Novel tire and production process thereof

A tire and process technology, applied to tire parts, reinforcing layers of pneumatic tires, tires, etc., can solve the problems of softness and insufficient rigidity, large deformation of sidewall parts, cracking of belt colloid, etc., and achieve wear resistance Good, reasonable spacing, and the effect of improving grip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

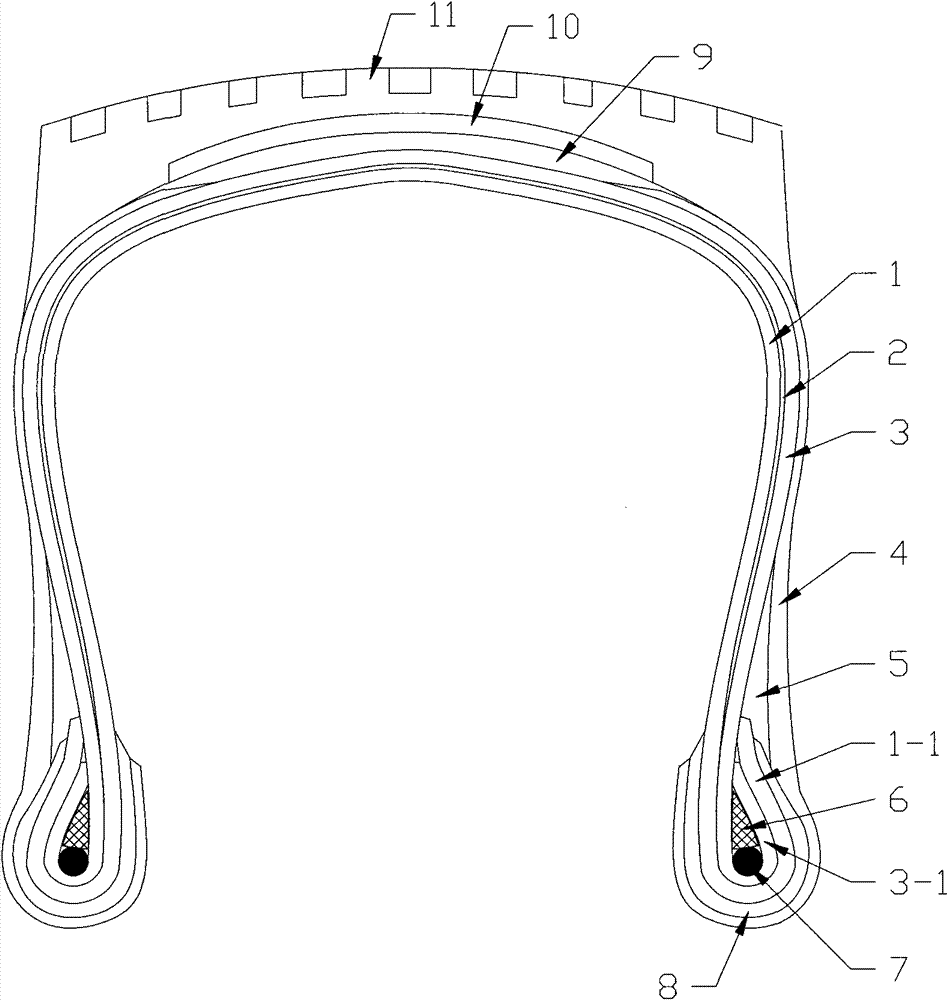

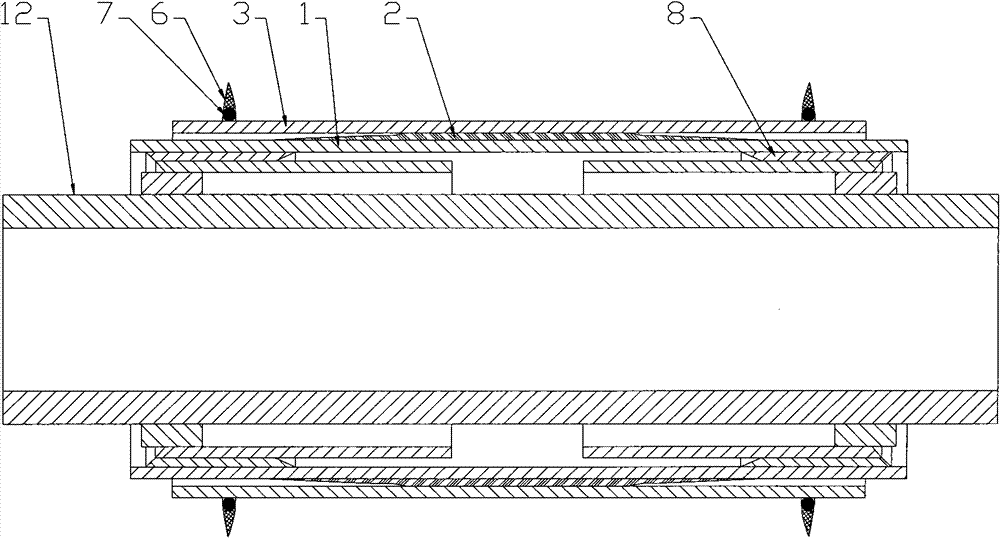

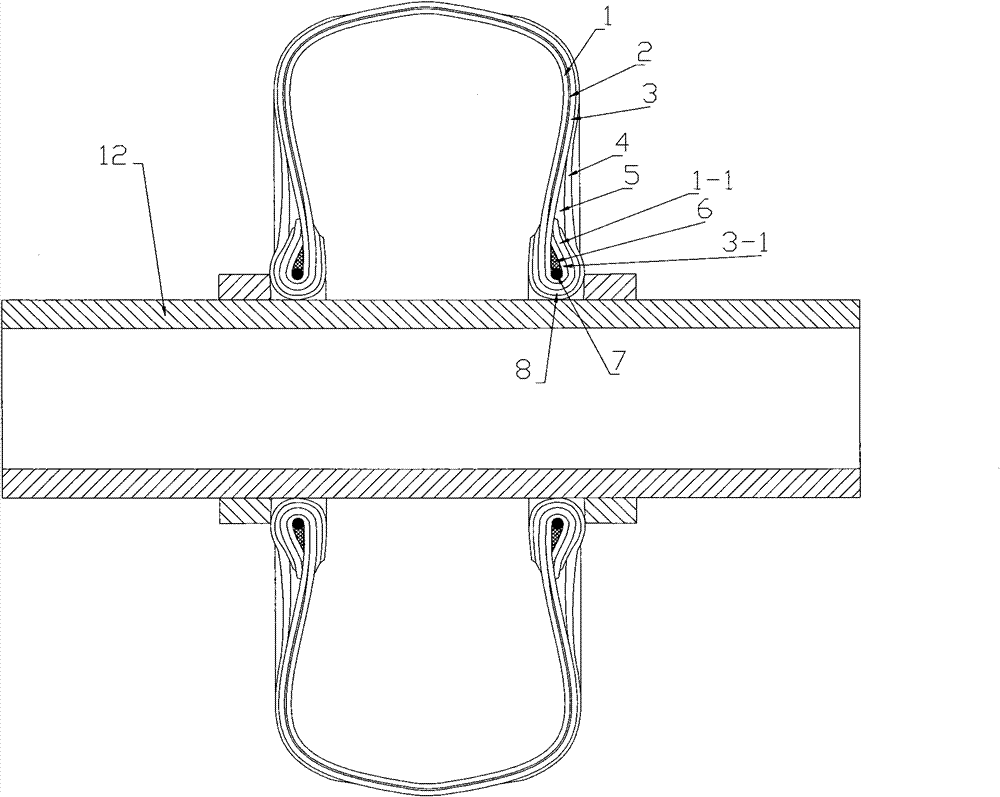

[0058] Such as figure 1 As shown, the present invention is a tire and its production process. The tire includes a carcass, a buffer layer 9, a belt layer 10, a sidewall and a tread 11, and the carcass includes an inner ply 1 and an outer ply 3. The two sides of the inner ply and the outer ply are provided with flanging, and the flanging is turned outward along the traveler 7 and attached to the outer ply 3, and the flanging 1-1 on both sides of the inner ply are respectively 7mm longer than the flanges 3-1 on both sides of the outer ply, the flanges 1-1 on both sides of the inner ply wrap the flanges 3-1 on both sides of the outer ply respectively, and the flanges on both sides of the inner ply are provided with In the inner sealing layer 8, both side flanges of the inner ply are wrapped by the encapsulation 5 arranged between the inner sealing layer 8 and the outer ply 3. The inner and outer plies are steel cords, and there is a colloidal interlayer 2 between the inner and o...

Embodiment 2

[0080] This embodiment is based on Embodiment 1, wherein the reinforcing portion 10-1 of the belt layer 10 is a three-layer cord, and the second loop portion of the cord bundle of the three-layer cord part of the belt layer reinforcing portion overlaps the first circle, starting from the third circle partially overlapping the previous two circles.

[0081] Correspondingly, in the process, when the cord bundle is wound, the belt forming drum is constantly rotating, and while it is rotating, a toggle mechanism is used to drive the cord bundle to run along the axial direction of the belt forming drum, and the belt Every time the belt layer forming drum rotates one circle, the distance of the belt layer routing driven by the toggle mechanism is greater than or equal to the width of the cord bundle. The driving mechanism drives the distance of the belt layer to be less than the width of the cord bundle, so that the second circle of the reinforcement partially overlaps the first cir...

Embodiment 3

[0083] This embodiment is based on Embodiment 1 or Embodiment 2, wherein the cords of the belt layer 10 are aromatic polyamide cords, including the following:

[0084]

[0085]

[0086] The strength of the aramid cord is also quite reliable under the condition that the carcass is a steel cord, and its cost is much lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com