Method for modifying polyester fabric biologically

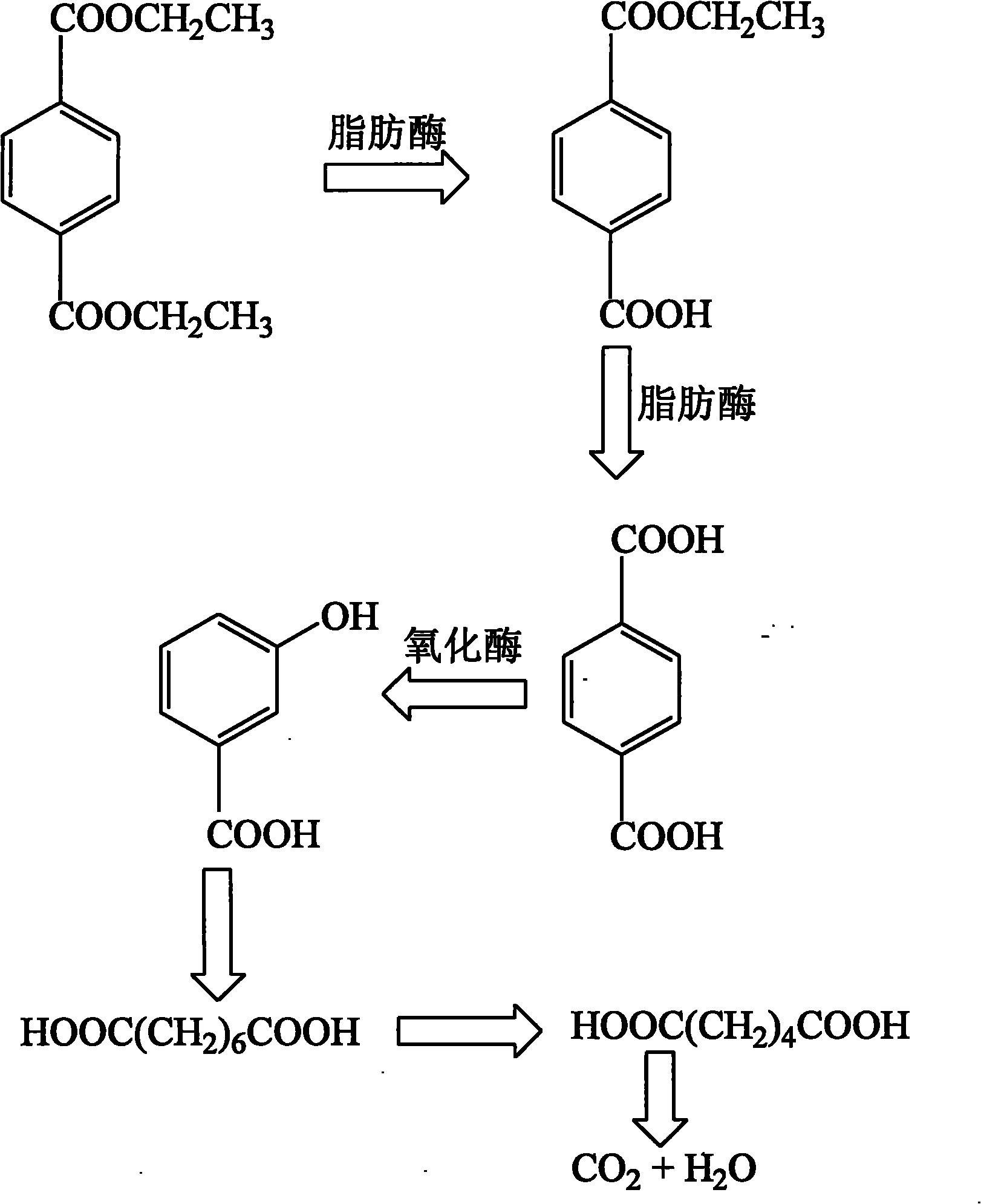

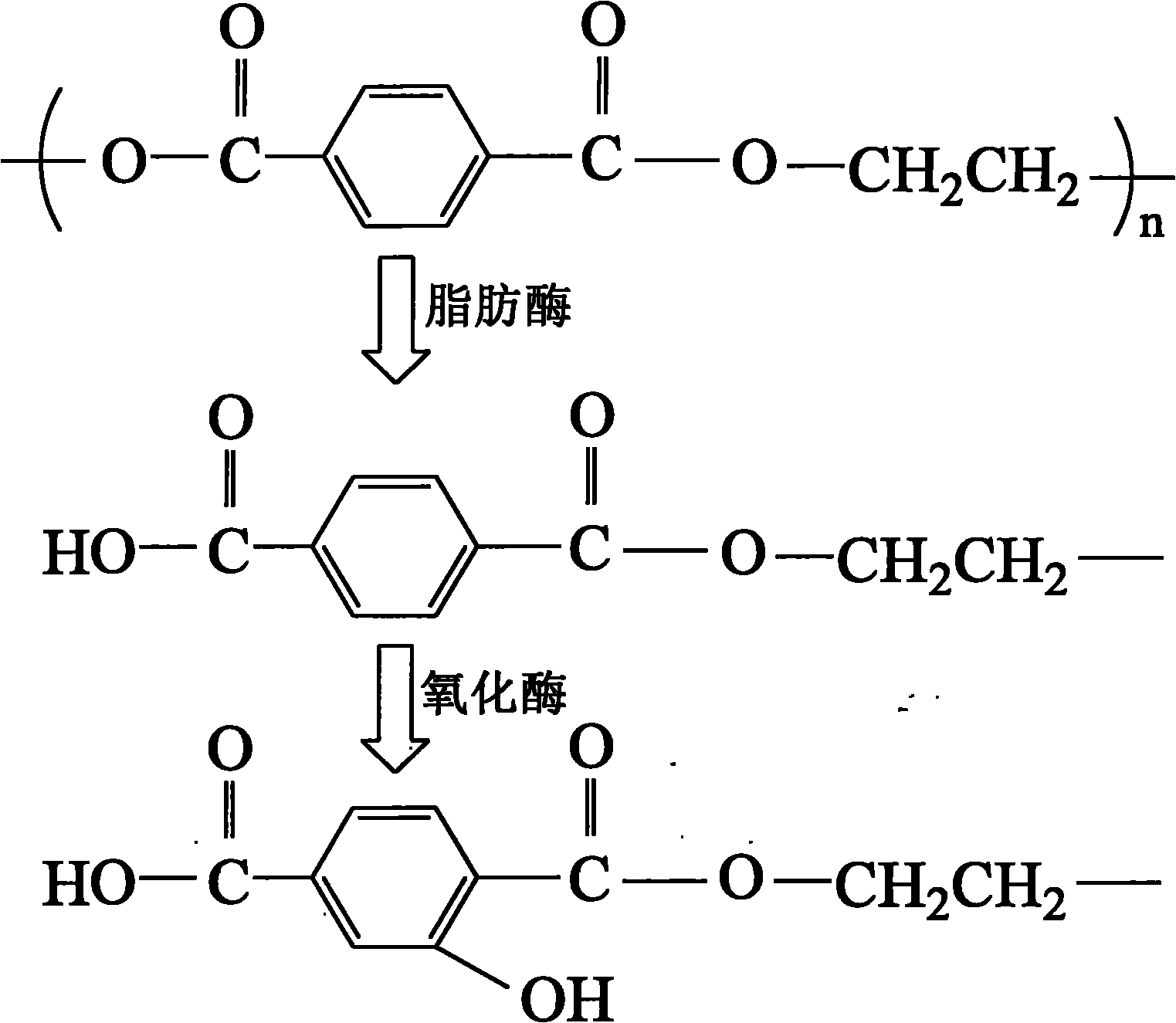

A polyester fabric, biological modification technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high crystallinity and glass transition temperature, and the modification effect is not obvious, so as to increase hydrophilicity Sexuality, improvement of wearing comfort and aesthetics, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] 2. Preparation of bacterial suspension: According to the composition of the liquid medium, prepare a liquid medium with a substrate concentration of 1-3g / L, put it in a 500ml Erlenmeyer flask, wrap and sterilize it at 121°C for 25min, cool the slant The seeds in the solid medium are transferred into the liquid medium, and shake cultured at 30-37°C and the rotation speed of the shaking incubator is 200r / min, so that the bacteria grow for 12-36h, and the bacterial suspension in the logarithmic growth phase is obtained. liquid; the composition of the liquid medium is: potassium dihydrogen phosphate 3g / L, disodium hydrogen phosphate 7g / L, ammonium chloride 1g / L, sodium chloride 5g / L, magnesium sulfate 0.25g / L, substrate The dosage is 1-3g / L. If the substrate concentration in the liquid medium is too low, it cannot meet the needs of cell growth, but if it is too high, it will inhibit the cell growth and affect the effect of fabric modification instead. It is better to contro...

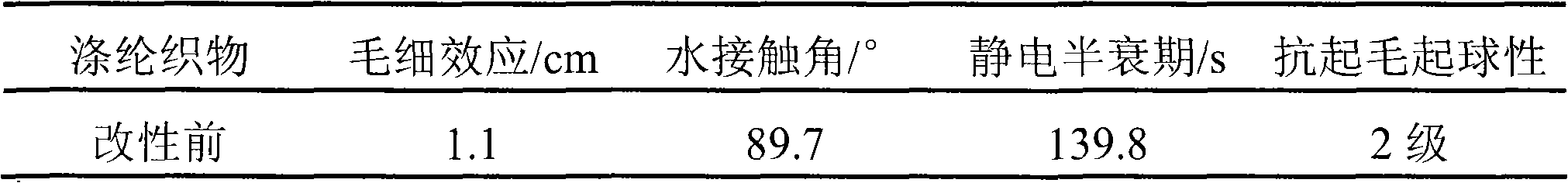

Embodiment 1

[0035] Using 3g / L DTP as the induction substrate, the polyester fabric was biomodified with unconcentrated Comamonas testosteroni.

[0036] Cultivate Comamonas testosteroni in a slant solid medium at 37°C for 18h, store it in a refrigerator at 4°C for later use; prepare 1 portion of liquid medium with a DTP concentration of 3g / L according to the composition of the liquid medium, 150ml, pack In a 500ml Erlenmeyer flask, wrap and sterilize at 121°C for 25 minutes. After cooling, transfer the seeds in the slant culture medium into it respectively, and vibrate and cultivate at 37°C and the speed of the shaking incubator at 200r / min to make the bacteria grow. 36h, which is the bacterial suspension in the logarithmic growth phase; put the polyester fabric in the aseptic operating table, sterilize it with ultraviolet light for 0.5h, add it to the bacterial suspension in the logarithmic growth phase, and place it at 37 ° C, the speed of the shaking incubator is Vibrating culture under...

Embodiment 2

[0042] Using 1g / L DTP as the induction substrate, the polyester fabric was biomodified with 2 times concentrated Comamonas testosteroni.

[0043] Cultivate Comamonas testosteroni in a slant solid medium at 30°C for 12 hours, and store it in a refrigerator at 4°C for later use; prepare 3 liquid mediums with a DTP concentration of 1g / L according to the composition of the liquid medium, each 150ml , respectively packed in 500ml Erlenmeyer flasks, wrapped and sterilized at 121°C for 25 minutes, after cooling, transfer the seeds in the slant culture medium to 2 portions of liquid culture medium respectively, at 30°C, the speed of the shaking incubator is 200r / min Under shaking culture, the thalline grows for 12h, which is the bacterial suspension in the logarithmic growth phase; after 2 parts of the bacterial suspension in the logarithmic phase are centrifuged (centrifuge speed 5000r / min, centrifugal 15min), collect the thalli; Add the obtained bacteria into the remaining 150ml of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com