Frame for fuel cell membrane electrode and bonding system of frame and membrane

A fuel cell membrane and membrane system technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problem of increasing optical identification and positioning and manipulator grasping actions, uneven edges of coating catalyst areas, and unfavorable smooth and fast production. problem, to reduce inefficiency, reduce application and peel times, and design clever results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

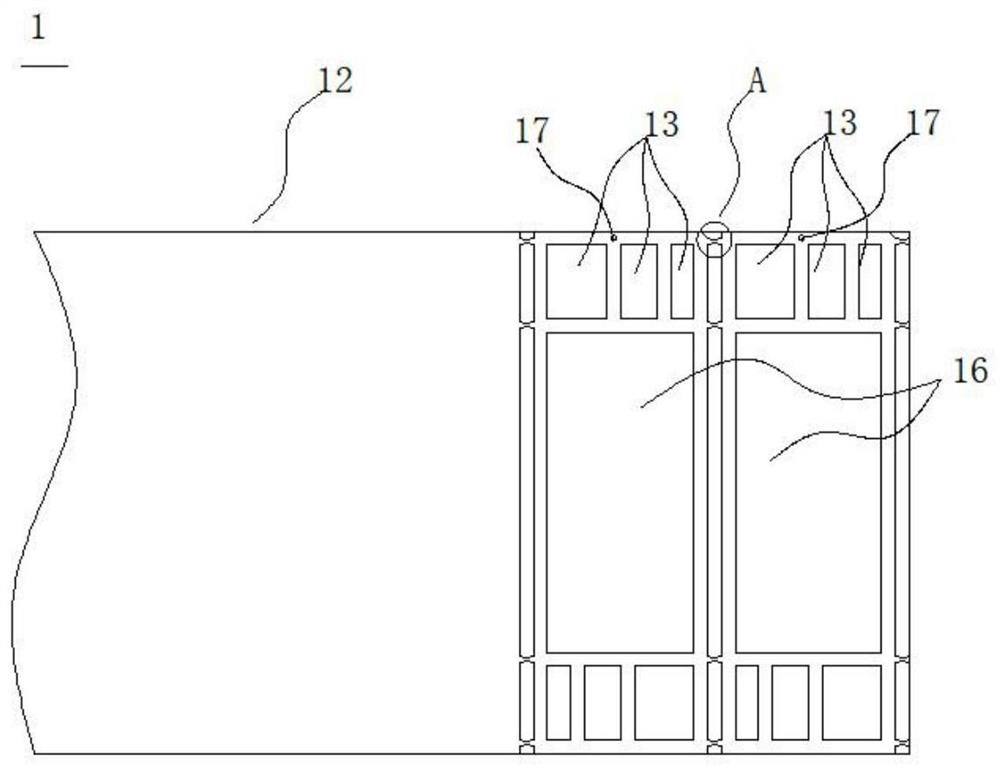

[0044] The basic structure of embodiment 1 frame

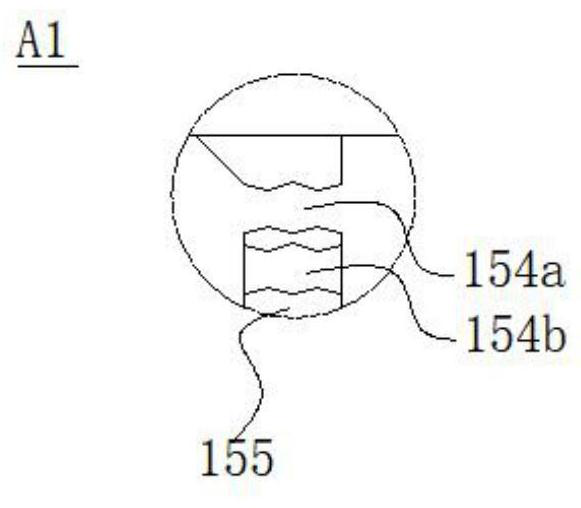

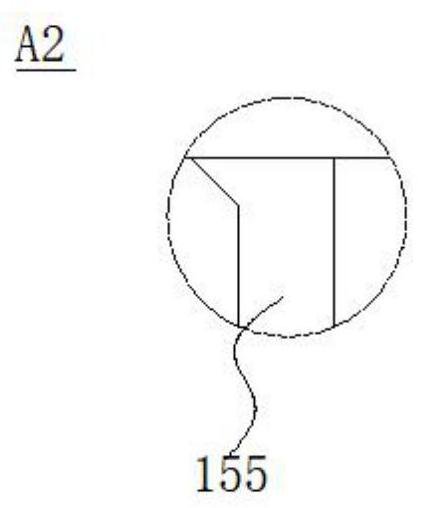

[0045] Frames are usually used in the production of membrane electrodes in roll form with backing paper. The frame continuous material 12 with backing paper is provided with several frames, and several connecting thin strips with connection function are arranged between adjacent frames, that is, the connecting thin strips 154a of the upper frame or the connecting thin strips 154b of the lower frame. There are positioning hole through-holes 17 for the positioning of the new three-in-one assembly of the present invention. The positioning hole through-holes 17 are on both sides of the traveling direction, and the through-holes pass through the backing paper. In the middle of the frame is a cut-out area, which is provided with a battery reaction area 16 for membrane assembly. The cut-out area also includes the fluid common channel blank space 13 of the frame on both sides of the battery reaction area 16, which belongs to the commo...

Embodiment 2

[0051] In conjunction with the accompanying drawings, the system of the present invention has the following structure:

[0052] The system includes a membrane system 3 , a lower frame system 2 and an upper frame system 4 ; wherein the upper frame system 4 is located above the lower frame system 2 . Membrane system 3 is located outside the upper and lower frame systems, and the cut film is absorbed by the migration suction plate 37 in the membrane system 3, and moved to the heat sealing table of the lower frame system 2 to transfer and provide the film. Reserve more space between the heat-sealing tables than is required for the traction plate transfer film.

[0053] The membrane system 3 includes a membrane roll 31, a membrane humidity control area 300, and a film shearing area connected in sequence, and the release liner area is connected to the membrane humidity control area 300;

[0054] Wherein, in the film humidity control area 300, the upper film nip roll and the lower f...

Embodiment 3

[0060] In this embodiment, the method for bonding the membrane of the fuel cell membrane electrode to the frame is described in detail in combination with the device mentioned in Embodiment 2. It should be pointed out that the time sequence of step S1 and step S2 is not strictly limited in the present invention, and step S1 and step S2 can be performed simultaneously in the actual production process. The forming and cutting of the frame in the present invention can be prepared in advance, or it can be prepared before assembly at the site where the new three-in-one is produced, and the frame is usually in the form of a roll with a backing paper. The opening of the exchange membrane installed in the frame is larger than the size of the exchange membrane, which is 0.2-1.5 mm larger than the size of each side.

[0061] S1. Lower frame feeding and positioning

[0062] Such as Figure 5 The lower frame feeding and positioning schematic diagram is shown, the lower frame coiled mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com