degreasing

[0015] Aviation gasoline is used for degreasing, and after natural cooling, it is transferred to the next process.

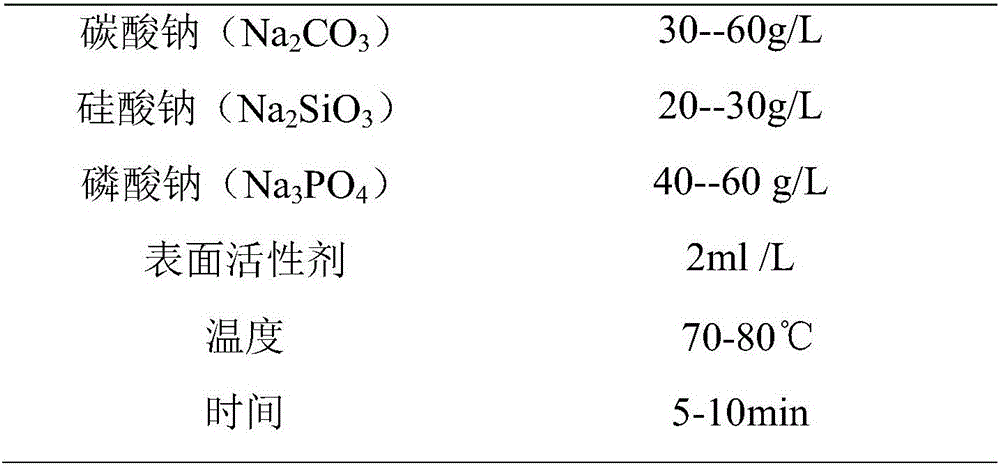

[0016] 2) Chemical degreasing

[0017] The chemical degreasing solution composition and process parameters are shown in Table 1:

[0018] Table 1 Chemical degreasing process

[0019]

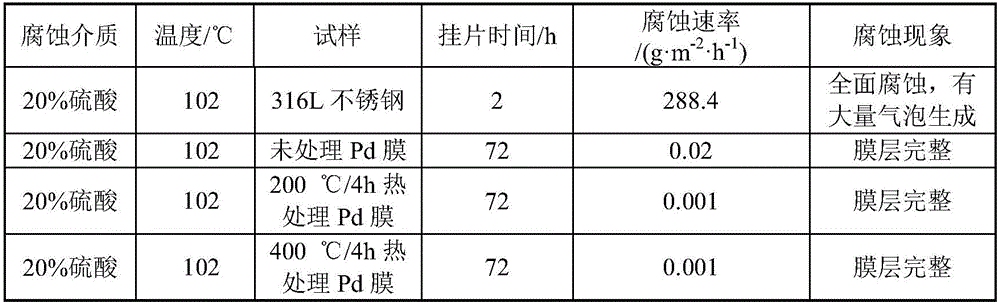

[0020] 3) Electrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com