Alkali-soluble resin, preparation method of alkali-soluble resin and photoresist

A technology of photoresist and soluble resin, which is applied in the field of alkali soluble resin and its preparation, and photoresist, which can solve the problem of incomplete removal of non-exposed areas, failure of photoresist, and rough surface and other problems, to achieve the effect of neat edges, enhanced stability, and reduced residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

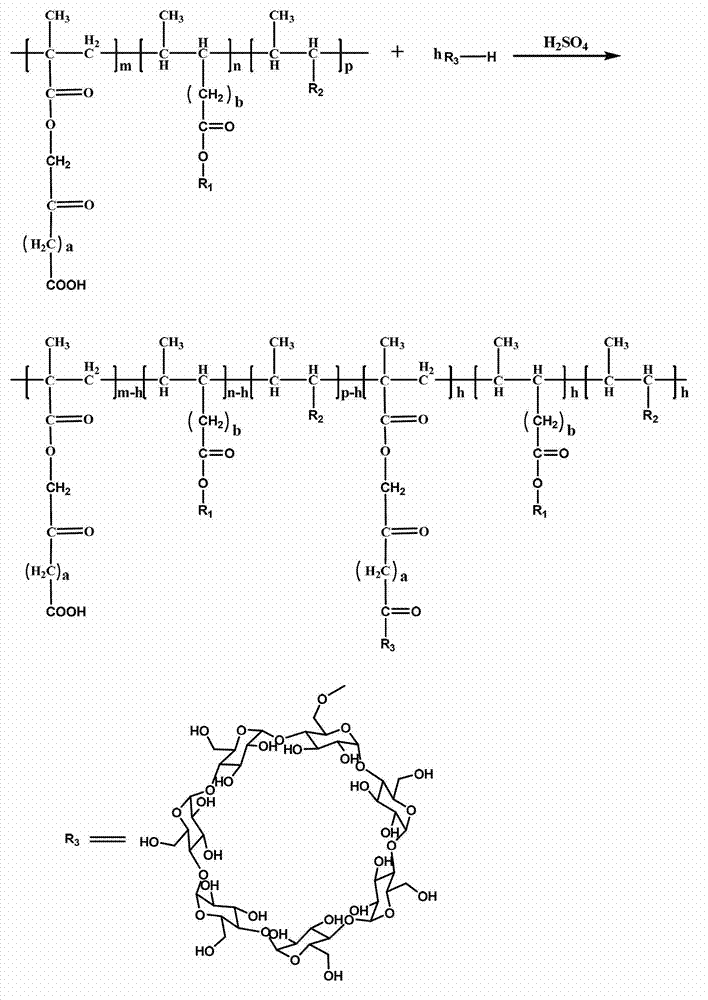

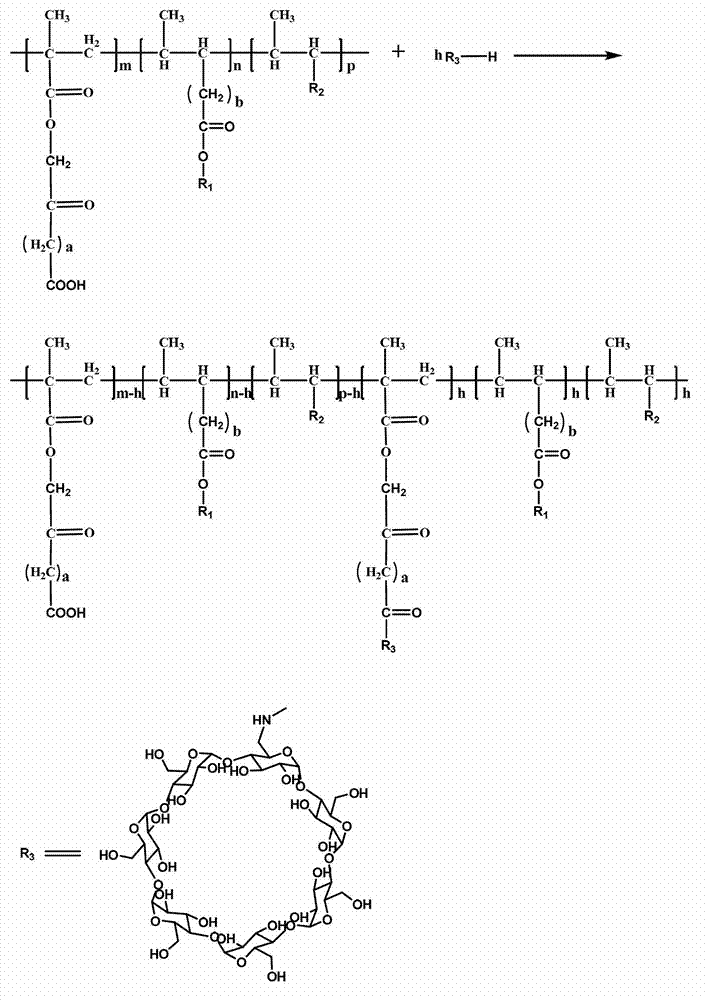

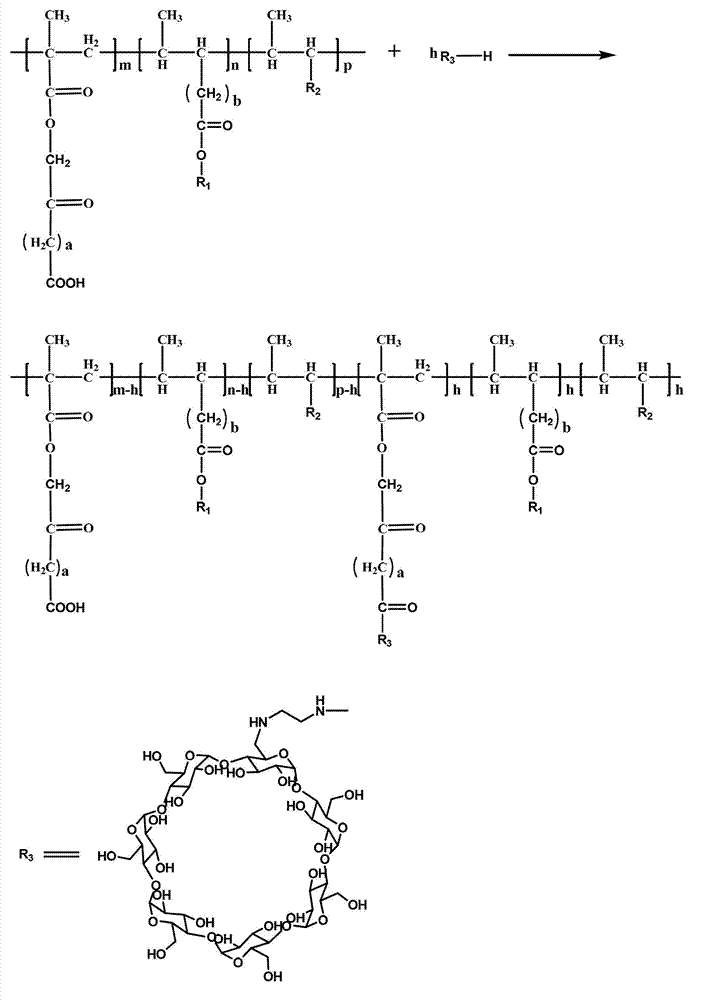

[0038] The preparation method of alkali-soluble resin of the present invention, comprises the steps:

[0039] Make the alkali-soluble resin and β-cyclodextrin or β-cyclodextrin derivative undergo esterification or amidation reaction in an organic solvent environment to obtain the base modified with β-cyclodextrin or β-cyclodextrin derivative Soluble resin.

[0040] The esterification reaction can be carried out according to methods known in the art, for example, the esterification reaction is carried out under a nitrogen atmosphere and in the presence of concentrated sulfuric acid.

[0041] The amidation reaction can be carried out according to methods known in the art, such as the amidation reaction in the presence of 1-hydroxybenzotriazole and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide conduct.

[0042] Among them, the organic solvent is generally used as a medium for the reaction and does not participate in the reaction. There are many types of organic solvents to choo...

Embodiment 1

[0055] First weigh 1 part by weight of alkali-soluble acrylic resin, dissolve it in 41 parts by weight of propylene glycol methyl ether acetate, add 5 parts by weight of β-cyclodextrin under a nitrogen atmosphere, then add 0.1 part by weight of concentrated sulfuric acid dropwise, and heat in an oil bath 60°C, react for 6h. During the reaction process, the water generated in the reaction is continuously removed by using the azeotropic method, and the reaction is pushed to the right. After the reaction, the solution was cooled to room temperature, and then the solvent was removed by rotary evaporation, washed with water, and dried in vacuum to obtain an alkali-soluble acrylic resin modified by β-cyclodextrin, such as figure 1 .

[0056] The ratio and position of modification of β-cyclodextrin were detected by proton nuclear magnetic spectrum.

[0057] Specific method: the chemical shift δ value of carboxyl proton is generally 10-12ppm, in 1 H NMR (CDCl 3 ,400MHz, ppm) on th...

Embodiment 2

[0059] First synthesize mono-(6-p-toluenesulfonyl)-β-cyclodextrin: add 50 parts by weight of water in the reactor, add 13 parts by weight of β-cyclodextrin in batches under stirring, keep the solution temperature with water bath Between 10-20°C. Sodium hydroxide aqueous solution (1 weight part sodium hydroxide is dissolved in 4 weight parts water) is added dropwise in the solution, after treating that β-cyclodextrin dissolves completely, continue stirring for 1 hour, then the acetonitrile solution of p-toluenesulfonyl chloride ( 2 parts by weight of p-toluenesulfonyl chloride dissolved in 6 parts by weight of acetonitrile) was slowly added dropwise to the above solution, and the stirring was continued at constant temperature for 2-2.5 hours. Remove the insoluble matter by filtration, adjust the pH value of the solution to 8-9 with 10% hydrochloric acid solution, place it at about 2°C for a day and night to precipitate a large amount of white precipitate, collect the precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com