Method for stiffening the structure strength of clutch driven disk vibration reduction disk and making reasonable distribution of the strength

A disc structure and clutch technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of unreasonable strength distribution and large material consumption, and achieve the effects of reasonable strength distribution, improved structural strength, and utilization of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

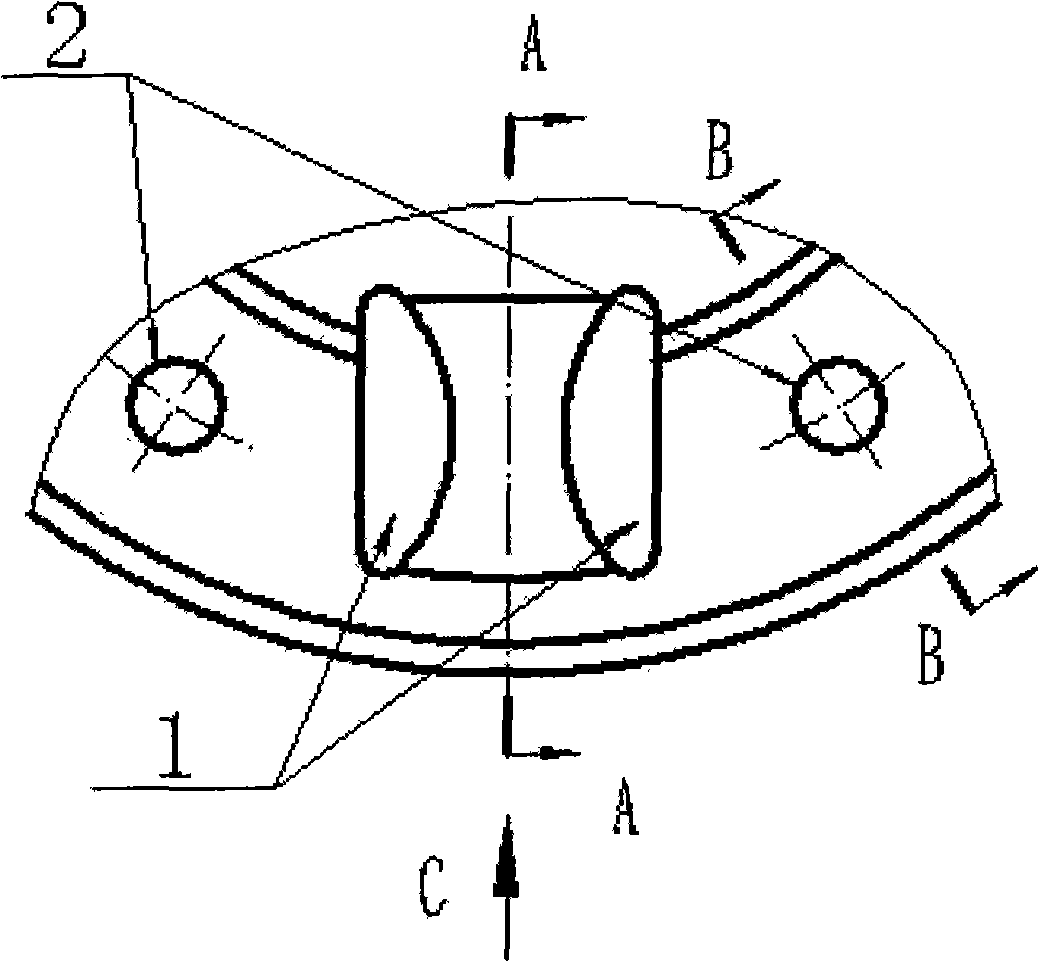

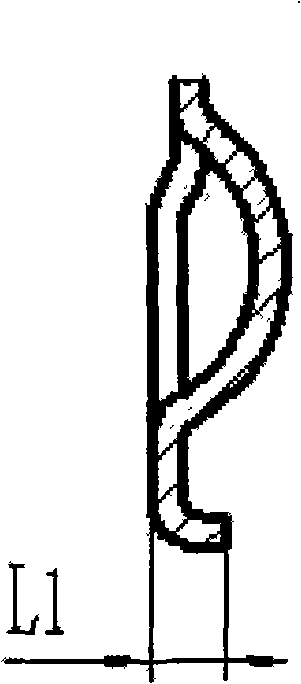

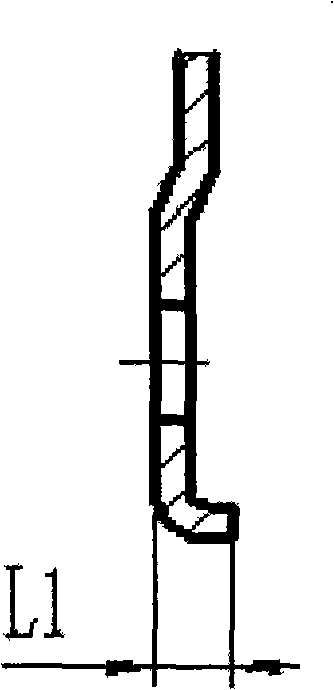

[0017] refer to Figure 1-Figure 6 , using the method of the present invention, for the existing outer circle diameter φ180mm, outer circle flanging height L 1 =L 2 The structure of the damping plate of the driven plate = 7mm is improved. After the improvement, the diameter of the outer circle is φ170mm, and the height of the flanging at the window of the shock absorbing plate is 3 L 1 =11.5mm, the flange 4 height L at the limit hole of the shock absorber 2 = 7 mm. Since the height of the flange 3 at the window of the damping disc is increased from 7mm to 11.5mm, the strength is enhanced.

[0018] During production, use a polygonal blanking blank twice the number of the damping disc window 1, punch out the corners of the polygon corresponding to the window 1 of the damping disc, and punch out the edge of the polygon corresponding to the limit hole 2 of the damping disc, which can effectively Use materials and save costs.

Embodiment 2

[0020] Adopt the method of the present invention, to existing outer circle diameter φ 170mm, outer circle flanging height L 1 =L 2 The structure of the damping plate of the driven plate = 5mm is improved, the outer diameter of the improved diameter is φ160mm, and the height of the flanging at the window of the damping plate is 3 L 1 =10mm, the flange 4 height L at the limit hole of the shock absorber 2 =5.5mm, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com