Patents

Literature

42 results about "Vapor deposition polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

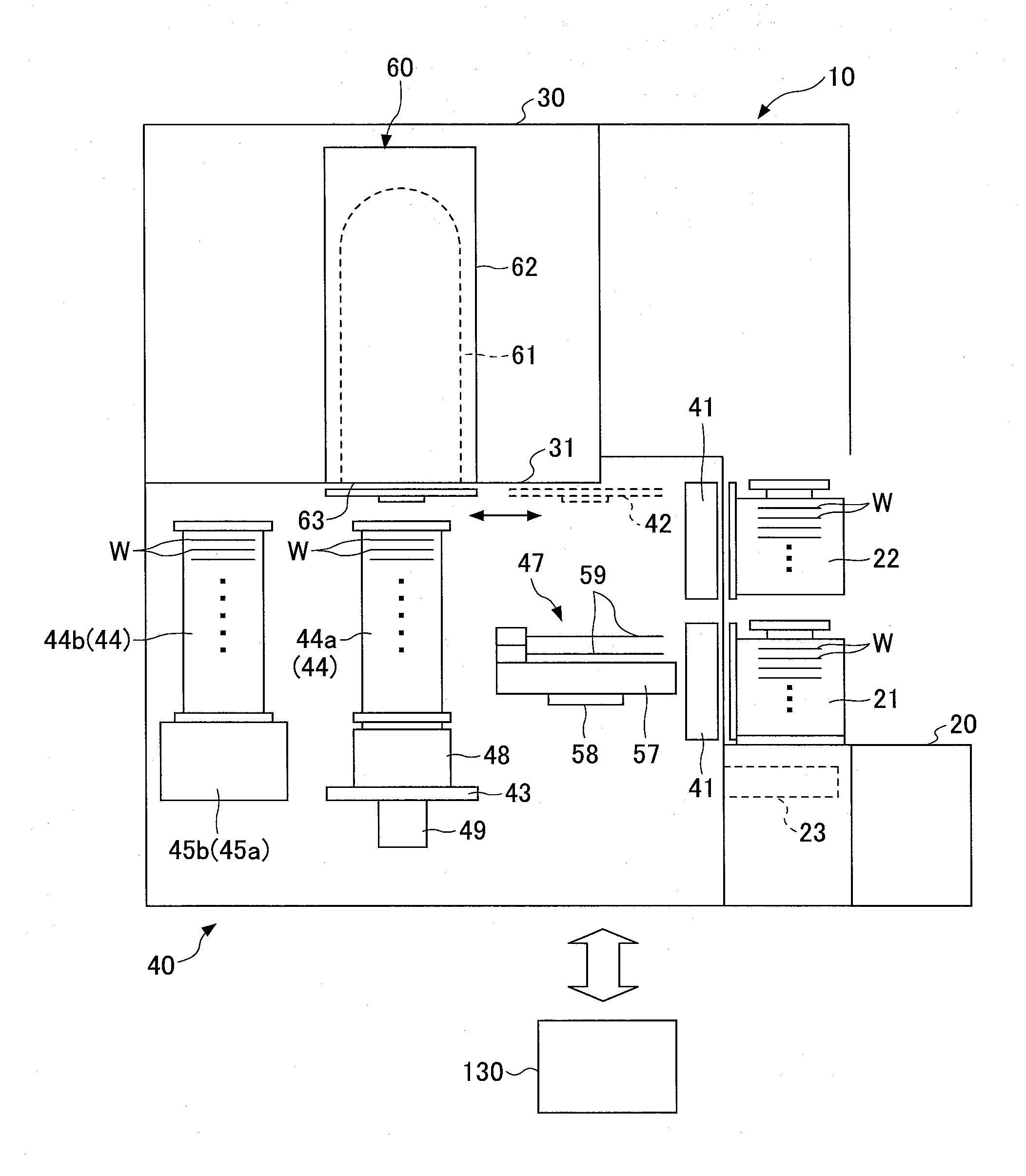

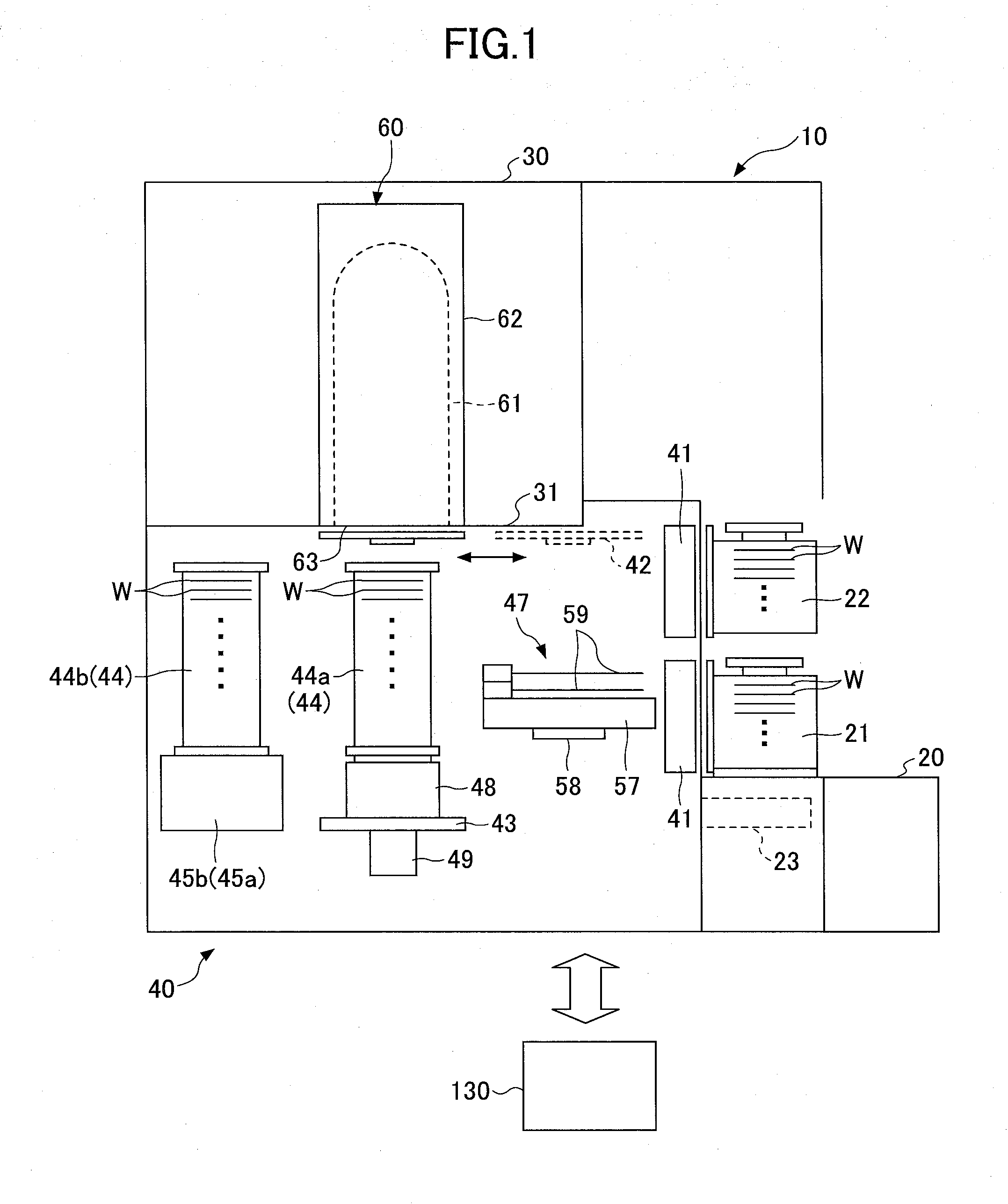

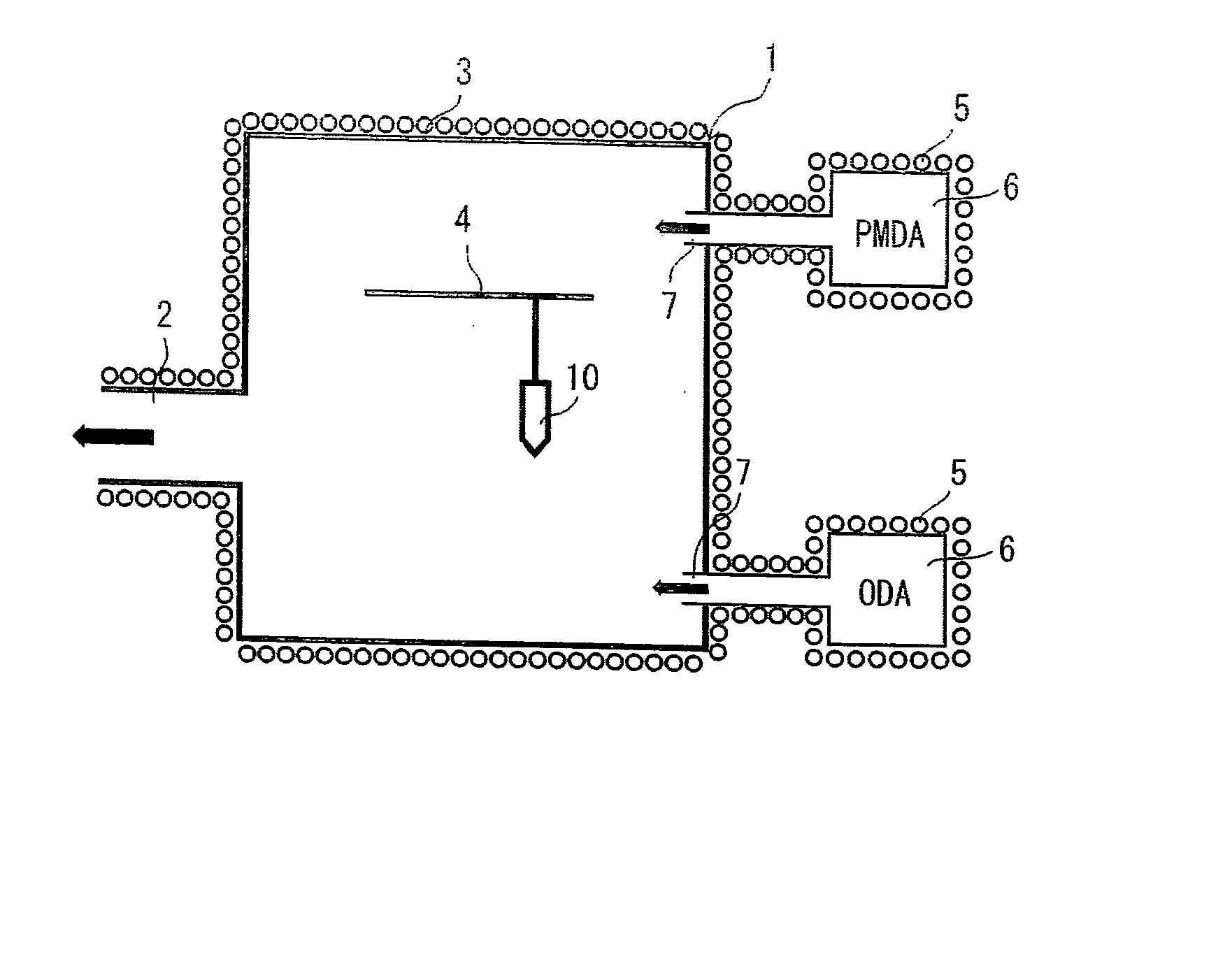

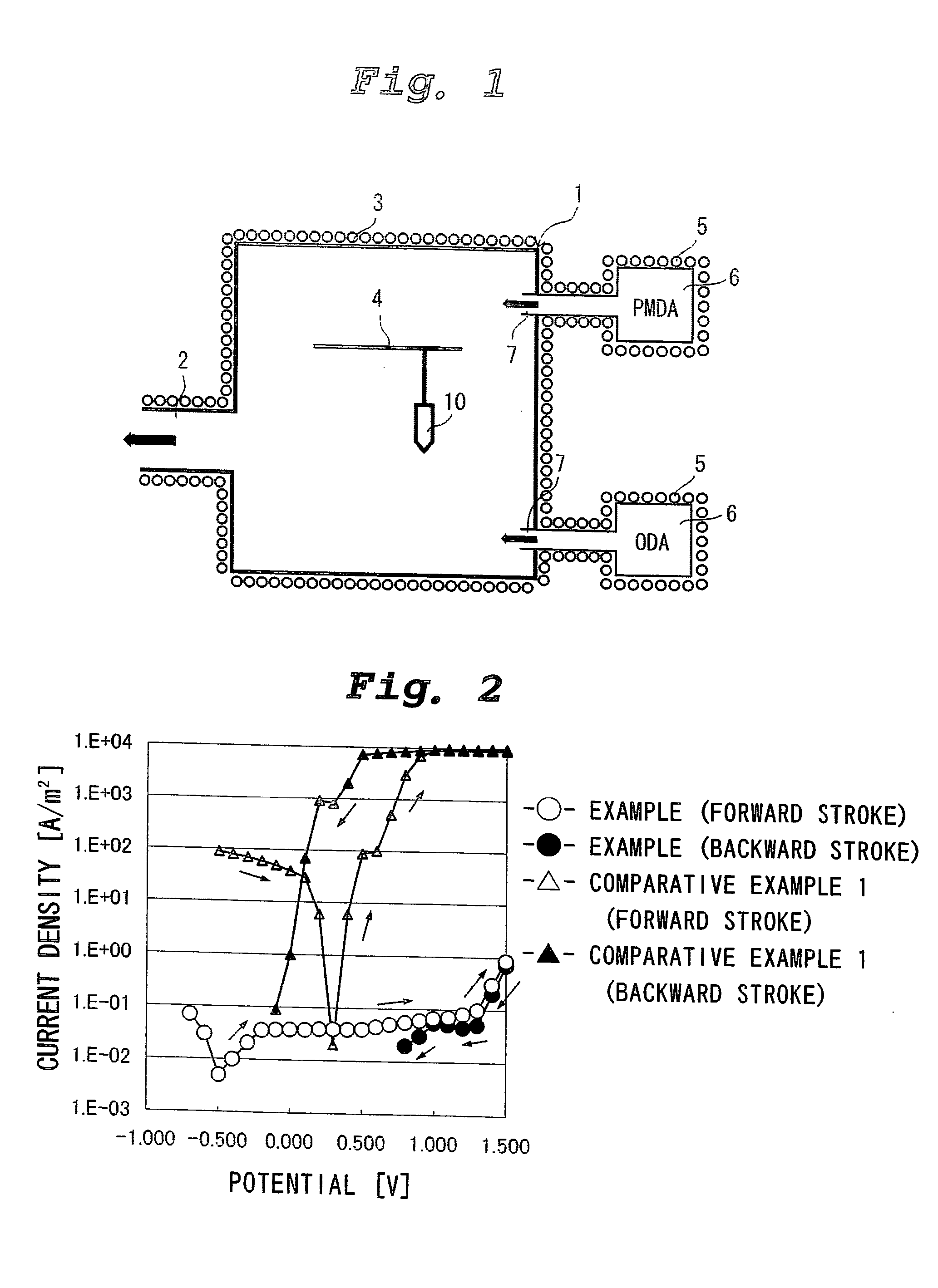

Film formation method and film formation apparatus

ActiveUS20150064931A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingOrganic filmVapor deposition polymerization

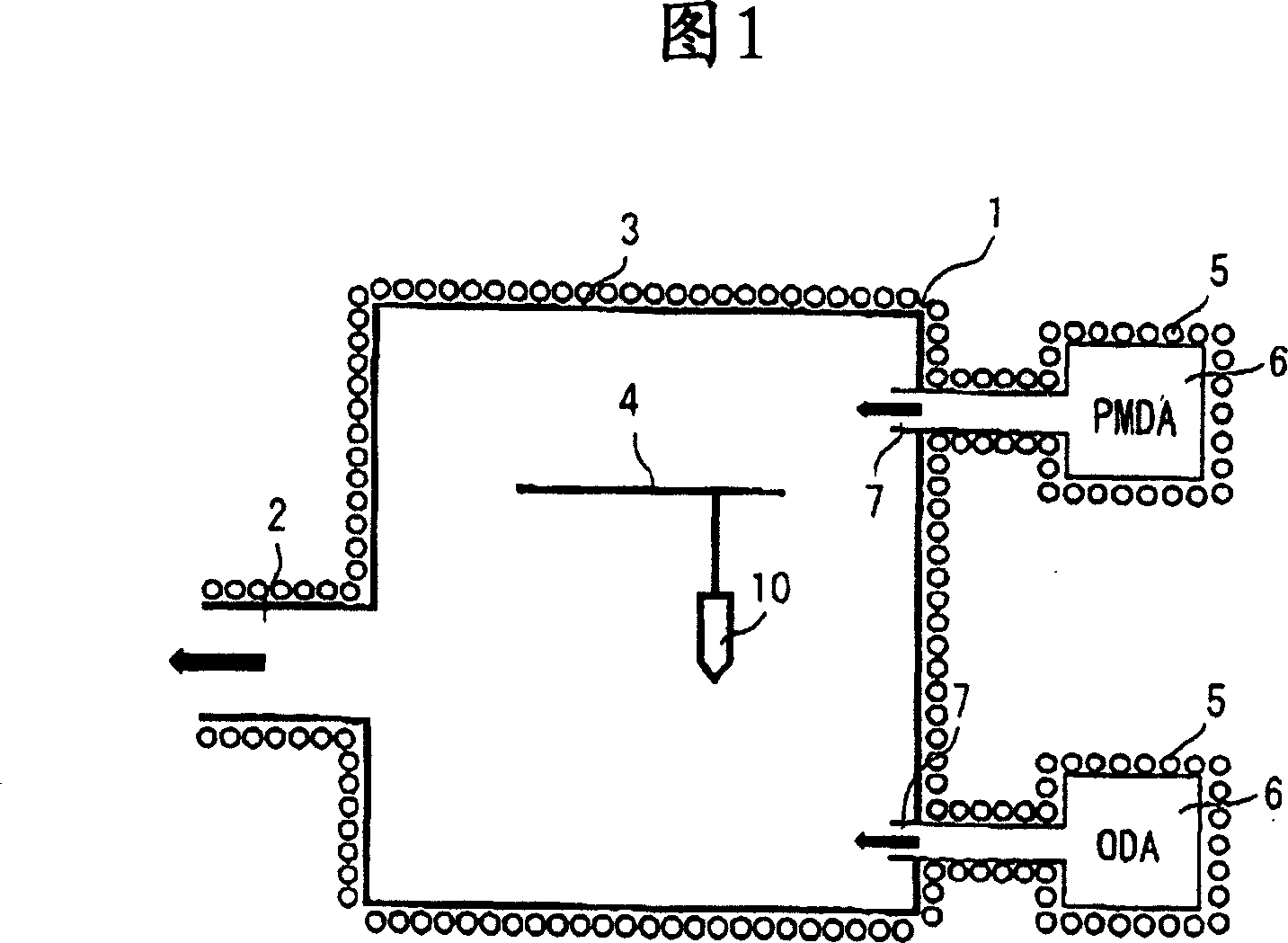

Disclosed is a film formation method, including vaporizing a plurality of raw material monomers in respective corresponding vaporizers, supplying the plurality of raw material monomers into a film formation apparatus, causing vapor deposition polymerization of the plurality of raw material monomers in the film formation apparatus to form an organic film on a substrate, and removing an impurity contained in at least one raw material monomer among the plurality of raw material monomers before the vapor deposition polymerization.

Owner:TOKYO ELECTRON LTD +1

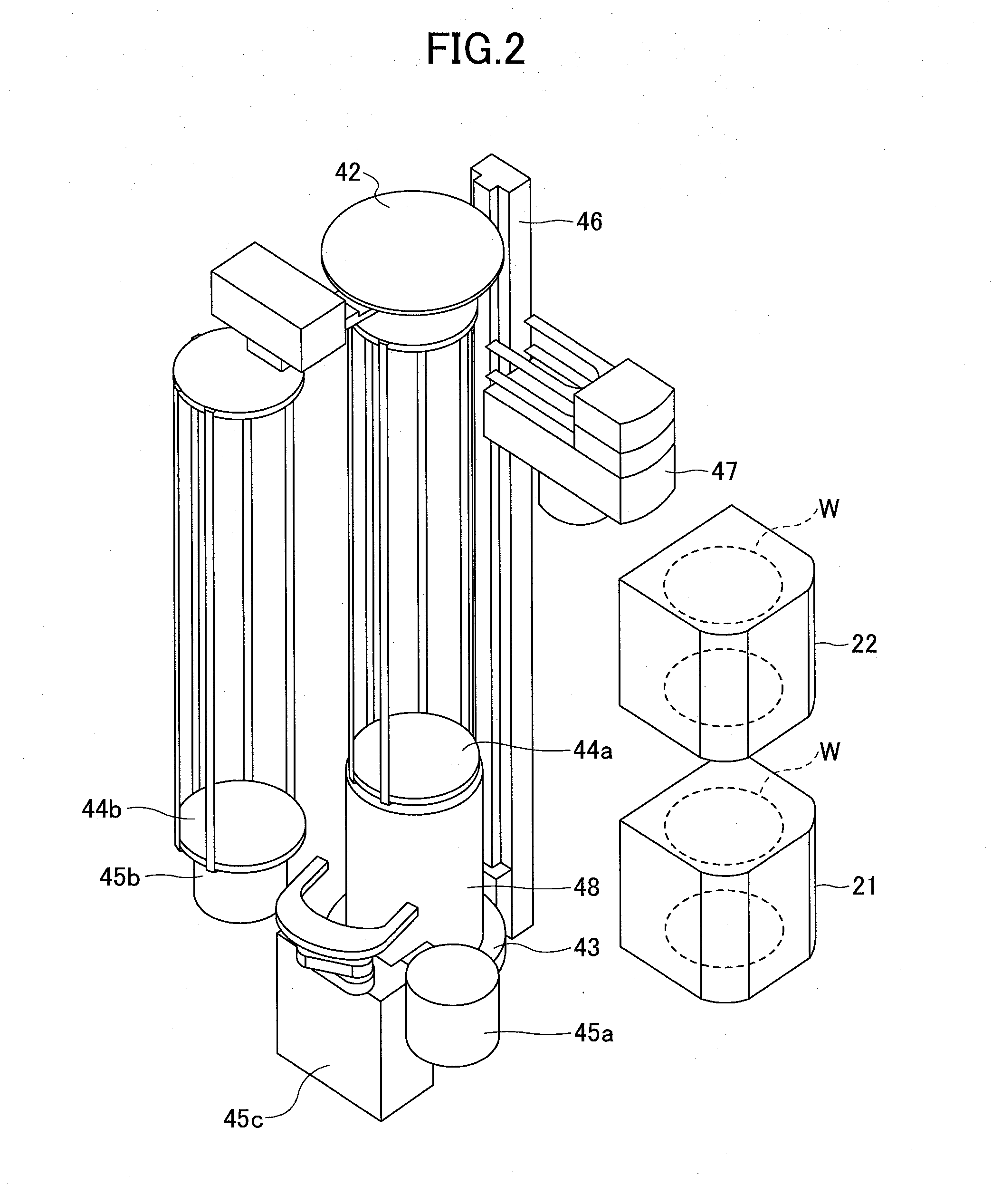

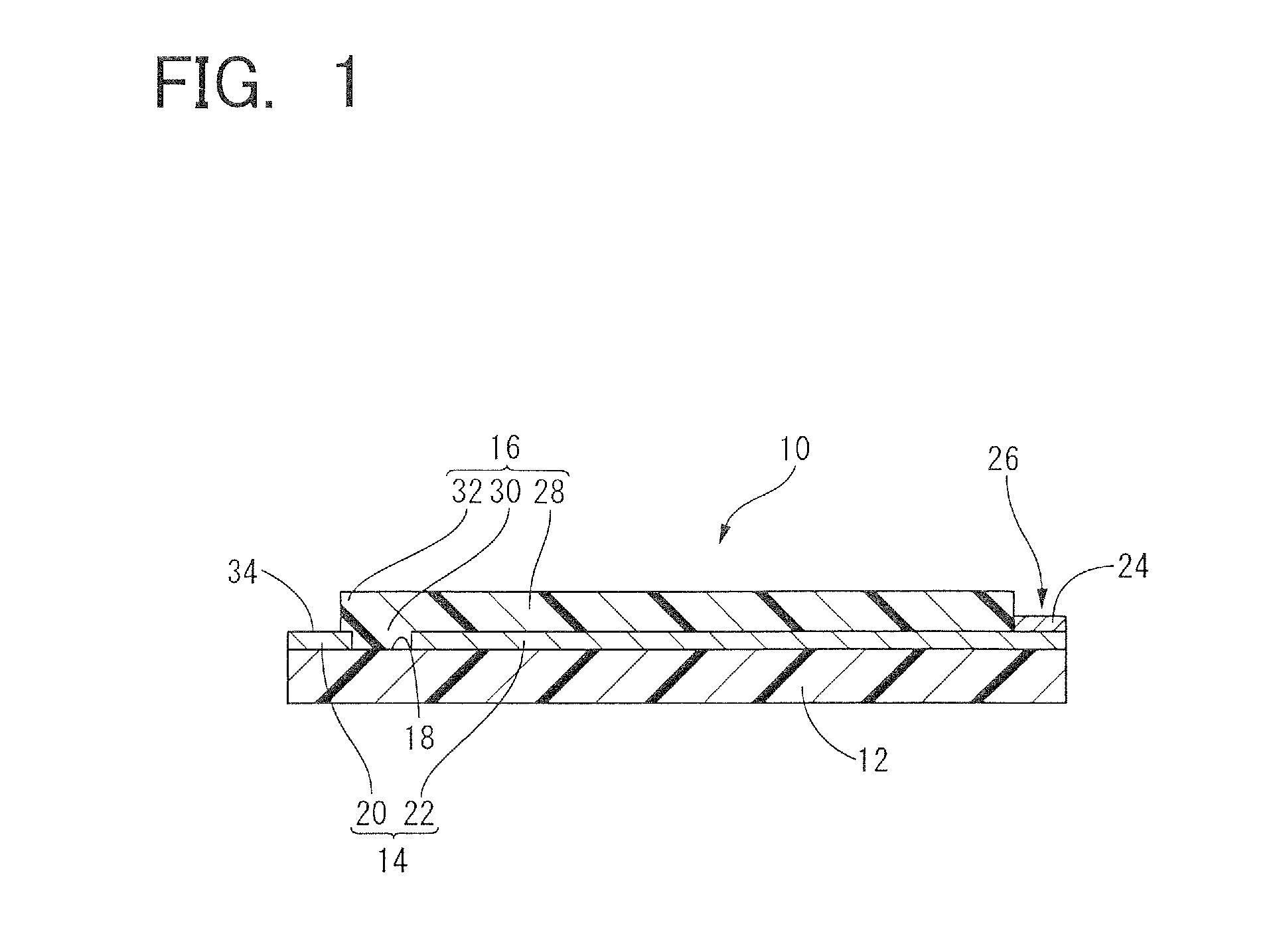

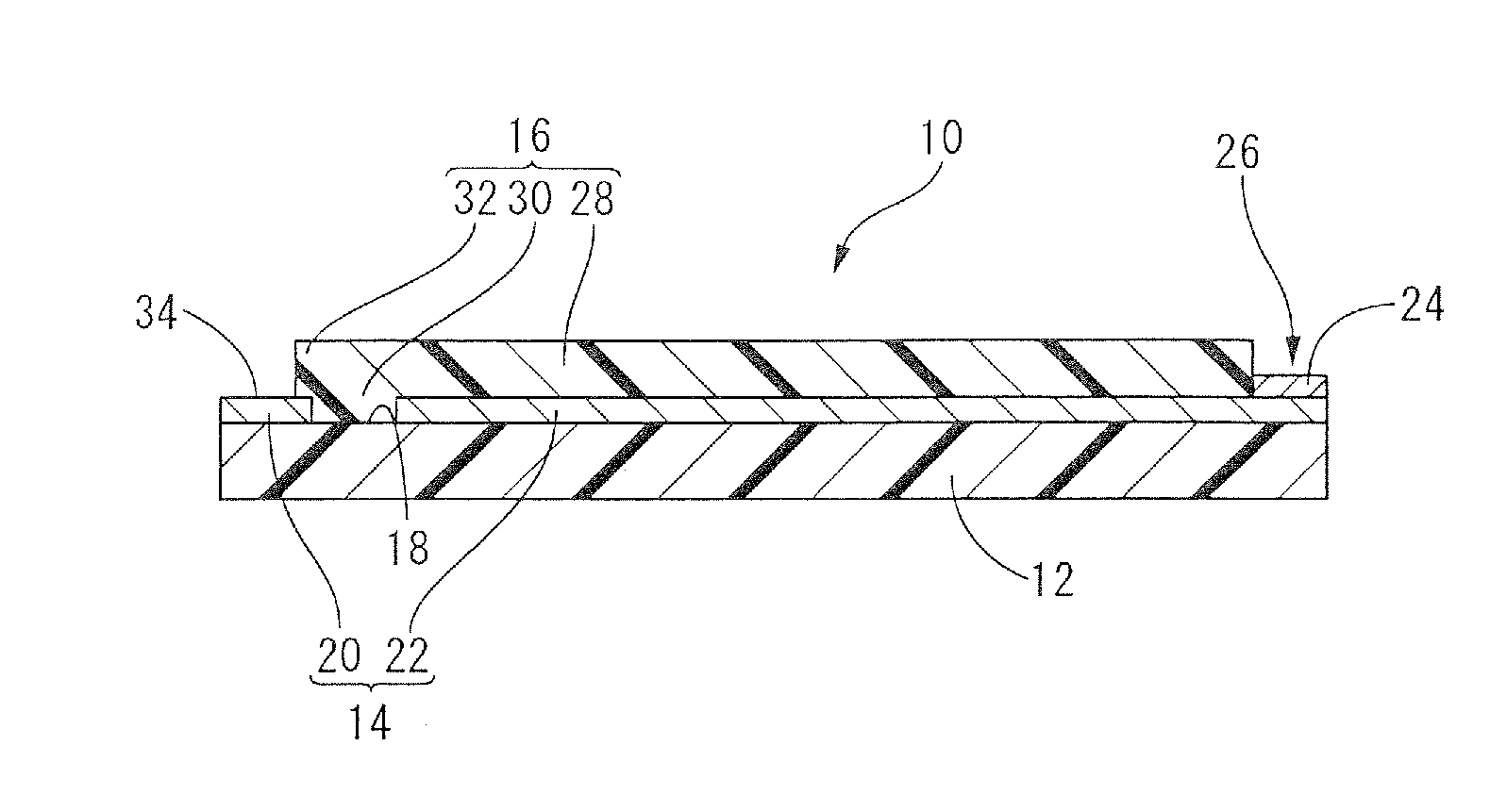

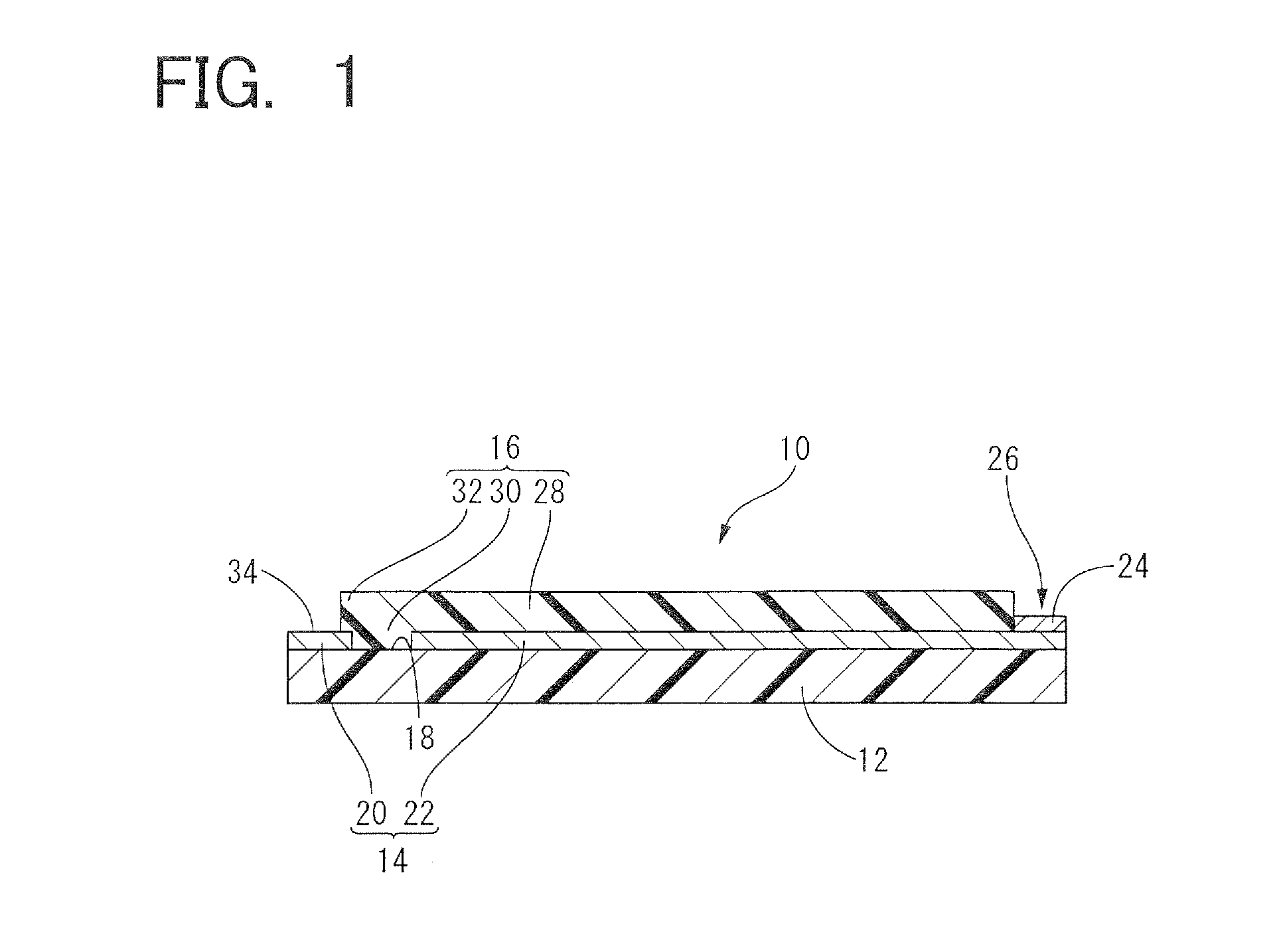

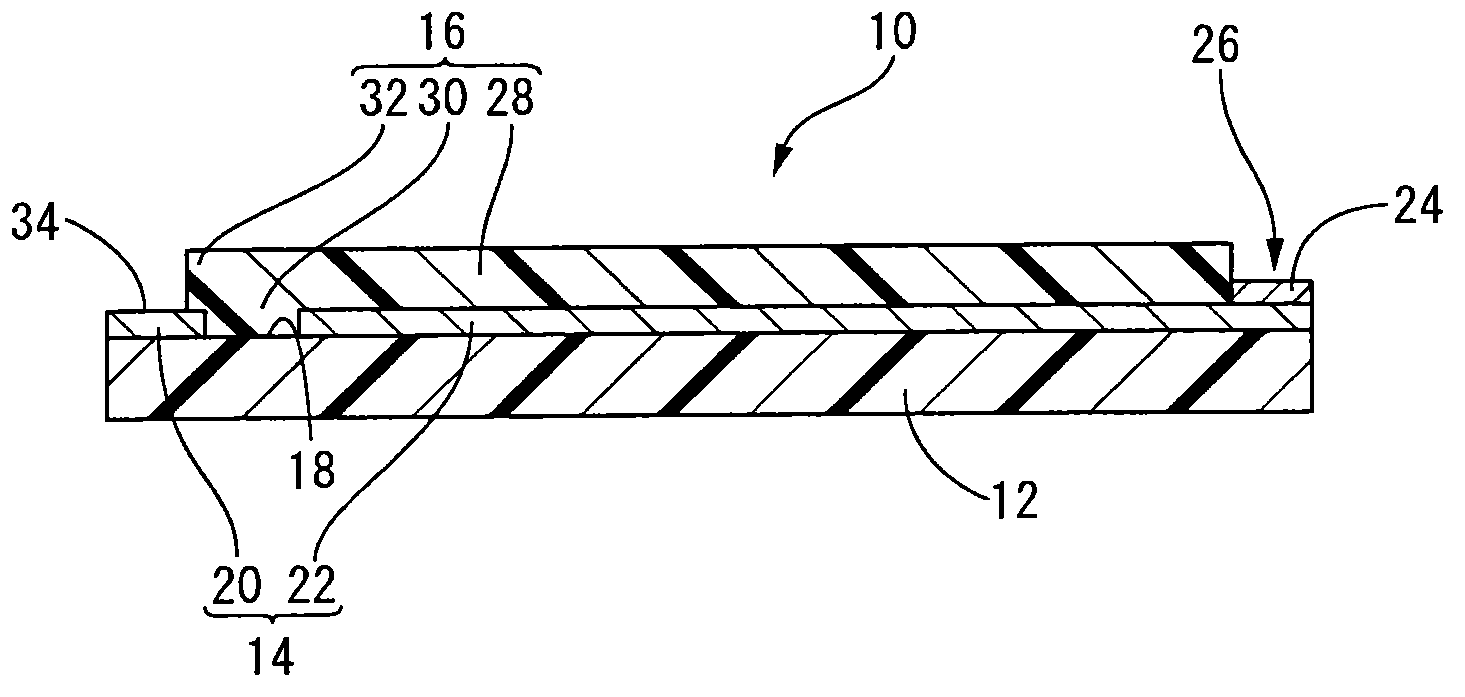

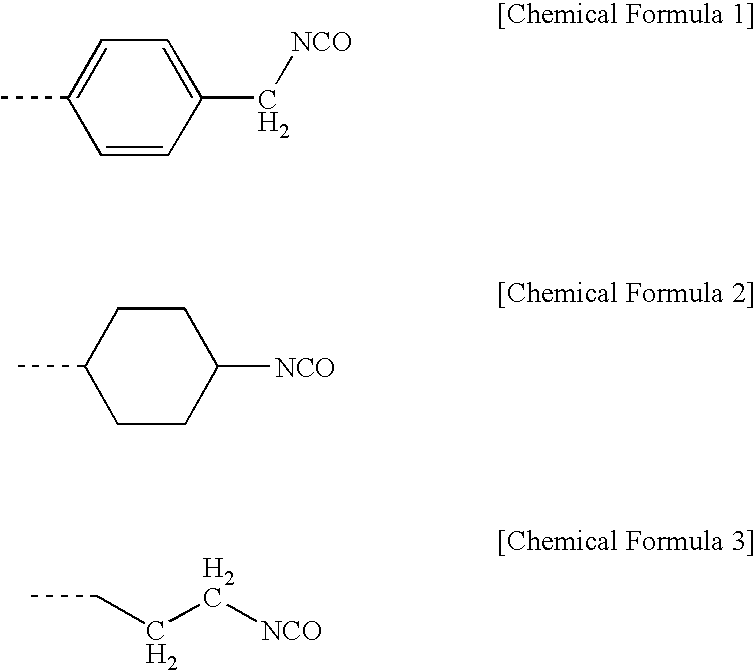

Film capacitor element, film capacitor, and method of producing the film capacitor element

InactiveUS8861178B2Effectively increased degree of adhesivenessSuitably producedFixed capacitor electrodesThin/thick film capacitorDielectricVapor deposition polymerization

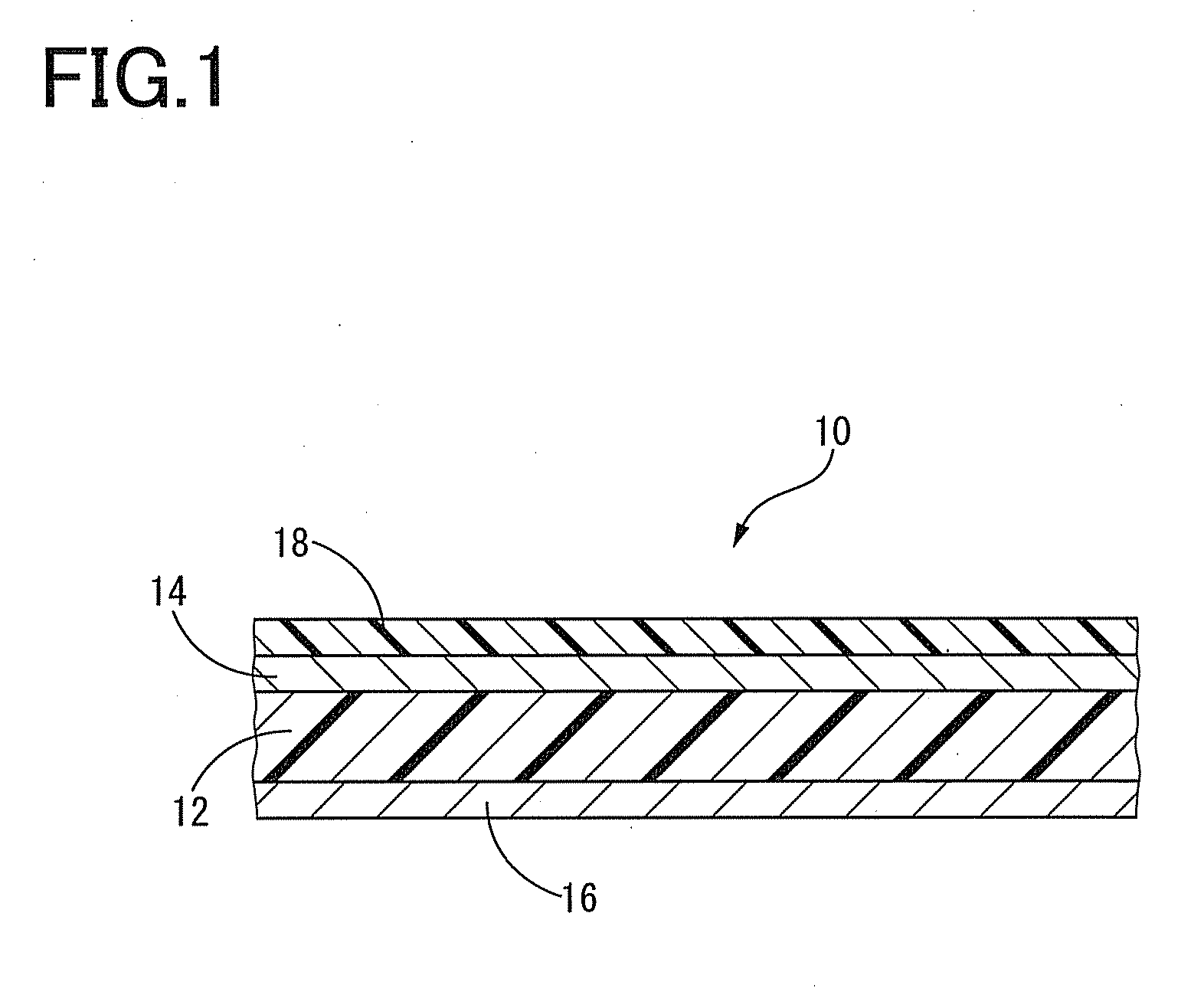

A film capacitor element including a base dielectric film layer 12, a vapor-deposition metal film layer 14 formed on the base dielectric film layer 12 and consisting of a first film portion 20 and a second film portion 22 that are spaced apart from each other by a margin portion 18, and a dielectric covering film layer 16 which is formed integrally on the second film portion 22 by vapor-deposition polymerization or coating and which has a covering portion 30 which fills the margin portion 18 and covers an entire area of an end face of the second film portion 22 on the side of the margin portion 18. The first film portion 20 including a non-covered portion 34 which is not covered by the dielectric covering film layer 16.

Owner:KOJIMA PRESS IND CO LTD

Film capacitor element, film capacitor, and method of producing the film capacitor element

InactiveUS20130314839A1Improve adhesionWidth minimizedThin/thick film capacitorStacked capacitorsVapor deposition polymerizationThin membrane

A film capacitor element including a base dielectric film layer 12, a vapor-deposition metal film layer 14 formed on the base dielectric film layer 12 and consisting of a first film portion 20 and a second film portion 22 that are spaced apart from each other by a margin portion 18, and a dielectric covering film layer 16 which is formed integrally on the second film portion 22 by vapor-deposition polymerization or coating and which has a covering portion 30 which fills the margin portion 18 and covers an entire area of an end face of the second film portion 22 on the side of the margin portion 18. The first film portion 20 including a non-covered portion 34 which is not covered by the dielectric covering film layer 16.

Owner:KOJIMA PRESS IND CO LTD

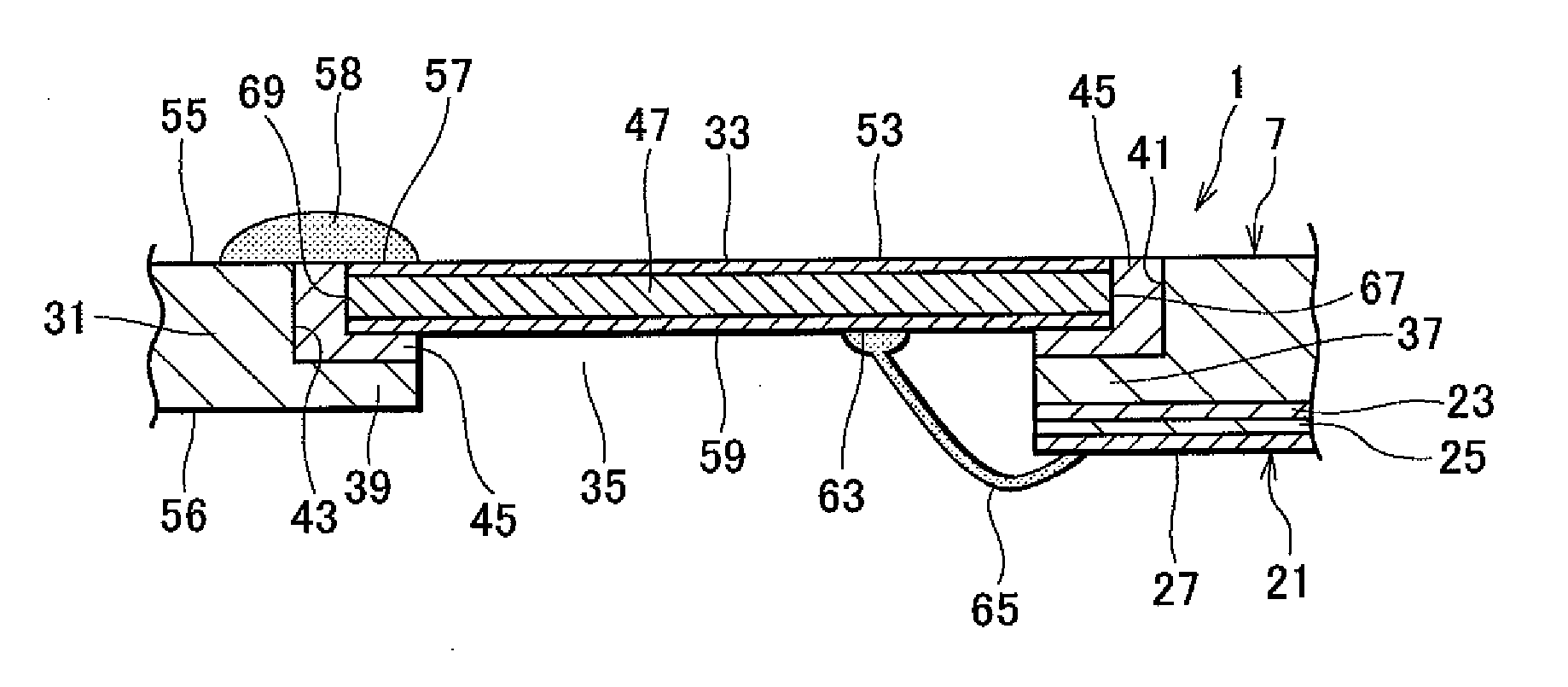

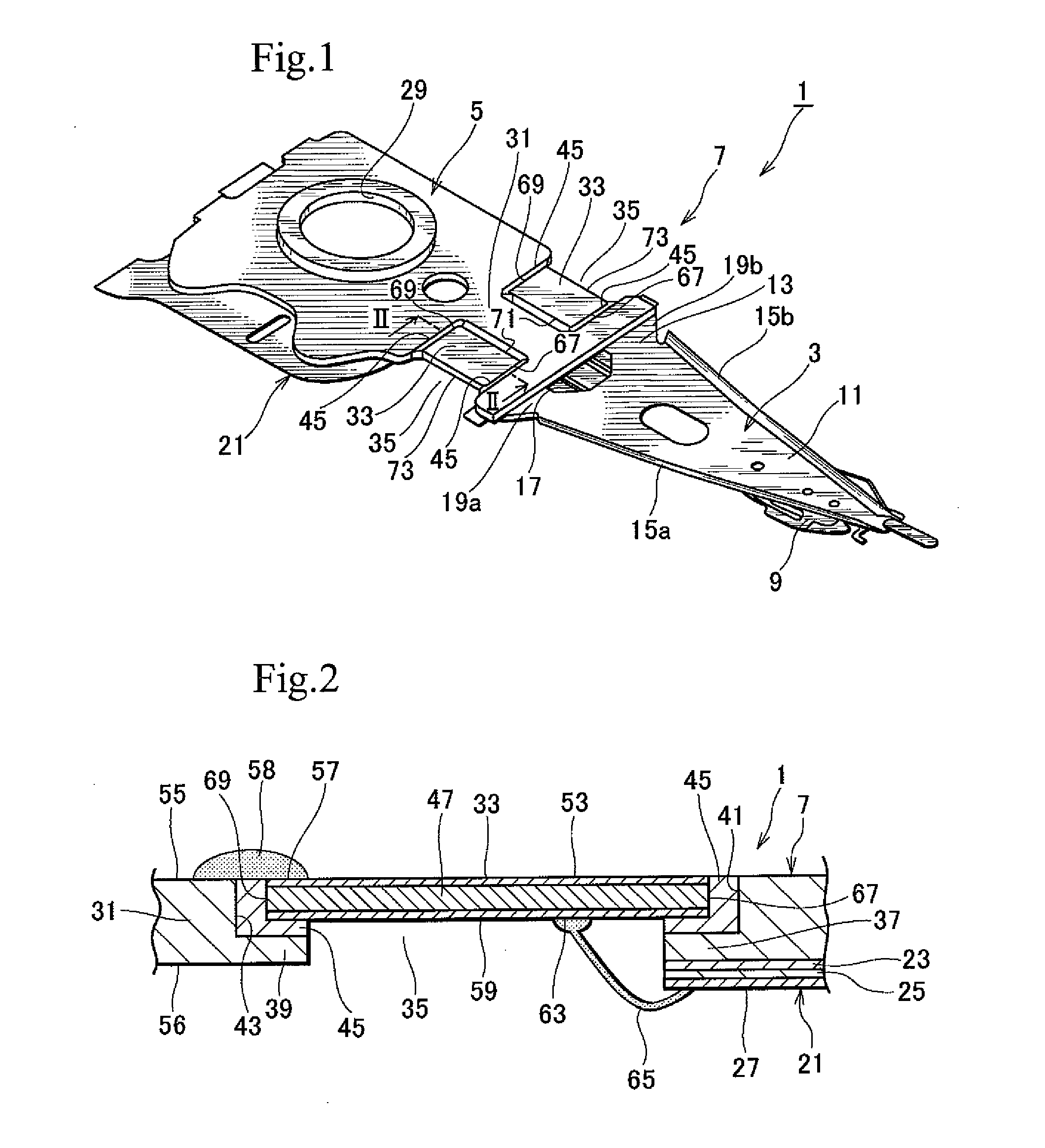

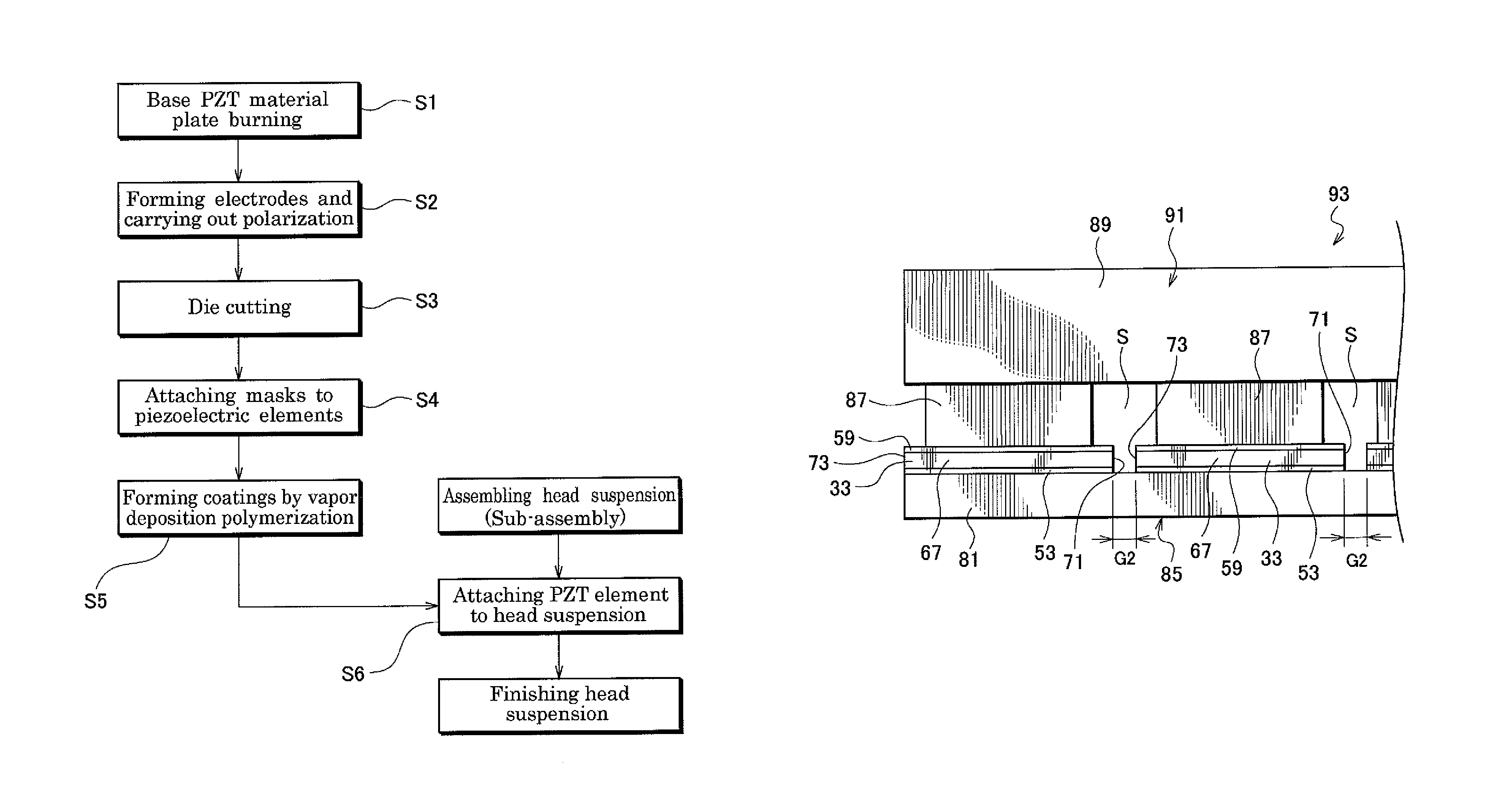

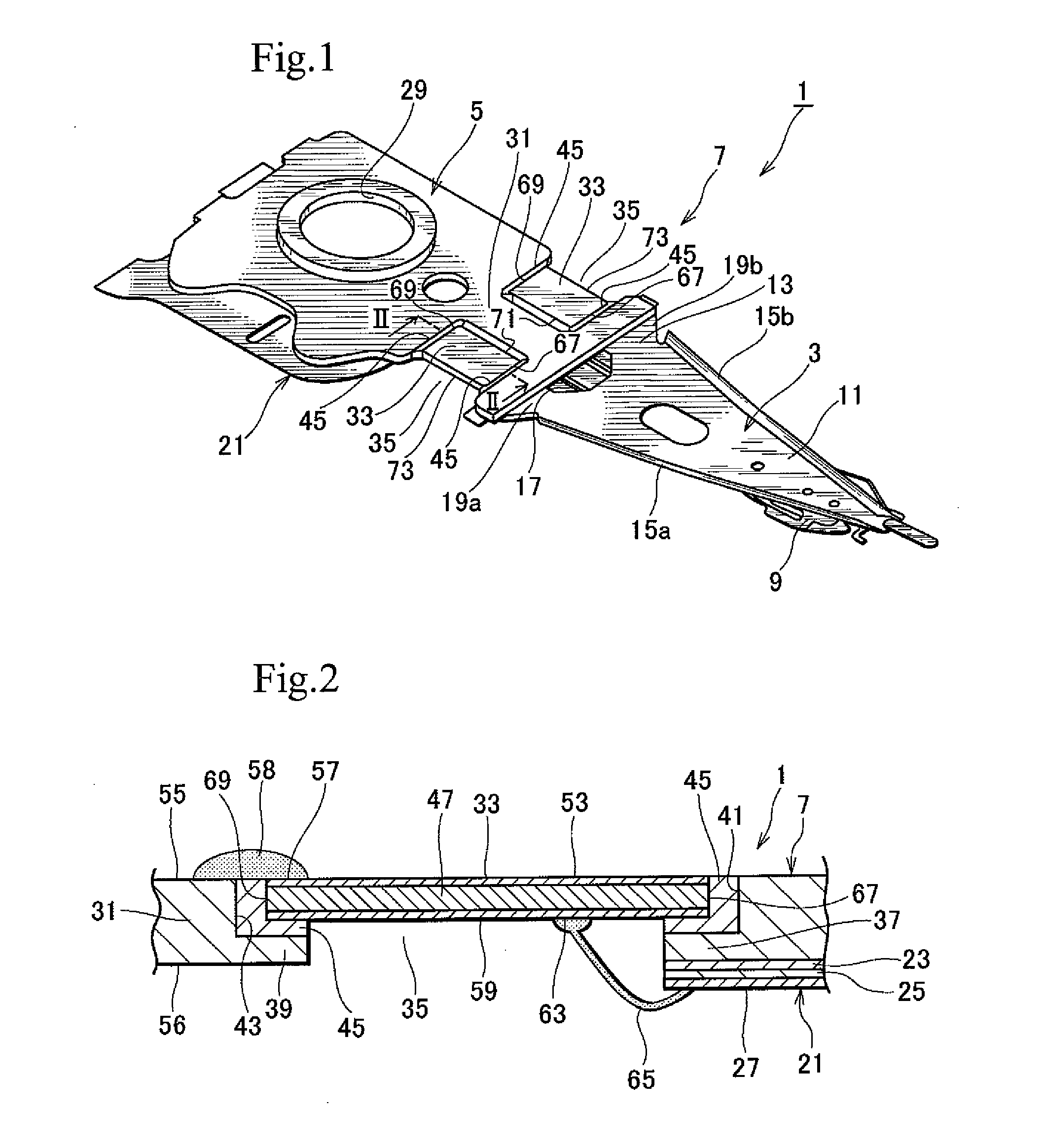

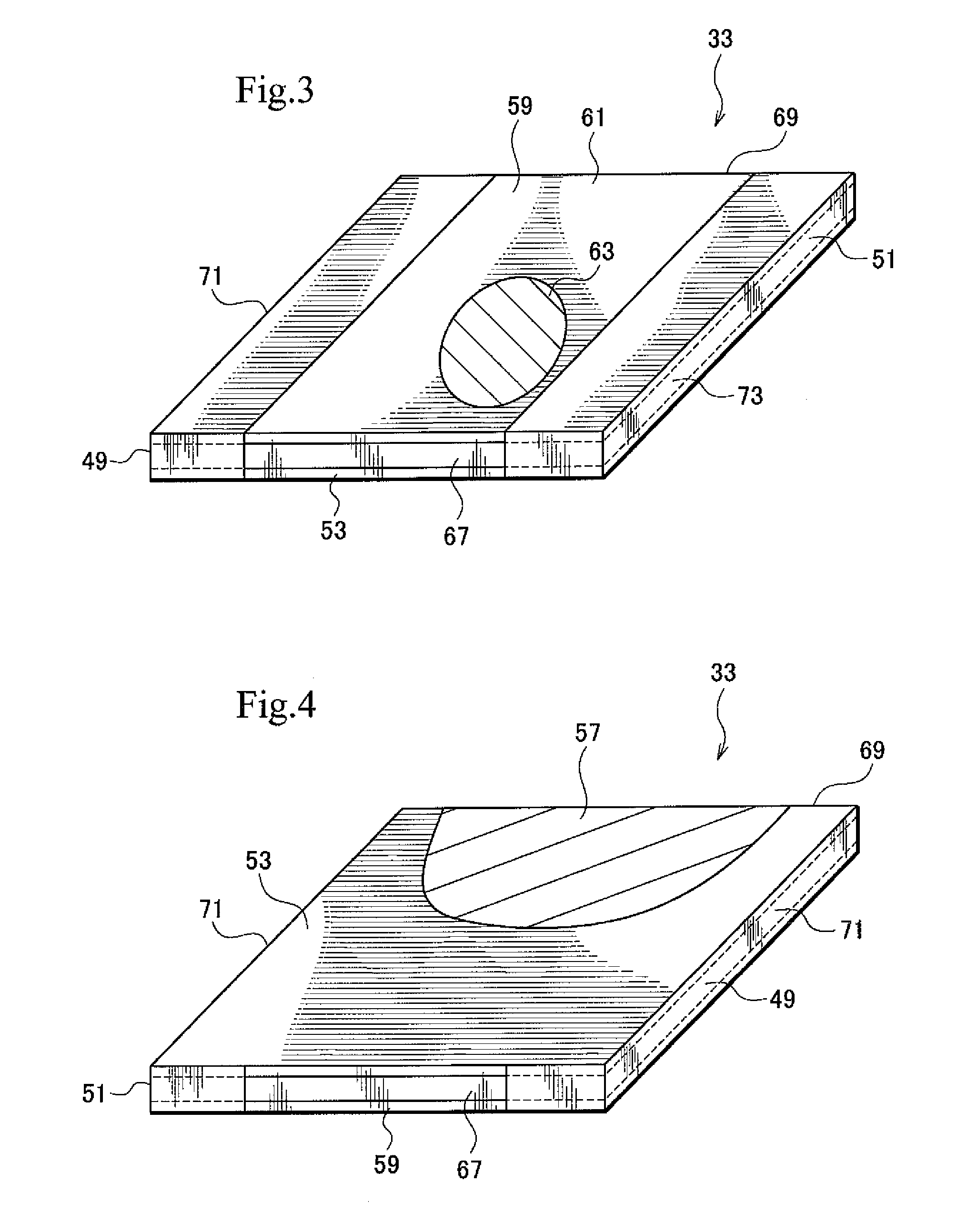

Method of manufacturing piezoelectric element, piezoelectric element, piezoelectric actuator, and head suspension

ActiveUS20120176703A1Easily and surely formingWithout deteriorationTrack finding/aligningPiezoelectric/electrostrictive device manufacture/assemblyVapor deposition polymerizationGas phase

An method of manufacturing a piezoelectric element easily and surely forms polymer coatings on peripheral end faces of the piezoelectric element without deteriorating a yield of the piezoelectric element. The method includes steps of cutting a piezoelectric element out from a base piezoelectric material plate so that peripheral end faces are formed to define a peripheral shape of the piezoelectric element, and forming polymer coatings on at least objective areas of the peripheral end faces of the piezoelectric element by vapor deposition polymerization, respectively.

Owner:NHK SPRING CO LTD

Encapsulated particles for enteric release

InactiveUS20100297251A1Convenient coatingEliminate chanceBiocidePretreated surfacesVapor deposition polymerizationActive agent

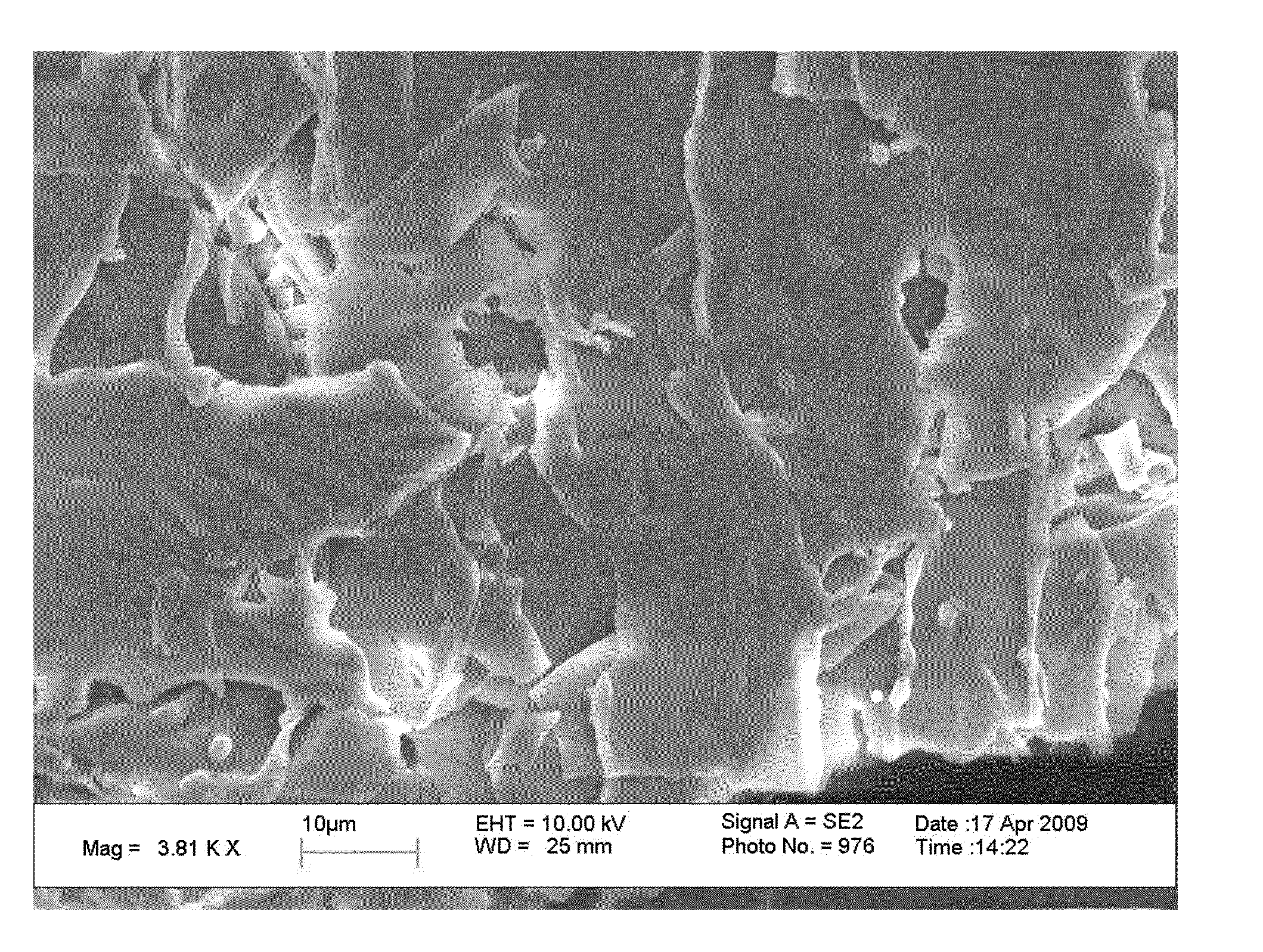

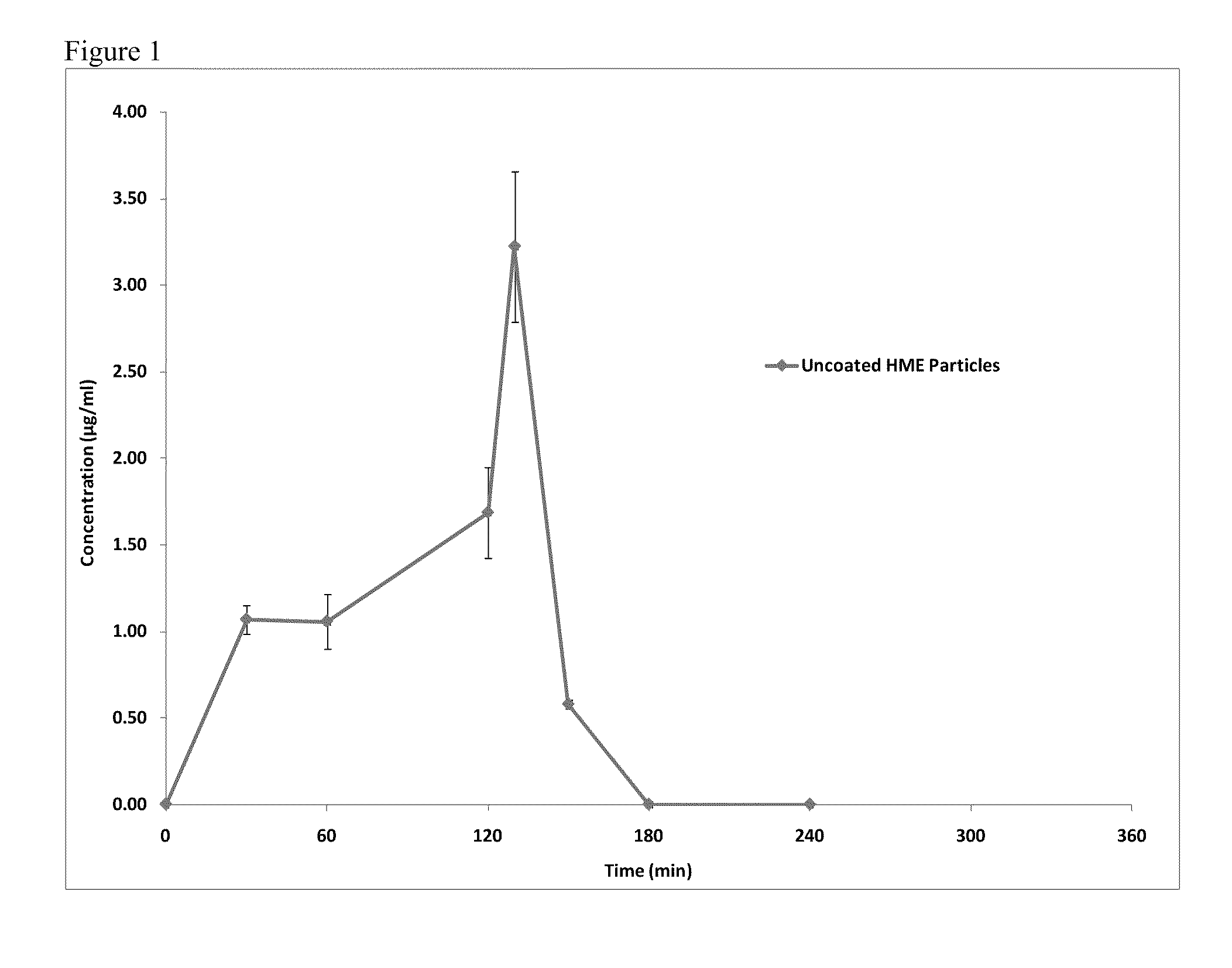

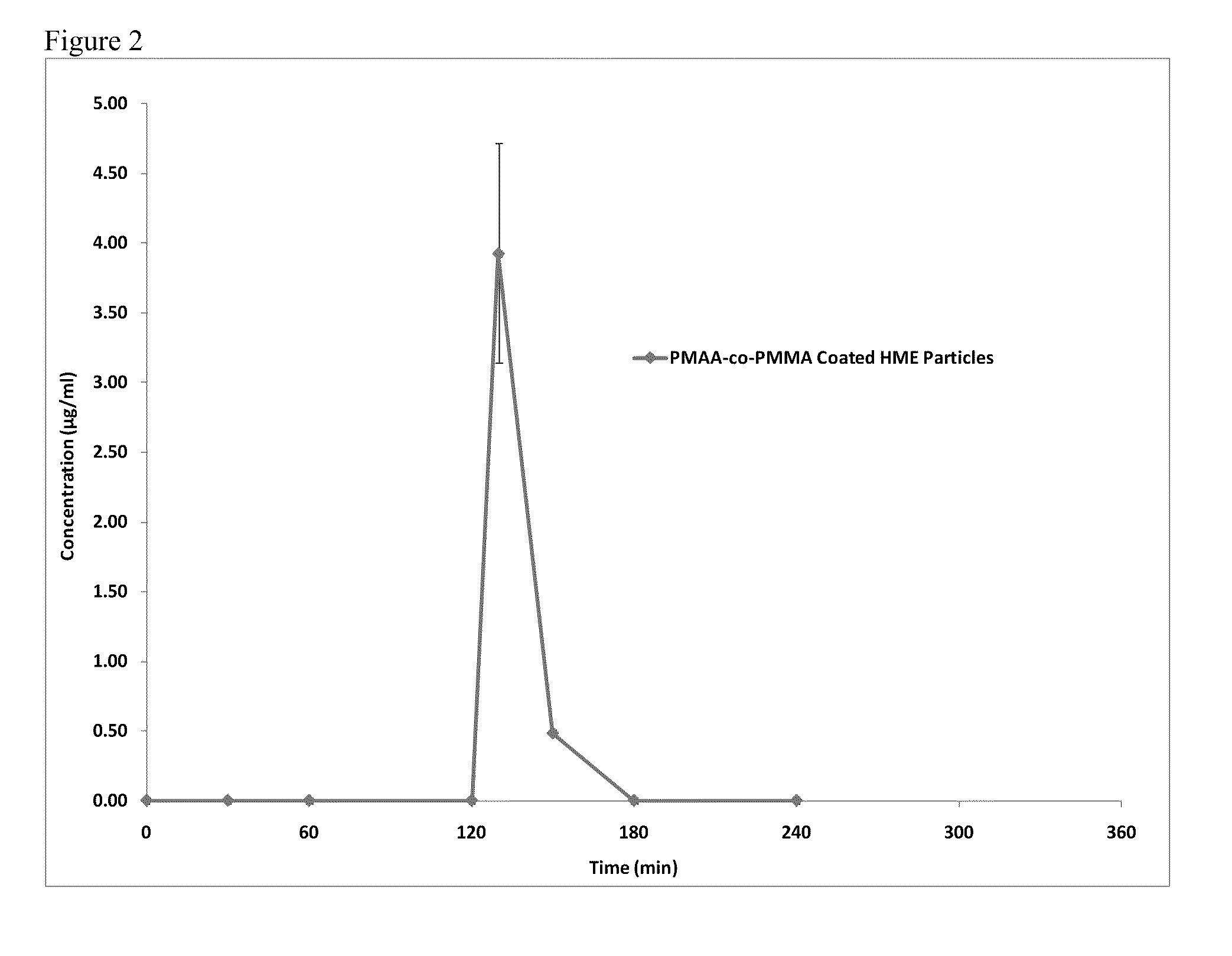

The present invention provides a system for delivery of an enteric coated active agent generally resistant to disintegration in an neutral environment having one or more active agents encapsulated by a polymer coating formed by chemical vapor deposition of one or more monomers on the one or more active agents to form a chemical vapor deposition polymer coating that controls the release of the one or more active agents in the gastrointestinal tract.

Owner:AEONCLAD COATINGS +1

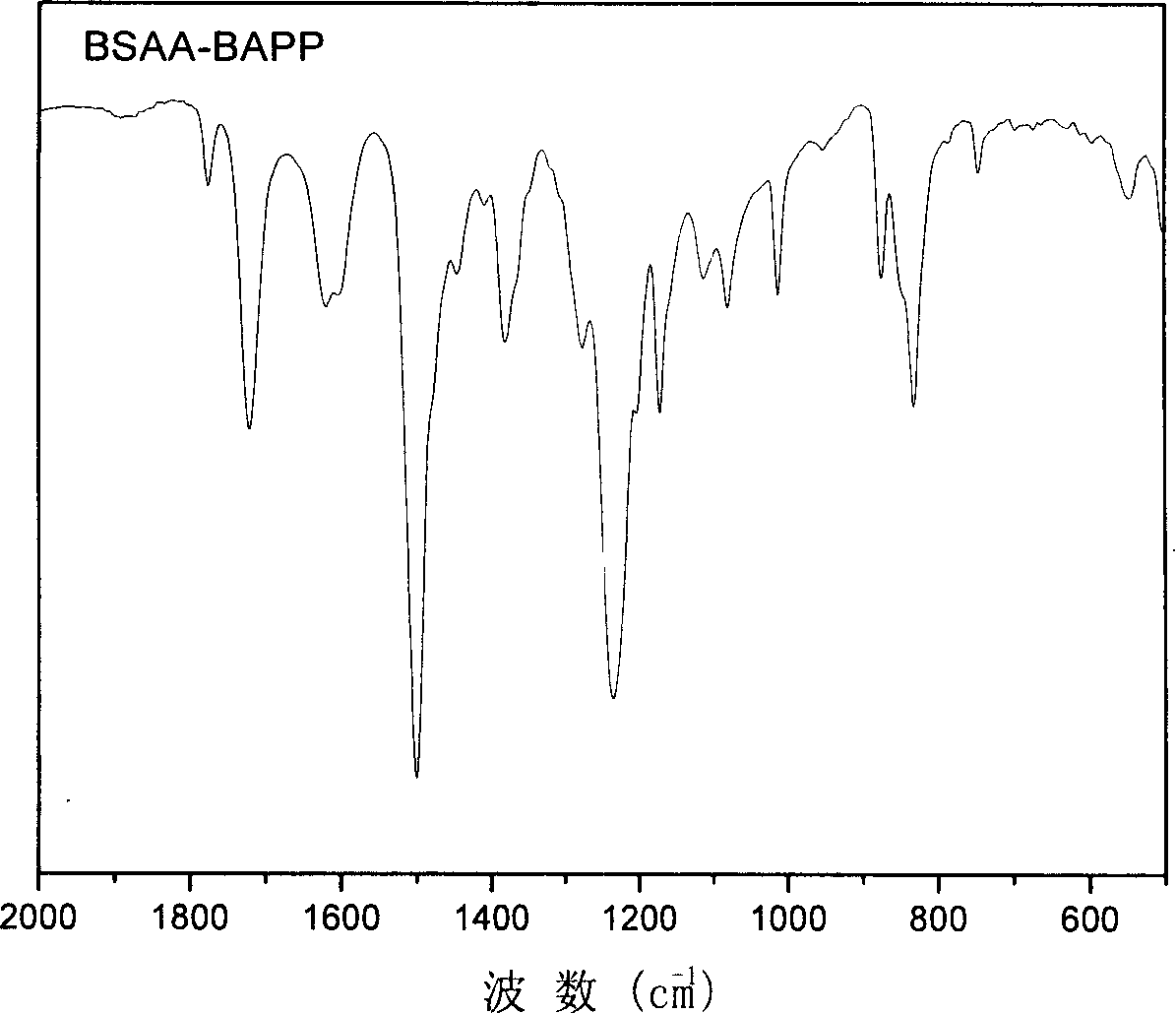

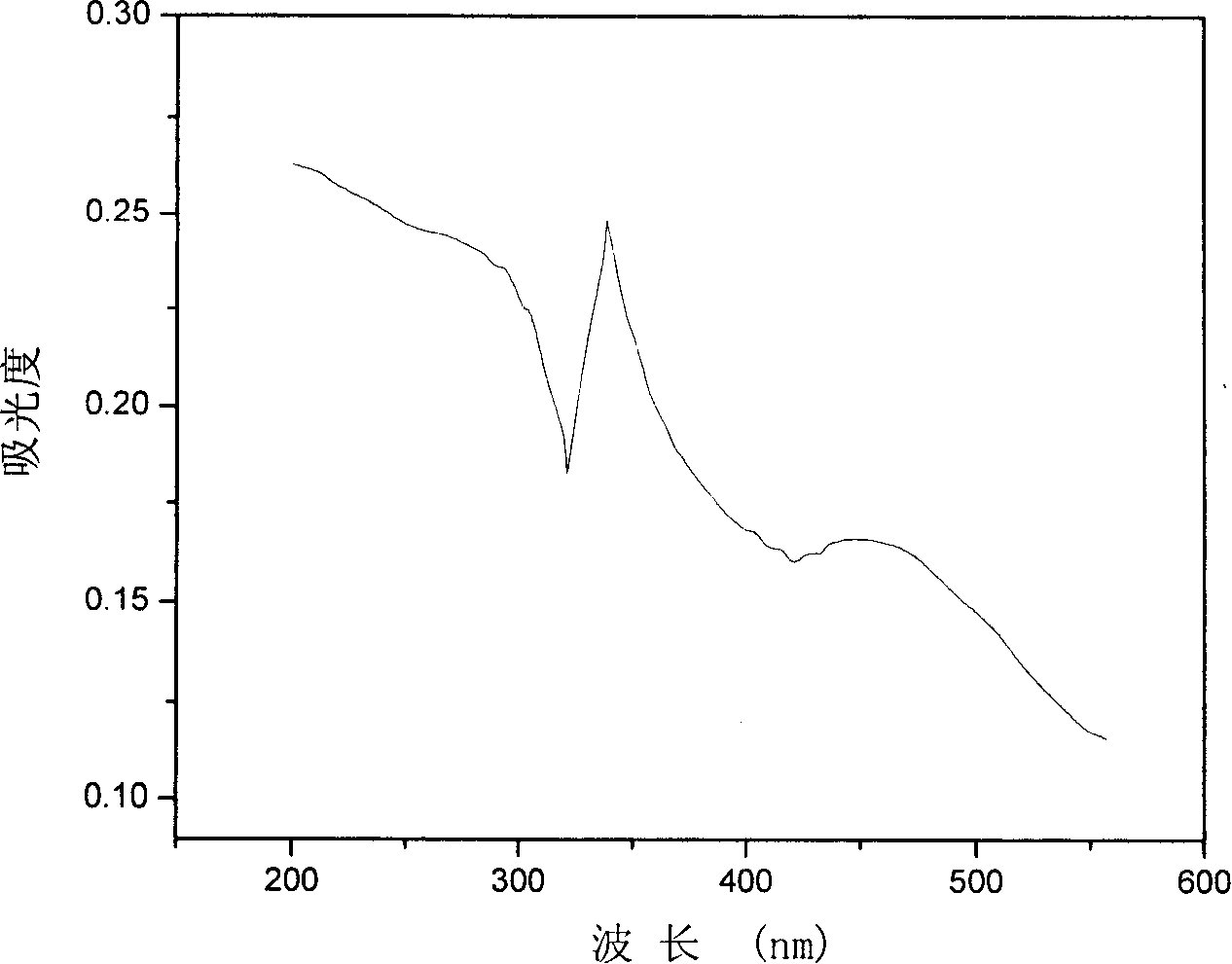

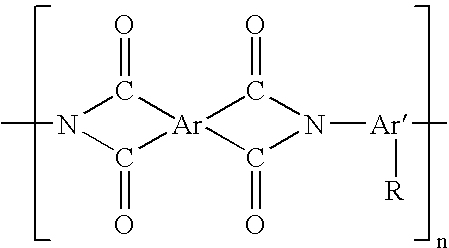

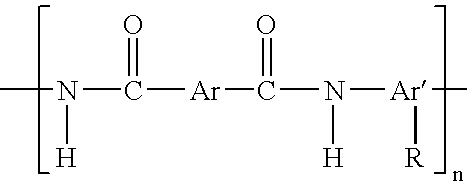

Bisphenol A-type polyimide material and method for making same

The invention belongs to the technical field of macromolecular materials and macromolecular synthesis, and in particular relates to the preparation of bisphenol A polyimide film by vapor deposition polymerization. The method for preparing polyimide is characterized in that bisphenol A dianhydride and diamine monomers are sublimated in vacuum and polymerized during vapor phase deposition. The polyimide prepared by this method not only maintains the good thermal stability and chemical stability of polyimide prepared by the traditional method, but also overcomes the shortcomings of the traditional method. The prepared polyimide film is uniform and dense, No pinholes, no catalyst, no solvent residue, high purity, and simplified reaction steps.

Owner:TONGJI UNIV

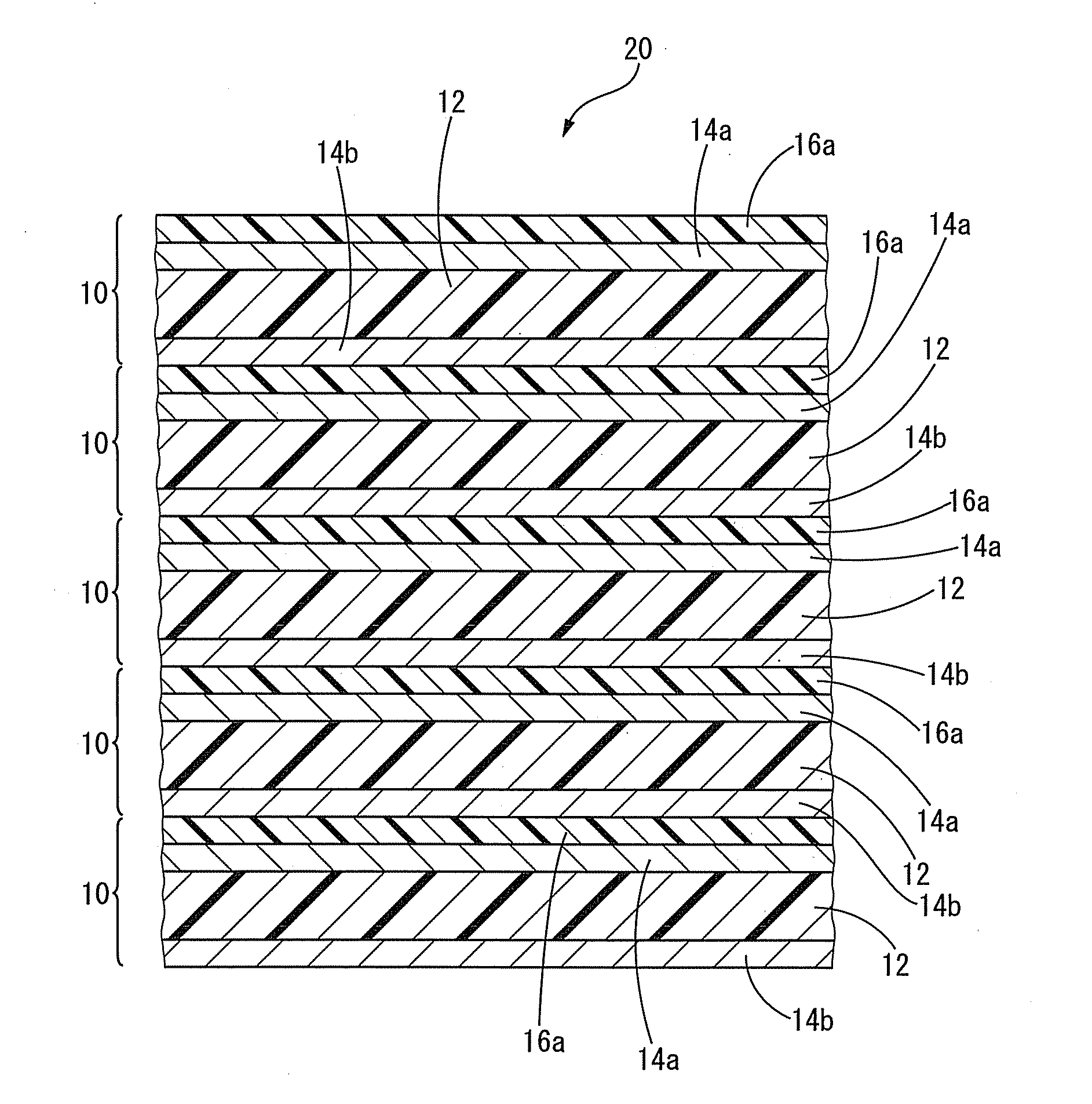

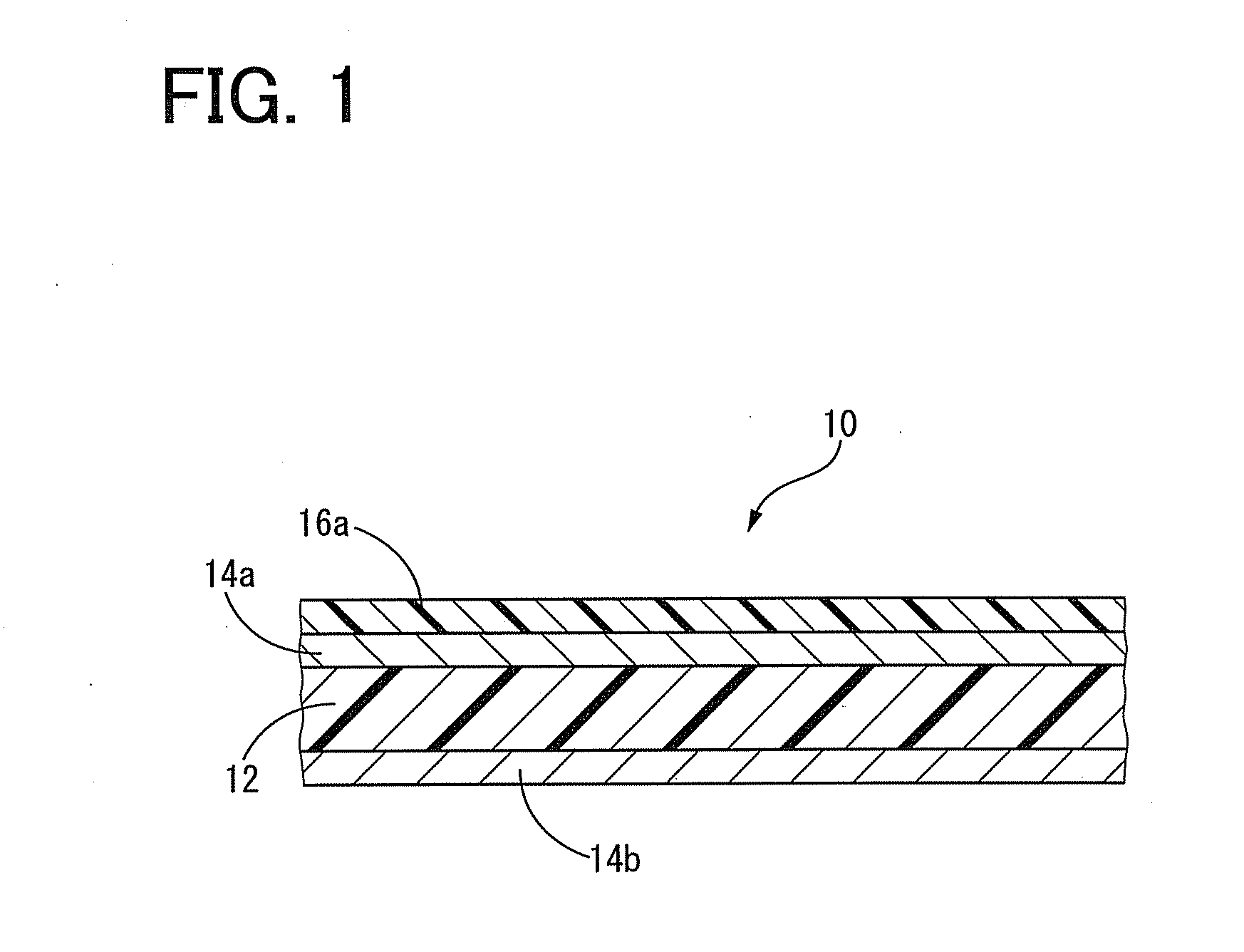

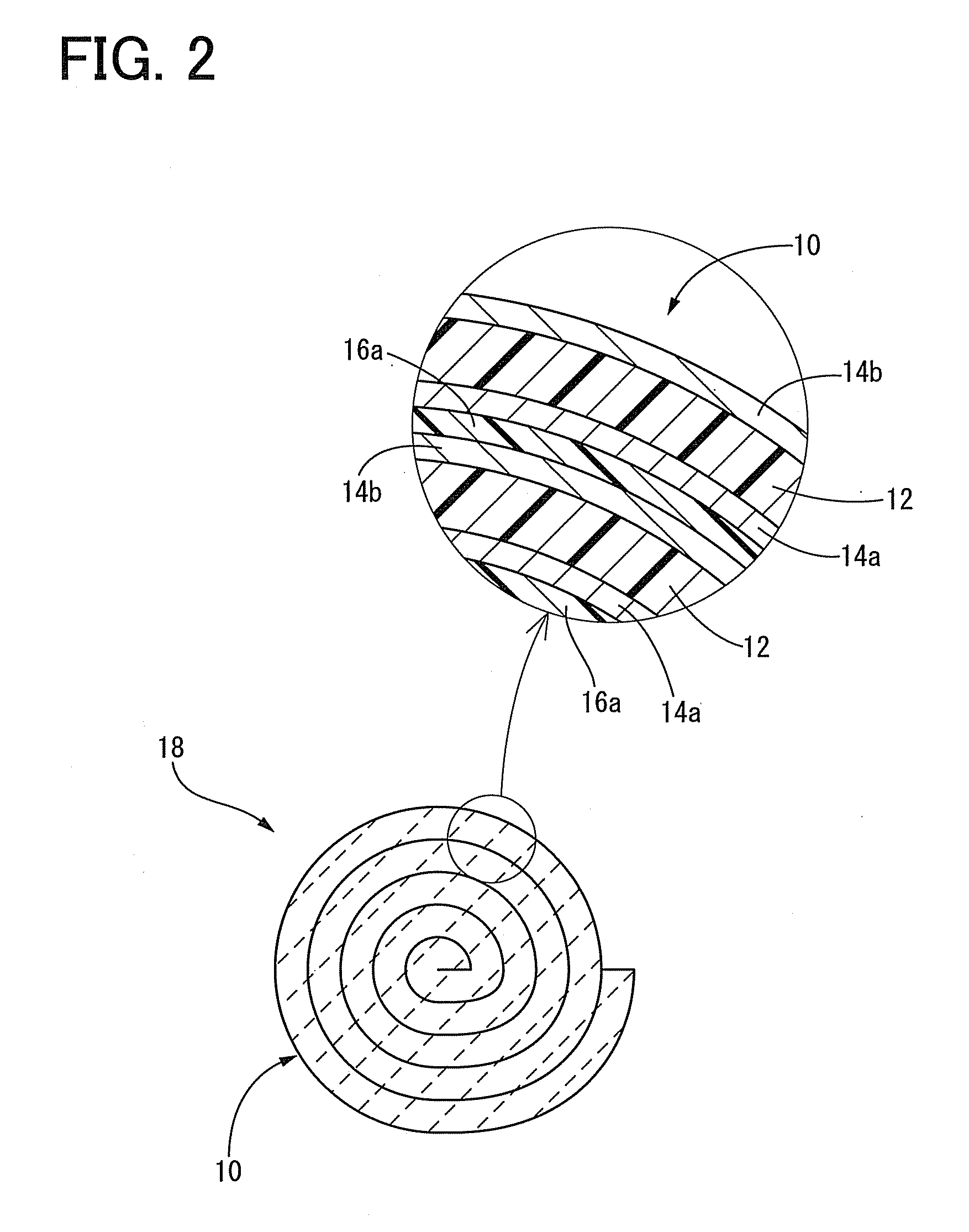

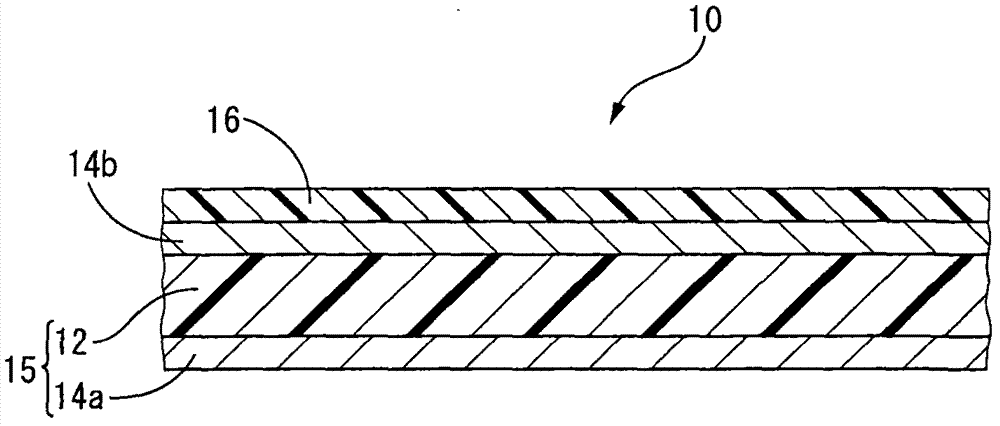

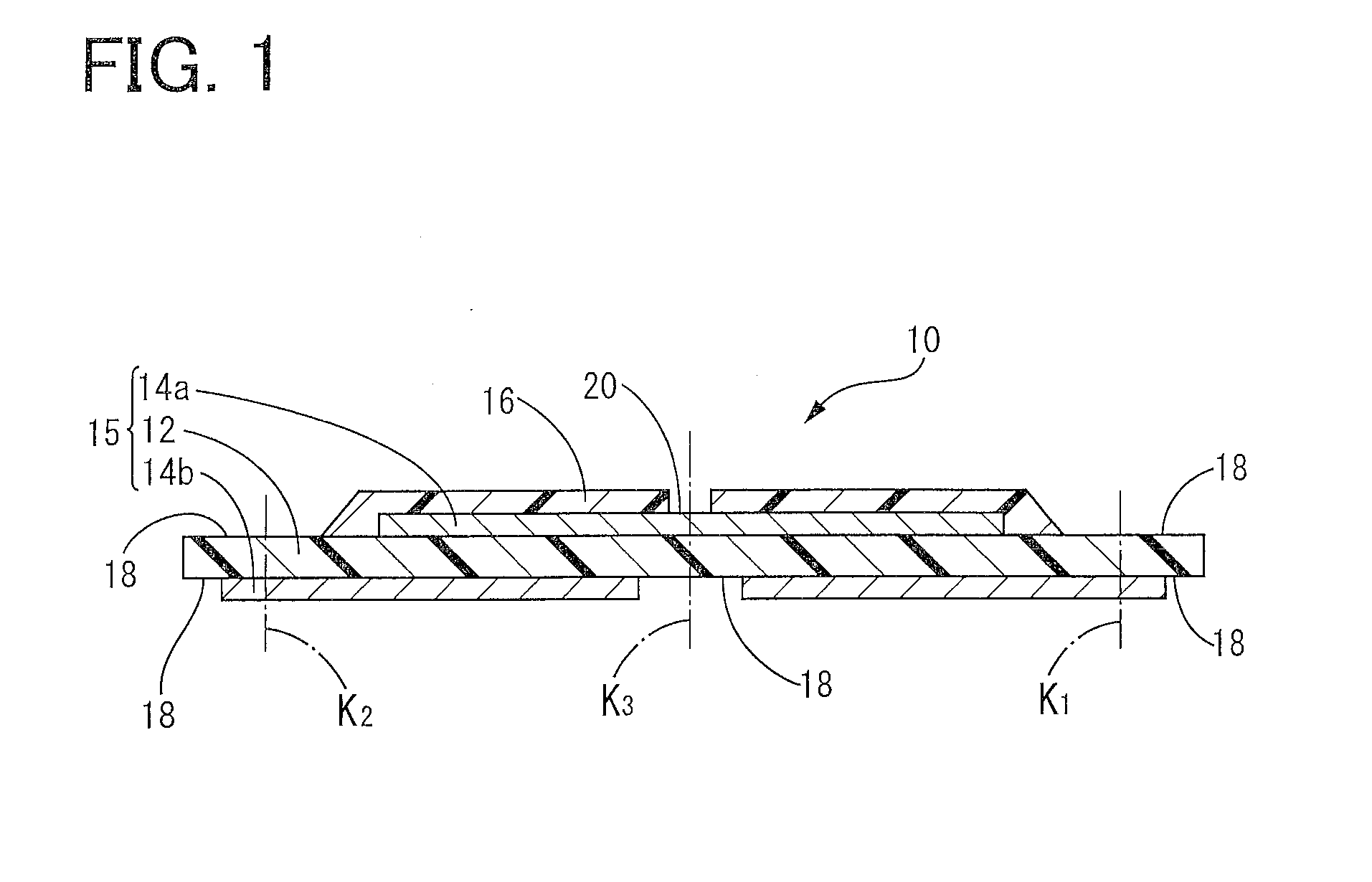

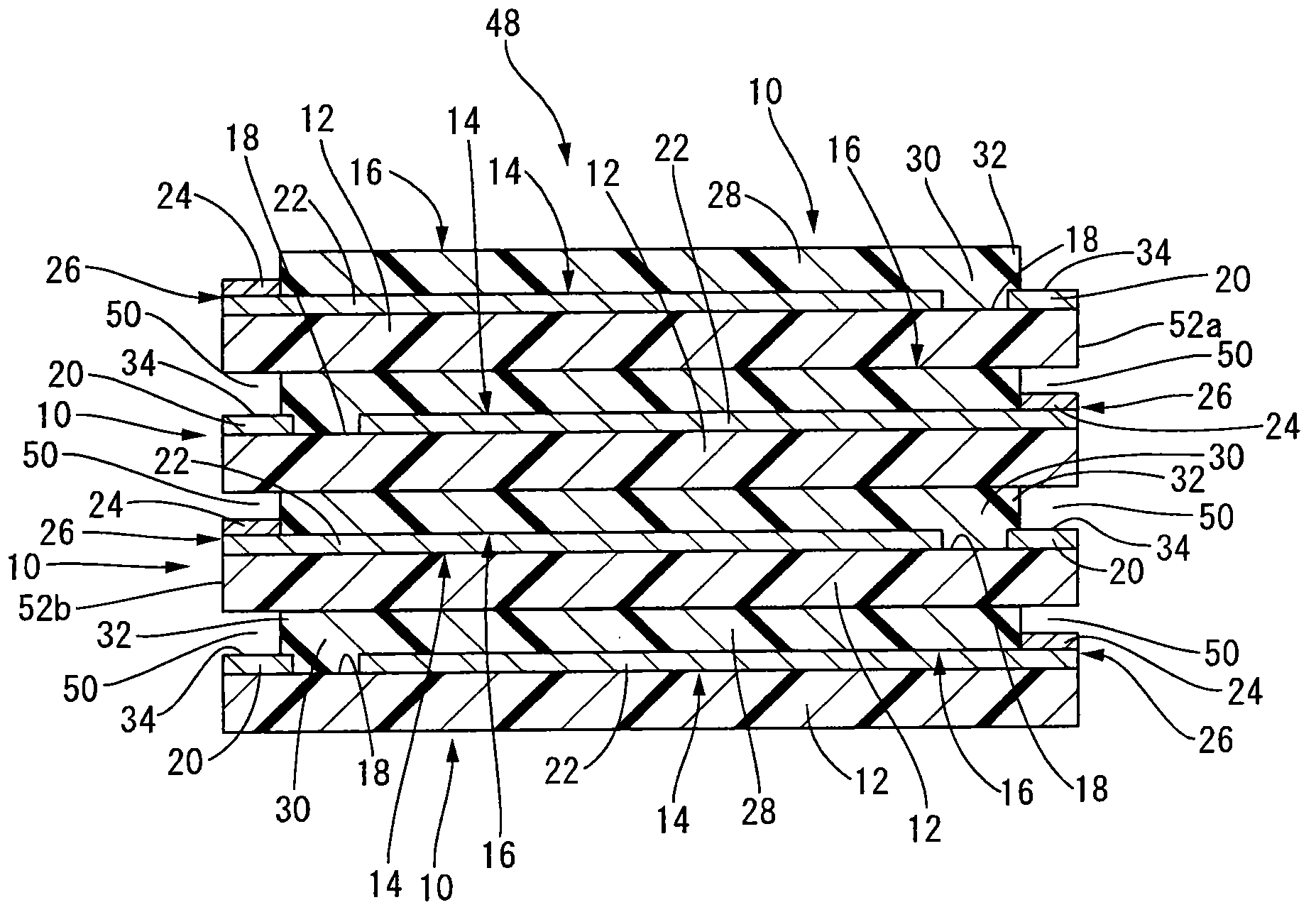

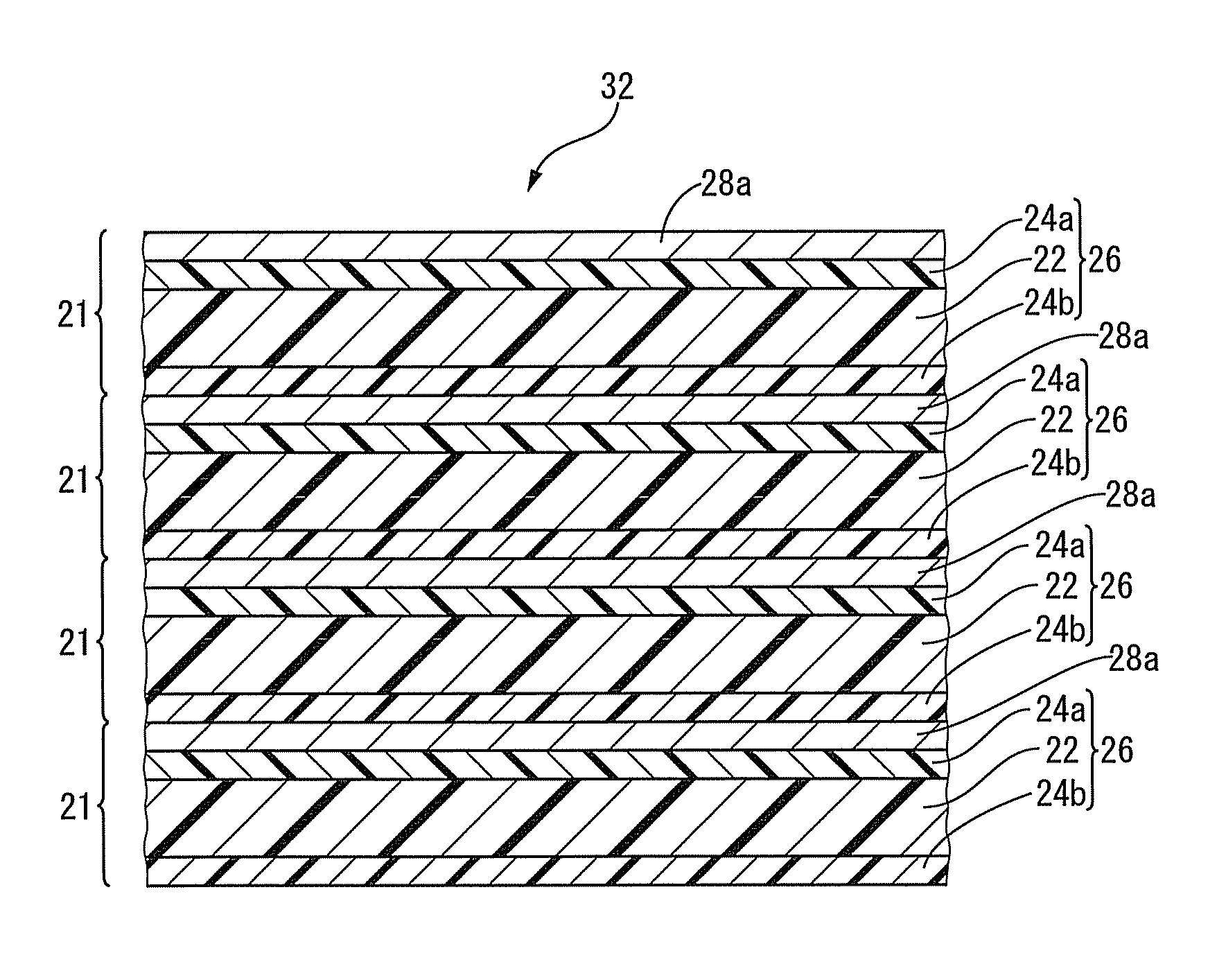

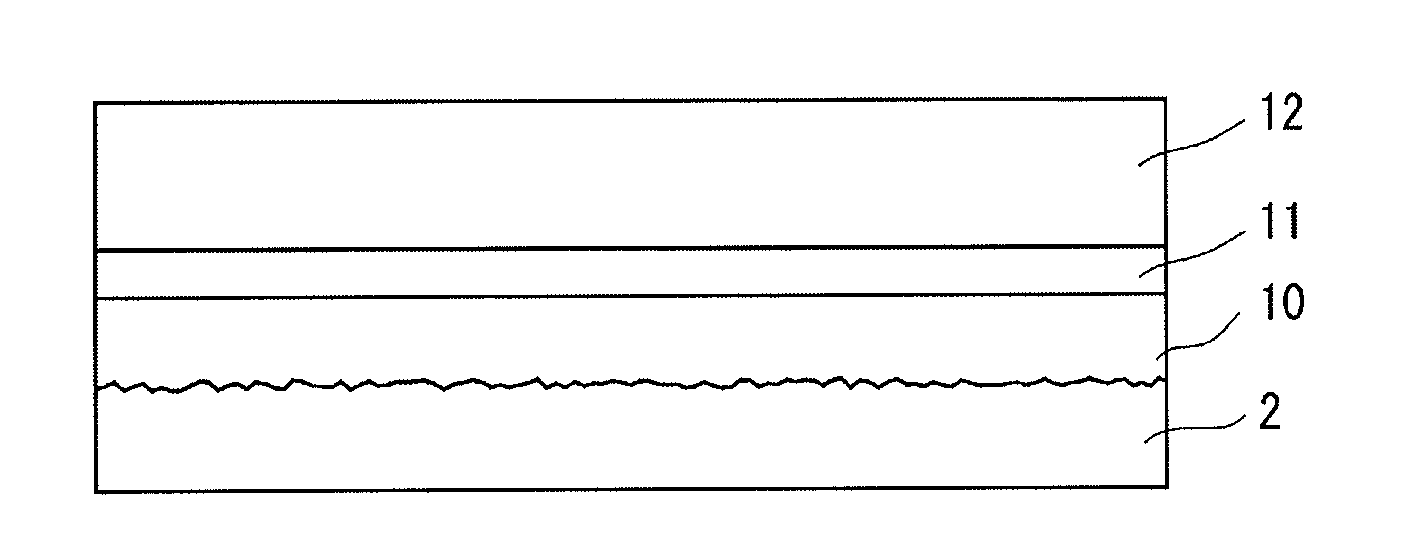

Film capacitor and method of producing the same

InactiveUS20110032656A1Increasing the thicknessAvoid wrinklesThin/thick film capacitorFixed capacitor electrodesVapor deposition polymerizationGas phase

A film capacitor is provided which has a smaller size and improved capacity while securing a sufficient withstand voltage. The film capacitor comprising a basic element 10 containing a plurality of dielectric layers and at least one vapor-deposited metal film layer 14a, 14b, where the plurality of dielectric layers consisting of a resin film layer 12 and at least one vapor-deposited polymer film layer 16a, and the at least one vapor-deposited polymer film layer 16a is formed on at least one of the resin film layer 12 and the at least one vapor-deposited metal film layer 14a, 14.

Owner:KOJIMA PRESS IND CO LTD

Film capacitor element, film capacitor, and method of producing the film capacitor element

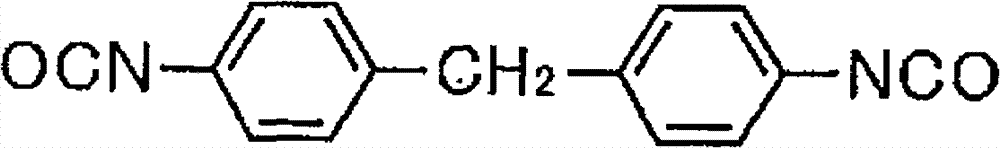

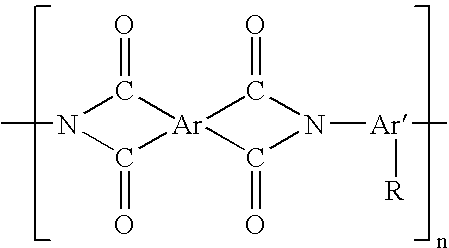

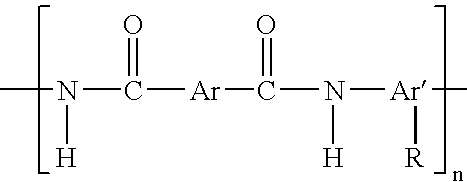

InactiveCN102737843ALess impuritiesImprove withstand voltageThin/thick film capacitorFixed capacitor dielectricDielectricVapor deposition polymerization

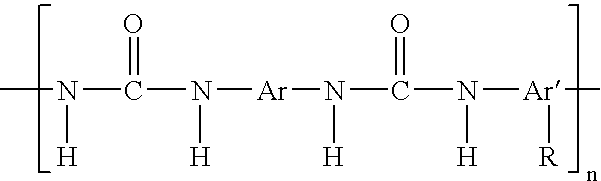

A film capacitor element is provided which has a smaller size and higher capacity while securing the sufficient withstand voltage at a high level and which can be efficiently produced. The film capacitor element including a laminated body including at least one dielectric film and at least one metal deposition film. The at least one dielectric includes at least one vapor-deposited polymer film. The at least vapor-deposited polymer film is formed by a deposition polymerization of a plurality of monomers each having a structure in which two benzene rings are linked via a linking group.

Owner:KOJIMA PRESS IND CO LTD

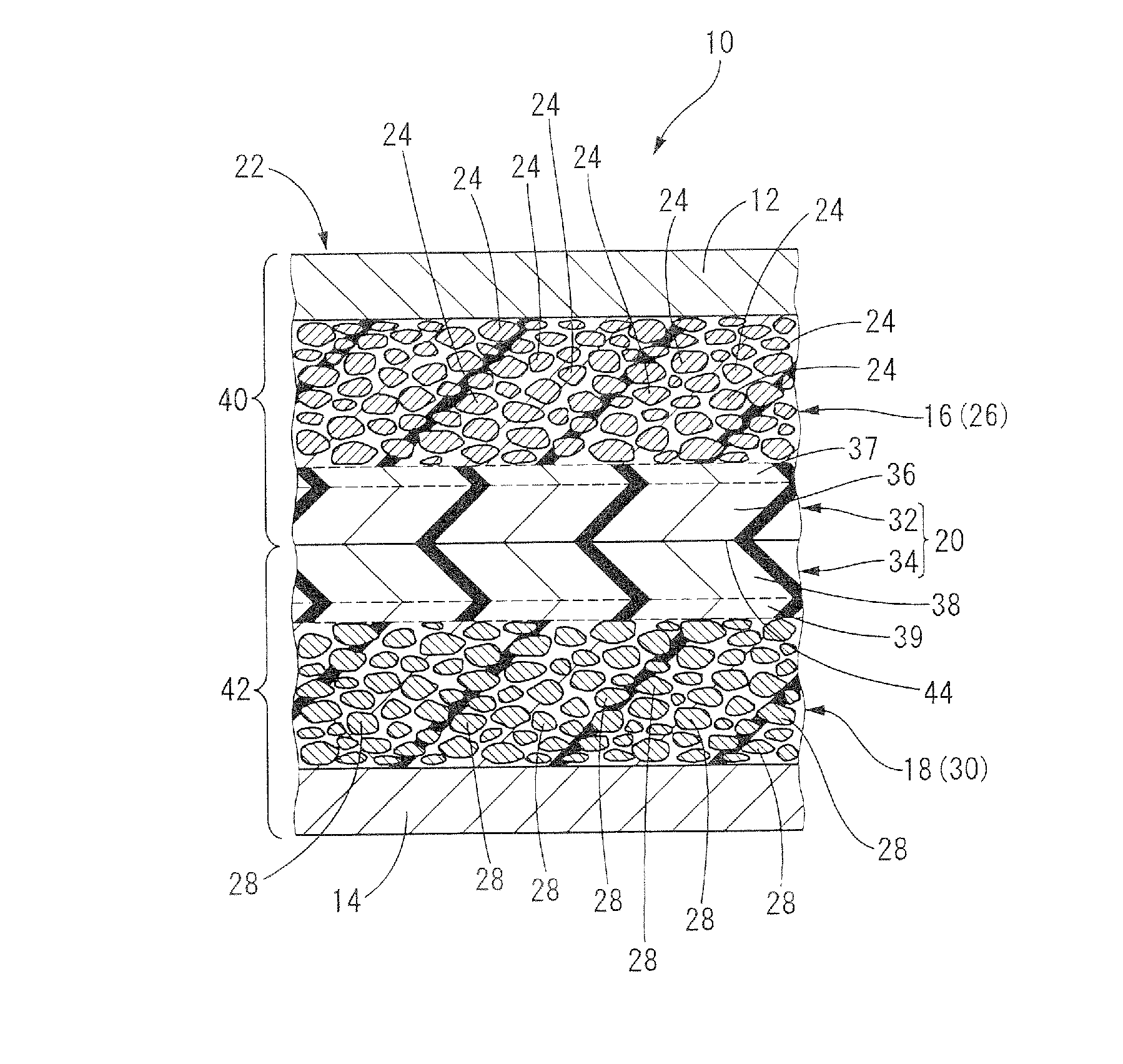

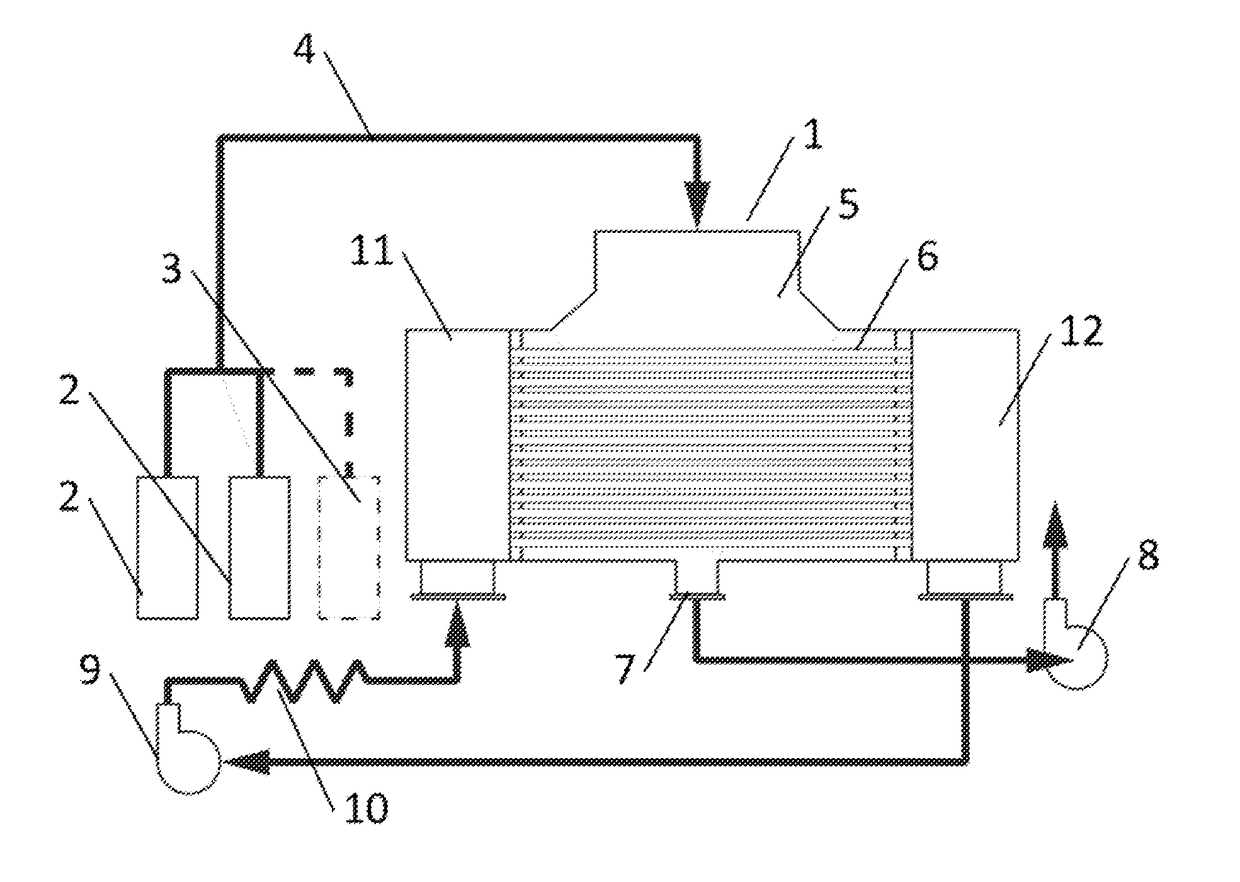

Lithium-ion secondary battery, and method of and apparatus for producing the same

InactiveUS20140030607A1Efficient outputSmall sizeAssembling battery machinesFinal product manufactureLithiumVapor deposition polymerization

A lithium-ion secondary battery 10 consisting of a laminar member 40 including a positive electrode collector layer 12, a positive electrode layer 16 consisting of a vapor-deposited polymer film 26 containing a positive electrode active substance 24, and positive-electrode-side vapor-deposited polymer films 36, 37, which are integrally laminated on each other, and a laminar member 42 including a negative electrode collector layer 14, a negative electrode layer 18 consisting of a vapor-deposited polymer film 30 containing a negative electrode active substance 28, and negative-electrode-side vapor-deposited polymer films 38, 39, which are integrally laminated on each other. The laminar members 40, 42 are superposed on each other such that the vapor-deposited polymer films 36, 37 are in contact with the vapor-deposited polymer films 38, 39. The vapor-deposited polymer films 36, 37, 38, 39 constitute a solid electrolyte layer 20.

Owner:KOJIMA PRESS IND CO LTD

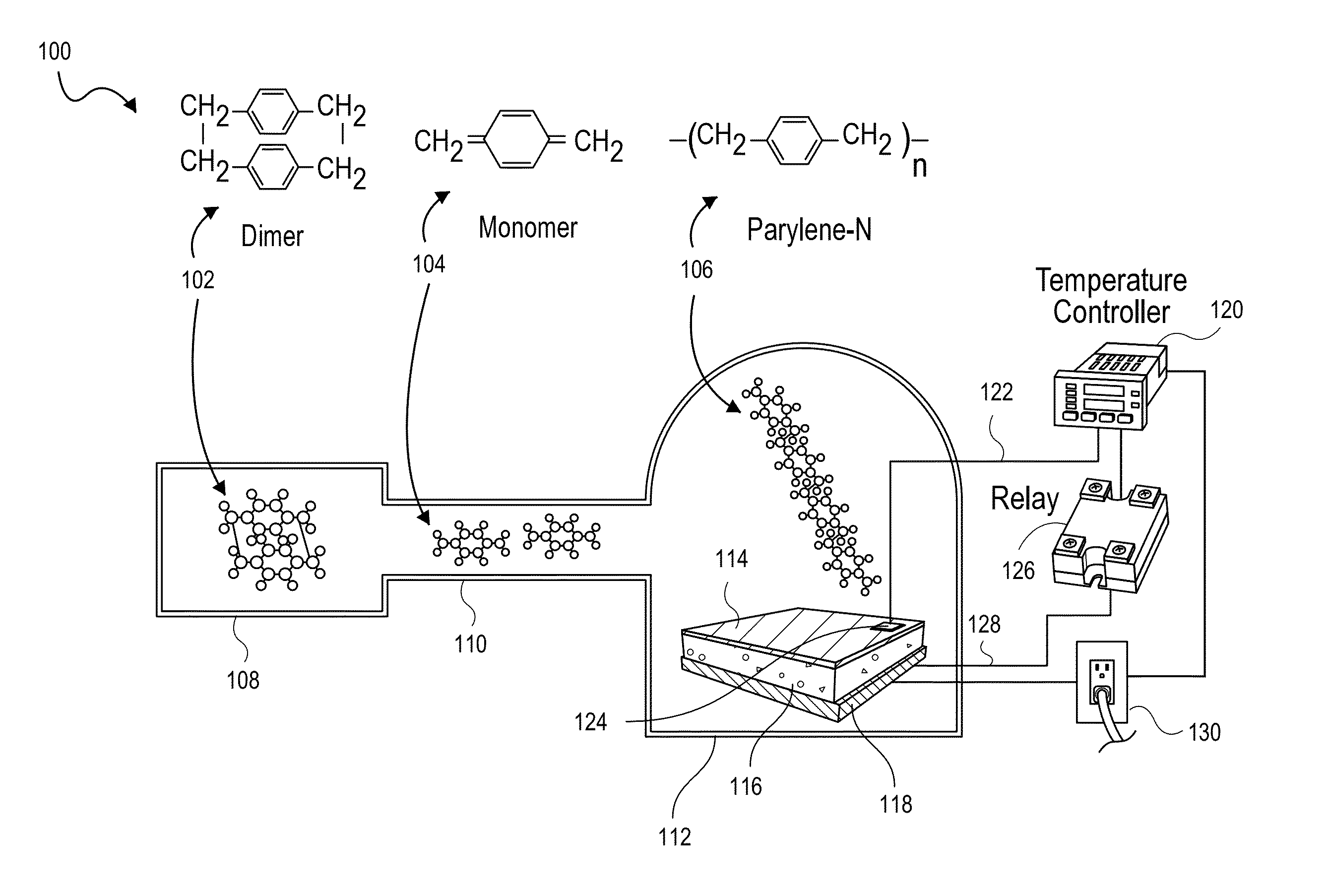

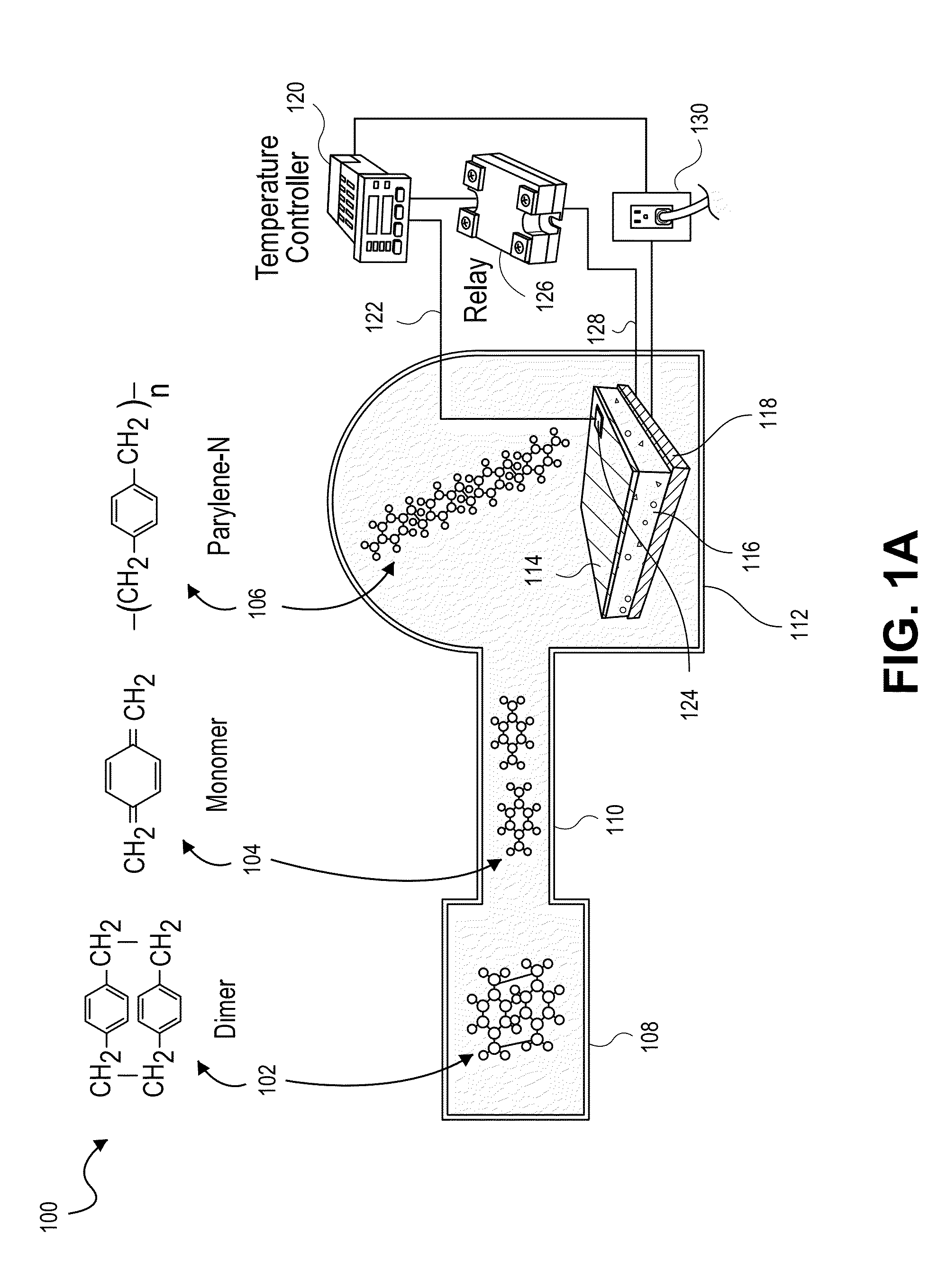

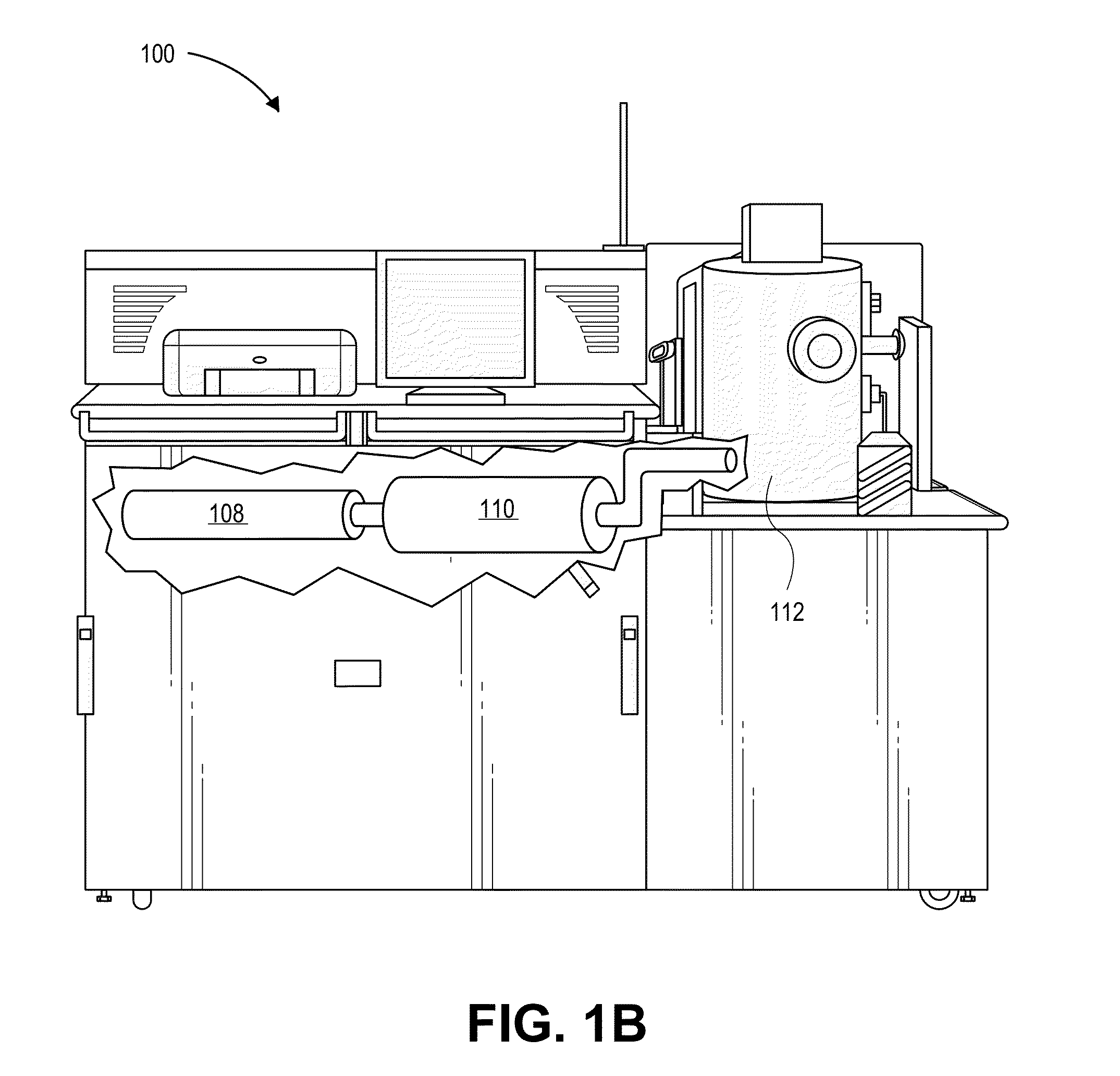

In-situ heated deposition of parylene to enhance pore penetration into silicone

Coating porous material, such as PDMS, with parylene N, C, D, and AF-4 by vapor deposition polymerization is described in which a temperature of the porous material's surface being coated is heated to between 60° C. and 120° C., or 80° C. and 85° C., during deposition. The parylene forms nano roots within the porous material that connect with a conformal surface coating of parylene. In some embodiments, a watertight separation chamber in an integrated microfluidic liquid chromatography device is fabricated by heating tunnels in micro-fabricated PDMS and depositing parylene within the heated tunnels.

Owner:CALIFORNIA INST OF TECH

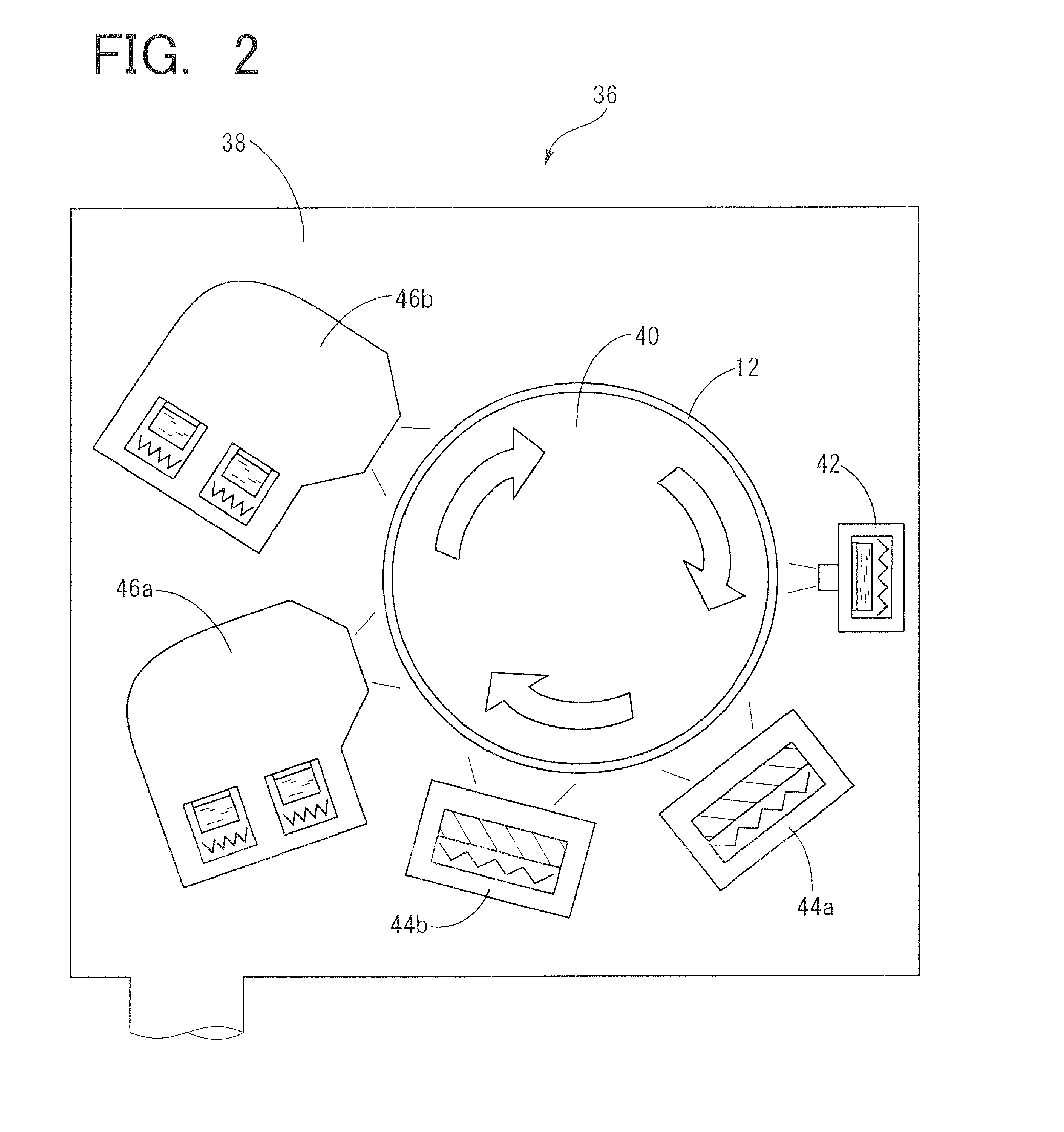

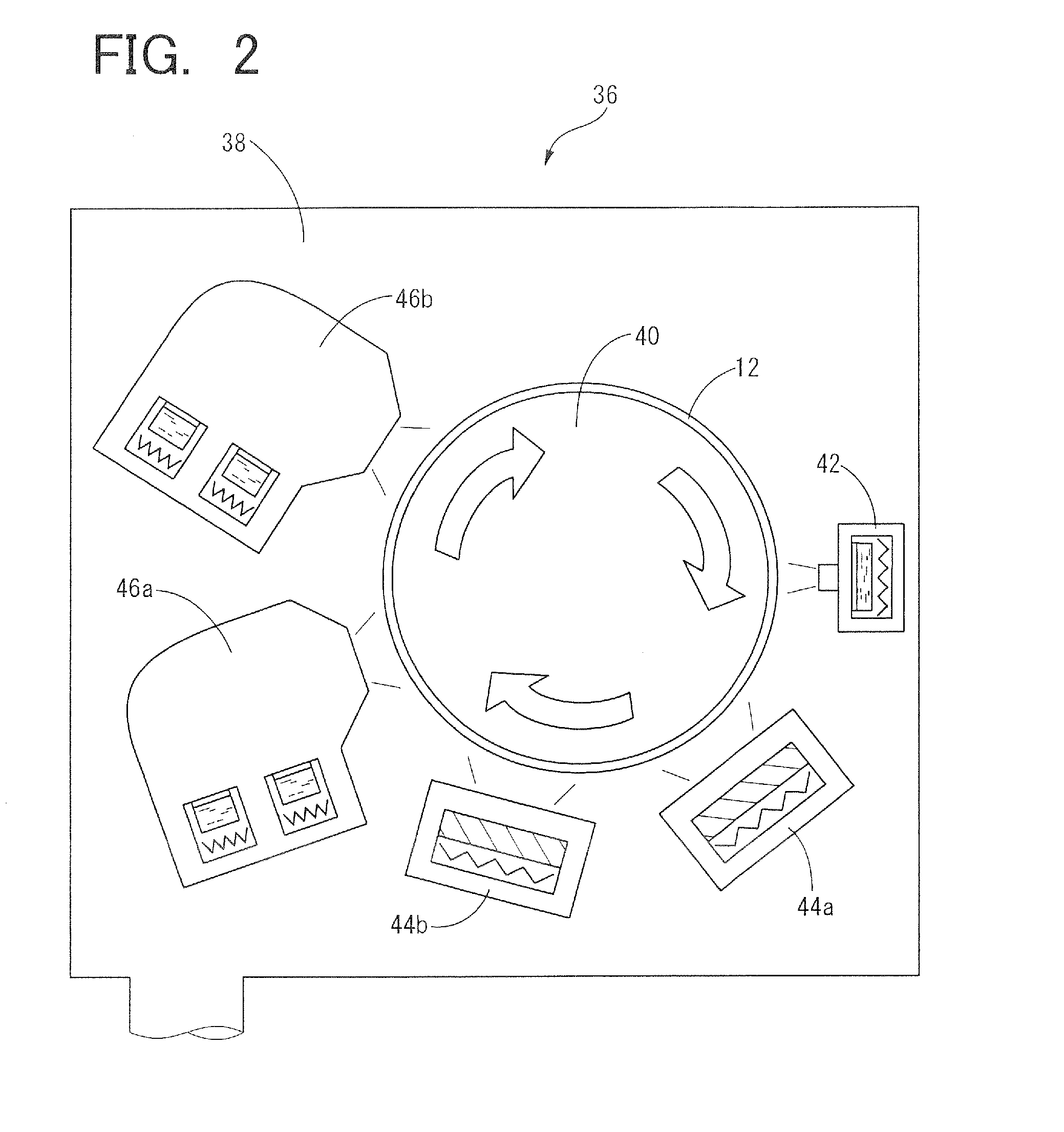

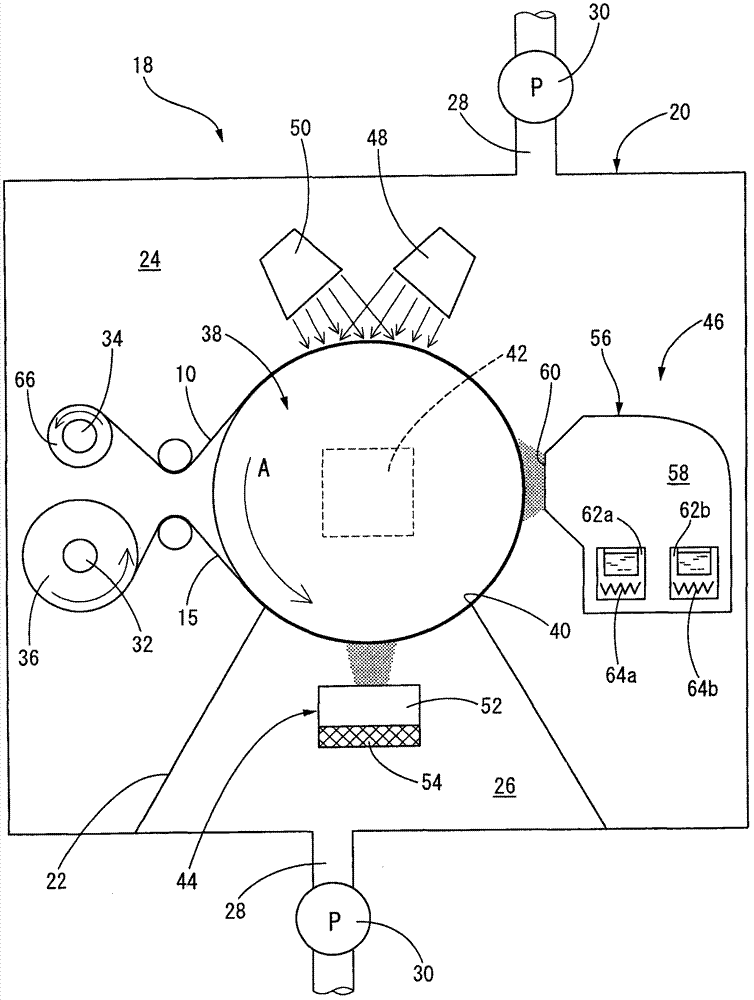

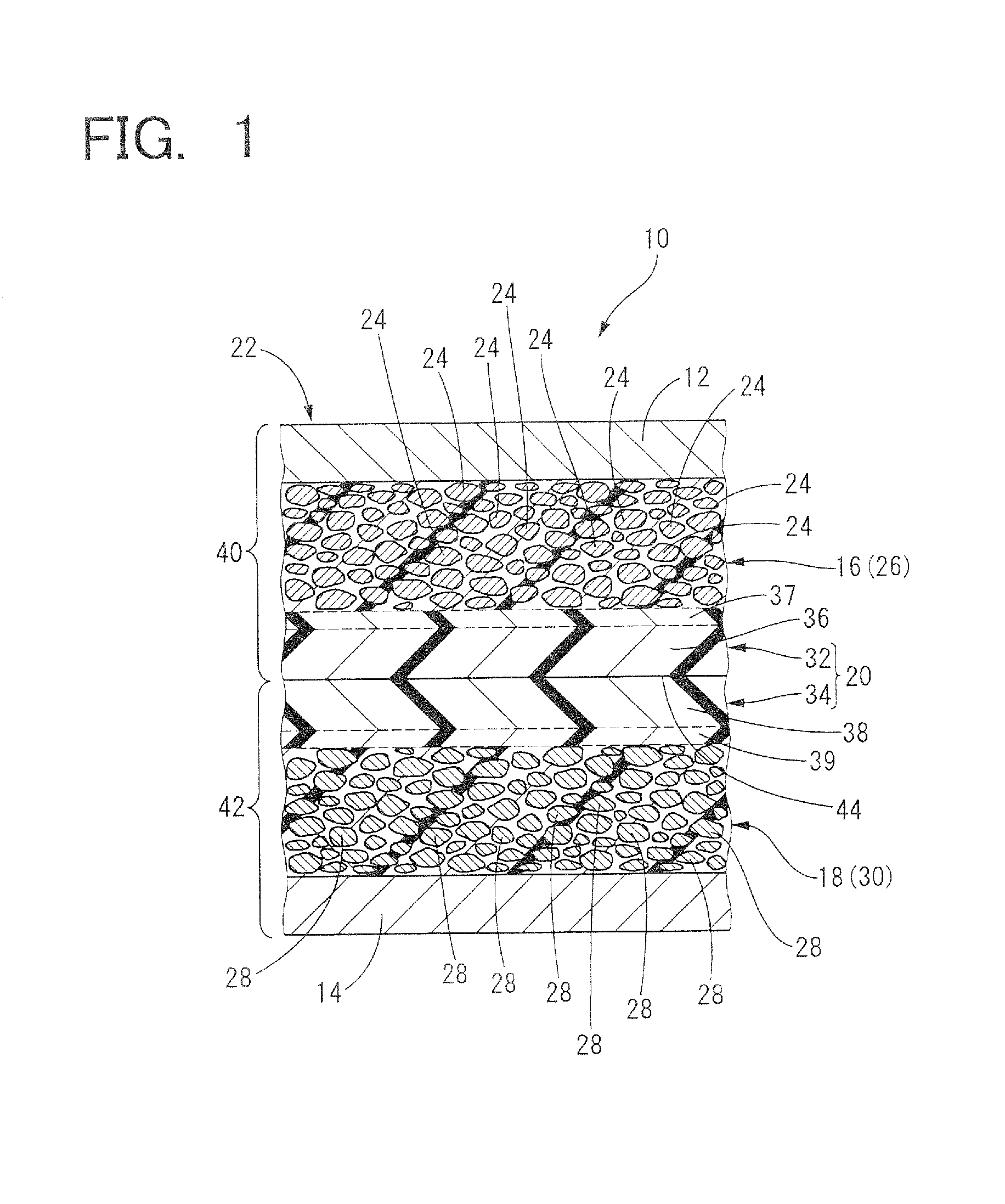

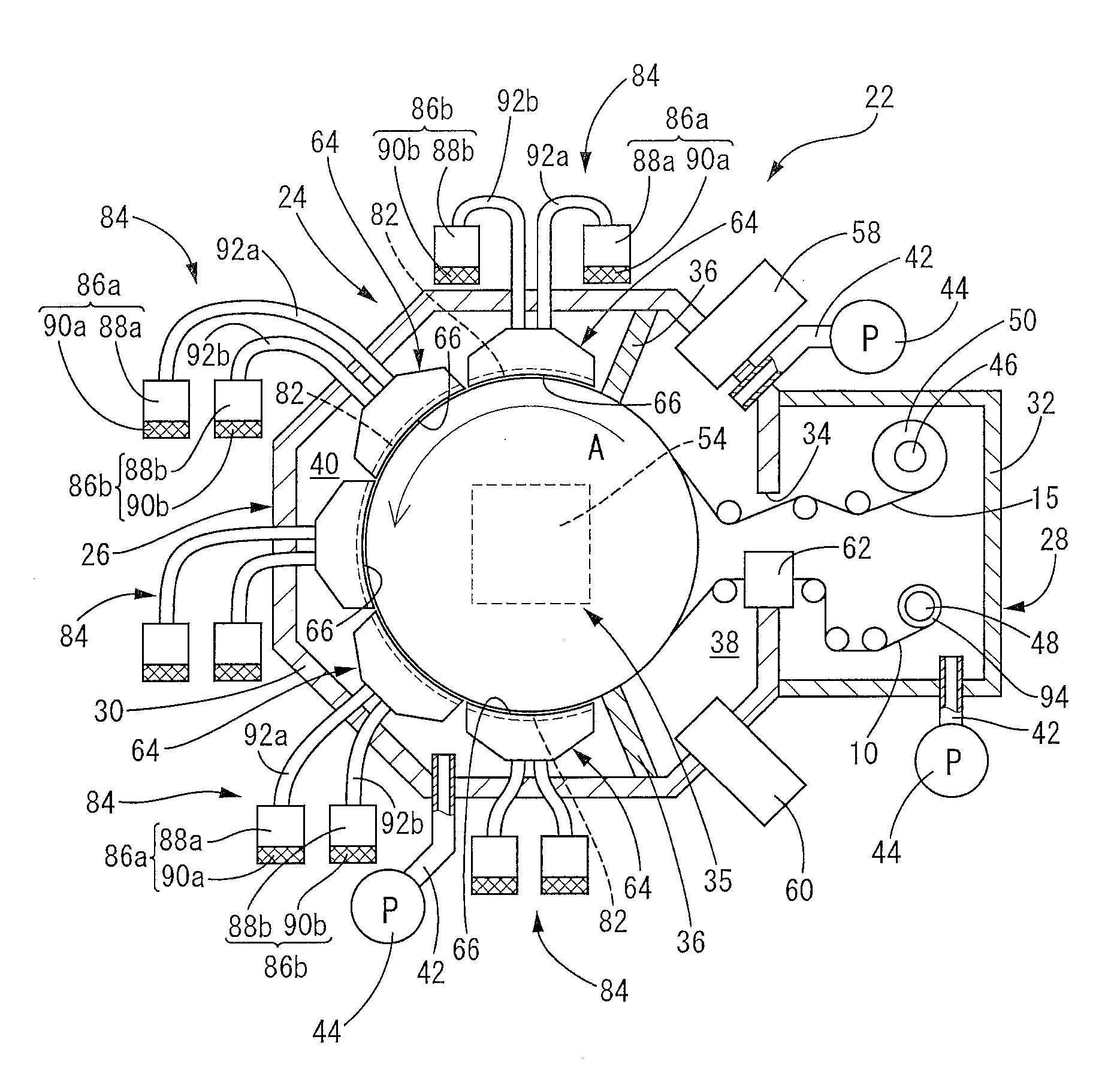

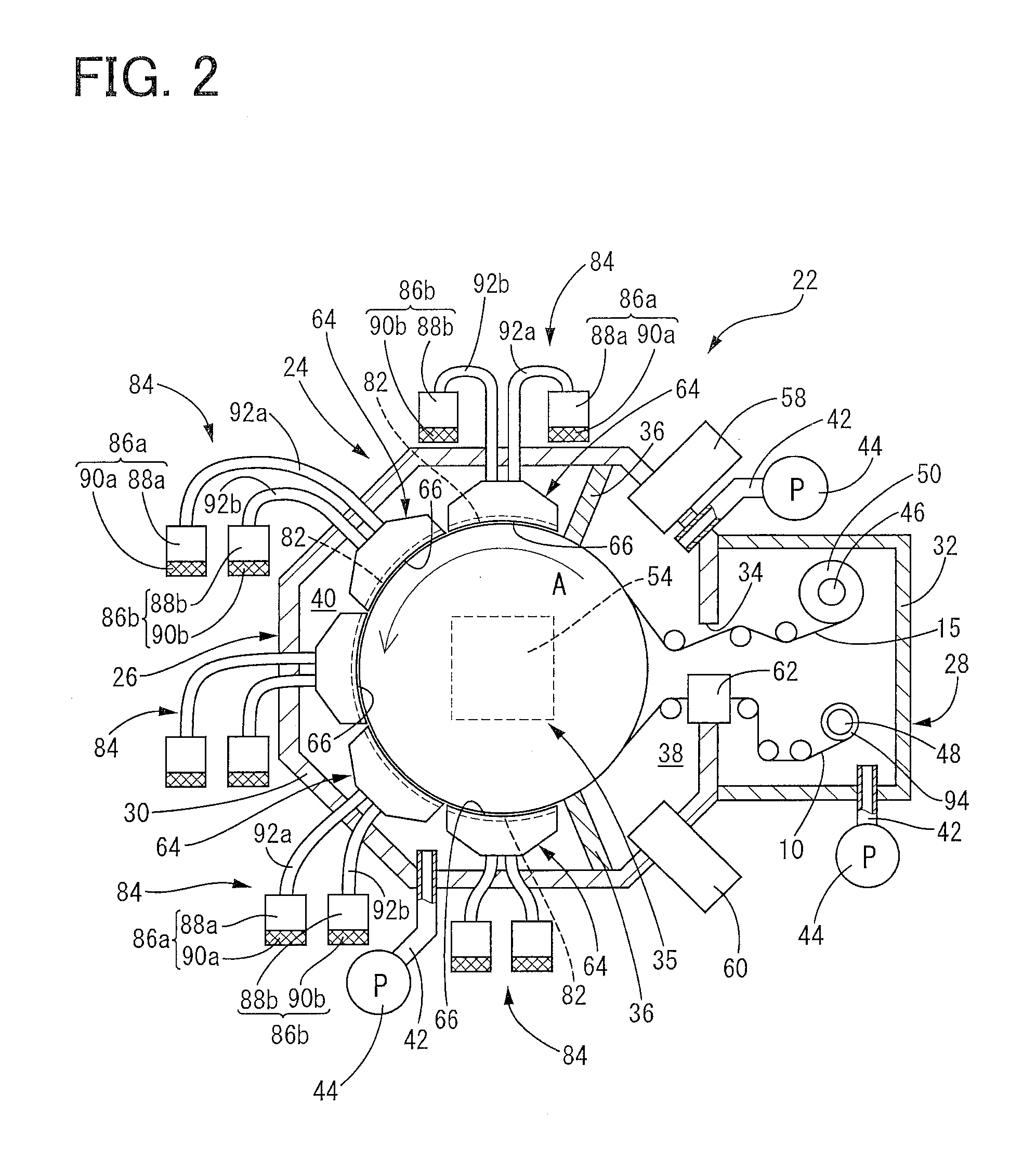

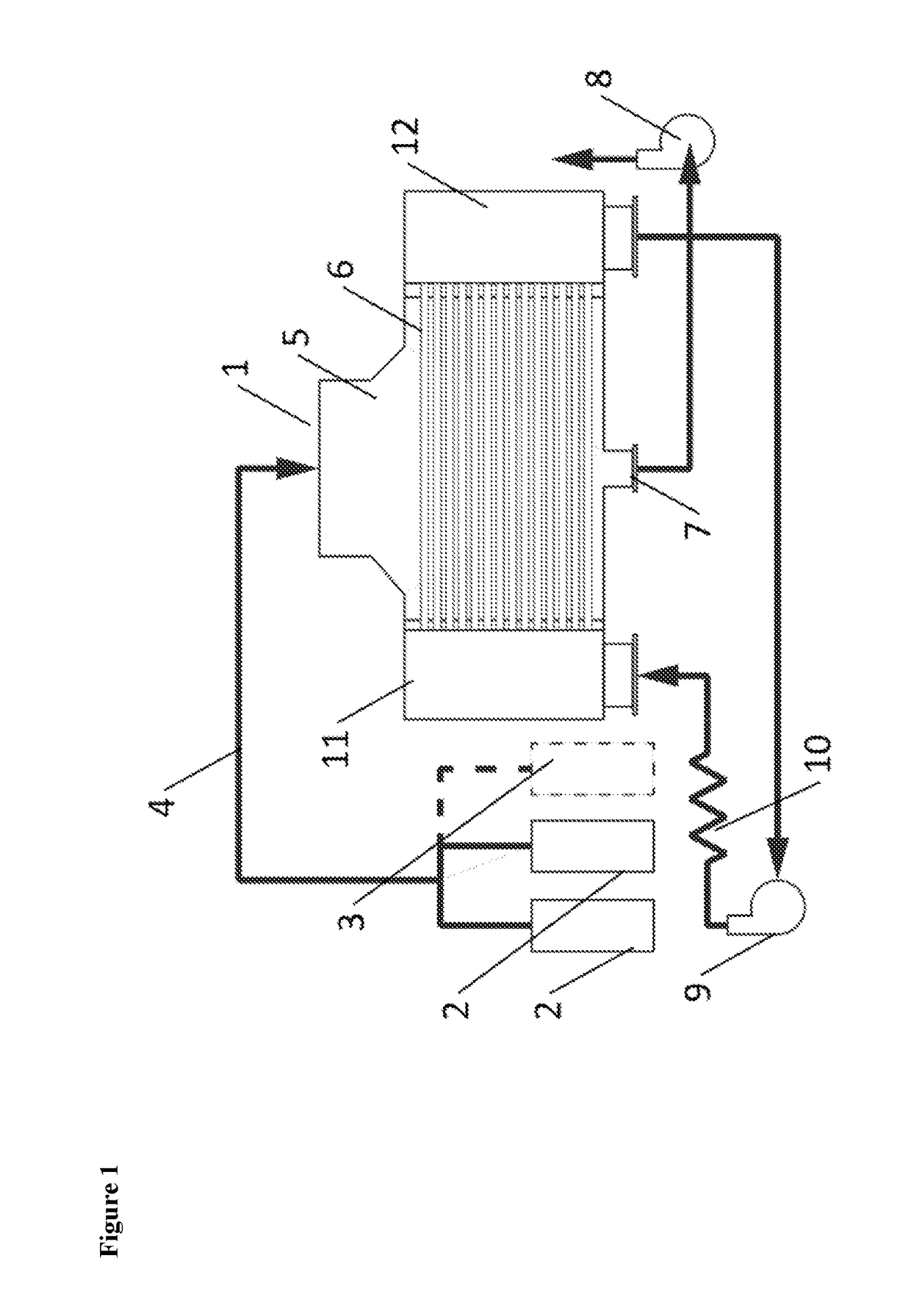

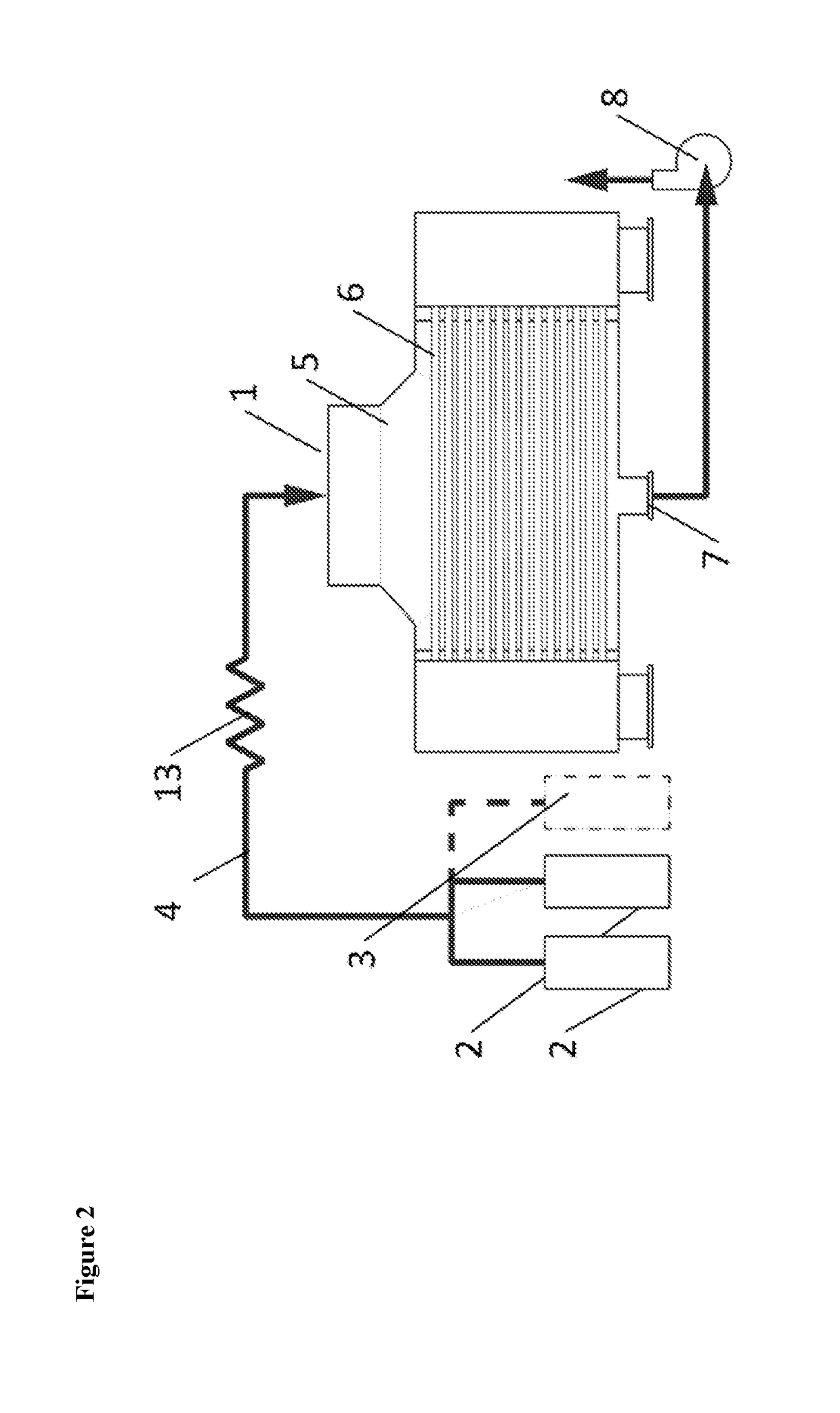

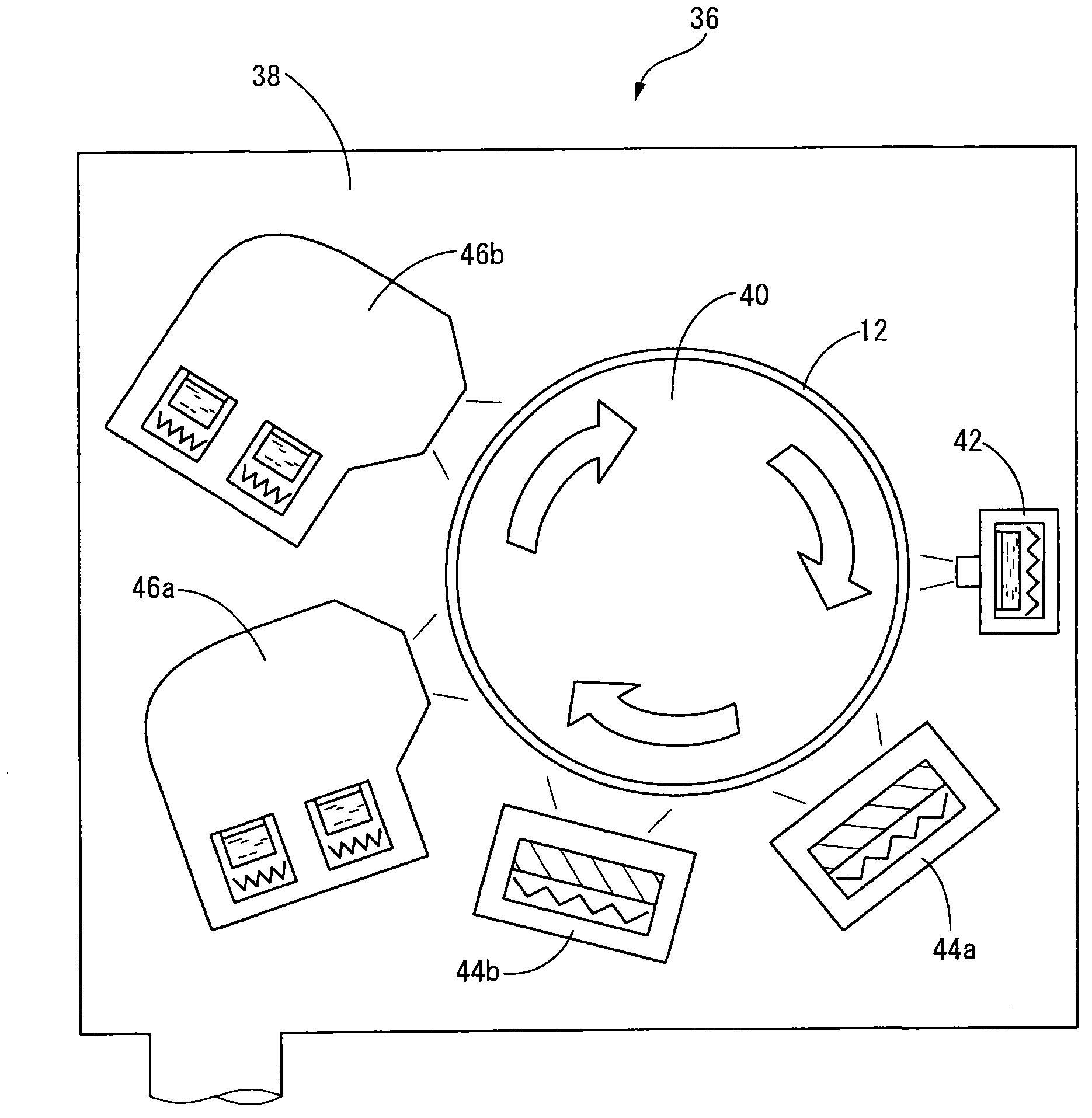

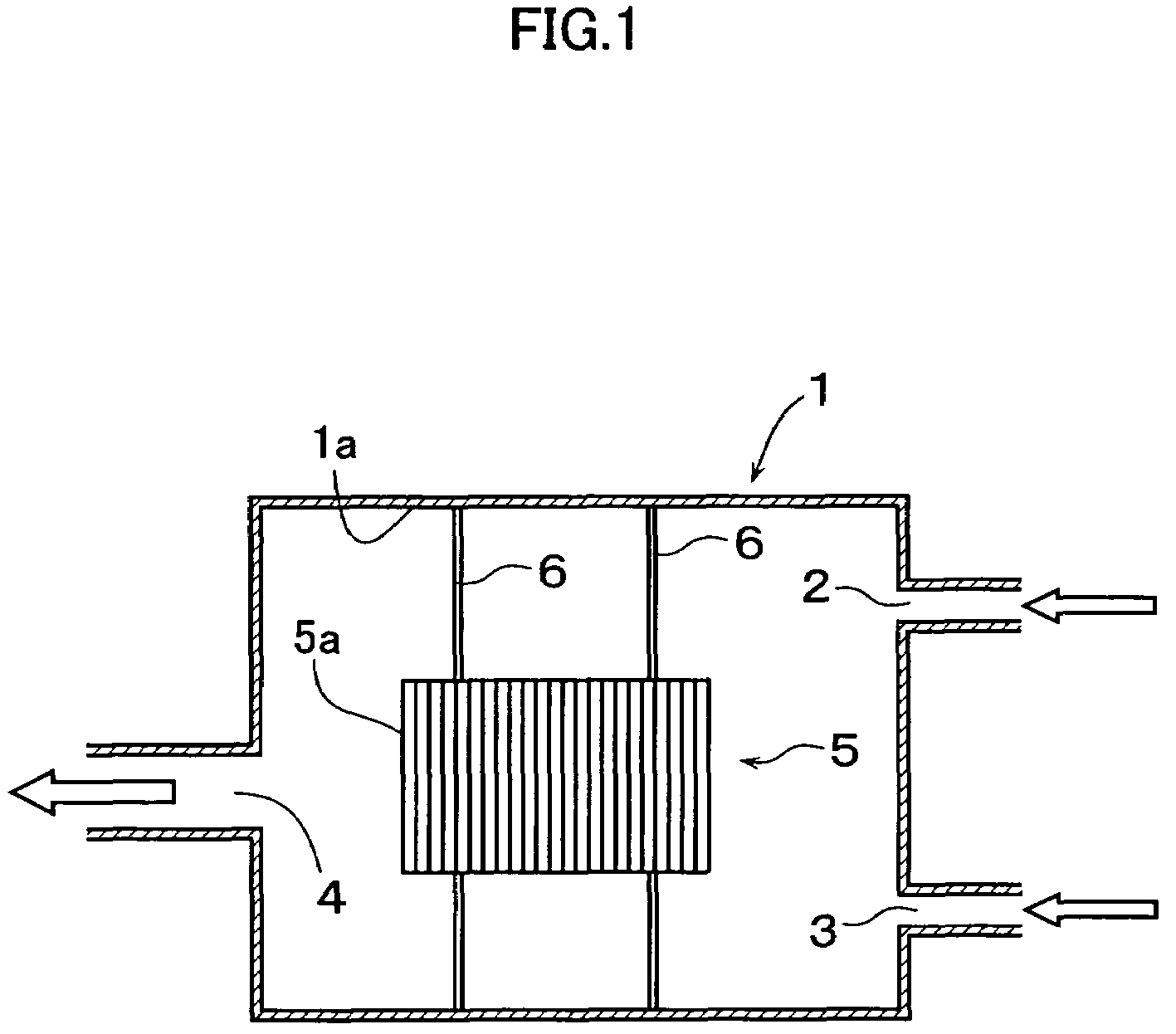

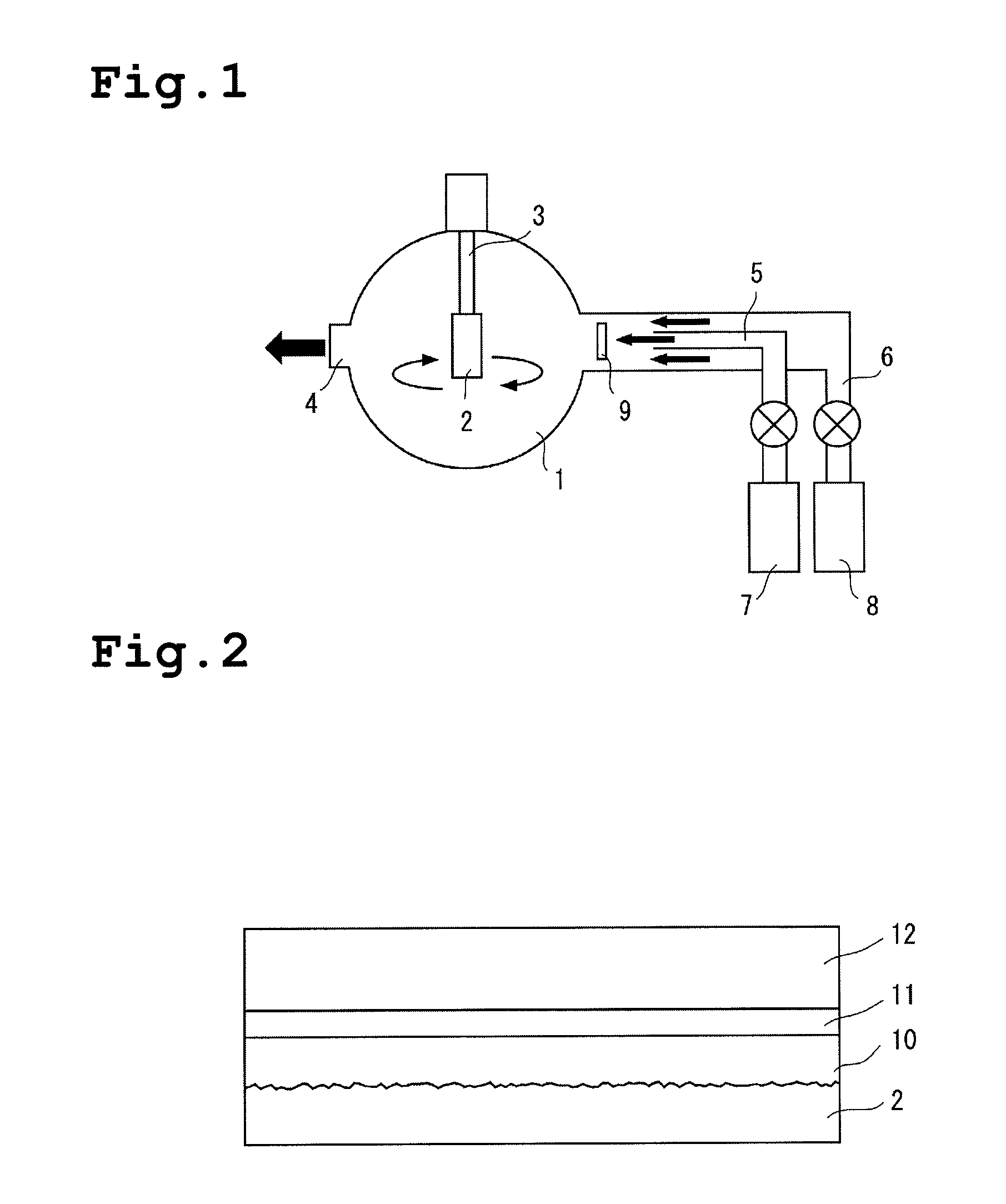

Apparatus for producing laminated body

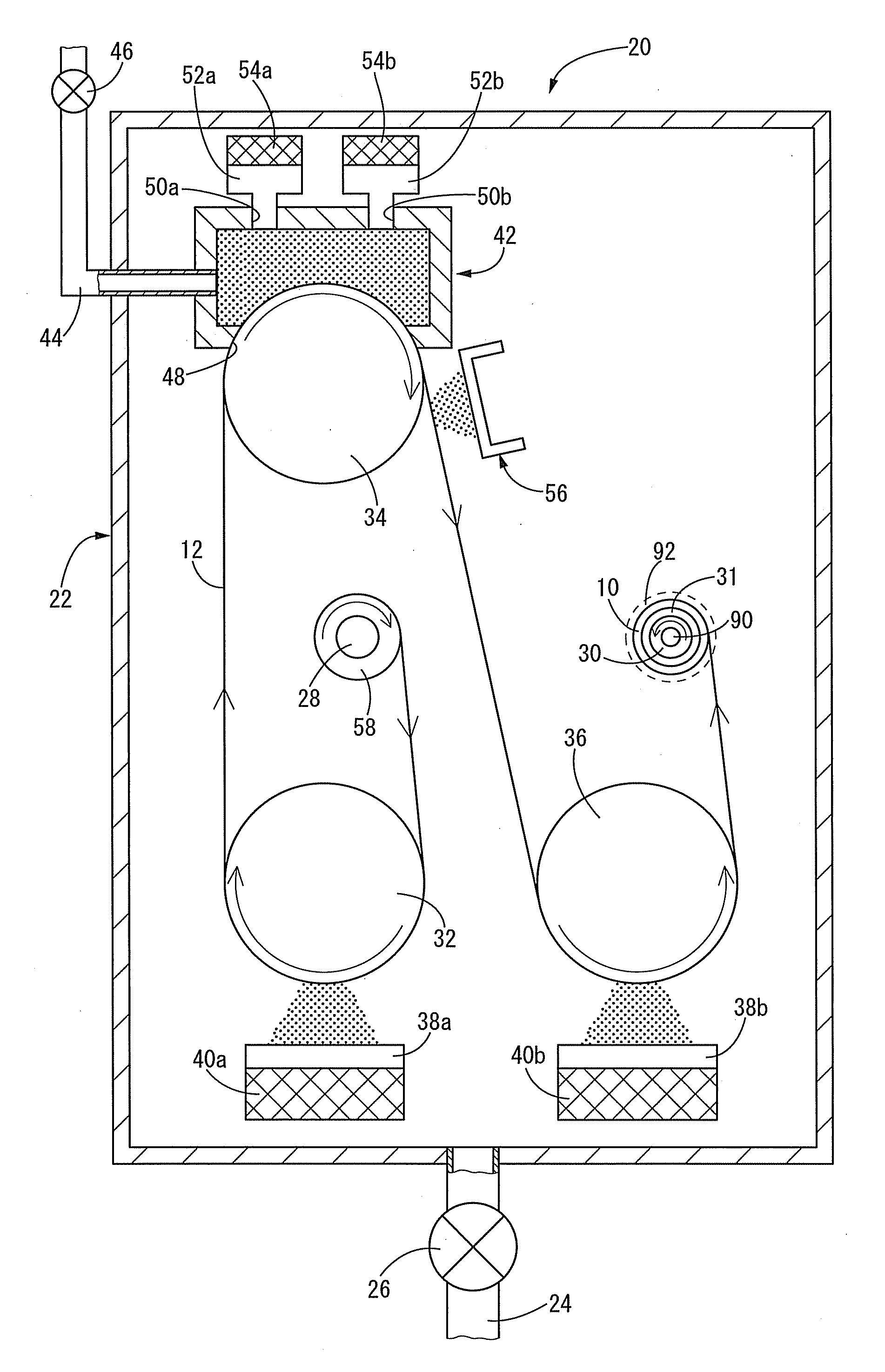

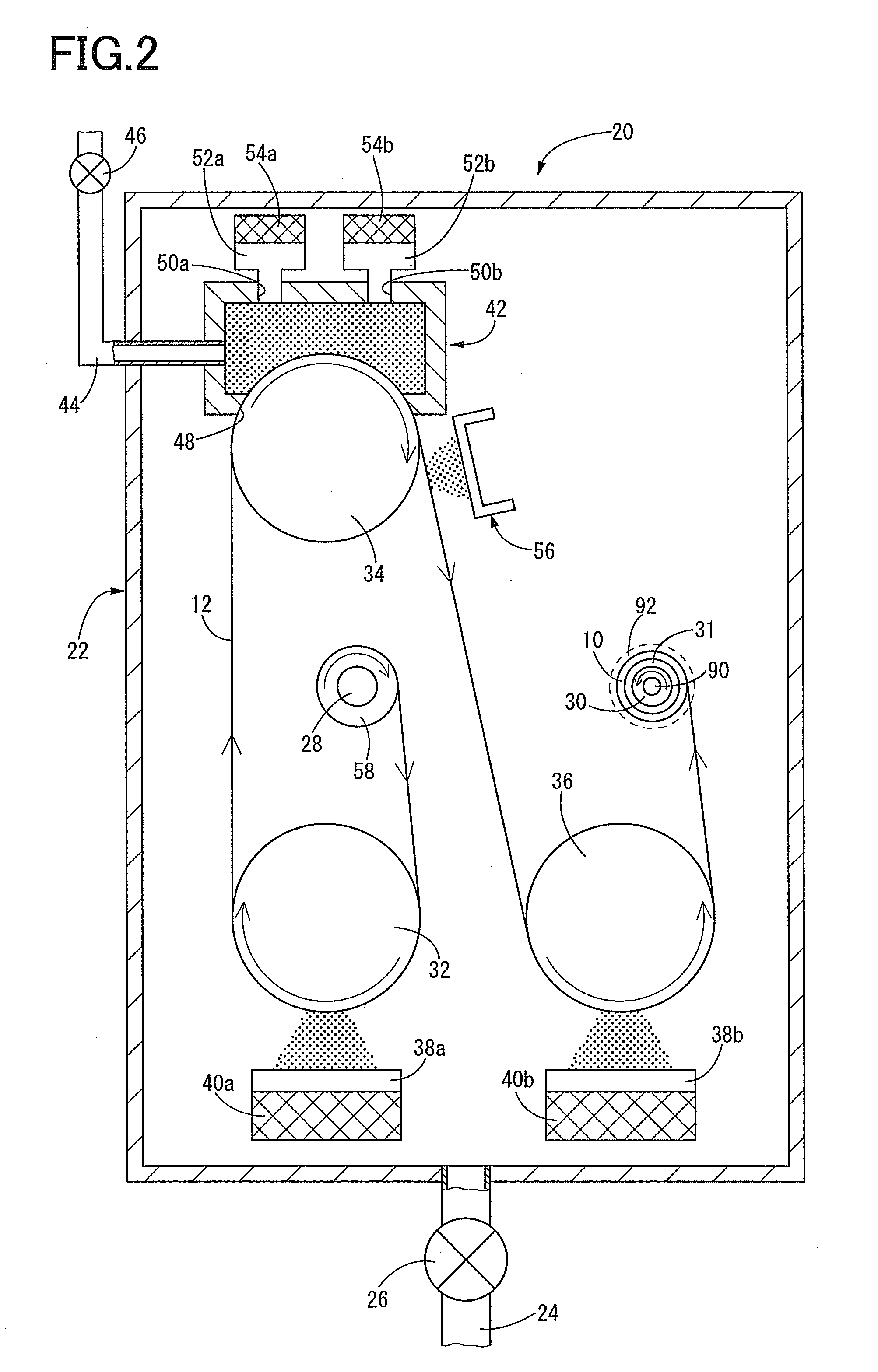

ActiveUS20120240854A1Easy to produceStable productionLiquid surface applicatorsVacuum evaporation coatingVapor deposition polymerizationGas phase

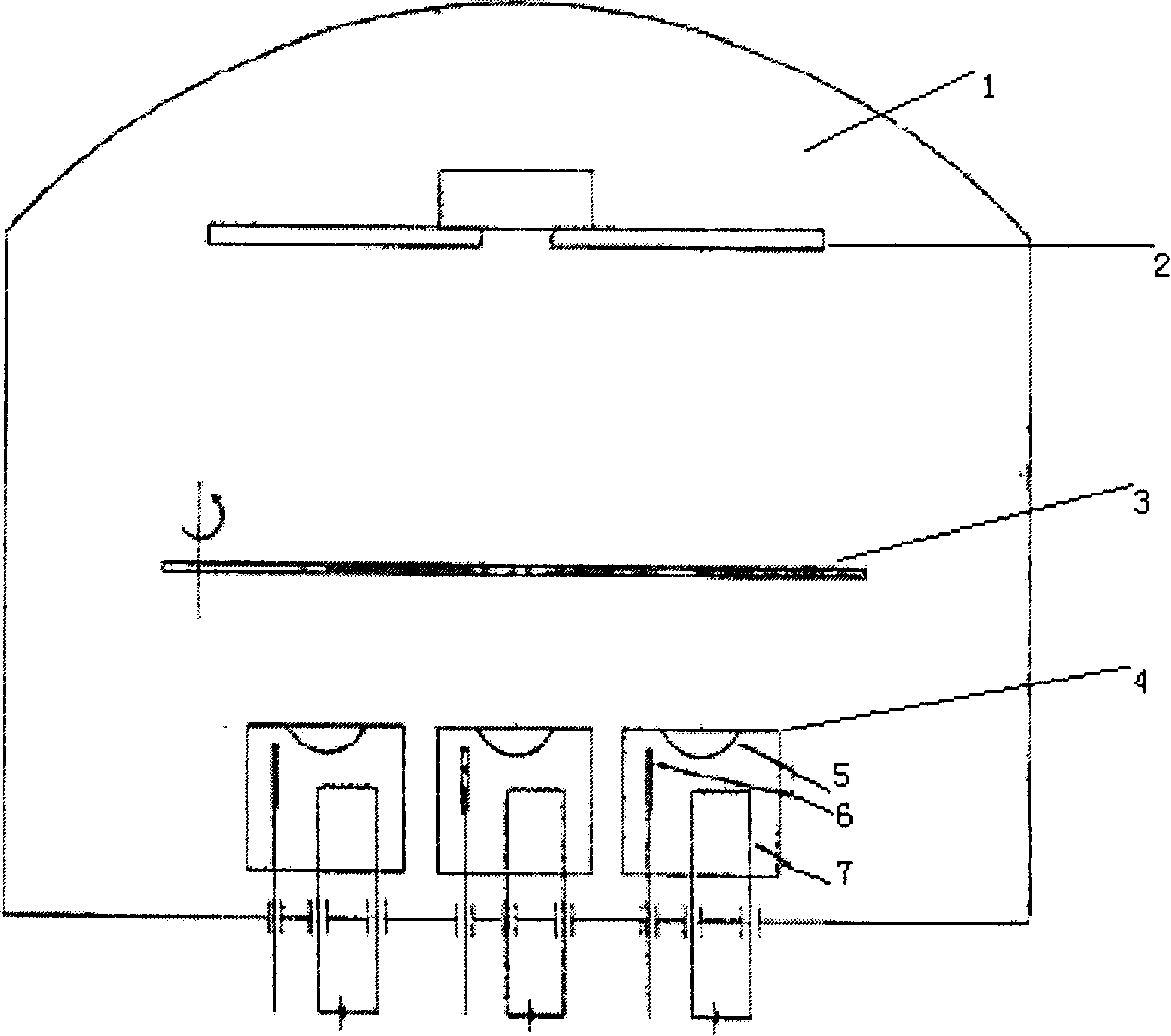

An apparatus is provided that can stably produce a laminated body including a vapor-deposited polymer film having a predetermined composition and thickness on a film substrate. The apparatus includes: a film substrate supply means 46 that supplies a film substrate 15 on an outer peripheral surface of a rotary drum 35 in a vacuum chamber 24; a plurality of blowoff members 64 positioned around the rotary drum 35, each of the plurality of blowoff members including a vapor outlet 66 opening inside the vacuum chamber 24 to the outer peripheral surface of the rotary drum 35 and an inner space constituting a deposition chamber; and at least one monomer vapor supply means 84 arranged to supply plural kinds of monomer vapor into the deposition chamber and blowoff the plural kinds of monomer vapor from the vapor outlet of each of the plurality of blowoff members.

Owner:KOJIMA PRESS IND CO LTD

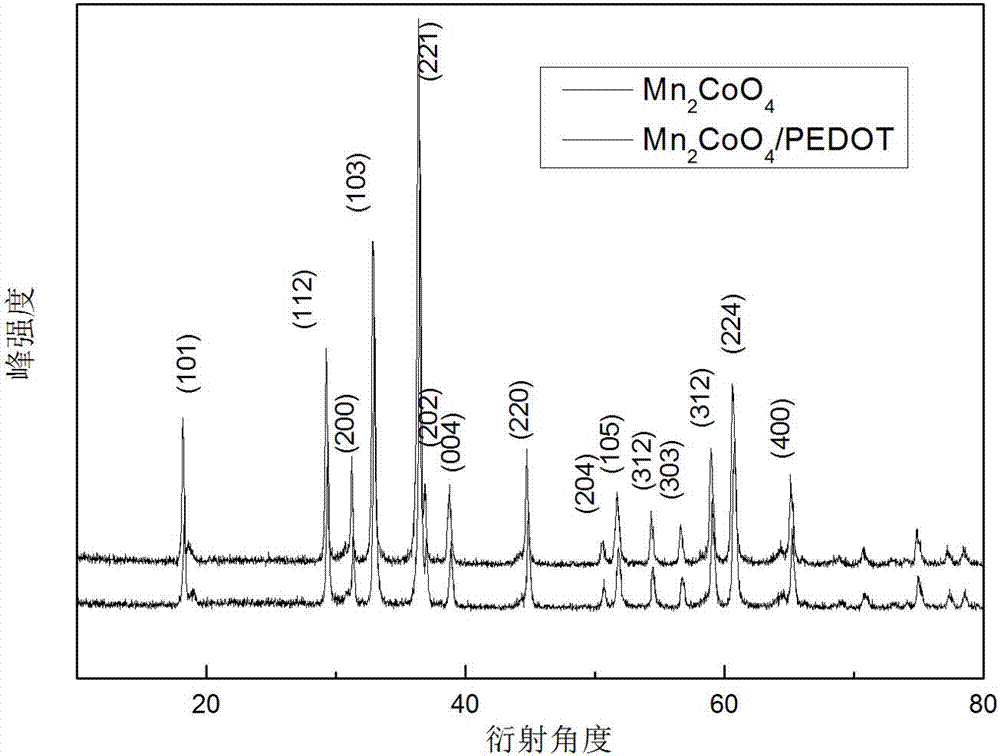

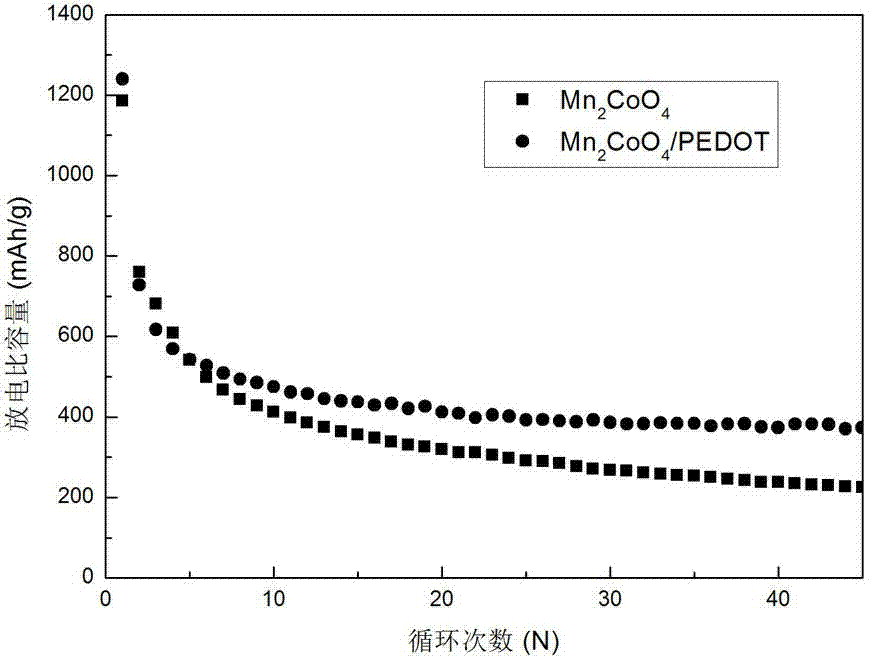

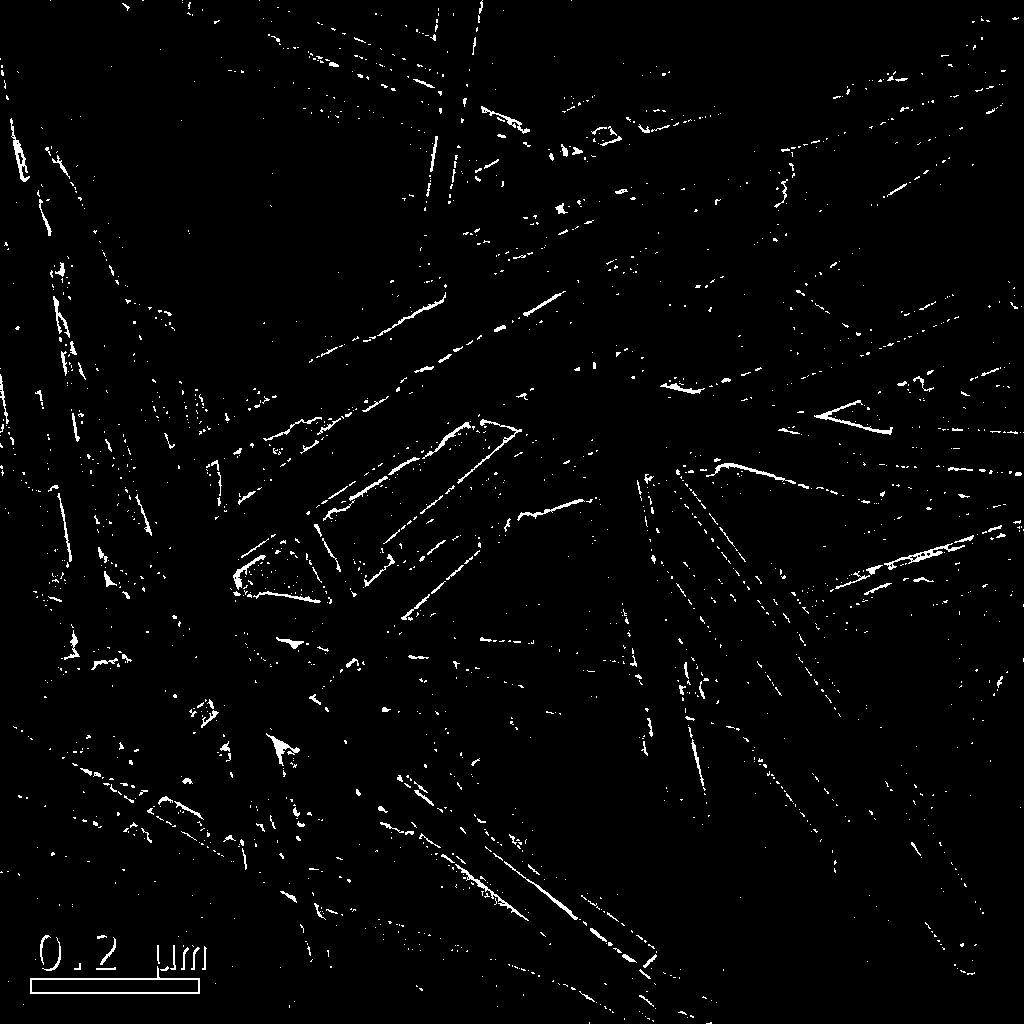

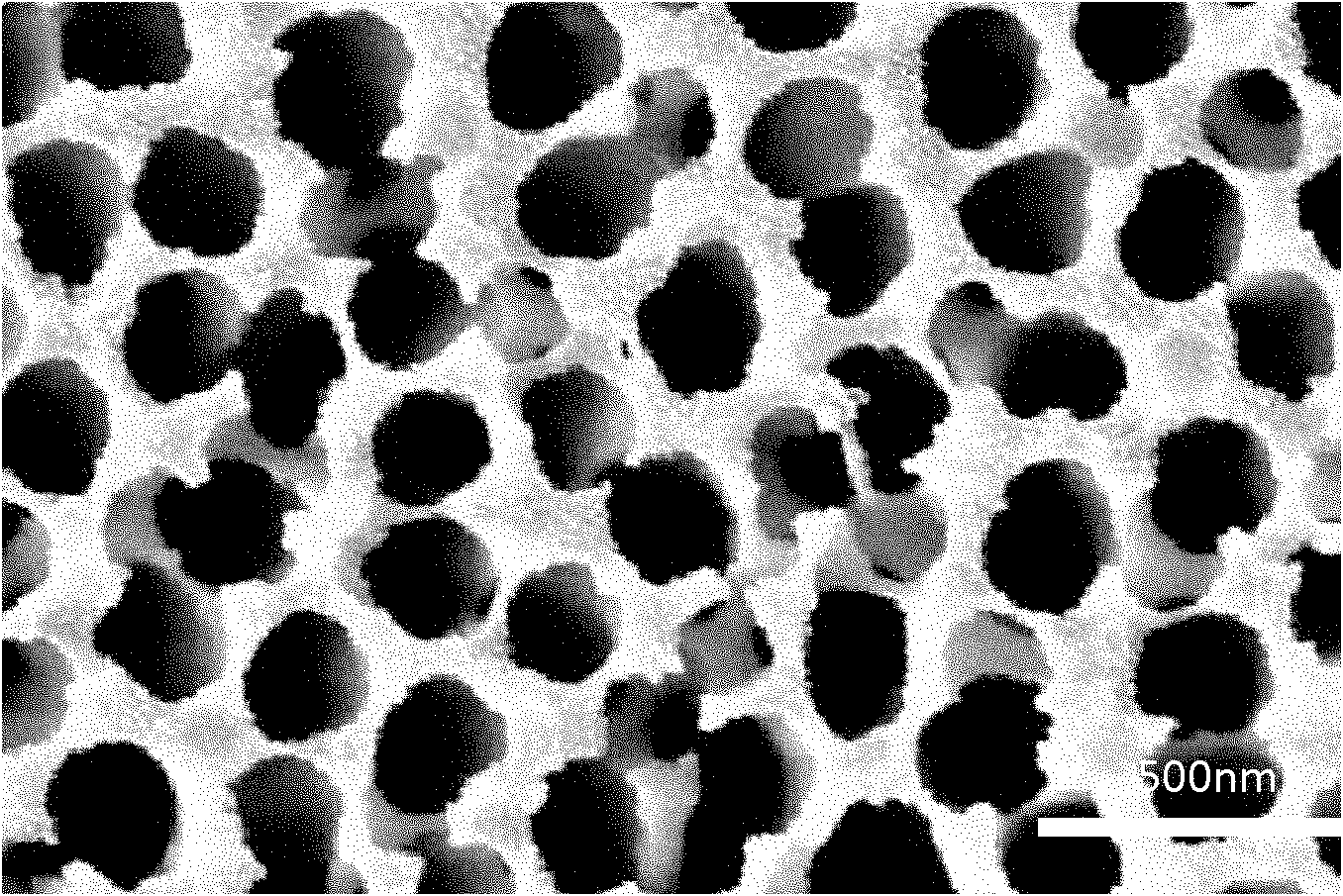

Preparation method of negative electrode material Mn2CoO4/poly(3,4-ethylenedioxythiophene)

InactiveCN104332626ALarge specific surface areaImprove conductivityCell electrodesSecondary cellsVapor deposition polymerizationConductive polymer

The invention provides a preparation method of a lithium ion secondary battery negative electrode material composite oxide Mn2CoO4 / poly(3,4-ethylenedioxythiophene) (PEDOT). The method comprises the steps of synthesizing Mn2CoO4 through a sol-gel process by using a manganese salt, a cobalt salt and an organic chelating reagent as raw materials, carrying out vapor deposition polymerization on EDOT to form PEDOT, and compounding the PEDOT with the Mn2CoO4 material. Mn2CoO4 particles synthesized through the method are small, have uniform dimension sizes and form a three dimensional netted structure, so the specific surface area of the material is increased, and the PEDOT is an excellent conductive polymer and has high conductivity, so the electrochemical performances of the composite negative electrode material are improved, has the advantages of simple preparation method and low cost, and is a promising material.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for preparing amorphous carbon nano tube and SBA-15 mesoporous molecular sieve from attapulgite clay as template and raw material

ActiveCN103864051AReduce pollutionEfficient use ofMaterial nanotechnologyCarbon nanotubesVapor deposition polymerizationFiltration

The invention discloses a method for preparing an amorphous carbon nano tube and an SBA-15 mesoporous molecular sieve by using attapulgite clay as a template and a raw material. The method comprises the following steps: firstly soaking attapulgite clay in a high-temperature hot acid solution, carrying out vapor deposition polymerization and carbonization on furfuryl alcohol serving as a raw material to load a carbon material on the surfaces of acidified attapulgite grains; then, carrying out high-temperature alkaline leaching to remove the template (attapulgite clay), washing with hot water, and drying to obtain the amorphous carbon nano tube; and finally, adding P123-containing acid liquor to alkaline leachate, and carrying out hydrothermal crystallization, suction filtration, washing with ethyl alcohol, washing with water, drying and calcining to obtain the SBA-15 mesoporous molecular sieve. According to the method disclosed by the invention, HF (Hydrogen fluoride) with corrosivity is not required, so that the environmental pollution caused by waste liquid discharge is reduced; meanwhile, the leachate is used for preparing the SBA-15 mesoporous molecular sieve, so that the effective utilization of silicon component in the attapulgite clay is realized.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Method of manufacturing piezoelectric element

ActiveUS9318135B2Easily and surely formingWithout deteriorationTrack finding/aligningPiezoelectric/electrostrictive device manufacture/assemblyVapor deposition polymerizationGas phase

An method of manufacturing a piezoelectric element easily and surely forms polymer coatings on peripheral end faces of the piezoelectric element without deteriorating a yield of the piezoelectric element. The method includes steps of cutting a piezoelectric element out from a base piezoelectric material plate so that peripheral end faces are formed to define a peripheral shape of the piezoelectric element, and forming polymer coatings on at least objective areas of the peripheral end faces of the piezoelectric element by vapor deposition polymerization, respectively.

Owner:NHK SPRING CO LTD

Method for preparing poly(N-2-carboxyethyl pyrrole)-anodic aluminum oxide composite membrane

InactiveCN102091533AImprove conductivityGood biocompatibilitySemi-permeable membranesVapor deposition polymerizationGas phase

The invention discloses a method for preparing a poly(N-2-carboxyethyl pyrrole)-anodic aluminum oxide composite membrane, relates to a composite membrane preparation technique and provides a method for preparing a poly(N-2-carboxyethyl pyrrole)-anodic aluminum oxide composite membrane with high hydrophily and high biocompatibility. The method comprises the following steps: placing a pretreated anodic aluminum oxide membrane and a N-2-carboxyethyl pyrrole monomer in a vapor phase deposition polymerization device, vacuumizing the vapor phase deposition polymerization device and performing a vapor phase deposition polymerization reaction; and after the reaction is accomplished, cooling, and removing impurities to obtain the poly(N-2-carboxyethyl pyrrole)-anodic aluminum oxide composite membrane. The prepared poly(N-2-carboxyethyl pyrrole)-anodic aluminum oxide composite membrane covers the oxide layer on the anodic aluminum oxide membrane, and lowers the non-specific absorption of the anodic aluminum oxide membrane. The preparation method is simple, and can be widely used in affinity separation.

Owner:XIAMEN UNIV

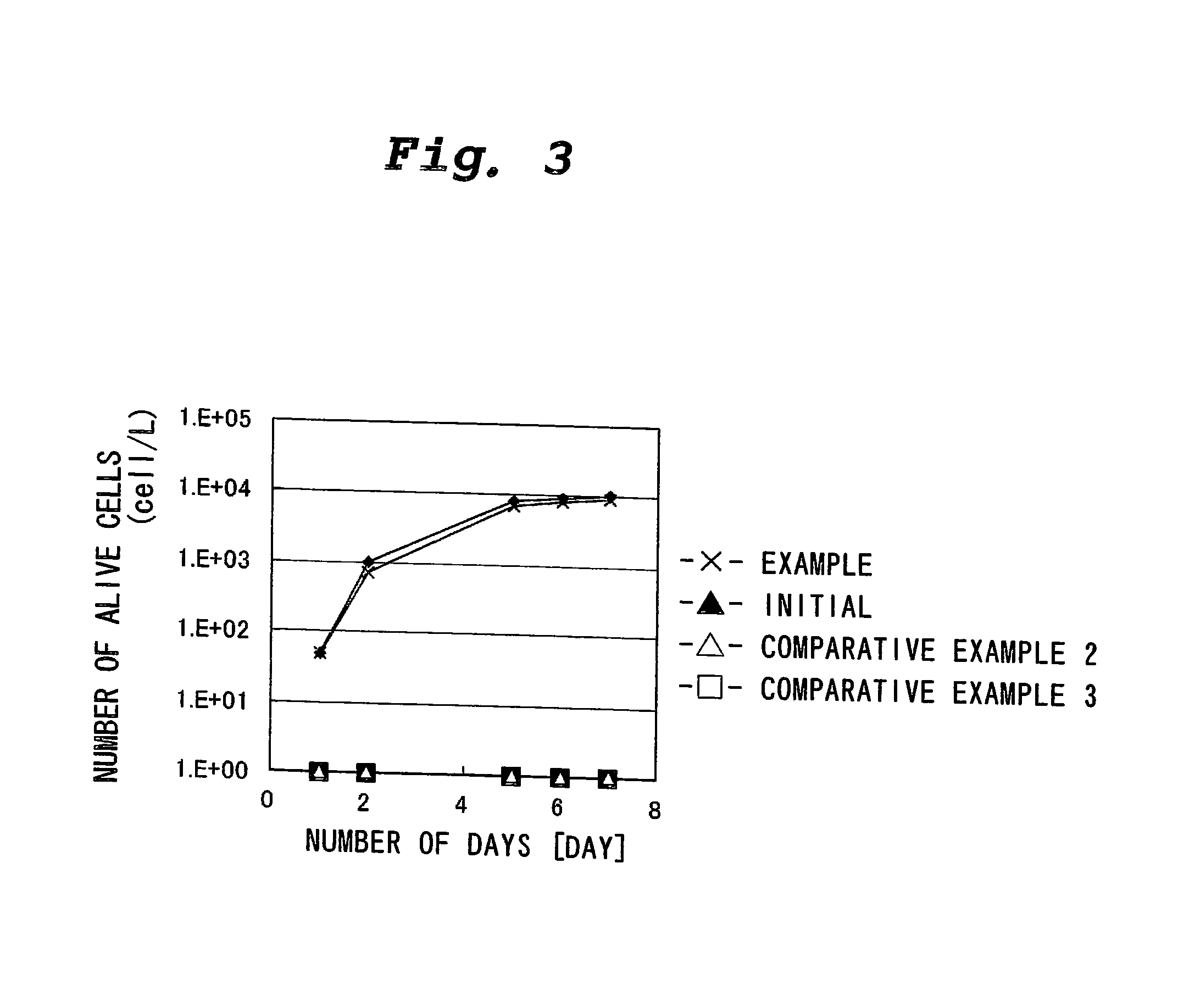

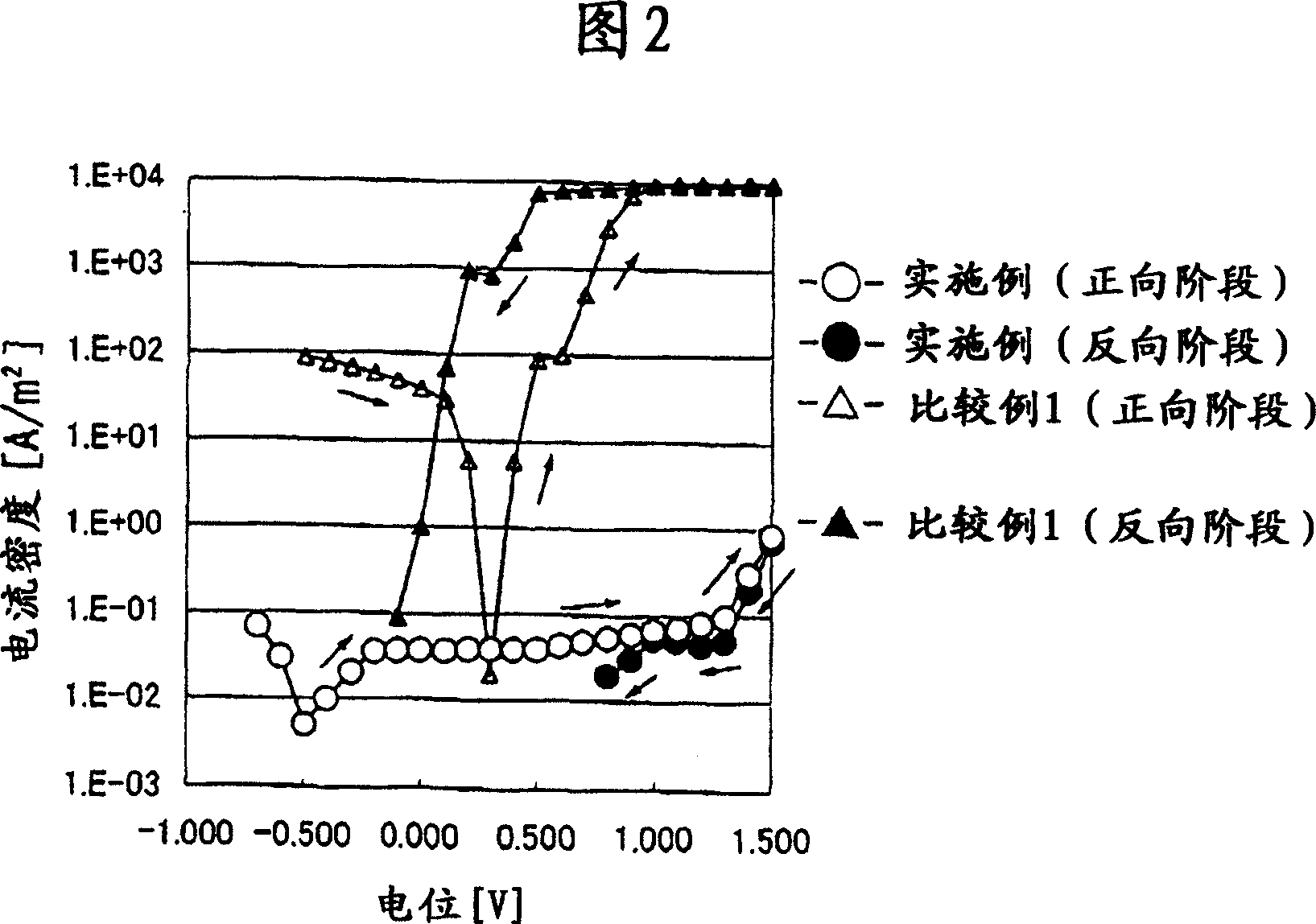

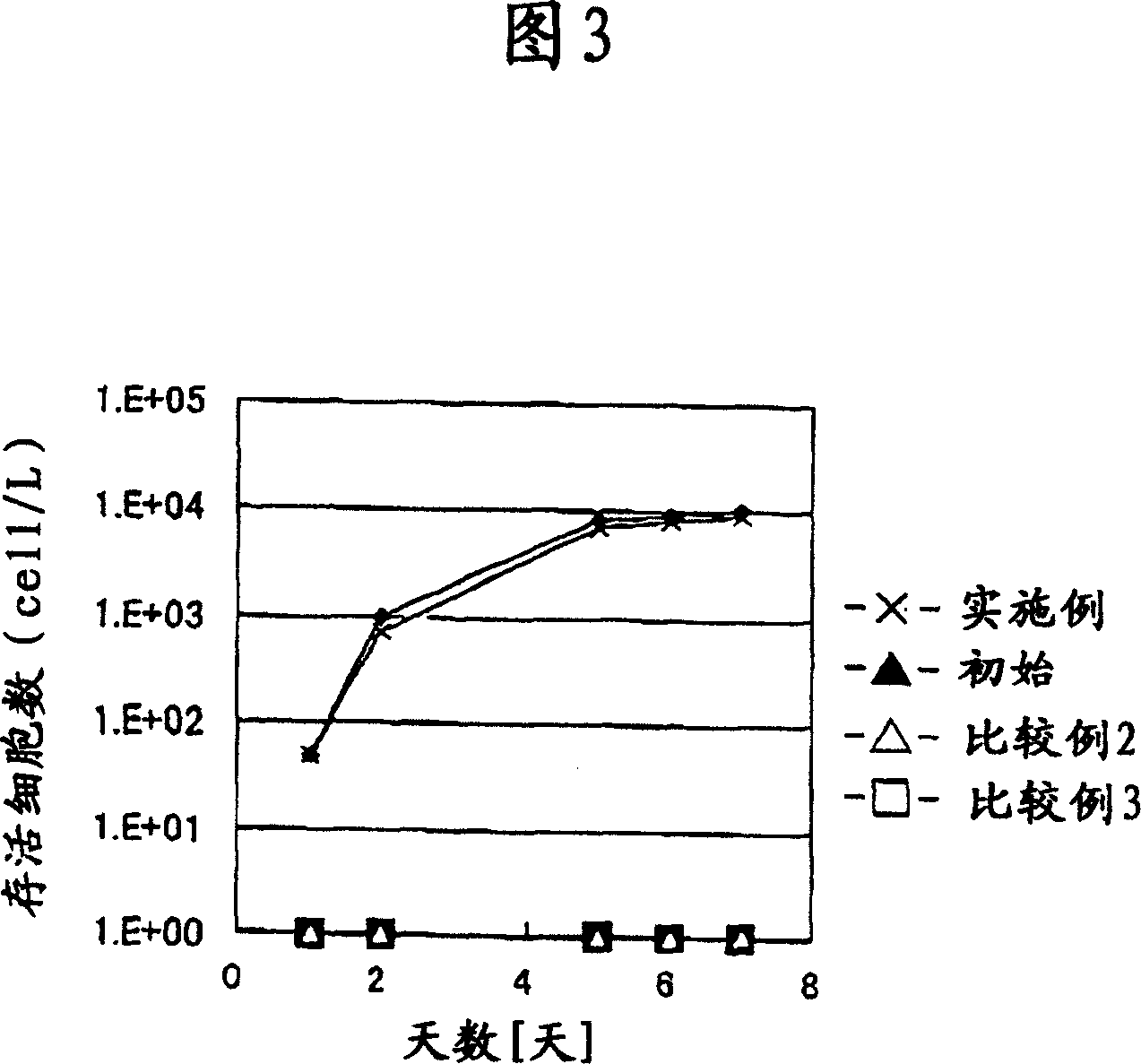

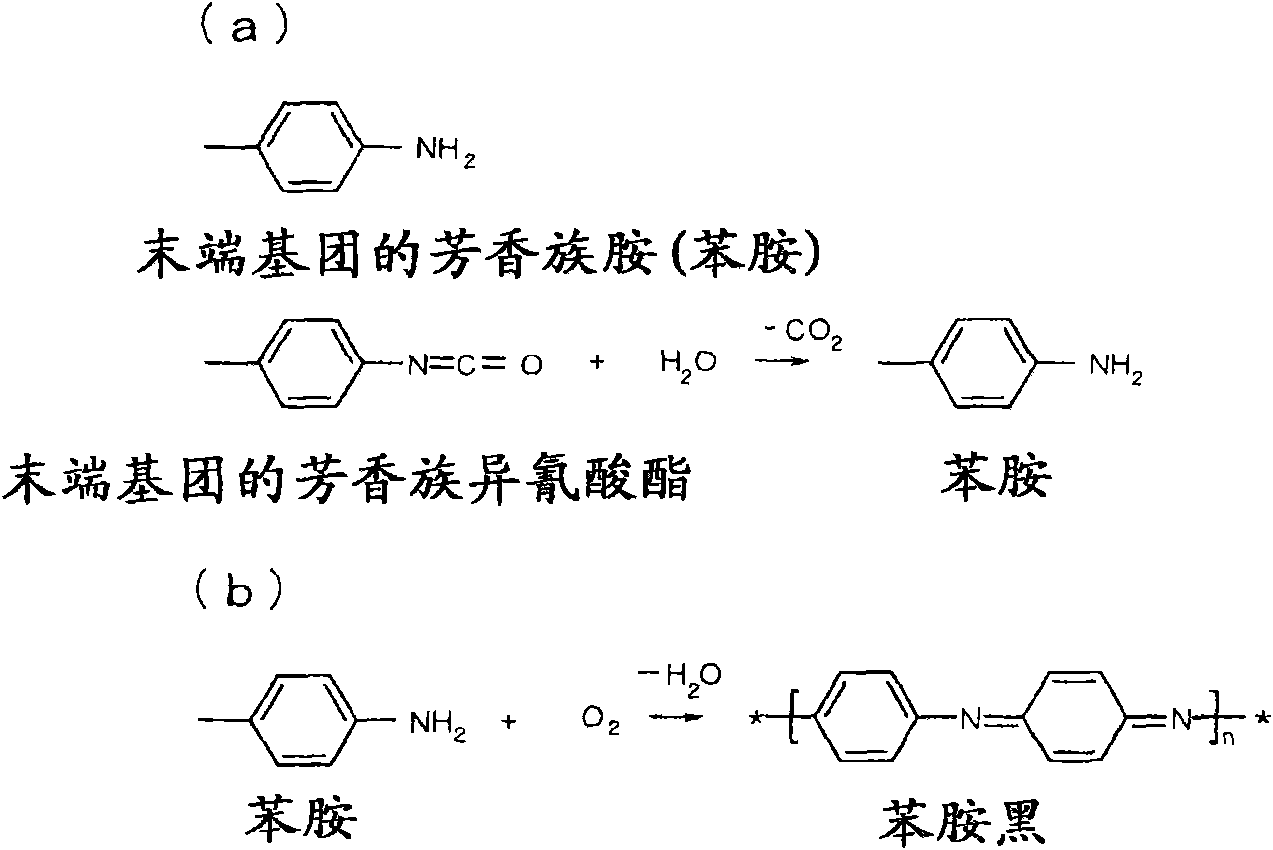

Anti-bacterial polymer and method for the preparation thereof, anti-bacterial polymer film and method for the preparation thereof, and article having such a film on the surface thereof

ActiveUS20040077819A1Good effectImprove heat resistanceBiocidePolyurea/polyurethane coatingsVapor deposition polymerizationGas phase

An anti-bacterial polymer of the present invention consists of a vapor deposition-polymerization reaction product of a diaminobenzoic acid monomer or halogen atom-containing diamine monomer and a monomer reactive with these monomers. The anti-bacterial polymer can be prepared by a method, which comprises the step of subjecting a gas obtained by evaporating a diaminobenzoic acid monomer or halogen atom-containing diamine monomer and a gas obtained by evaporating a monomer reactive with these monomers to vapor deposition-polymerization, in a vacuum, to thus form an anti-bacterial polymer. The method permits the formation of a film having a desired thickness even on the surface having a complicated shape such as the surface of, for instance, a heat exchanger.

Owner:ULVAC INC

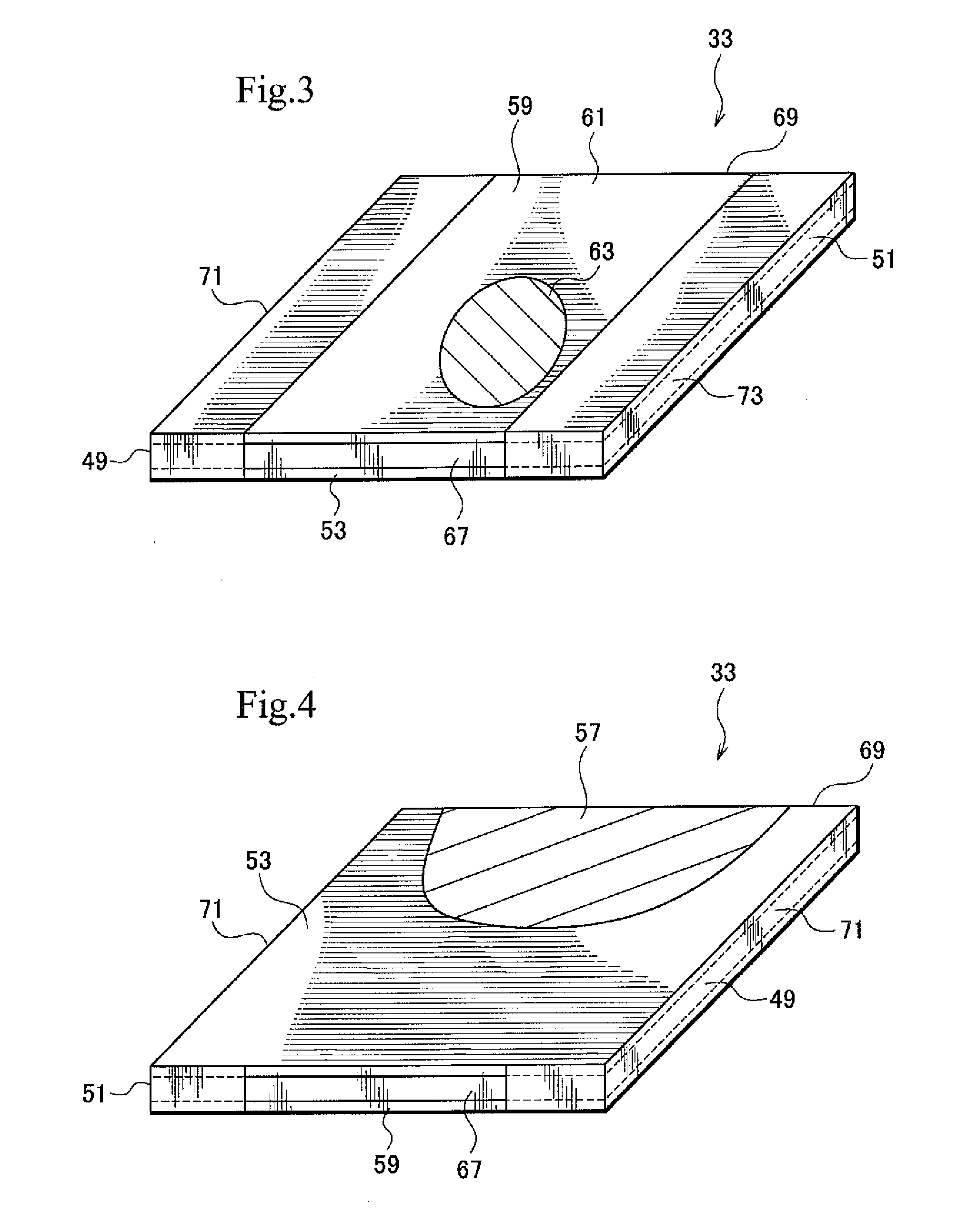

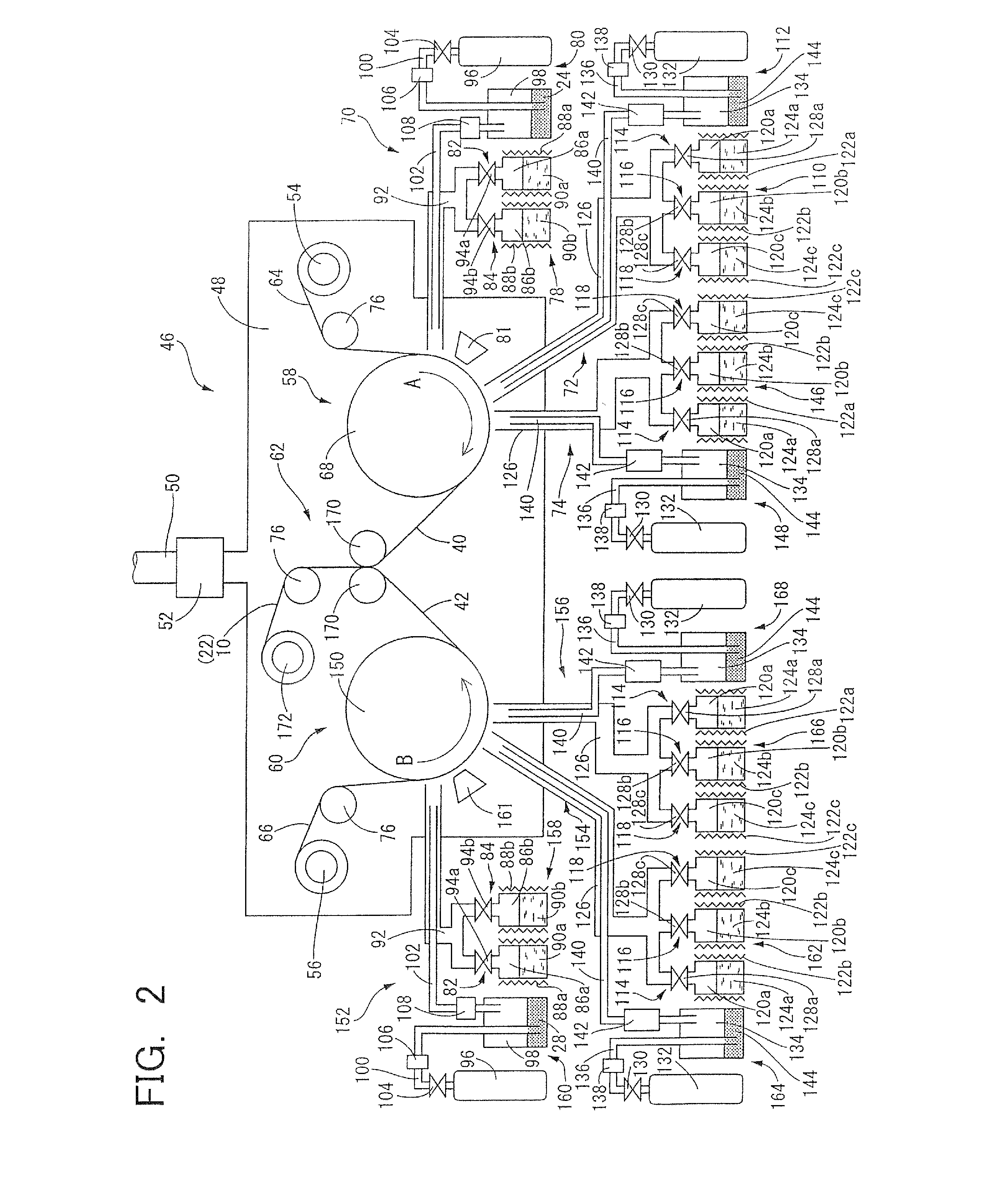

Apparatus for producing multilayer sheet and method of producing the multilayer sheet

InactiveUS20110091661A1Low costIncrease production capacityLiquid surface applicatorsThin/thick film capacitorProduction rateVapor deposition polymerization

An apparatus for producing a multilayer sheet including a resin film, a vapor-deposited metal film and a vapor-deposited polymer film at a low cost and with excellent productivity is provided which comprises: a vacuum chamber which is made to be in a vacuum state by exhaust means; a feeding roller; a take up roller; a first to third rollers, first metal vapor deposition means for forming a first vapor-deposited metal film on one surface of a resin film at a periphery of the first roller; vapor deposition polymerization means for forming a vapor-deposited polymer film on the first vapor-deposited metal film by vapor deposition polymerization at a periphery of the second roller; and second metal vapor deposition means for forming the second vapor-deposited metal film on the other surface of the resin film at a periphery of the third roller.

Owner:KOJIMA PRESS IND CO LTD +1

Methods for the vapor phase deposition of polymer thin films

InactiveUS20180009001A1Avoid high pressureCoatingsSpecial surfacesVapor deposition polymerizationGas phase

Disclosed are methods for forming thin polymeric films on a surface of an article by deposition from the vapor phase. In certain embodiments, the method comprises depositing the polymeric film in situ inside a space or enclosure contained within the article. In other embodiments, the method comprises depositing a film from vapor phase by thermal degradation of an initiator precursor without the need for an external filament.

Owner:MASSACHUSETTS INST OF TECH

Corrosion Preventing Method

Owner:ULVAC INC

Film capacitor element, film capacitor, and method of producing the film capacitor element

InactiveCN103426631AReduce adverse effectsGood adhesionThin/thick film capacitorStacked capacitorsDielectricVapor deposition polymerization

A film capacitor element including a base dielectric film layer 12, a vapor-deposition metal film layer 14 formed on the base dielectric film layer 12 and consisting of a first film portion 20 and a second film portion 22 that are spaced apart from each other by a margin portion 18, and a dielectric covering film layer 16 which is formed integrally on the second film portion 22 by vapor-deposition polymerization or coating and which has a covering portion 30 which fills the margin portion 18 and covers an entire area of an end face of the second film portion 22 on the side of the margin portion 18. The first film portion 20 including a non-covered portion 34 which is not covered by the dielectric covering film layer 16.

Owner:KOJIMA PRESS IND CO LTD

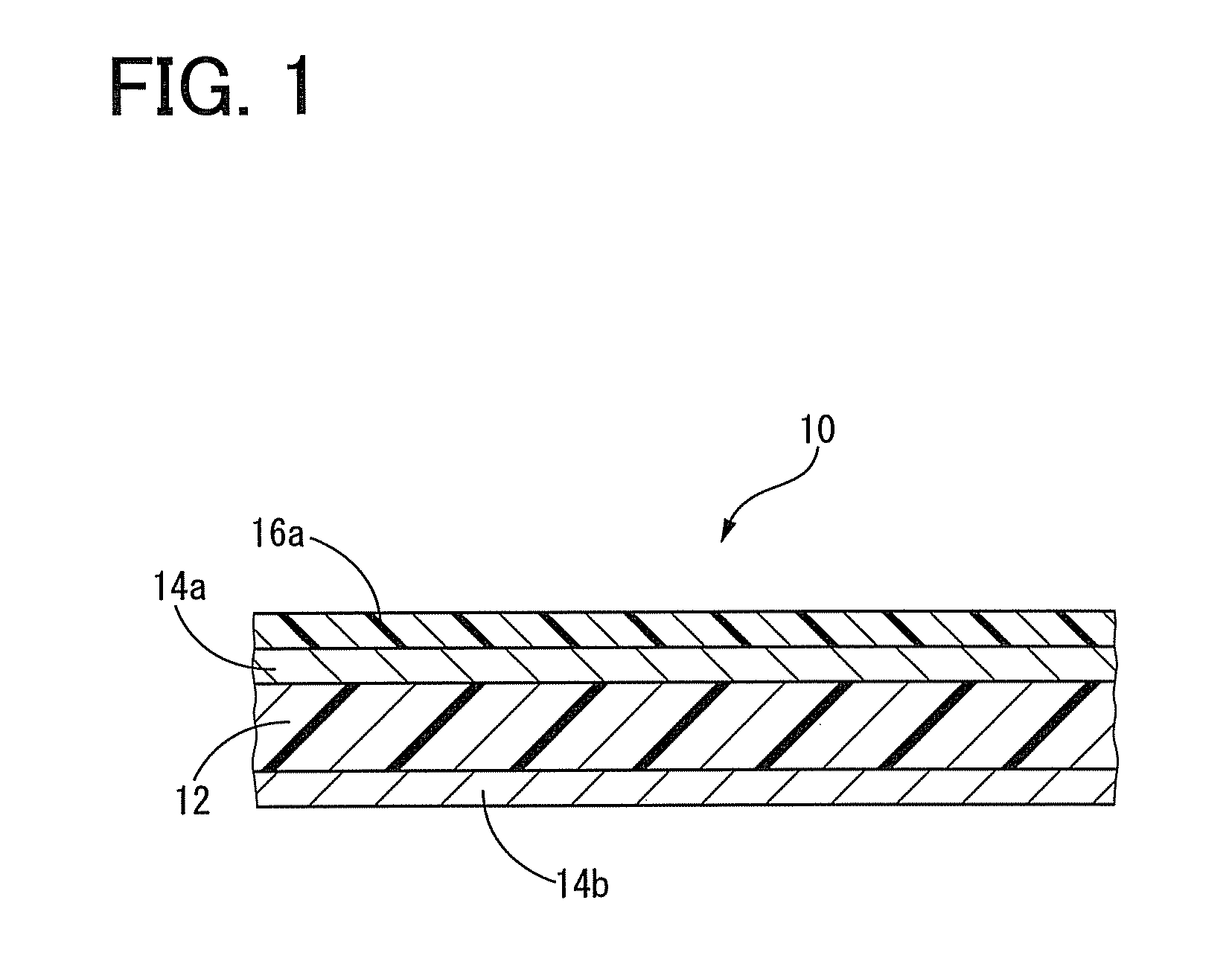

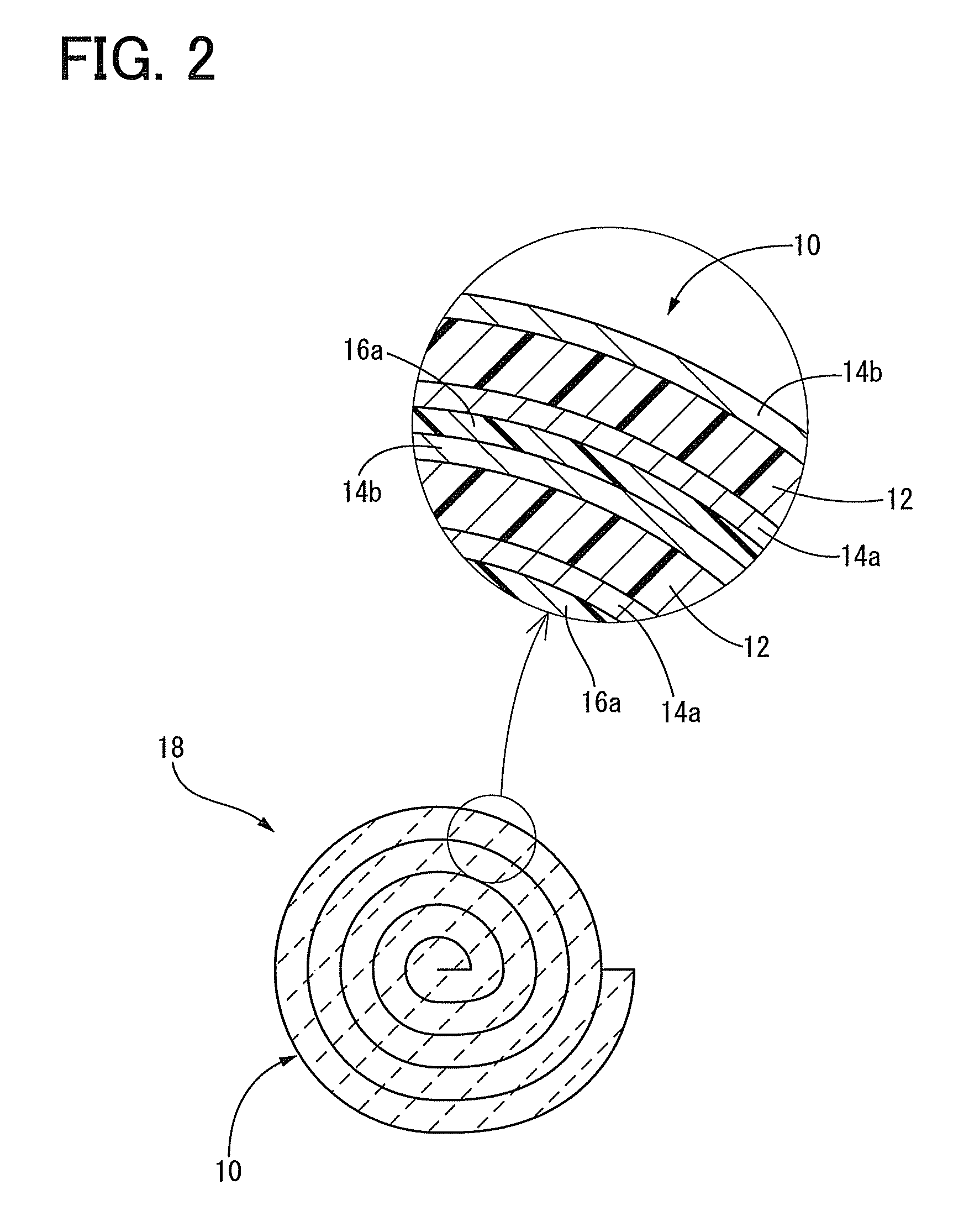

Film capacitor and method of producing the same

InactiveUS8228661B2Simple structureIncrease capacityThin/thick film capacitorFixed capacitor electrodesVapor deposition polymerizationGas phase

A film capacitor is provided which has a smaller size and improved capacity while securing a sufficient withstand voltage. The film capacitor comprising a basic element 10 containing a plurality of dielectric layers and at least one vapor-deposited metal film layer 14a, 14b, where the plurality of dielectric layers consisting of a resin film layer 12 and at least one vapor-deposited polymer film layer 16a, and the at least one vapor-deposited polymer film layer 16a is formed on at least one of the resin film layer 12 and the at least one vapor-deposited metal film layer 14a, 14b.

Owner:KOJIMA PRESS IND CO LTD

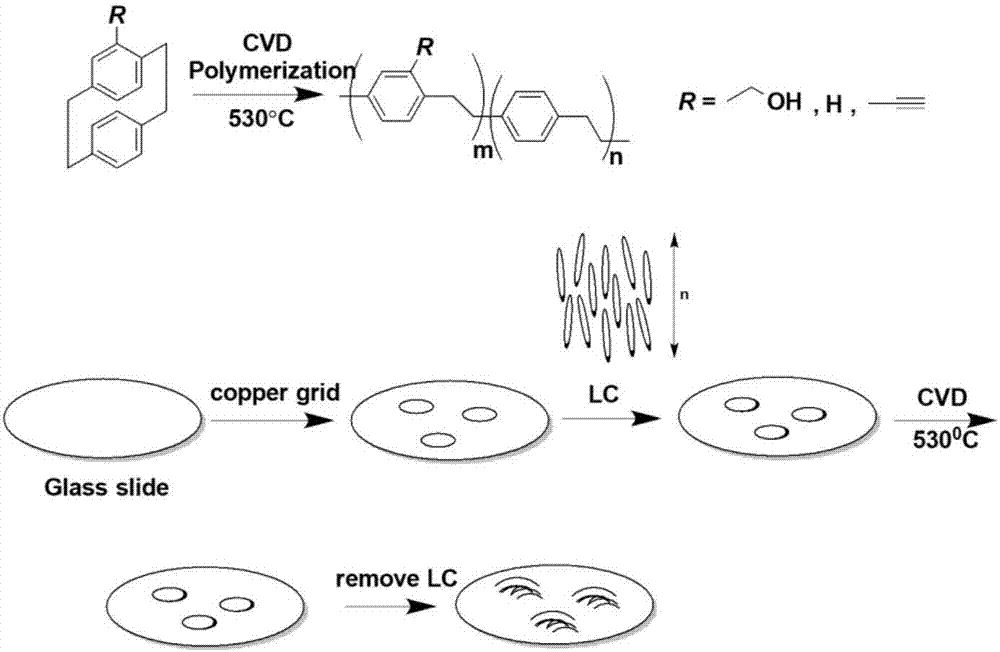

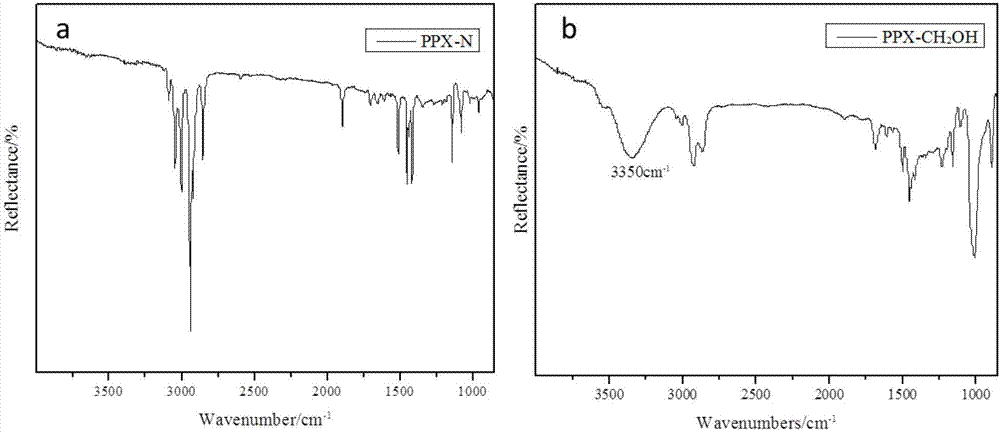

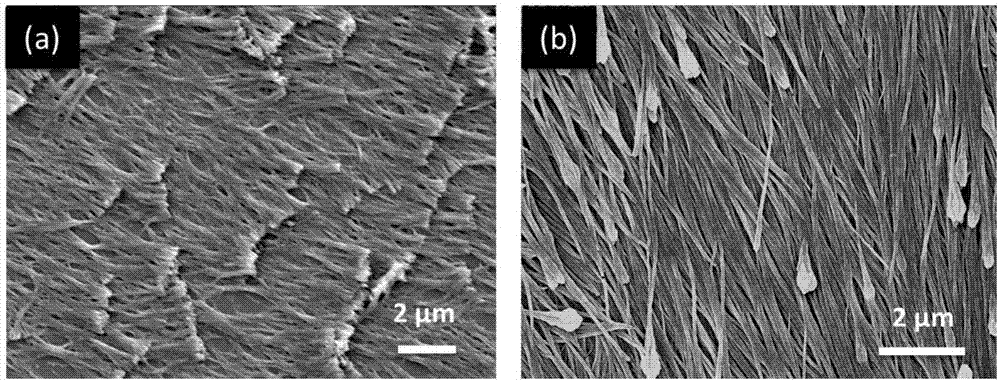

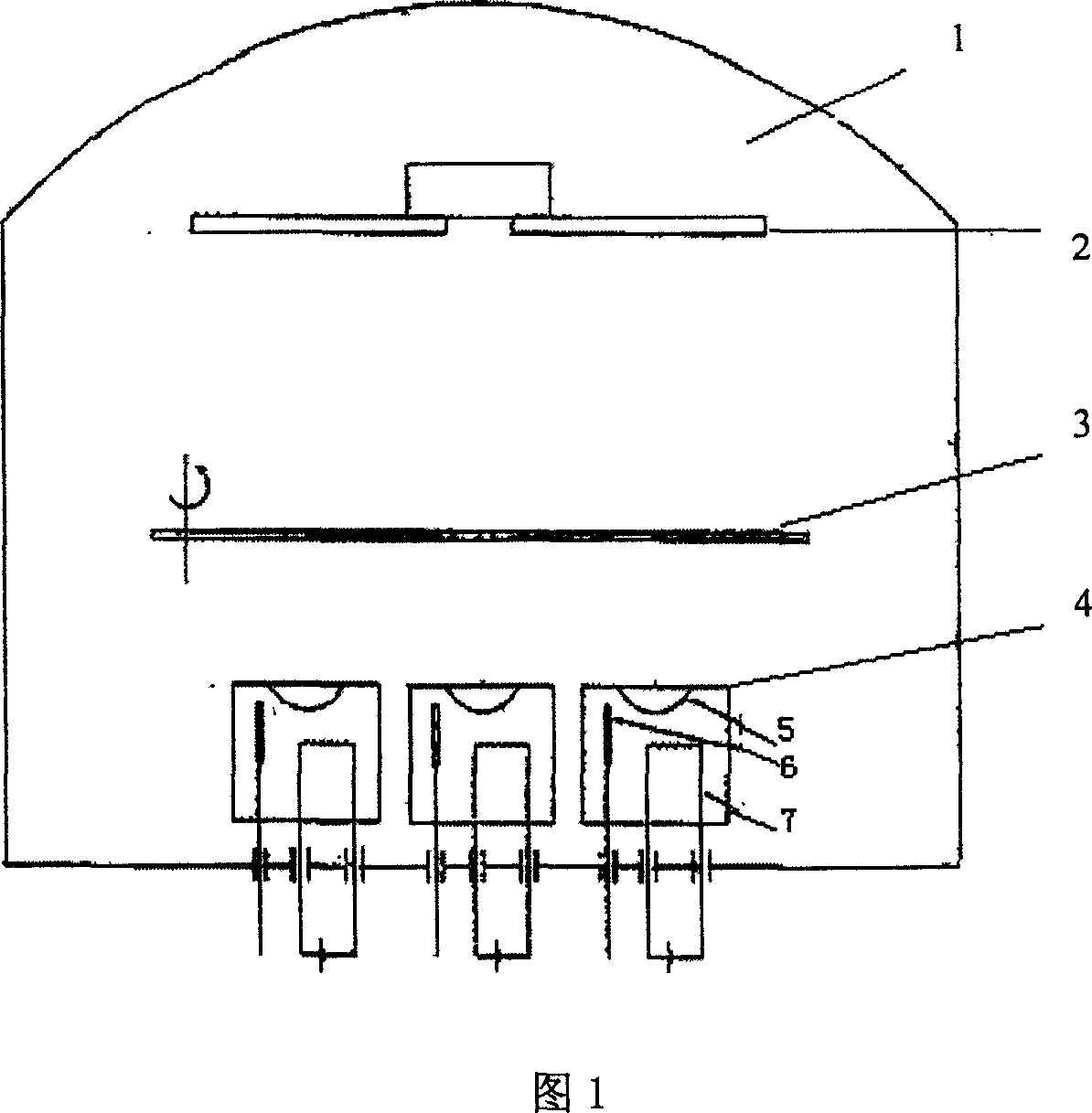

Method for preparing poly-p-xylylene nano fibers through chemical vapor deposition

ActiveCN107474225AAvoid serious pollution and other disadvantagesSolve Post-Processing IssuesMonocomponent synthetic polymer artificial filamentFiberXylylene

The invention discloses a method for preparing poly-p-xylylene nano fibers through chemical vapor deposition and belongs to the technical field of materials. The method disclosed by the invention comprises the following steps: by adopting a chemical vapor deposition technology, by taking poly-p-xylylene as a precursor and taking nematic liquid crystal as a template, successfully preparing the poly-p-xylylene nano fibers through a vapor deposition polymerization reaction. The preparation method has the characteristics of being controllable in size, shape and composition of the fibers, the defects such as solvent after-treatment problems, severe environmental pollution and the like existing in the fiber preparation by the traditional electrospinning method are overcome, and the obtained nano fibers can be applied to drug delivery systems, tissue engineering, micro-fluid devices and the like and have extremely high application values.

Owner:SHAANXI UNIV OF SCI & TECH

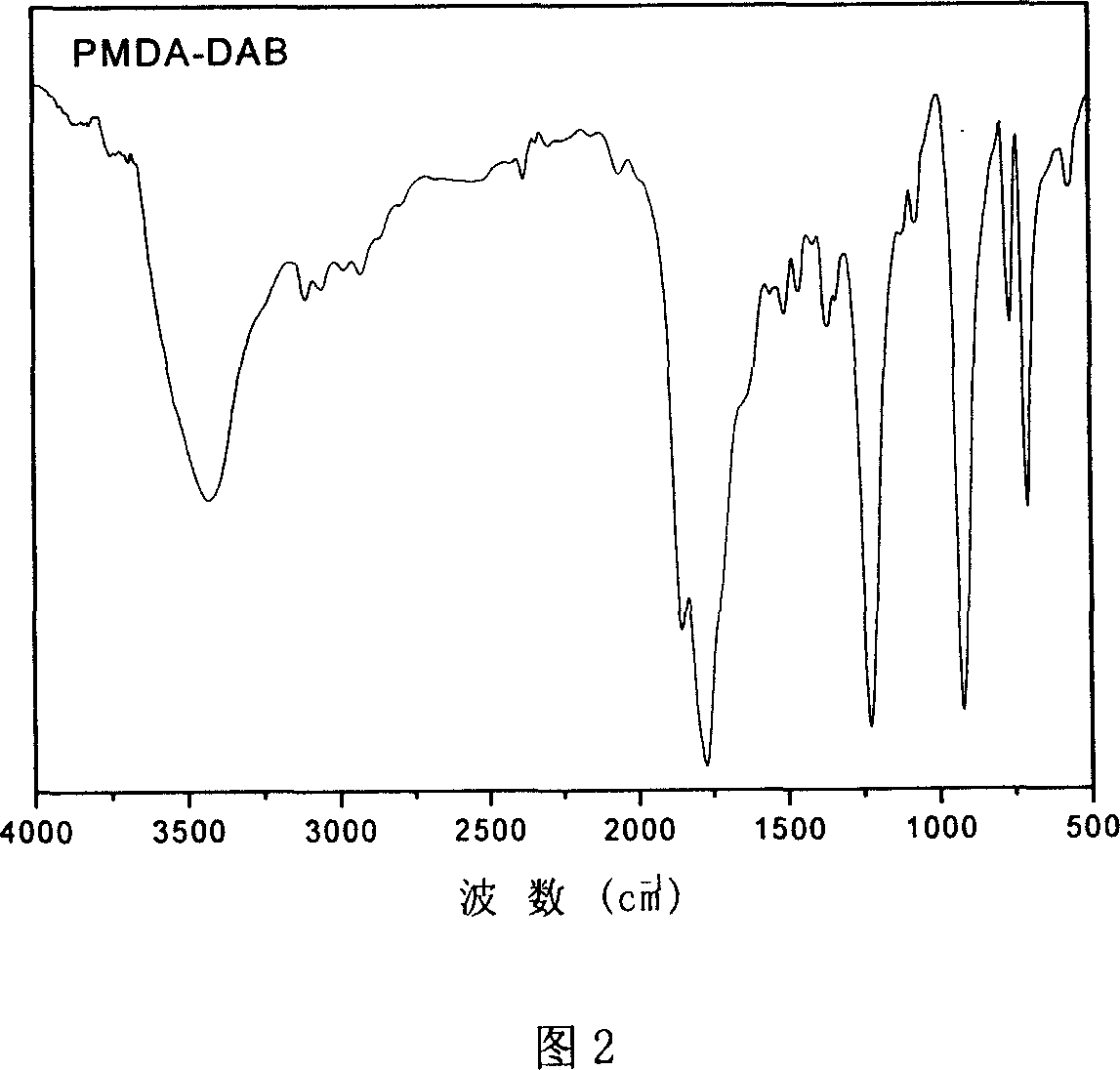

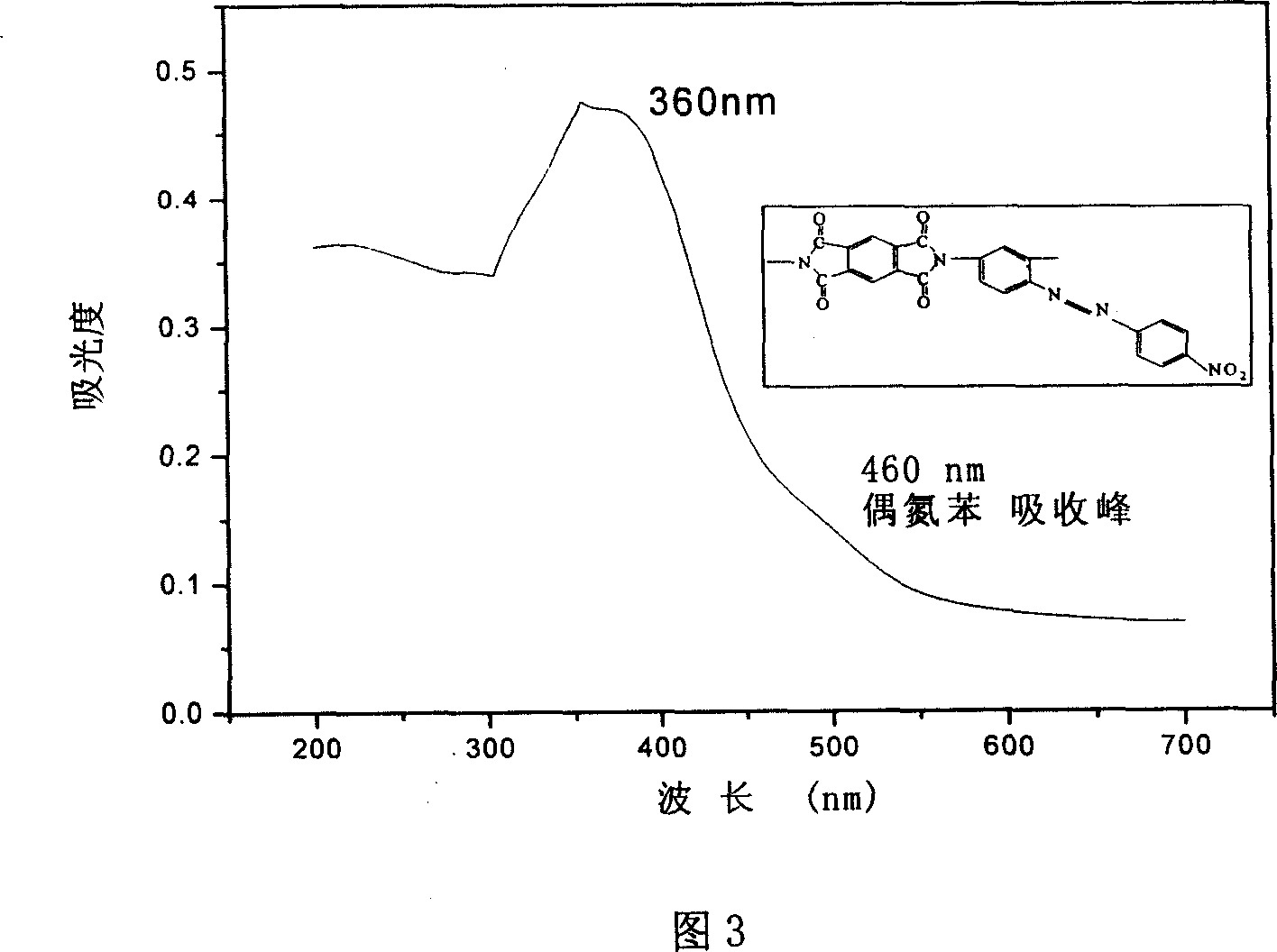

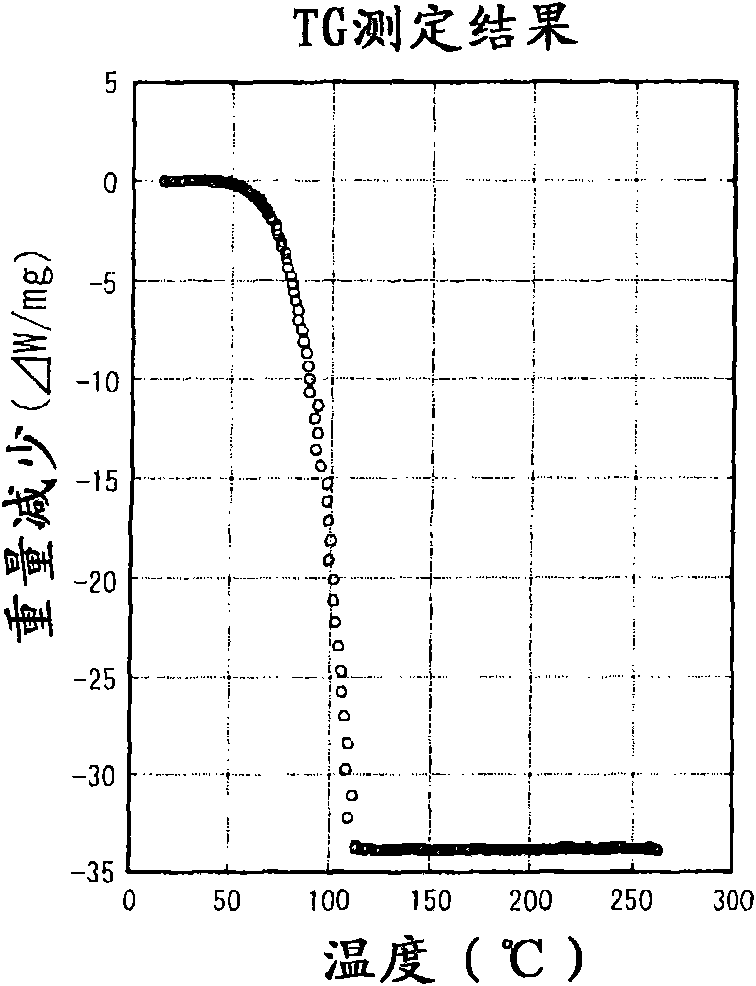

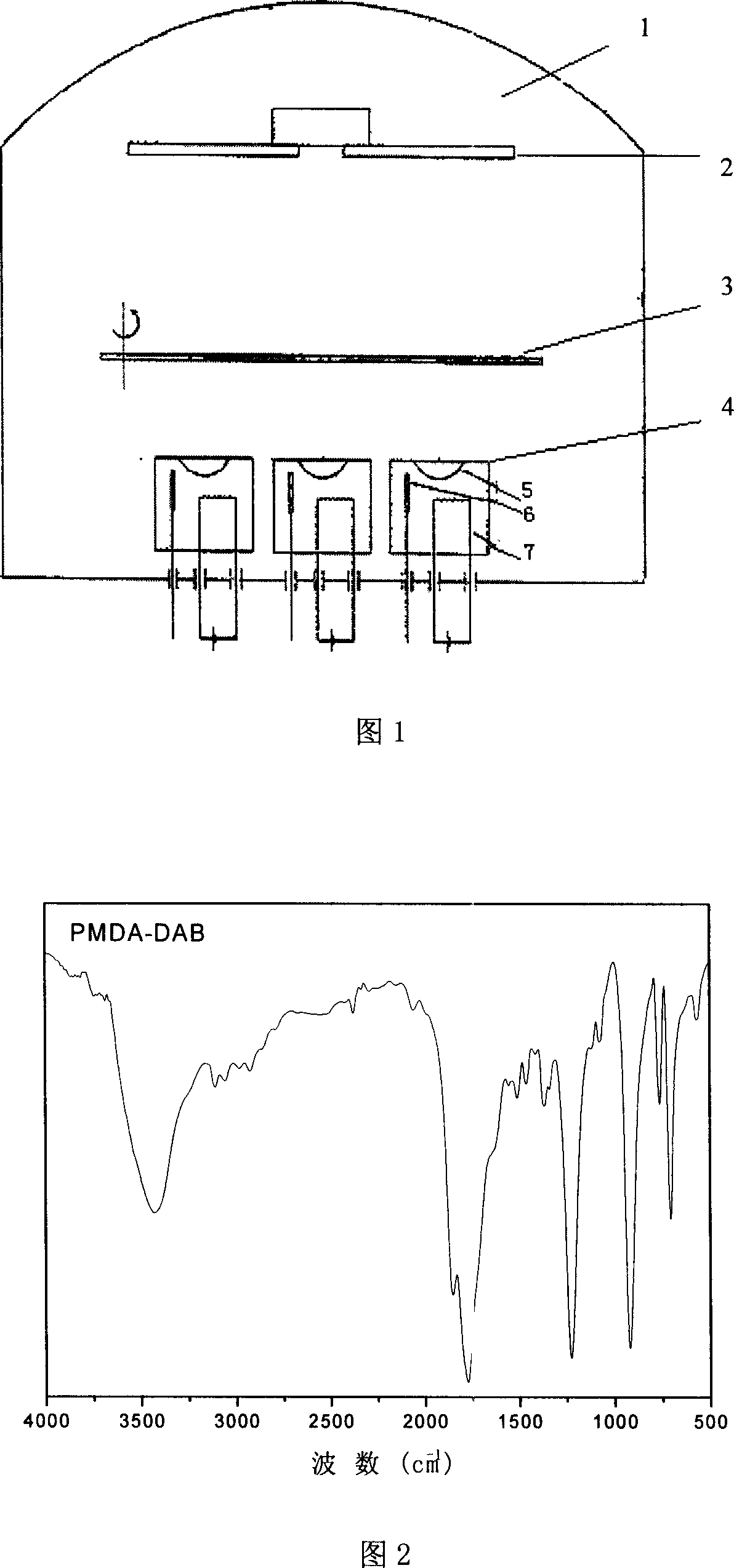

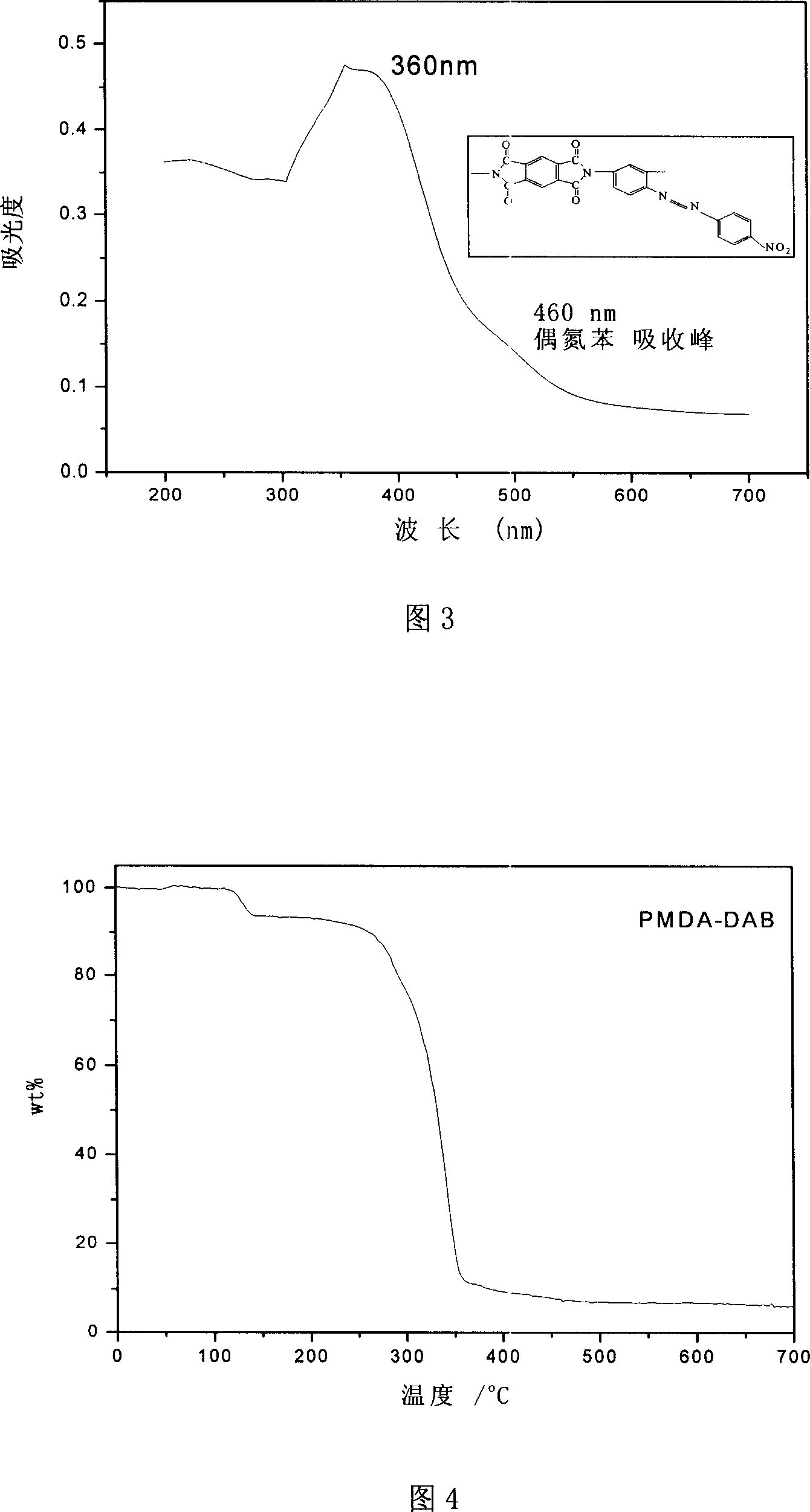

Film of polyimide containing color base group, and preparation method

This invention relates to a method for preparing polyimide thin film containing chromophore. The polyimide thin film, prepared by vapor deposition polymerization, can retain good thermal stability and chemical stability as that prepared by traditional method, and has such advantages as high uniformity, high compactness, no pin holes, no need for catalyst, no residual solvent, high purity and simple process. The polyimide thin film is suitable for fabricating photoelectrical devices such as optical switch.

Owner:TONGJI UNIV

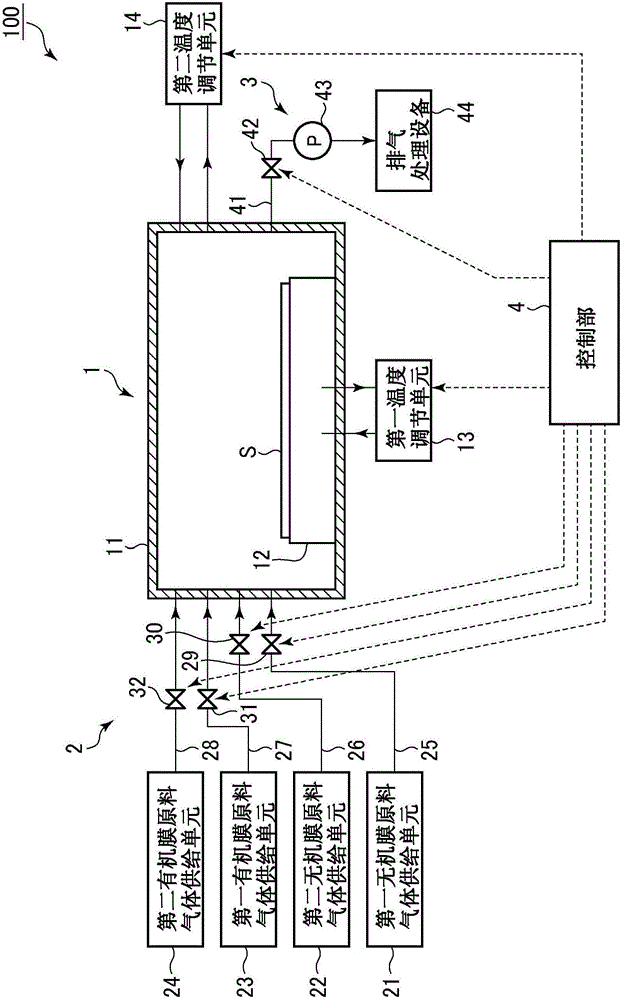

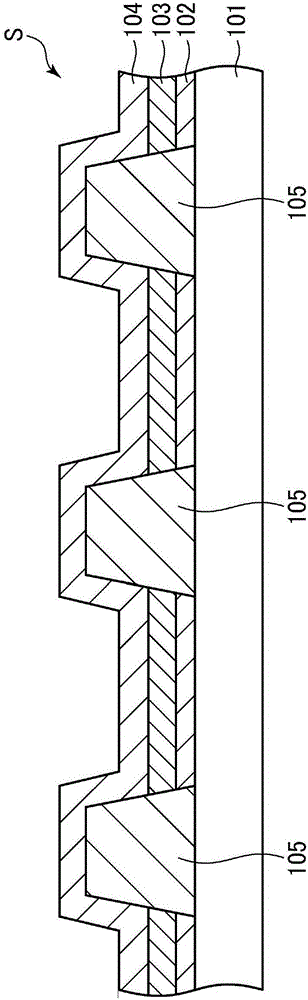

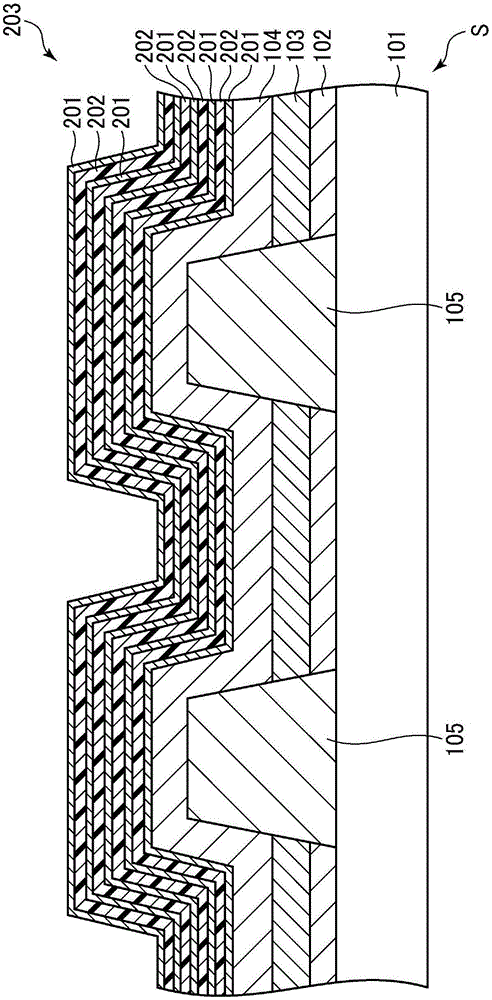

Laminated sealing film forming method and forming apparatus

ActiveCN106257705AReduce film thicknessThe overall thickness is thinSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmForeign matter

The invention provides a laminated sealing film forming method and forming apparatus, which is capable of forming a laminated sealing film having a thin film thickness and having a high sealing performance while suppressing a decrease in productivity and adhesion of foreign matters. In the laminated sealing film forming method, a laminated sealing film (203) having a structure stacked by an inorganic film (201) and an organic film (202) is formed on an organic EL element (S) obtained by forming a plurality of organic EL layers (102) serving as a light emitting layer on a substrate (101), and a step of forming the inorganic film (201) using an atomic layer deposition method and a step of forming the organic film (202) using a vapor deposition polymerization method are alternately repeated in a processing vessel (11).

Owner:TOKYO ELECTRON LTD

Anti-bacterial polymer and method for the preparation thereof, anti-bacterial polymer film and method for the preparation thereof, and article having such a film on the surface thereof

ActiveUS7279543B2Good effectImprove heat resistanceBiocidePolyurea/polyurethane coatingsVapor deposition polymerizationGas phase

Owner:ULVAC INC

Corrosion preventing method

InactiveCN101056661AAnti-corrosionBiocompatibleDental implantsArch wiresVapor deposition polymerizationGas phase

A method of corrosion prevention accompanied by bioaffinity so as to realize the application of Ni-Ti alloy to biomaterial usage. There is provided a method of corrosion prevention for a metal base material for use in biomaterials, characterized in that the metal base material is furnished with a polyamide coating through vapor deposition polymerization.

Owner:ULVAC INC

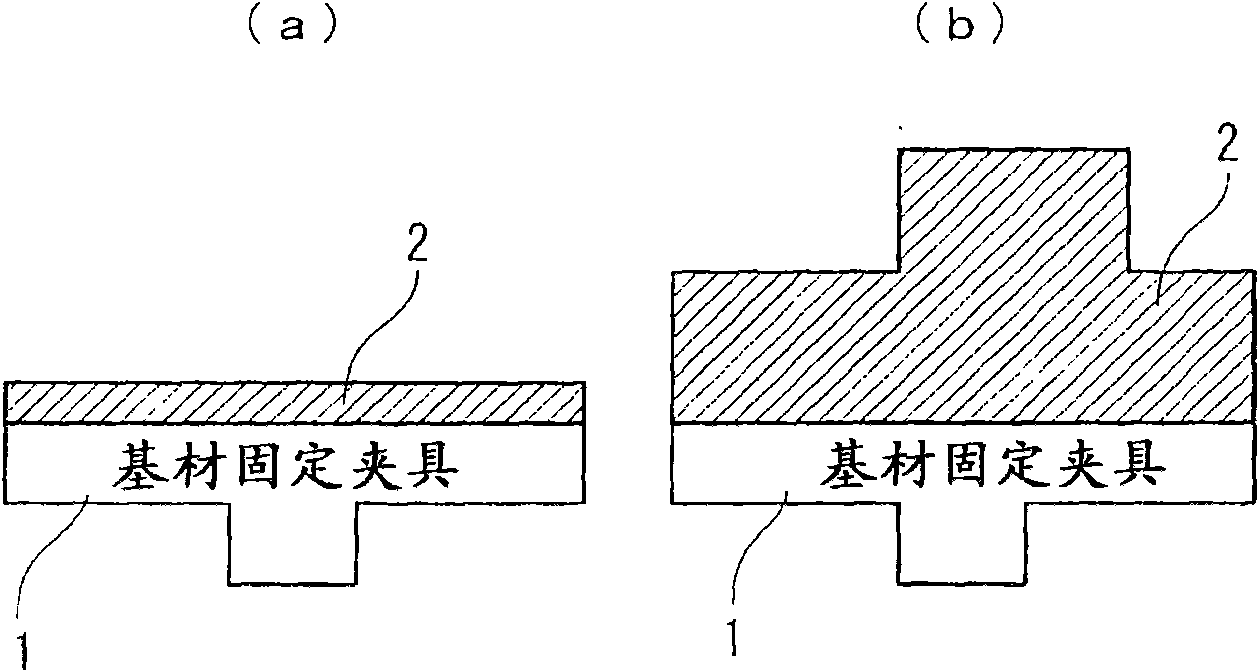

Method for lamination of decorative metal film on resin base material, and resin base material having decorative metal film thereon

ActiveUS8524369B2Reduce thicknessSufficient glossFilm/foil adhesivesSynthetic resin layered productsVapor deposition polymerizationPolyresin

The present invention provides a method for laminating a decorative metal film on a resin base material with excellent adhesion to the resin base material and with a sufficient gloss imparted to the decorative metal film, and a resin base material having a decorative metal film. The method laminates a polymeric planarizing film on the resin base material using a vapor deposition polymerization method, and then laminates the decorative metal film on the planarizing film.

Owner:ULVAC INC

Polyurea film and method of forming the same

InactiveCN101631889AHigh transparencyHigh hardnessLiquid surface applicatorsVacuum evaporation coatingVapor deposition polymerizationActivation energy

A polyurea film excelling in transparency, light stability and mass productivity is formed on a resin molding substratum in accordance with a vacuum vapor deposition polymerization technique. The polyurea film is obtained by a vacuum vapor deposition polymerization conducted using an aromatic alkyl, or alicyclic, or aliphatic diisocyanate monomer and an aromatic alkyl, or alicyclic, or aliphatic diamine monomer. The diisocyanate monomer and the diamine monomer are selected from among those in relationship such that a difference in activation energy needed for detachment from the substratum is 10 kJ or less.

Owner:ULVAC INC +1

Film of polyimide containing color base group, and preparation method

This invention relates to a method for preparing polyimide thin film containing chromophore. The polyimide thin film, prepared by vapor deposition polymerization, can retain good thermal stability and chemical stability as that prepared by traditional method, and has such advantages as high uniformity, high compactness, no pin holes, no need for catalyst, no residual solvent, high purity and simple process. The polyimide thin film is suitable for fabricating photoelectrical devices such as optical switch.

Owner:TONGJI UNIV

Manufacturing method of insulating part for rail transit

InactiveCN114434522AEasy to manufactureImprove production efficiencyMetal working apparatusSimple Organic CompoundsVapor deposition polymerization

The invention relates to the technical field of rail transit, and discloses a manufacturing method of an insulating part for rail transit, which comprises the following steps: adding an organic compound A, a catalyst A and a catalyst B into a reaction chamber with the temperature of 139 DEG C, carrying out addition polymerization reaction for 1-2 hours, and standing for 2-3 hours after the addition polymerization reaction is completed to obtain a polymer A. The polymer A is prepared by the following steps of: adding the polymer A into the reaction chamber; according to the manufacturing method of the insulating part for the rail transit, an organic compound A, a catalyst A and a catalyst B are subjected to vapor deposition polymerization operation at a specific temperature, a polymer A obtained after standing is conducted for three hours is polypropylene, the polypropylene is an organic substance with extremely high insulating performance, and the marble particles are filled in the polypropylene, so that the insulating part for the rail transit is obtained. And the insulation material A is used as a rail insulation material of the base layer, so that the compression resistance stability can be enhanced, the insulation capability can be greatly improved, the manufacturing mode of the insulation part is simple, and the manufacturing efficiency of the insulation part is greatly improved.

Owner:株洲九通路用装备实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com