Embedded automated guided vehicle

A technology of automatic guidance and transport vehicles, which is applied in the directions of transportation and packaging, storage devices, packaging, etc., can solve the problems of high cost of transport vehicles, increased repair and maintenance costs, complicated robot structure, etc., and achieve simple and compact structure design, easy maintenance The effect of low maintenance cost and small range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

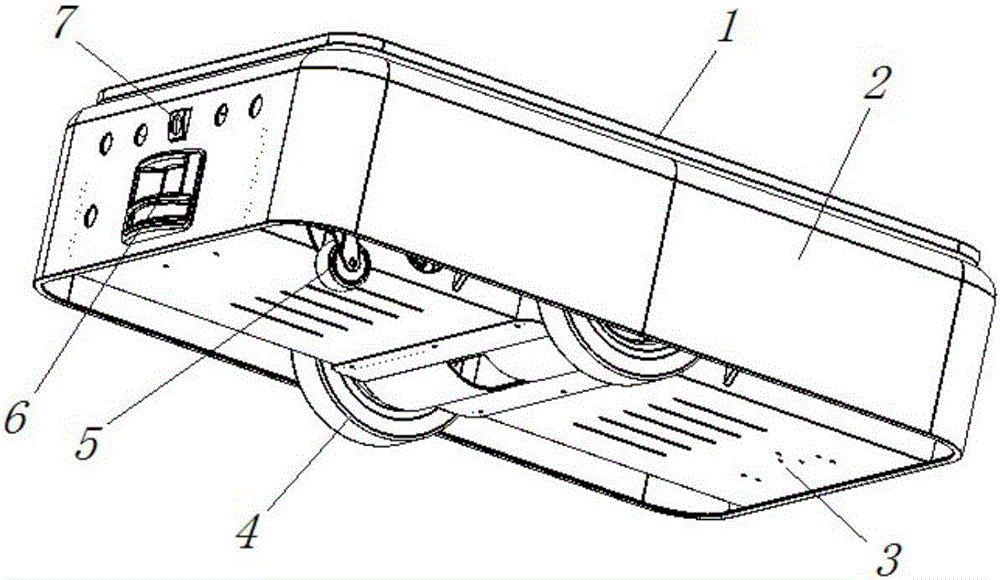

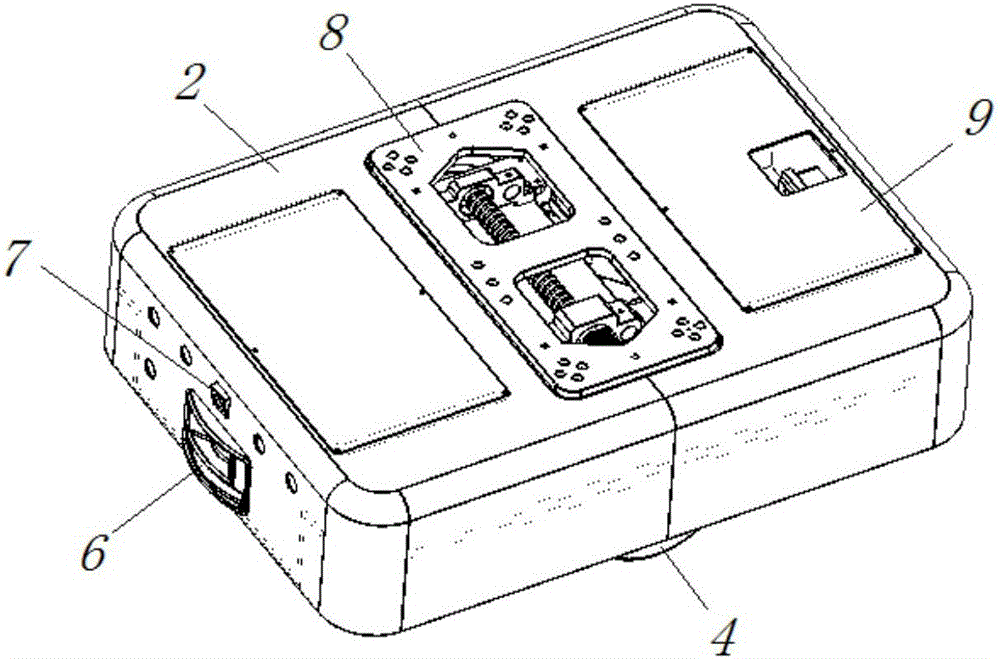

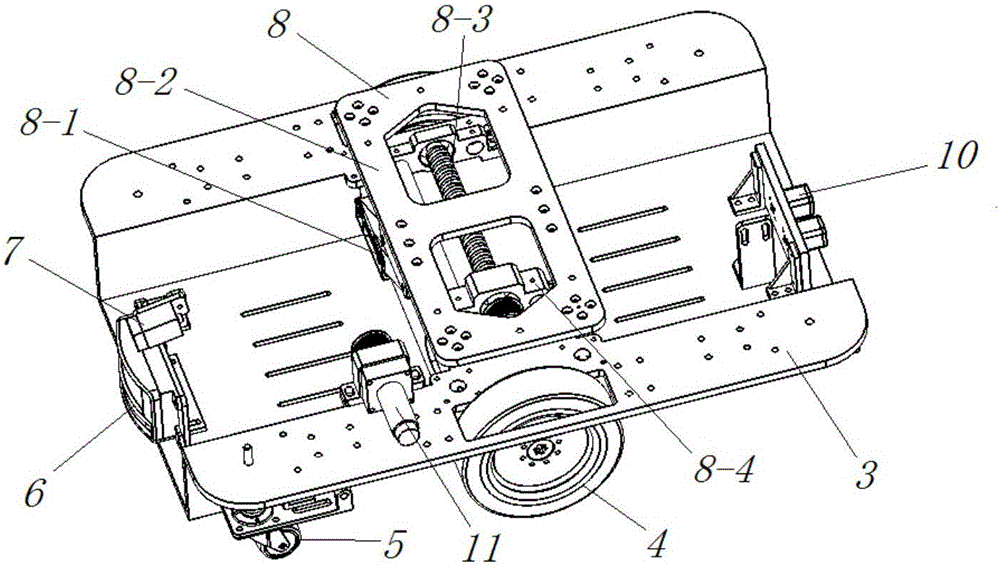

[0026] See figure 1 with figure 2 The shallow-entry automatic guided transport vehicle of the present invention comprises a mobile chassis device 3, a lifting mechanism 8 is installed in the middle of the mobile chassis device 3, and a housing 2 is also buckled on the mobile chassis device 3, and the lifting mechanism 8 is formed by The window opened in the middle part of the housing 2 is exposed, and the top plate 1 positioned directly above the housing 2 is installed on the top of the lifting mechanism 8 .

[0027] Working process: Control the movement by moving the chassis device 3. When the transport vehicle moves to the bottom of the shelf, the top plate 1 is raised to a certain height by controlling the lifting mechanism 8, and the top plate 1 lifts the whole shelf to a certain height to get off the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com