Production process of grained pyrograph

A production process and texture technology, which is applied in the field of texture heat transfer production technology, can solve the problems of increasing demand, achieve the effects of improving elasticity and washing performance, benefiting environmental protection, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

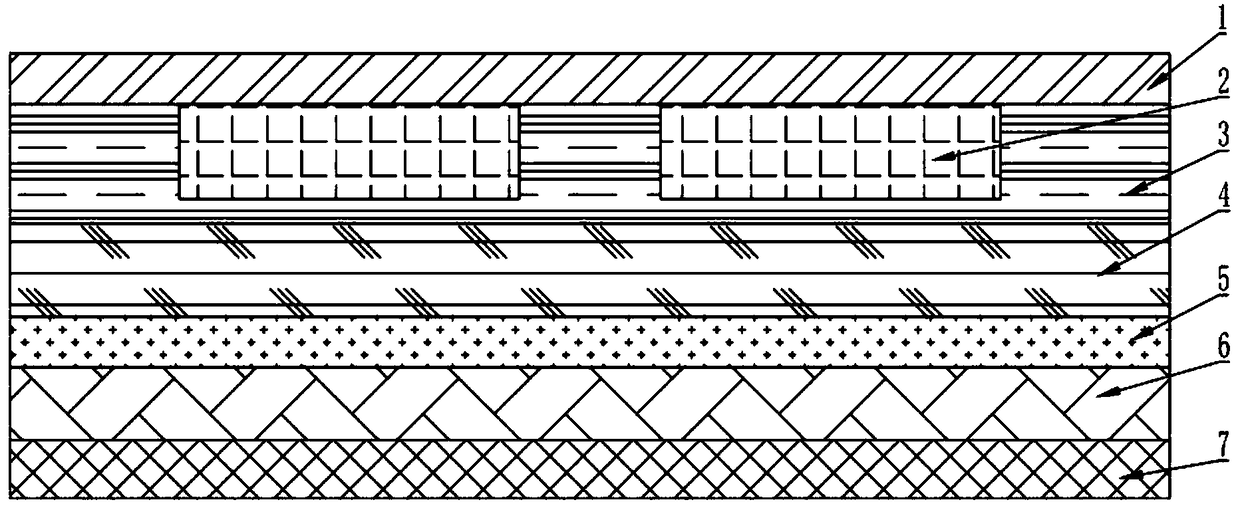

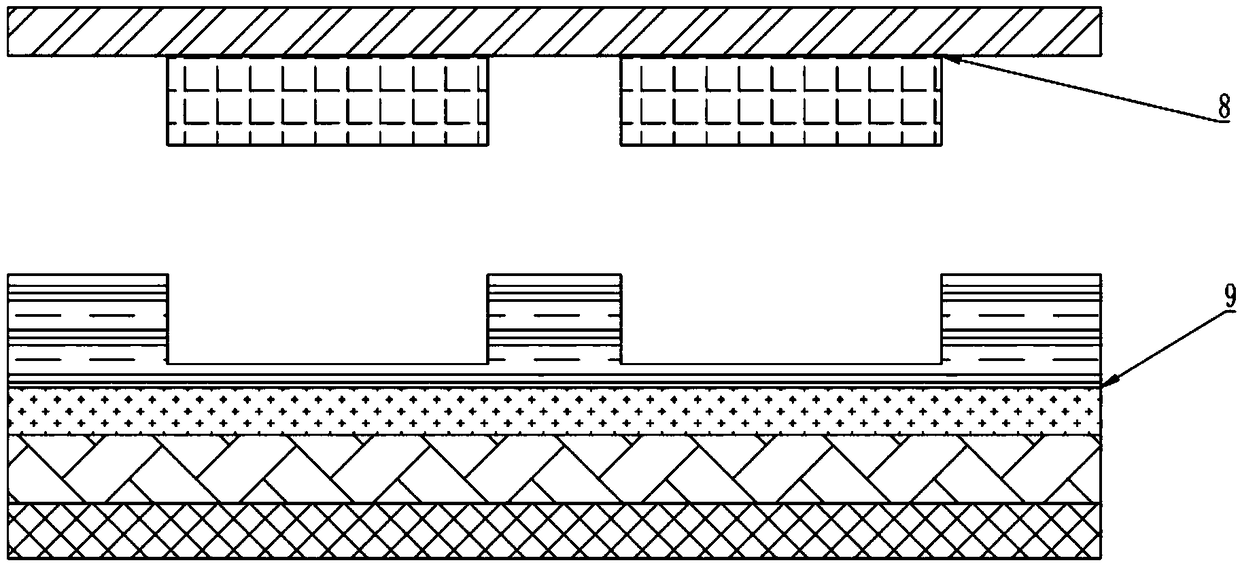

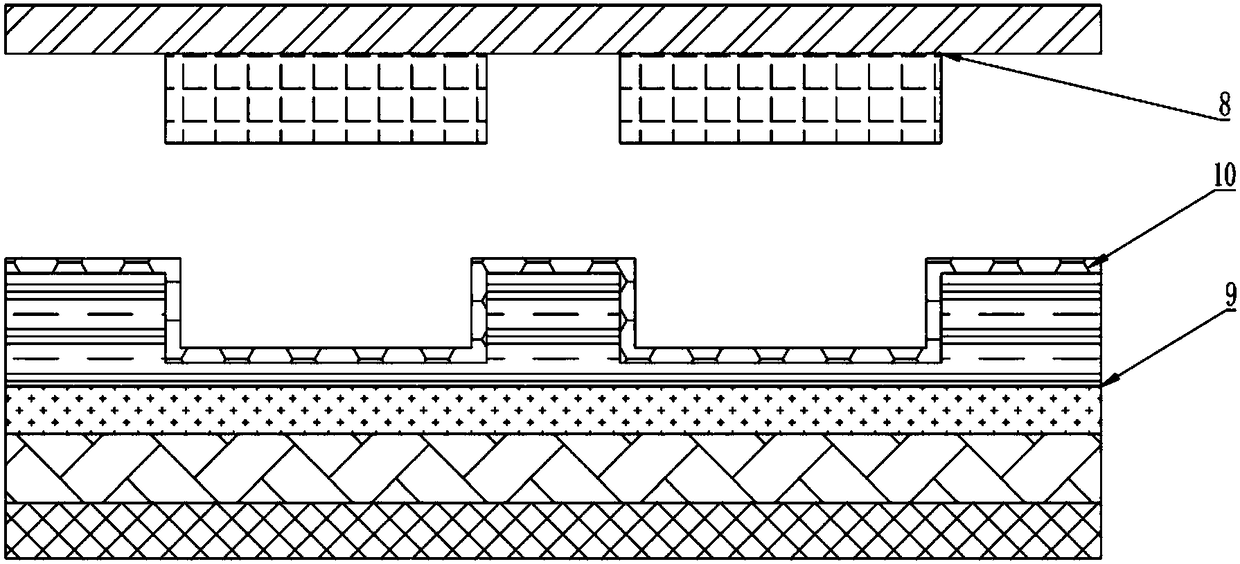

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Make a carrier with texture, use a clear PET sheet coated with the mixture, then I coat the silicone rubber slurry with 2% catalyst to print any design or pattern on this sheet through 43T filament Screen print at least once, and dry in a tunnel oven at 80°C for 2 minutes to dry completely. In this process, use smooth or sub-surface silica gel to control the sub-surface or glossy effect of the texture effect, which can be increased by adding Or reduce the number of printing passes and increase or reduce the mesh number of the screen printing screen to control the depth and thickness of the generated lines;

[0029] Step 2: After drying, the silicone rubber will produce lines on the surface of the PET film. Use a screen plate with a size slightly larger than the pattern of 0.18mm to print a high-concentration transparent water-based resin on the surface of the silicone rubber, which makes the surface of the silicone rubber change again. To be smooth, this layer o...

Embodiment 2

[0040] Based on the method of Embodiment 1, it is also possible to continue to print thicker coatings on the basis of flat heat transfer with lines, so as to achieve the effect of thick plate printing. The final product not only has three-dimensional lines but also has a certain thickness, which has a strong three-dimensional effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com