Hole flanging method and die for forming high flange on thin plate

A flange and die technology, applied to metal extrusion dies and other directions, can solve the problems of not widely used, easy to break, easy to jump out of the die surface, etc., to achieve the effect of simple die structure, improve processing efficiency, and avoid potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

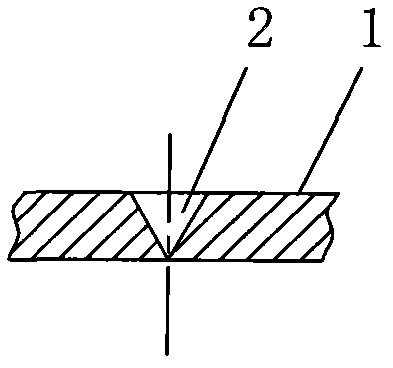

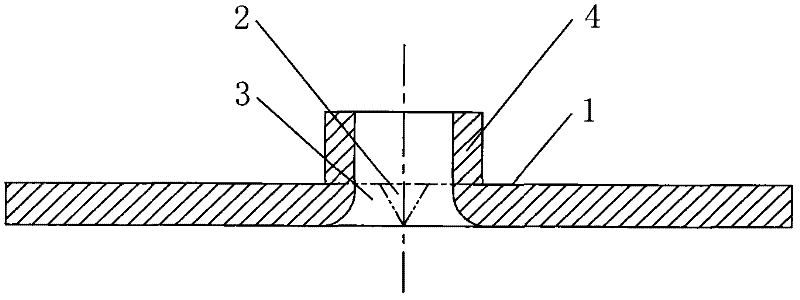

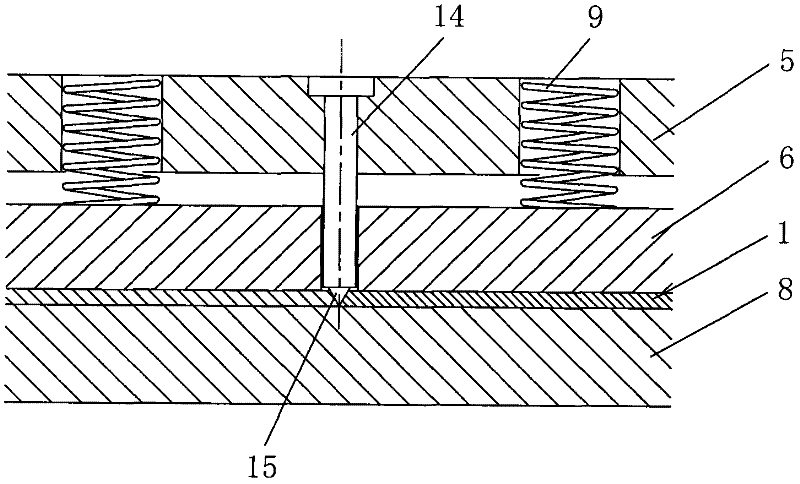

[0024] Such as figure 1 with figure 2 As shown, the hole-turning method of the present invention has no waste material generation, and the straight body height of the flange 4 formed by the hole-turning is very high, and the edge of the flange 4 will not produce sharp sharp angles. The method comprises the following steps: A, extruding Pressure cone hole: the cone hole 2 is vertically extruded on the sheet metal base material 1. During the extrusion process, as the cone hole 2 gradually expands, the metal material at the extruded part produces plastic deformation and flows to the cone hole 2 to form a accumulation area 3. The conical hole 2 formed by the final extrusion should not pierce the sheet metal base material 1, so as to avoid the generation of waste; B. Reverse turning hole: from the back of the sheet metal base material 1 to the corresponding position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com