Water assistant jetting and forming method

An injection molding, water-assisted technology, applied in the field of water-assisted injection molding, can solve the problems such as the inability to obtain nitrogen at will, the high cost of manufacturing plastic products, and the uneven thickness of plastic products, and achieve the effect of shortening the curing and molding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

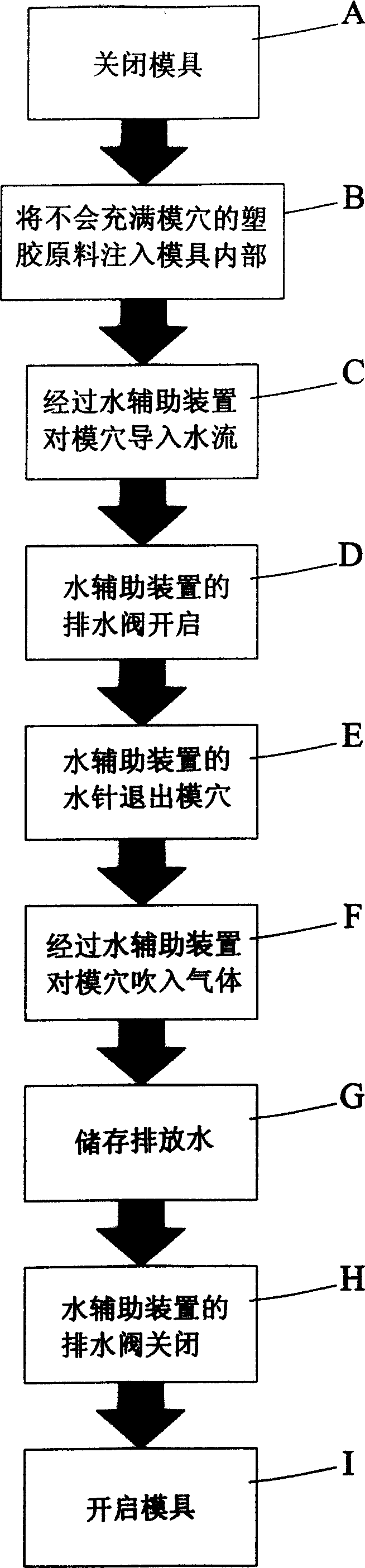

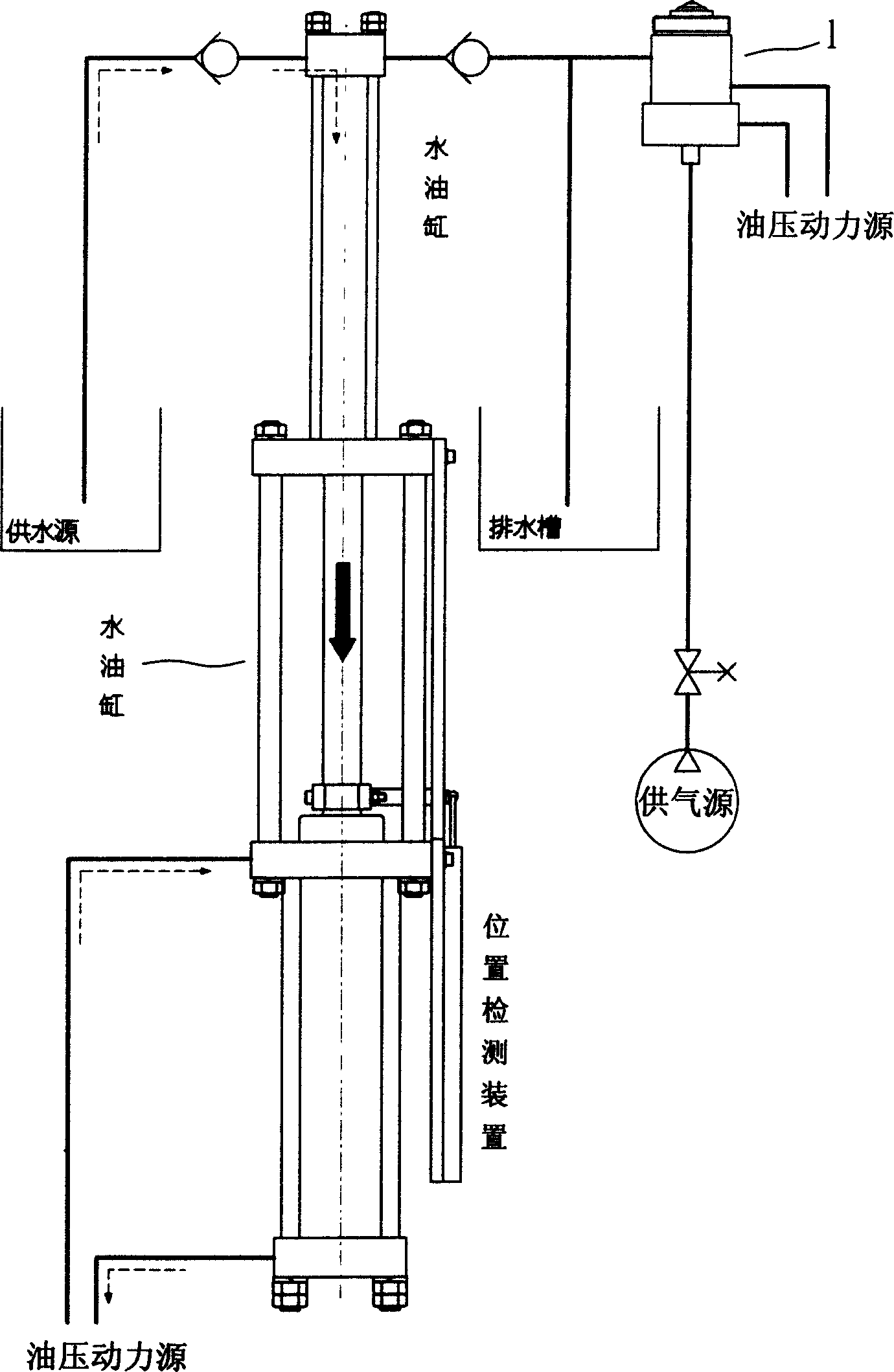

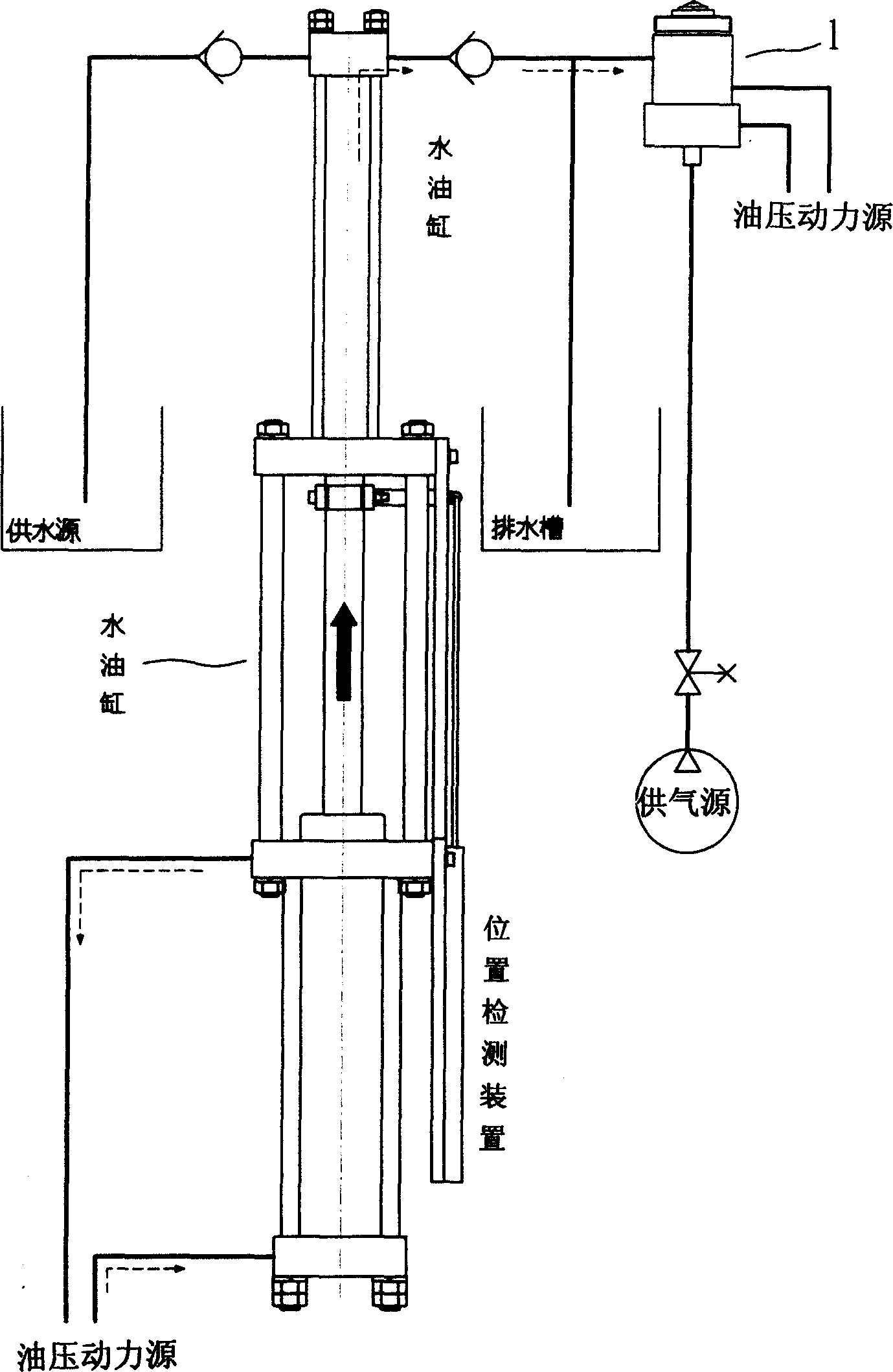

[0029] see figure 1 As shown, a water-assisted injection molding method of the present invention is to close the mold A, inject the plastic material that will not fill the mold cavity into the interior of the mold B, introduce water flow C into the mold cavity through the water auxiliary device, and drain the water auxiliary device. It is realized by manufacturing procedures such as opening D, the water needle of the water auxiliary device exiting the mold cavity E, blowing gas F into the mold cavity through the water auxiliary device, storing and discharging water G, closing the drain valve of the water auxiliary device H, and opening the mold I;

[0030] Please refer to Figure 5 , wherein the mold A is closed: the movable template 2 leans against the fixed template 3 to close the mold 4;

[0031] Inject the plastic material that will not fill the mold cavity into the mold B: After the signal that the mold closing is completed is confirmed, the plastic material that melts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com