Process of preparing calcium-adding fireproof magnesium alloy in magnetic field

A magnesium alloy and magnetic field technology, which is applied in the field of preparation to improve the mechanical properties of magnesium alloys, can solve problems such as the inability to prevent the burning of magnesium alloy melts, the inability to use the ignition point of calcium-magnesium alloys, and the deterioration of mechanical properties of magnesium alloys, etc., to achieve strength indicators. Inexpensive, smooth effect of liquid pocket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

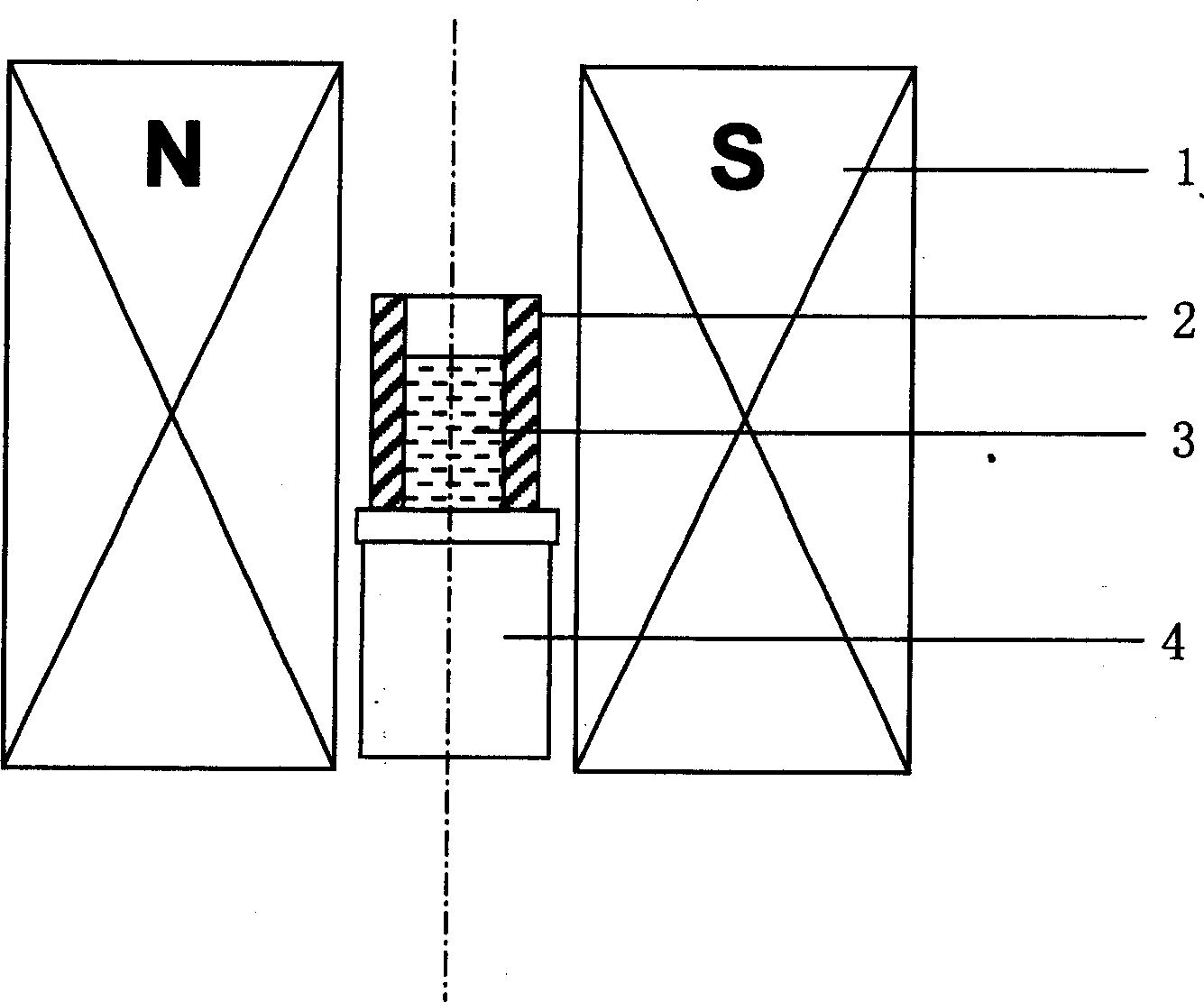

Image

Examples

Embodiment 1

[0024] Put a magnesium alloy (AZ91D) in a crucible, put it into a pit furnace, heat it to 720°C and keep it warm until the raw material melts, add about 3wt% of calcium and stir it evenly and keep it warm, add hexachloroethane for refining and degassing, and then Pouring into the mold, the mold is placed in the magnetic field generating device. After pouring, turn on the magnetic field generating device to solidify the alloy under the action of the magnetic field, air-cool under atmospheric conditions, turn off the magnetic field generating device after solidification, and demould.

[0025] The chemical composition (wt%) of AZ91D alloy is shown in Table 1:

[0026] Al

Zn

mn

be

Si

Cu

Fe

Ni

Mg

9.03

0.64

0.33

0.0014

0.031

0.0049

0.0011

0.0003

balance margin

[0027] By adopting the method of the invention, under the action of a magnetic field of 0.6 tesla, adding 3wt% calcium...

Embodiment 2

[0033] Put a certain amount of AE42 magnesium alloy in a crucible, put it into a pit furnace and heat until the raw material melts, then add about 2wt% of calcium, stir evenly, and keep warm at 720°C for 20 minutes. After degassing and refining, pour it into a mold, and air-cool under atmospheric conditions, and solidify under the action of a 0.5T magnetic field. After adding 2wt% calcium, the AE42 magnesium alloy did not burn during melting and pouring. Under the action of the magnetic field, the room temperature tensile strength of the AE42 alloy after calcium addition increased by about 120% compared with the AE42 alloy without magnetic field treatment, and increased by about 20% compared with the general cast AE42 alloy, and its high temperature mechanical properties Also increased by 10-20%.

Embodiment 3

[0035] Put a certain amount of MB1 magnesium alloy in a crucible, put it into a pit furnace and heat until the raw material melts, then add about 4wt% of calcium, stir evenly, and keep it warm at 720°C for 20 minutes. After degassing and refining, pour it into a mold, and air-cool under atmospheric conditions, and solidify under the action of a 0.35T magnetic field. After adding 4wt% calcium, the MB1 magnesium alloy did not burn during melting and pouring. Under the action of the magnetic field, the room temperature tensile strength of the MB1 alloy after calcium addition increased by about 100% compared with the MB1 alloy without magnetic field treatment, and increased by about 10% compared with the general cast MB1 alloy, and its high temperature mechanical properties Also increased by 5 to 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com