Boron trichloride purification apparatus

A purification device, boron trichloride technology, applied in the direction of boron halide compounds, boron halides, etc., can solve the problems such as the degree of purification needs to be improved, achieve excellent adsorption effect, reduce energy consumption, and increase the effect of gas contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

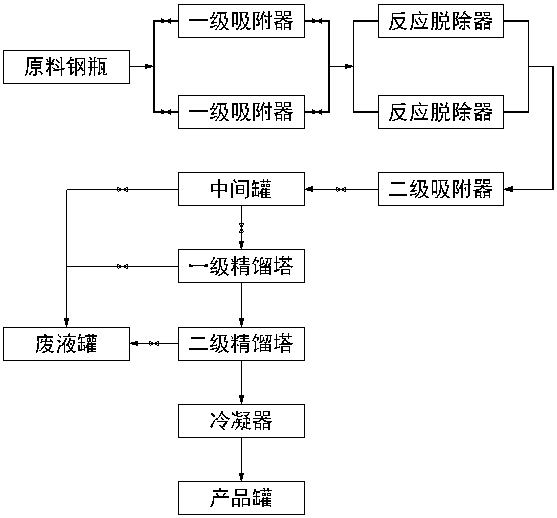

[0021] In order to easily understand the technical means, creative features, purpose and effect of the present invention, the present invention will be further explained in conjunction with specific drawings below.

[0022] Such as figure 1 As shown, a boron trichloride purification device includes a raw material cylinder, a primary adsorber, a reaction remover, a secondary adsorber, an intermediate tank, a primary distillation tower, a secondary distillation tower, Condenser, product tank, the first-stage adsorber is a two-way parallel structure, the reaction remover is a two-way parallel structure, a cold and hot coil jacket is installed on the periphery of the intermediate tank, and the middle The residual waste liquid discharge outlet of the tank, the primary distillation tower and the secondary distillation tower are connected with a waste liquid tank.

[0023] The solid adsorbent in the primary adsorber is spherical activated carbon adsorbent.

[0024] The first-stage adsorbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com