Movable integrated device for producing precast concrete planks and production process

A prefabricated concrete slab and production process technology, applied in the direction of lifting equipment braking device, unloading device, supply device, etc., can solve the problems of difficult relocation, long transportation lines for finished products, and long installation period, so as to make full use of space, The effect of sufficient product quality and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

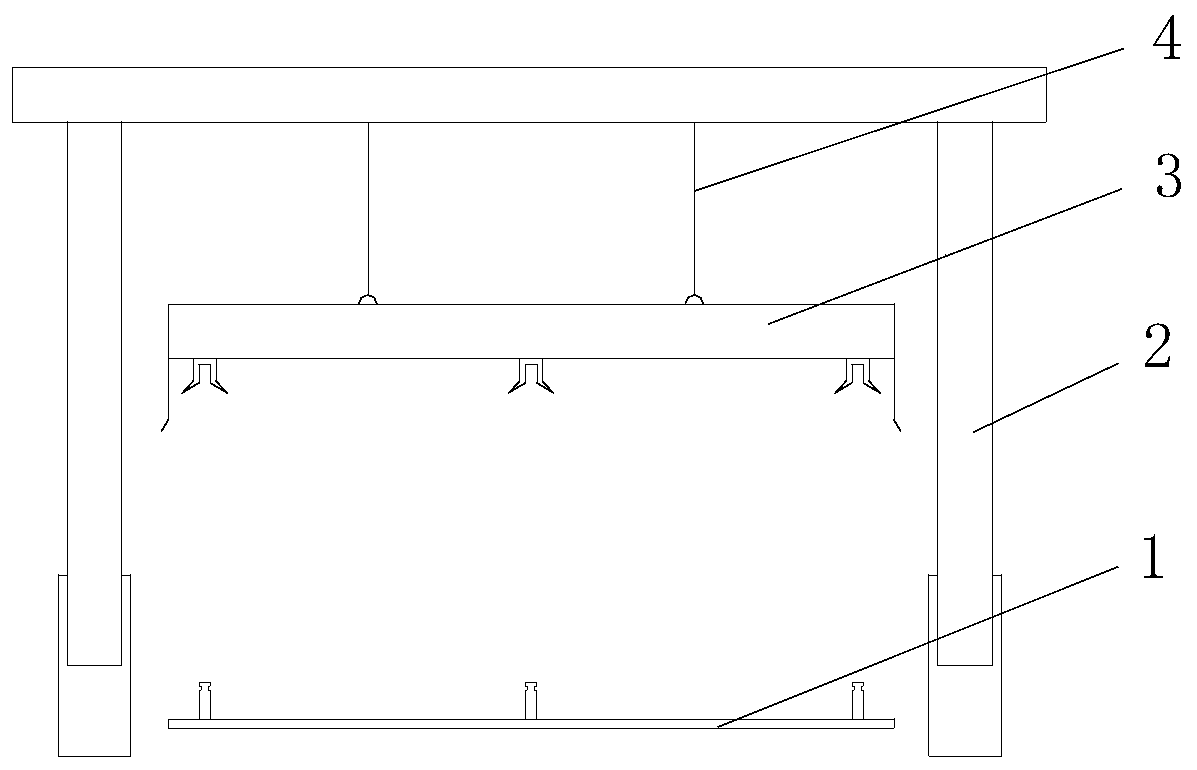

[0070] Such as Figure 3-4 As shown, a mobile integrated device for producing precast concrete slabs provided by the present invention includes a mold platform 1, a walking gantry frame 2, a mold platform hanger 3, a gantry sling 4, a distributing machine 5, a mold platform base 6 and a take-off Mold spreader 7, in which the mold table 1 is set on the membrane table station for forming the precast concrete slab; the mold table base 6 is used to overlap the mold table 1; the traveling gantry 2 spans both sides of the mold table 1 And it can walk, the top of the walking gantry 2 is provided with a gantry sling 4; the mold table spreader 3 is connected to the gantry sling 4 on the walking gantry 2, and the mold table spreader 3 is used for hoisting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com