Hot extrusion forming method of stainless steel rail

A forming method and extrusion forming technology, applied in the direction of metal extrusion dies, etc., can solve the problems of scrapping rails in the heating process, and achieve the effects of not being restricted by blanks, increasing the economic benefits of the enterprise, and stabilizing the forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope of the claims also belong to the protection scope of the present invention.

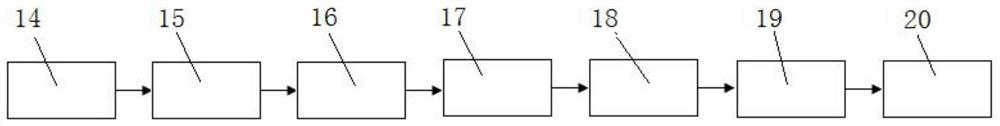

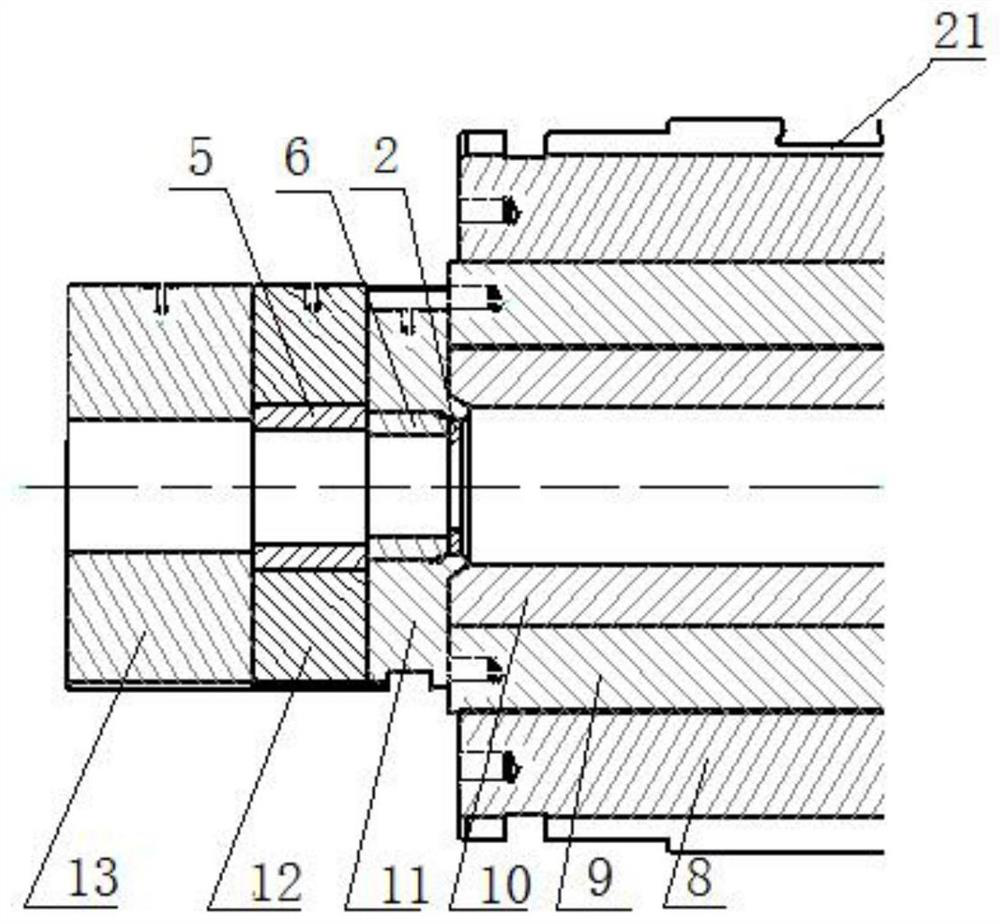

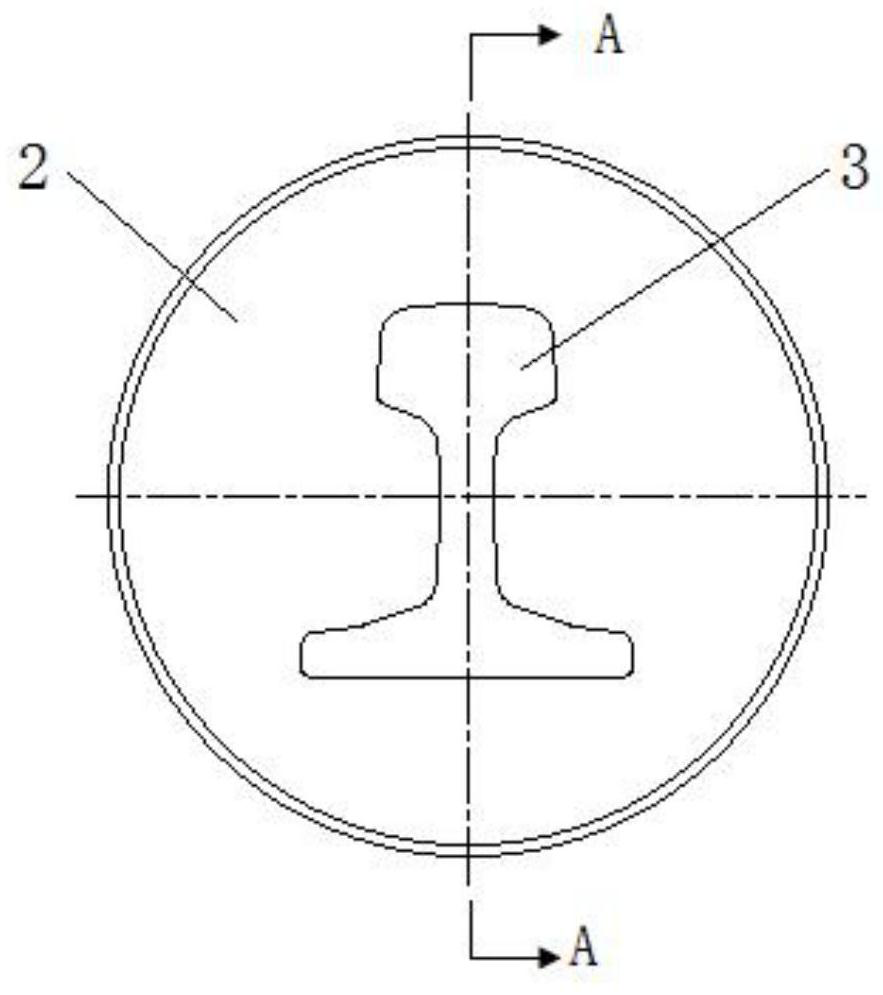

[0026] The hot extrusion molding of the stainless steel rail of the present invention utilizes a hot extrusion molding system to carry out extrusion molding, such as figure 1 As shown, the hot extrusion molding system includes machining equipment 14 , heating equipment 15 , lubricating equipment 16 , hot extrusion equipment 17 , cooling bed 18 , heat treatment equipment 19 and inspection equipment 20 . Processing equipment, induction heating equipment, lubrication equipment, hot extrusion equipment, cooling bed, heat treatment equipment and inspection equipment are set up in sequence. The machining equipment includes lathes, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com