Contour line quality detection method

A quality inspection method and contour line technology, applied in the field of measurement, can solve problems such as the inability to determine the actual deviation, the large difference in quality of qualified products, and rough interval comparison, etc., to improve the detection speed and efficiency, high accuracy, and reduce The effect of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method for detecting the quality of contour lines provided by the invention, the method is carried out in conjunction with a photoelectric measuring instrument, and comprises the following steps:

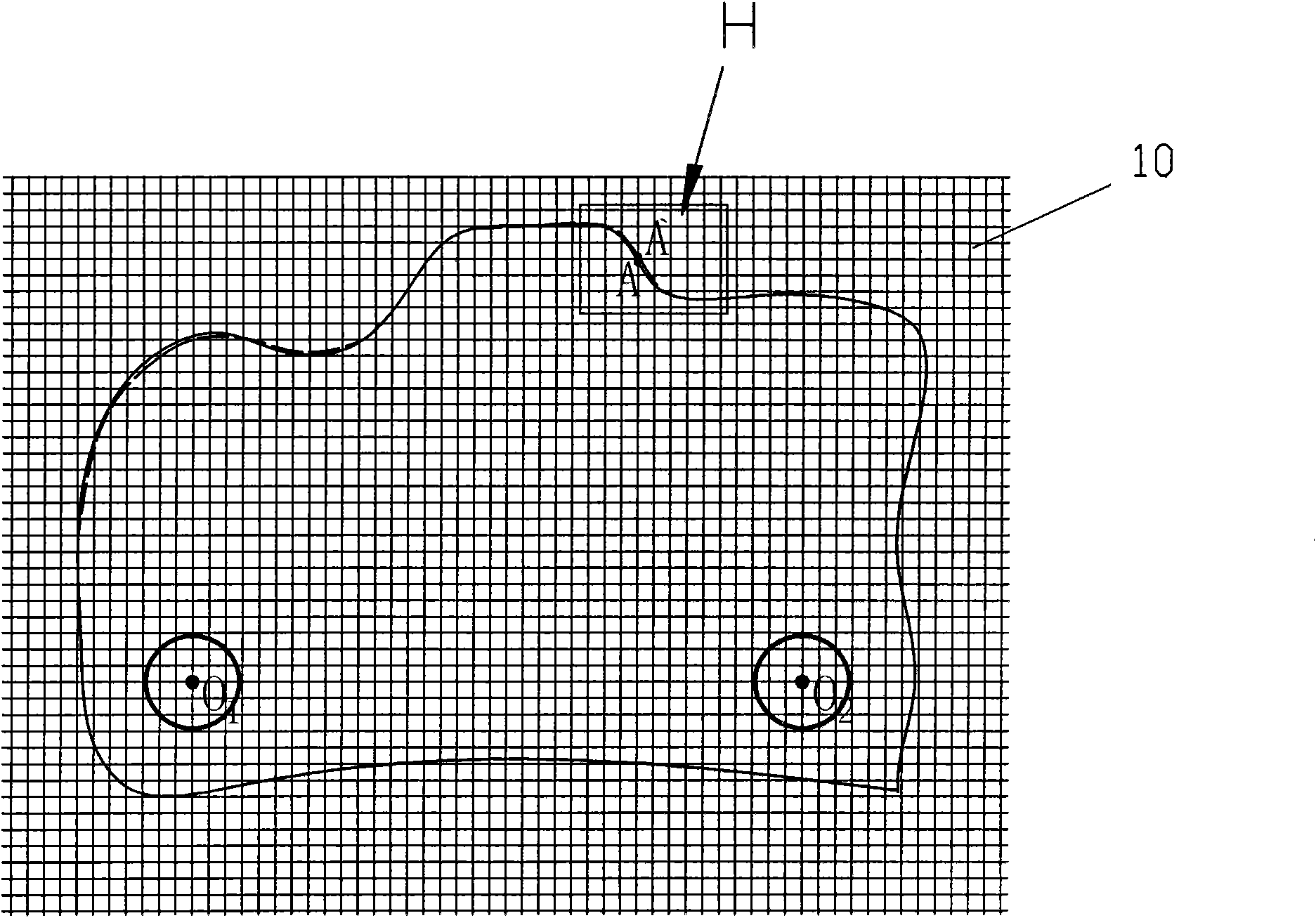

[0018] 1) Input the standard graphics into the computer, and read the corresponding points or lines of the standard graphics in the world coordinate system of the computer as a reference, then construct a virtual grid in the computer, and record the outline of the virtual grid and the standard graphics the coordinates of the intersection point;

[0019] 2) Put the product under test into the measuring platform of the measuring instrument, and the measuring instrument will input the image of the product under test into the above-mentioned computer;

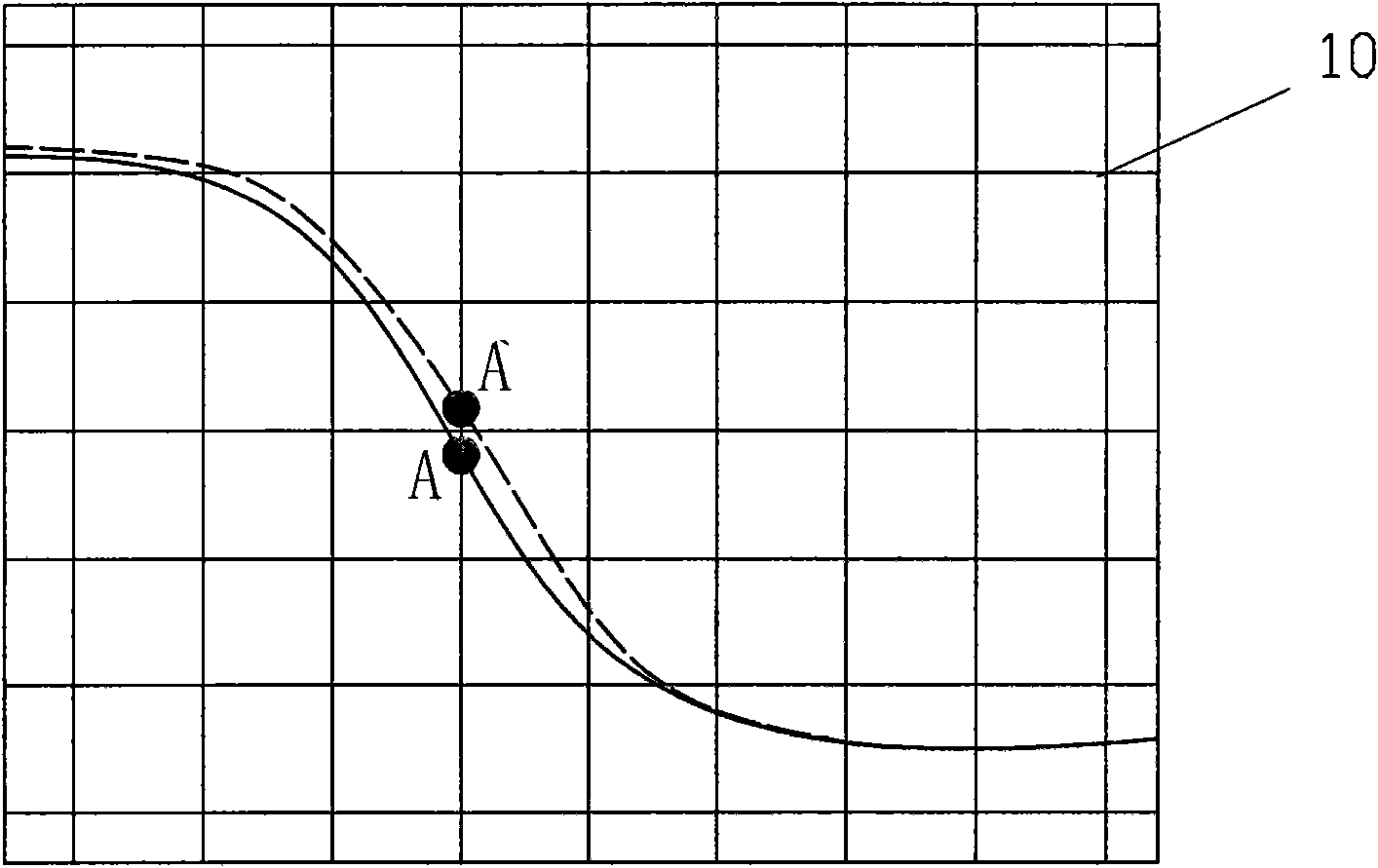

[0020] 3), according to the reference point or line obtained in step 1), locate the image of the product under test, make the image fall into the virtual grid, and then read the coordinates of the intersection of the virtual g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com