Method for precipitating and clarifying coal slime water assisted by extra electric field

A technology of applying an external electric field and slime water, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve clarified water concentration, increased viscosity, high cost of slime water treatment, and large sedimentation Reduce the area and other problems, achieve the effects of reducing the type and amount of chemicals used, eliminating the increase in ash content of coal slime and corroding production equipment, and simplifying the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

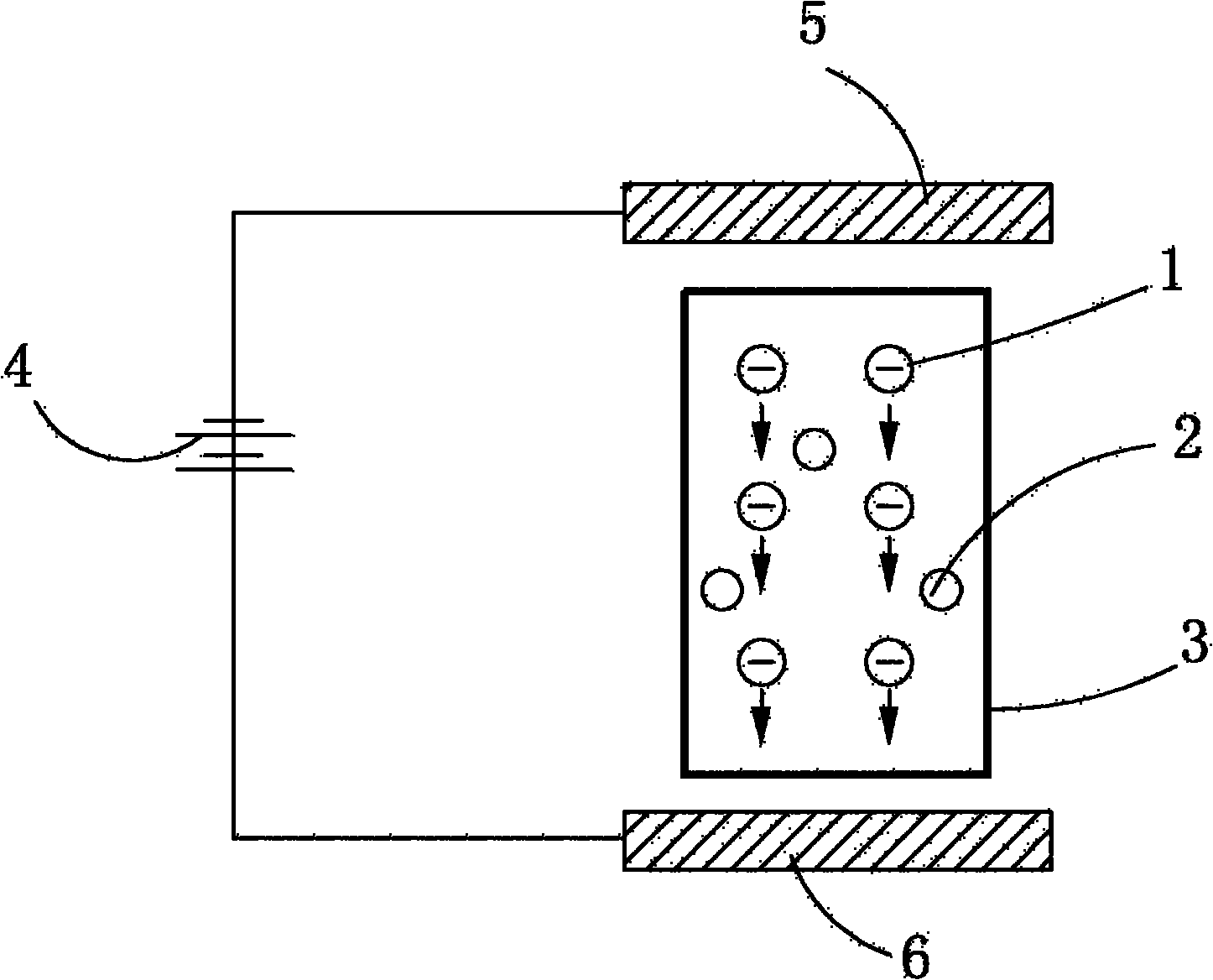

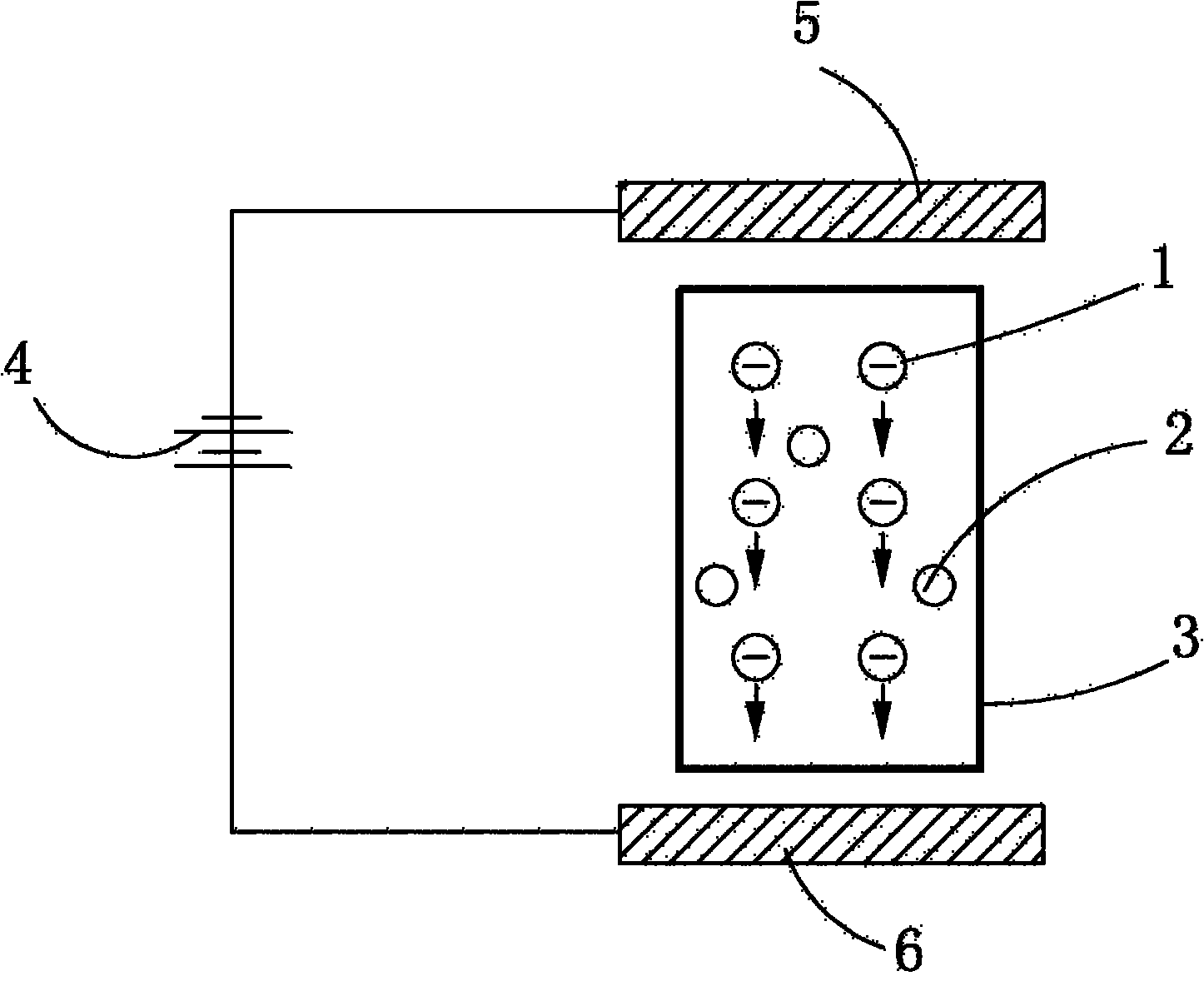

[0027] figure 1 As shown, the present embodiment utilizes the negative charges that the coal slime particles in the coal slime water have to apply an electric field to the coal slime water, so that the coal slime particles in the coal slime water with negative charge move towards the anode plate under the effect of the applied electric field. Realize the rapid settlement of slime particles in the slime water, figure 1 It includes negatively charged coal slime particles 1 , uncharged particles 2 , coal slime water settling facilities 3 , voltage-adjustable working power supply 4 , cathode plate 5 and anode plate 6 .

[0028] In the specific implementation, the direction of the applied electric field should be set to: make the applied force of the applied electric field on the slime particles in the slime water have a vertical downward component force consistent with the gravity direction of the slime particles, and the applied electric field and gravity The combined effect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com