Industrial Cloth Laminating Machine

A technology of industrial cloth and laminating machine, which is applied in the directions of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of complex production process of industrial cloth, prolonging the processing time of cloth, reducing the production efficiency of cloth, etc. Flexible production methods, reduced installation and maintenance difficulties, and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing description and specific embodiment, the present invention will be described in further detail:

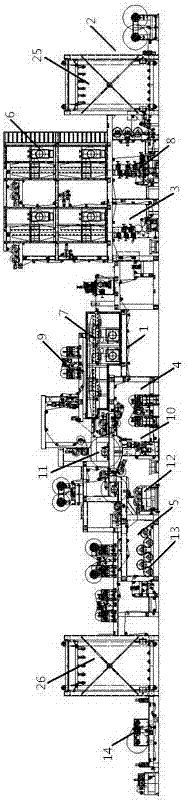

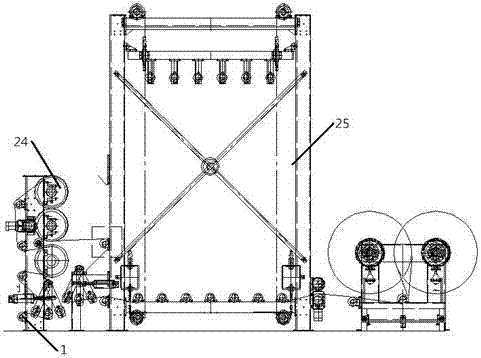

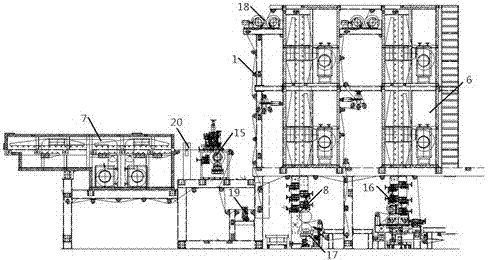

[0026] see Figure 1-Figure 2 , an industrial cloth laminating machine, including a cloth feeding mechanism 2, a coating mechanism 3, a film pasting mechanism 4 and a material receiving mechanism 5 connected in series by a feeding roller table 1, and the cloth feeding mechanism 2 includes a cloth ironing mechanism Device 24, the cloth ironing device 24 is close to the side of the coating mechanism 3, the coating mechanism 3 includes a vertical oven 6, a horizontal oven 7 and a dipping device 8, and the film sticking mechanism 4 includes a sending table 9, The film processing device 10 and the large cylinder 11, the material receiving mechanism 5 includes a total pressure table 12, a cooling belt 13 and a winding device 14, in order to ensure that the final finished selvedge is neat, the cooling belt 13 and the winding device 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com