Method for impregnating low-viscosity electrolyte used for electrolytic capacitor

An electrolytic capacitor and electrolyte technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of large impedance of capacitors, easy bottom of capacitors, large vapor pressure, etc., to meet low temperature performance, low cost, improve stability and effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Capacitor core pack is discharged on the mesh screen, obtains core pack screen;

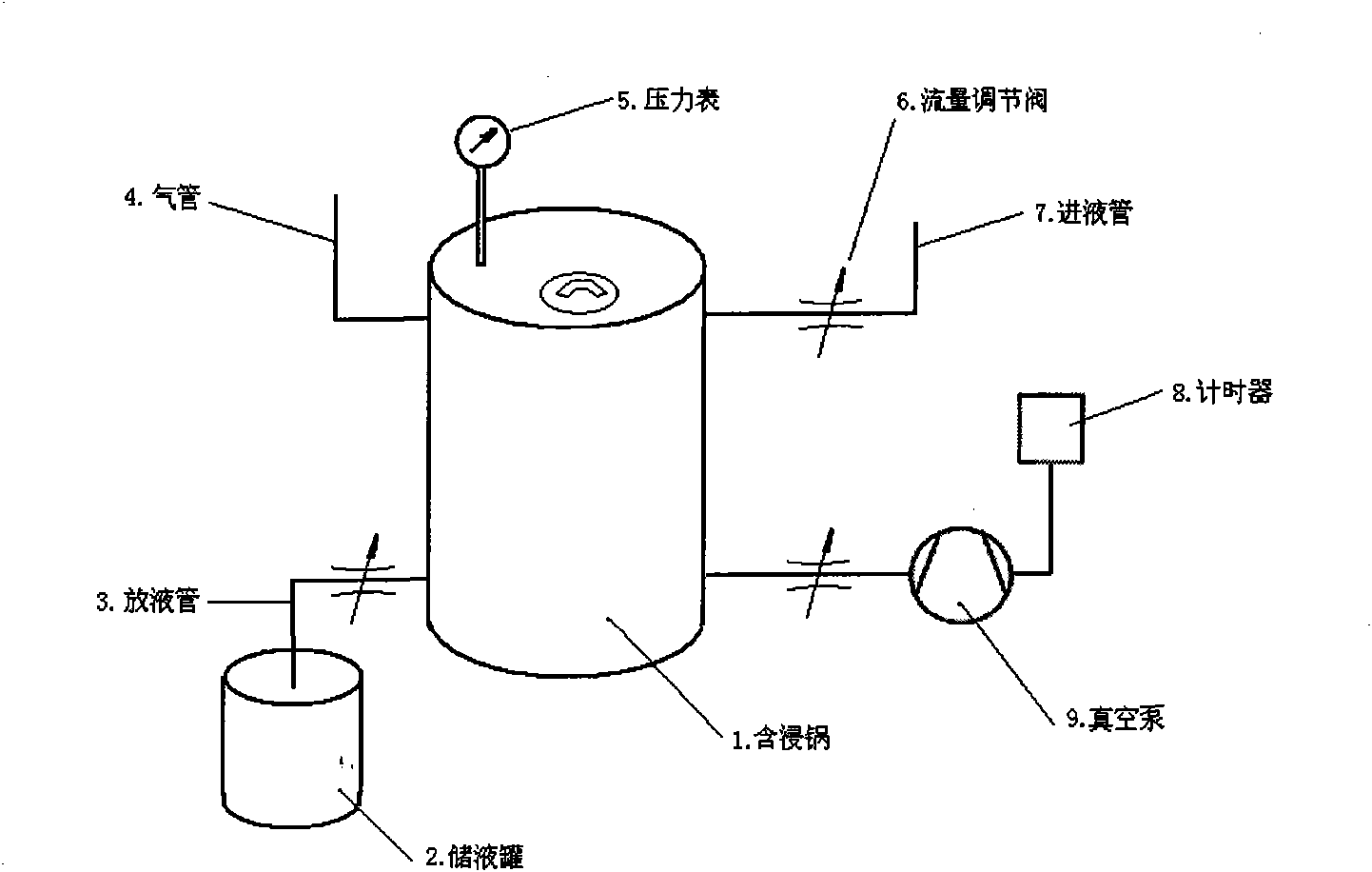

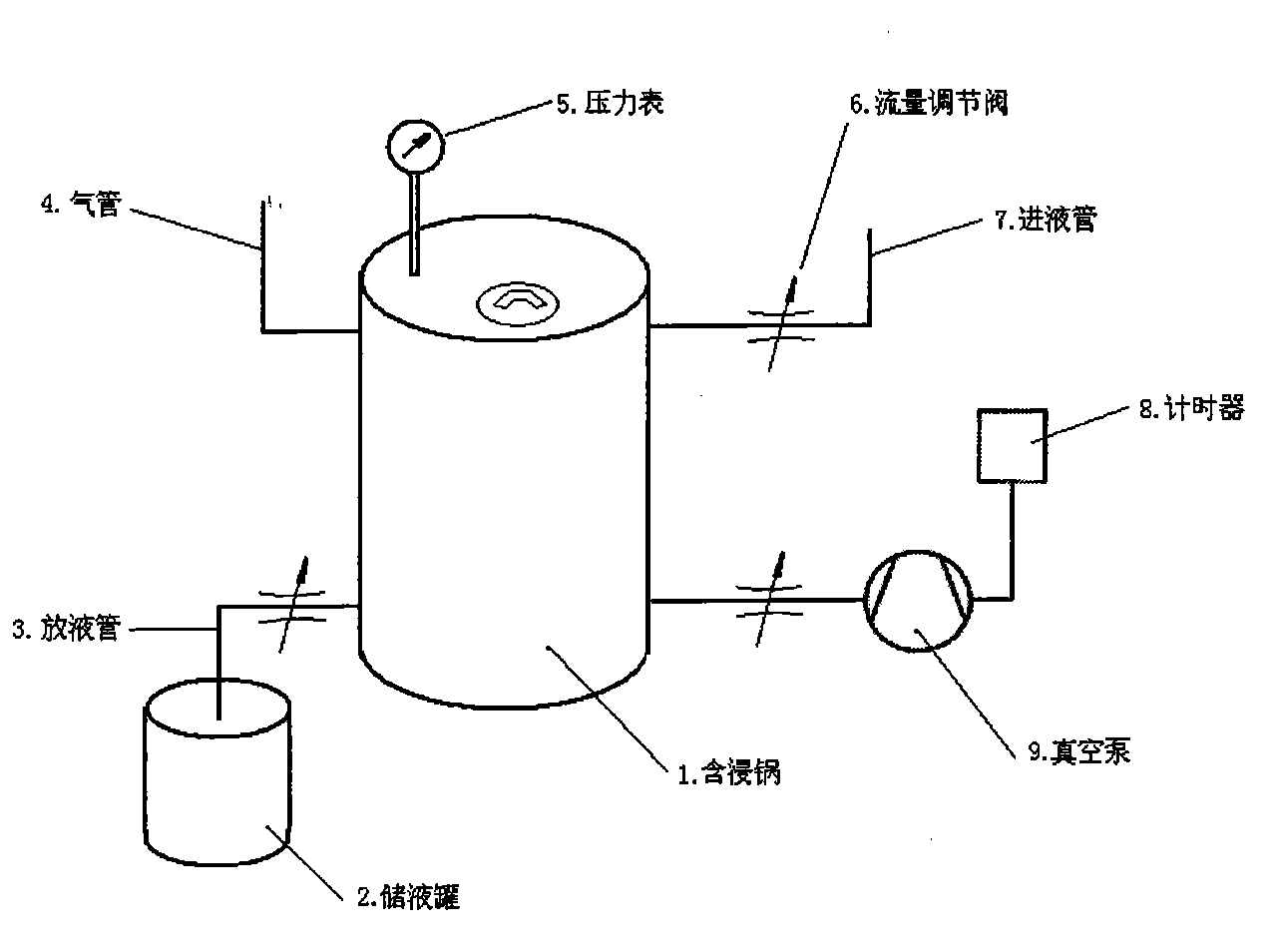

[0025] (2) Then put the above-mentioned 3-layer core-coated sieve in the impregnation container, seal it, start the vacuum pump to start vacuuming, and the time is 20 to 60 minutes;

[0026] (3) Inhale the low-viscosity electrolyte solution (viscosity value at 25°C: 3-17mm2 / s) from the liquid storage tank, and continue to maintain the vacuum state for 10-50 minutes; then restore the normal pressure state and stabilize it for 20-50 minutes;

[0027] (4) Apply positive pressure to the above-mentioned impregnation container, the positive pressure value is 2Mpa ~ 5Mpa, by applying positive pressure, the electrolytic fluid will flow out of the impregnation container and be exiled into the liquid storage tank; after the electrolyte is completely discharged, pump the impregnation container again Vacuum for 10 to 30 minutes, the purpose is to use the pressure difference between the inside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com