Ferro-manganese double metal oxide modified bio-carbon photo-Fenton composite material and preparation method thereof

A bimetallic oxide and composite material technology, which is applied in the field of iron-manganese bimetallic oxide modified biochar photo-Fenton composite materials and its preparation, can solve the problem of affecting the reusability of biochar, affecting the catalytic performance and activity of biochar Site reduction and other issues, to achieve the effect of strong magnetism, strong hydrogen peroxide decomposition ability, and improved catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

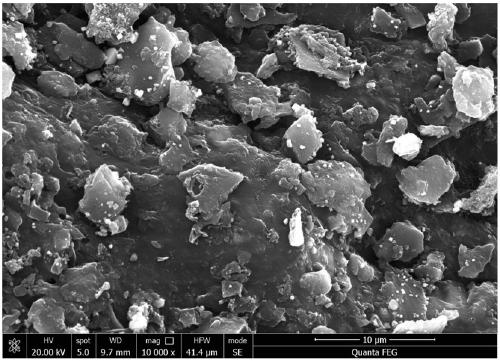

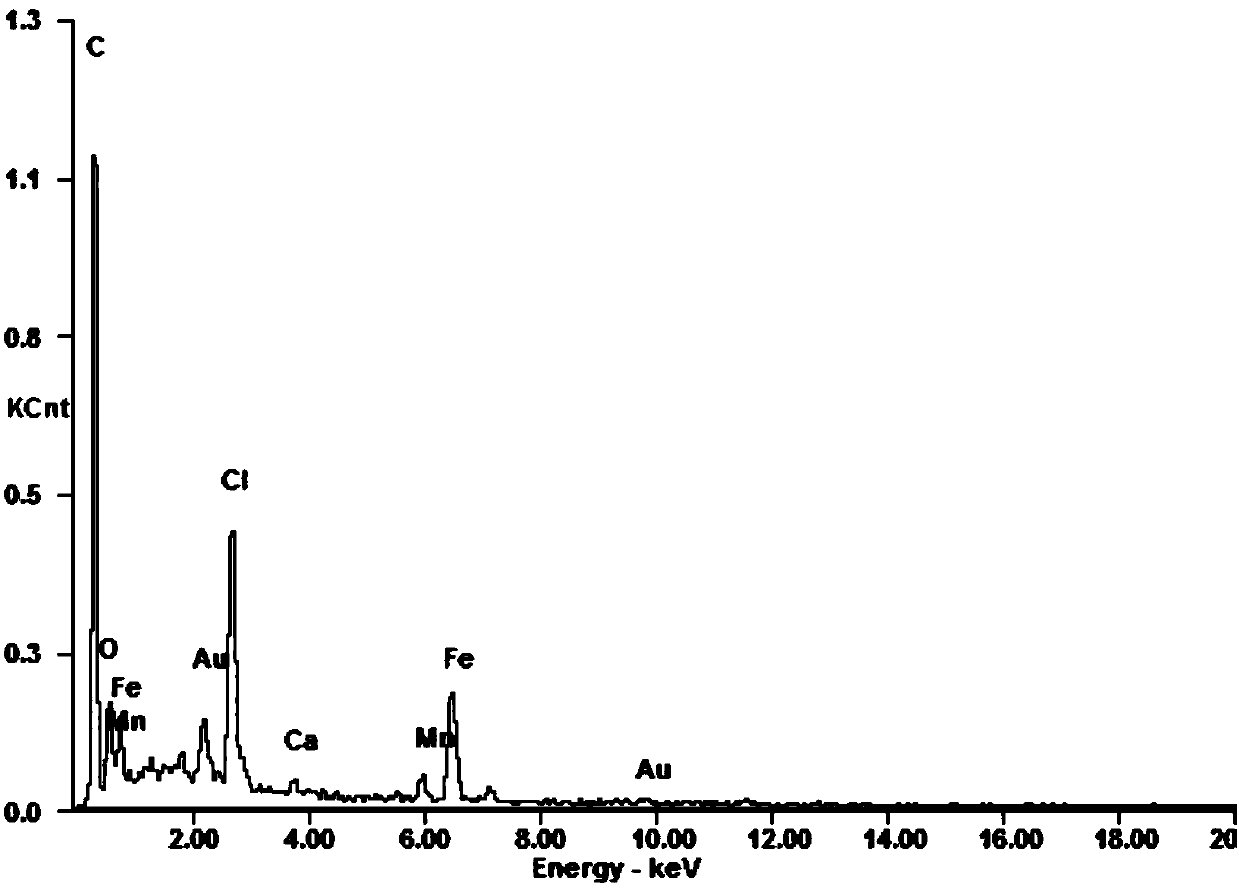

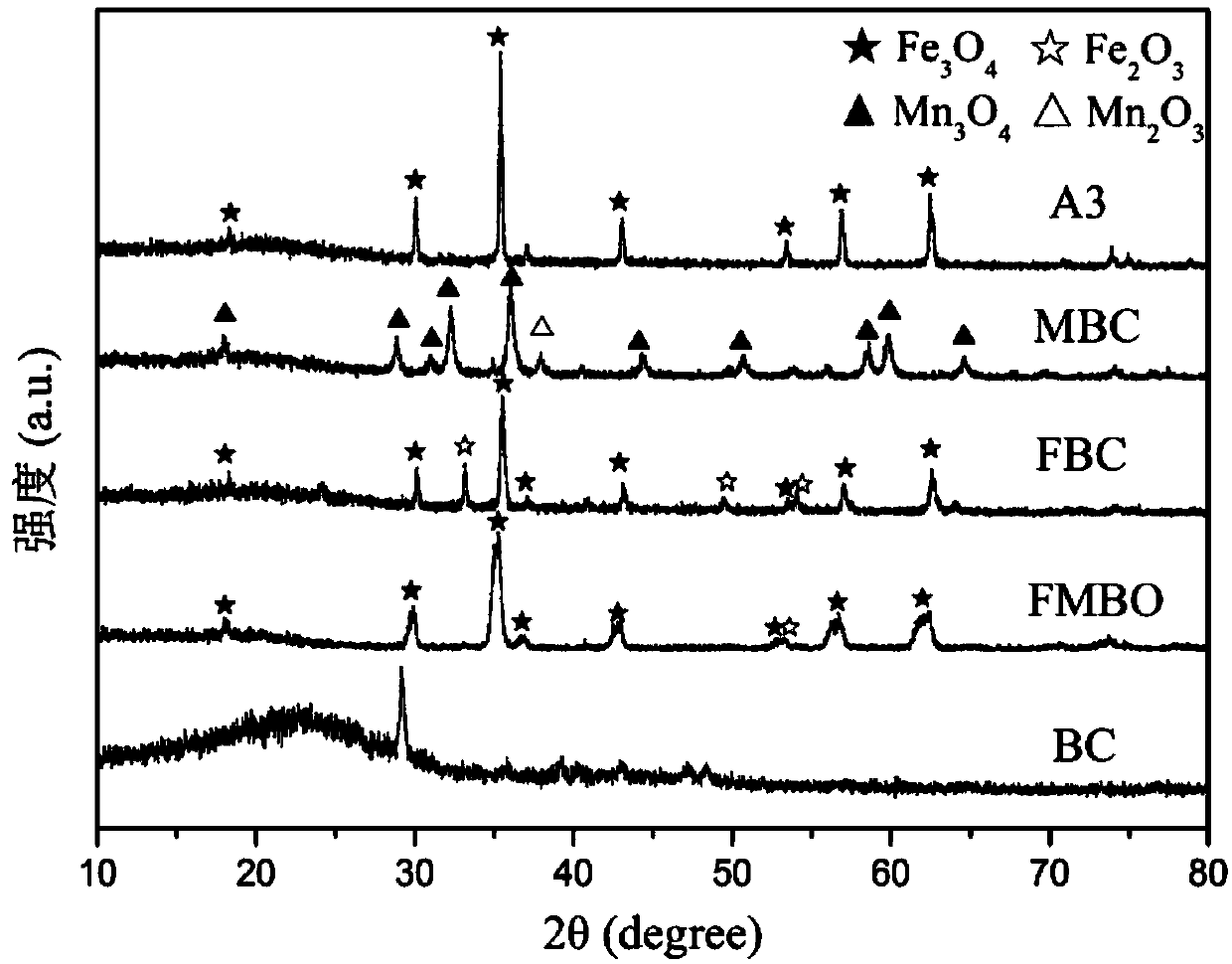

[0036] A biochar light-Fenton composite material modified by iron-manganese double metal oxides, including biochar and iron-manganese double-metal oxides, the iron-manganese double-metal oxides are attached to the biochar, and the iron-manganese double-metal oxides are iron oxides mixture of manganese and manganese oxides, iron oxides including Fe 3 o 4 and Fe 2 o 3 ; The manganese oxide includes Mn 3 o 4 and Mn 2 o 3 .

[0037] In this embodiment, in the iron-manganese double metal oxide-modified biochar photo-Fenton composite material, the mass ratio of biochar to iron-manganese double metal oxide is 50:23.

[0038] A method for preparing the iron-manganese double metal oxide modified biochar photo-Fenton composite material of the above-mentioned present embodiment, comprising the following steps:

[0039] (1) Wash the pine needles, dry them at 105° C., pulverize them with a pulverizer, and pass through a 100-mesh sieve to obtain biomass powder. Dissolve 36.04g of f...

Embodiment 2

[0042] An iron-manganese double-metal oxide modified biochar light-Fenton composite material is basically the same as the iron-manganese double-metal oxide modified biochar light-Fenton composite material in Example 1, the only difference being: the iron in Example 2 The mass ratio of biochar to iron-manganese double metal oxide in the biochar modified by manganese double metal oxide was 25:29.

[0043] A preparation method of the iron-manganese double metal oxide modified biochar-light Fenton composite material of the above-mentioned present embodiment is basically the same as the preparation method of the iron-manganese double-metal oxide modified biochar-light Fenton composite material in Example 1 , the difference is only: the consumption of ferric chloride solution and manganese chloride solution in the step (1) of the preparation method of Example 2 is 30mL.

[0044] The iron-manganese bimetallic oxide modified biochar photo-Fenton composite material (FMBC) prepared in E...

Embodiment 3

[0046] An iron-manganese double-metal oxide modified biochar light-Fenton composite material is basically the same as the iron-manganese double-metal oxide modified biochar light-Fenton composite material in Example 1, the only difference being: the iron in Example 3 The mass ratio of biochar to iron-manganese double metal oxides in the biochar-photo-Fenton composites modified by manganese double metal oxides was 5:7.

[0047] A preparation method of the iron-manganese double metal oxide modified biochar-light Fenton composite material of the above-mentioned present embodiment is basically the same as the preparation method of the iron-manganese double-metal oxide modified biochar-light Fenton composite material in Example 1 , the difference is only: the consumption of ferric chloride solution and manganese chloride solution in the step (1) of the preparation method of Example 3 is 45mL.

[0048] The iron-manganese bimetallic oxide modified biochar photo-Fenton composite mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com