Manufacturing method for irregular-section differential-shrinkage polyester filament yarn

A technology of polyester filament and manufacturing method, applied in filament/thread forming, single-component polyester artificial filament, textile and papermaking, etc., can solve the problems of increased manufacturing cost and complicated spinning process, and achieve high economic benefits , the effect of flexible production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

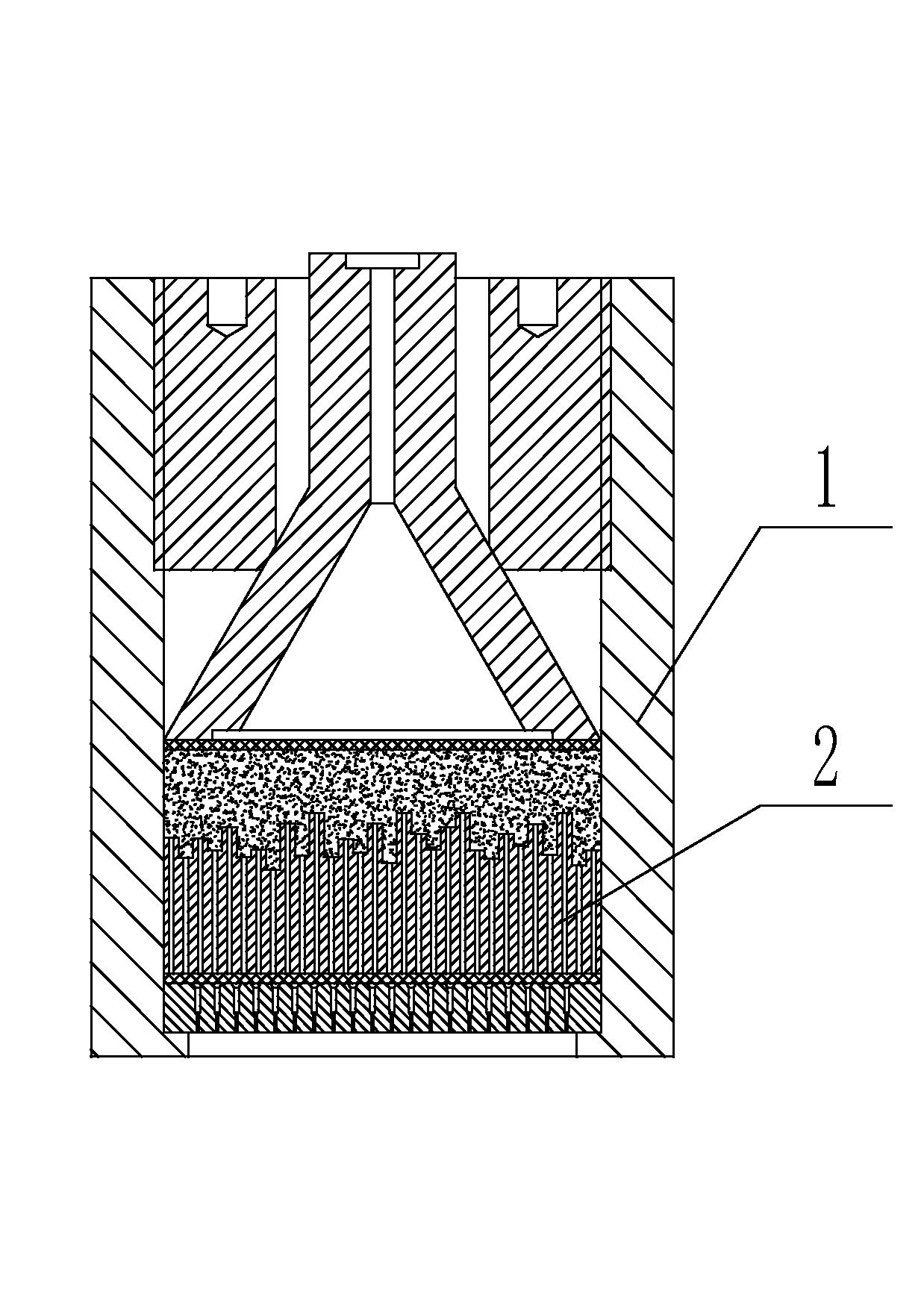

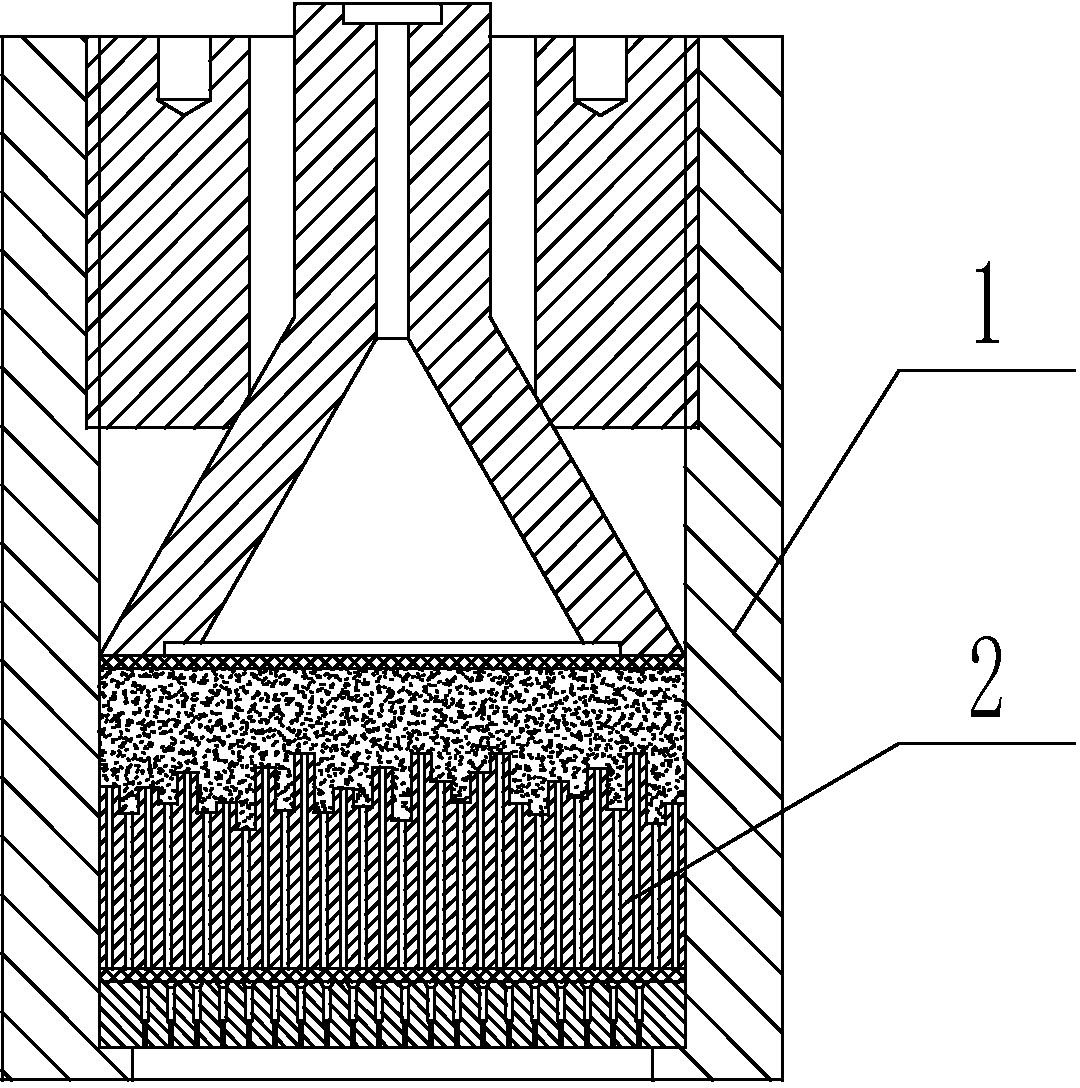

[0014] A method for manufacturing polyester filaments with different cross-sections and different shrinkages. A polyester is used as a spinning raw material. The polyester melt is extruded through a screw extruder, and then sent to the spinning assembly 1 for spinning after passing through a metering pump. Obtain the as-spun filament bundle, the structure of described spinning pack 1 is as follows figure 1 As shown, its distributing plate 2 is irregular concavo-convex type, and in described primary silk tow, thin monofilament fineness is at 0.4 dtex, and thick monofilament fineness is at 3dtex, and primary silk tow is through cooling, oiling, After drafting, networking and winding, different cross-section and different shrinkage polyester filament products are obtained. The spinning and winding speed is 4500 m / min. The different shrinkage difference of the obtained different cross-section and different shrinkage polyester filament products exceeds 15%. The difference is 5~6 ti...

Embodiment 2

[0016] A method for manufacturing polyester filaments with different cross-sections and different shrinkages. A polyester is used as a spinning raw material. The polyester melt is extruded through a screw extruder, and then sent to the spinning assembly 1 for spinning after passing through a metering pump. Obtain the as-spun filament bundle, the structure of described spinning pack 1 is as follows figure 1 As shown, its distributing plate 2 is irregular concavo-convex type, and in described spun silk tow, thin monofilament fineness is at 1 dtex, and thick monofilament fineness is at 6 dtex, and spun silk tow is cooled, oiled, After drafting, networking and winding, different cross-section and different shrinkage polyester filament products are obtained. The spinning and winding speed is 5300 m / min. The different shrinkage difference of the obtained different cross-section and different shrinkage polyester filament products exceeds 15%. The difference is 5~6 times.

Embodiment 3

[0018] A method for manufacturing polyester filaments with different cross-sections and different shrinkages. A polyester is used as a spinning raw material. The polyester melt is extruded through a screw extruder, and then sent to the spinning assembly 1 for spinning after passing through a metering pump. Obtain the as-spun filament bundle, the structure of described spinning pack 1 is as follows figure 1 As shown, the distribution plate 2 is an irregular concave-convex shape. Among the primary filament bundles, the fineness of the single filaments is 0.7 dtex, and the fineness of the thick single filaments is 4.5 dtex. The primary filament bundles are cooled and oiled. , drafting, networking and winding to obtain different cross-section and different shrinkage polyester filament products, wherein the spinning and winding speed is 5000 m / min, and the different shrinkage difference of the obtained different cross-section and different shrinkage polyester filament products excee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com