Hot air reflow furnace

A reflow soldering furnace, hot air technology, applied in welding equipment, auxiliary devices, electrical components, etc., can solve the problems of gear chain matching clearance and processing and assembly errors, low accuracy of rail width adjustment, inconvenient control, etc., to achieve effective Synchronous adjustment, improve production efficiency and quality, reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

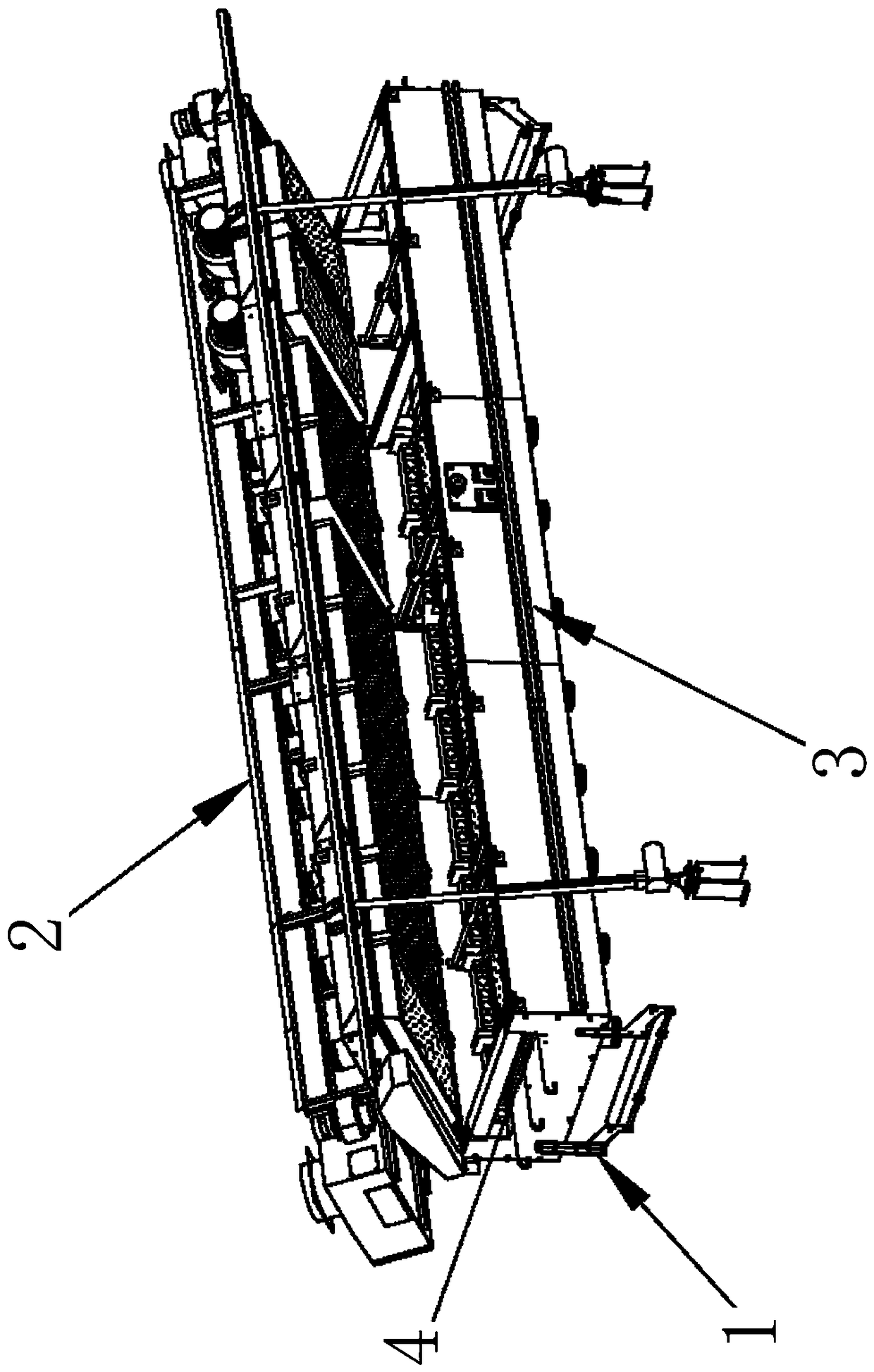

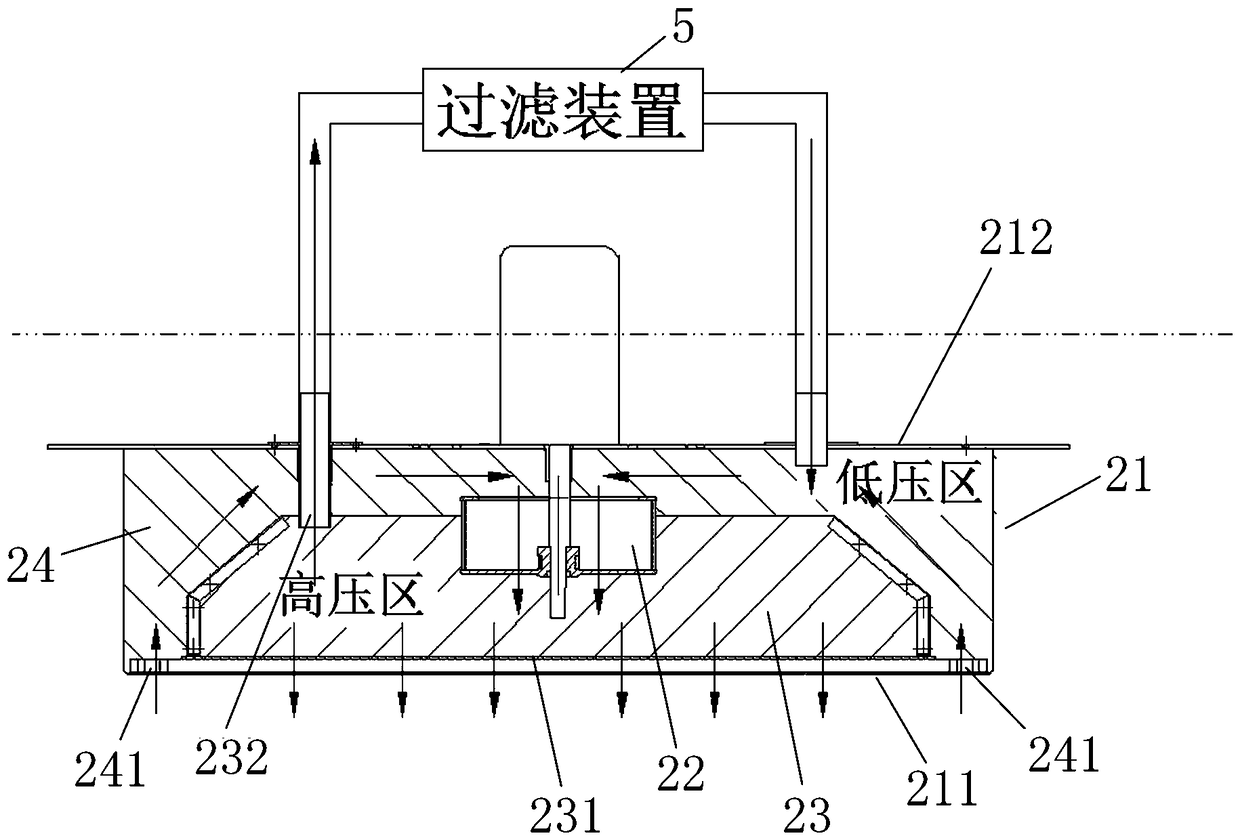

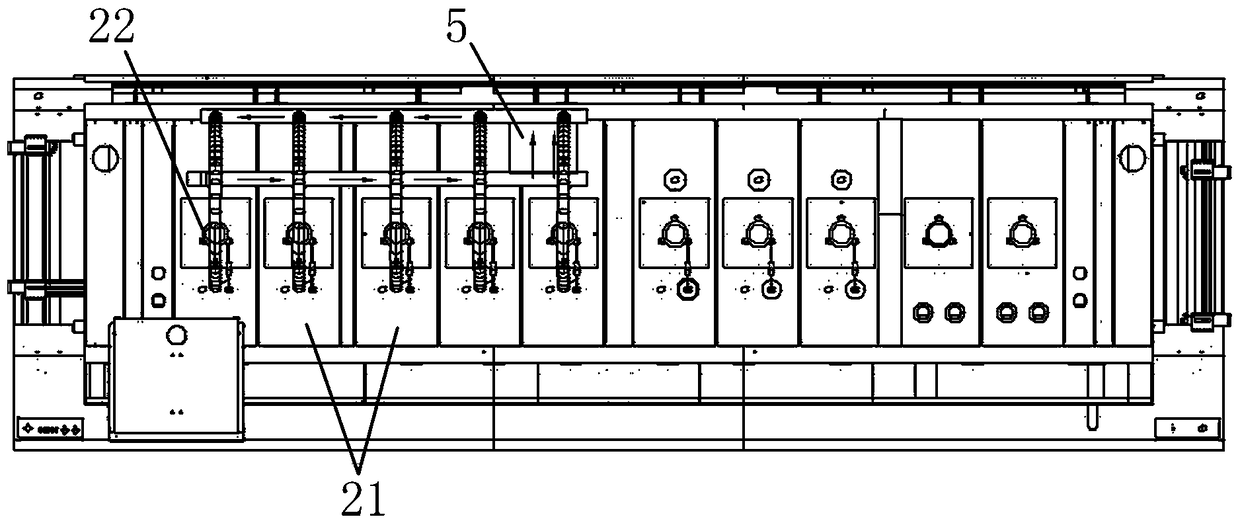

[0026] refer to Figure 1~7 As shown, the present invention relates to a hot-air reflow soldering furnace, which includes a furnace frame 1 and an upper furnace 2, a lower furnace 3, and a transportation system 4 installed on the furnace frame 1, and the upper furnace 2 and the lower furnace 3 are separated in the transportation The upper and lower sides of System 4. Wherein, the upper furnace 2 has a furnace body 21 and a fan 22 installed on the furnace body 21, the furnace body 21 has a first side 211 facing the transportation system 4 and a second side 212 away from the first side, The structure between the first side 211 and the second side 212 has an inner tank 23 and an outer tank 24. The inner tank 23 is connected to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com