High-weather-fastness aluminum alloy and preparing method thereof

A high weather resistance, aluminum alloy technology, applied in the direction of metal material coating process, can solve problems such as poor weather resistance, and achieve the effects of low reaction temperature, tight bonding, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

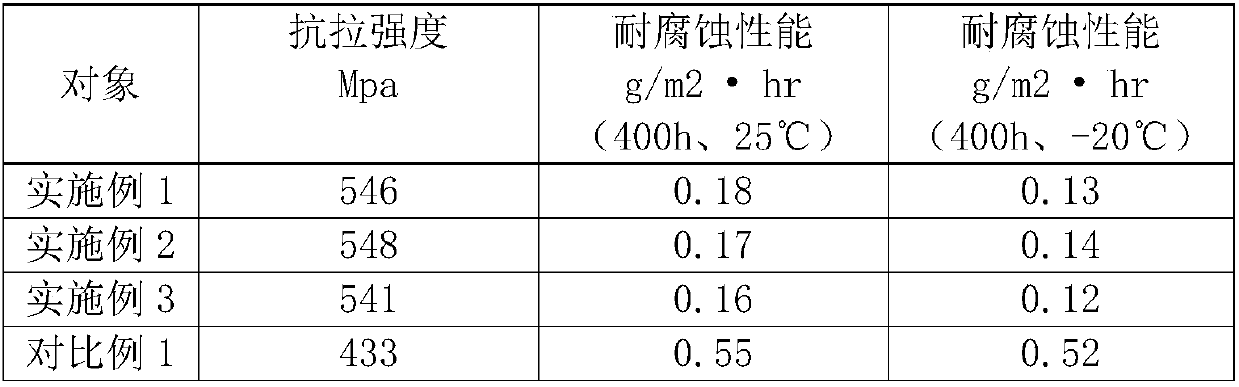

Examples

Embodiment 1

[0021] The preparation method of the high weather resistance aluminum alloy of this embodiment includes:

[0022] (1) Put the aluminum alloy powder in a melting furnace, raise the temperature to 1000°C to melt it, keep it warm for 20 minutes, then add rare earth powder accounting for 0.65% by weight of the aluminum alloy powder, and continue to heat up to 1400°C, at 800r / min Stir for 30 minutes and hold for 45 minutes, lower the temperature of the furnace to 745°C and then cast to obtain an aluminum alloy ingot, wherein the rare earth powder is Y with a weight ratio of 3:4:7. 2 o 3 , La 2 o 3 and CeO 2 The composition of the mixture; the aluminum alloy ingot is subjected to double-stage homogenization treatment at 400°C / 12h+460°C / 12h, and the aluminum alloy ingot is subjected to multiple rolling treatments, and then solution treated at 465°C for 60min , and then quenched, placing the quenched aluminum alloy ingot in a drying oven for aging treatment at 120°C for 24 hours t...

Embodiment 2

[0027] The preparation method of the high weather resistance aluminum alloy of this embodiment includes:

[0028] (1) Put the aluminum alloy powder in a melting furnace, heat it up to 1200°C to melt it, keep it warm for 150 minutes, then add rare earth powder accounting for 0.8% by weight of the aluminum alloy powder, continue to heat up to 1500°C, and heat it at 1000r / min Stir for 20 minutes and hold for 30 minutes, lower the temperature of the furnace to 750°C and then cast to obtain an aluminum alloy ingot, wherein the rare earth powder is Y with a weight ratio of 3:4:7. 2 o 3 , La 2 o 3 and CeO 2 The composition of the mixture; the aluminum alloy ingot is subjected to double-stage homogenization treatment at 400°C / 12h+460°C / 12h, and the aluminum alloy ingot is subjected to multiple rolling treatments, and then solution treated at 465°C for 60min , and then quenched, placing the quenched aluminum alloy ingot in a drying oven for aging treatment at 120°C for 24 hours to ...

Embodiment 3

[0033] The preparation method of the high weather resistance aluminum alloy of this embodiment includes:

[0034] (1) Put the aluminum alloy powder in a melting furnace, raise the temperature to 1100°C to melt it, keep it warm for 18 minutes, then add rare earth powder accounting for 0.7% by weight of the aluminum alloy powder, and continue to heat up to 1450°C, at 900r / min Stir for 25 minutes and hold for 40 minutes, lower the temperature of the furnace to 748°C and then cast to obtain an aluminum alloy ingot, wherein the rare earth powder is Y with a weight ratio of 3:4:7. 2 o 3 , La 2 o 3 and CeO 2 The composition of the mixture; the aluminum alloy ingot is subjected to double-stage homogenization treatment at 400°C / 12h+460°C / 12h, and the aluminum alloy ingot is subjected to multiple rolling treatments, and then solution treated at 465°C for 60min , and then quenched, placing the quenched aluminum alloy ingot in a drying oven for aging treatment at 120°C for 24 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com