Film of polyimide containing color base group, and preparation method

A polyimide film and chromophore technology, applied in the field of functional polymer materials, can solve problems such as pores, difficulty in obtaining high-quality polyimide materials, and difficulty in volatilization

Inactive Publication Date: 2010-12-01

TONGJI UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are many kinds of polyimides, and there are also multiple approaches in the synthesis. The most commonly used method at present is the solution method (StrunskusT., GrunzeM., Polyimides, Dekker, NewYork, 1996: 187), but there are also some defects in the solution method. The synthesis reaction of polyimide prepared by solution method is carried out in high boiling point aprotic solvents such as dimethylformamide (DMF), N-methylpyrrolidone (NMP), and in the preparation process of polyimide film Among them, these high-boiling aprotic solvents are difficult to volatilize completely, and at the same time, volatiles are released during the cyclization (imidization) of polyamic acid, which is easy to generate pores in the material, and it is difficult to obtain high-quality, non-porous polyamides. imide material

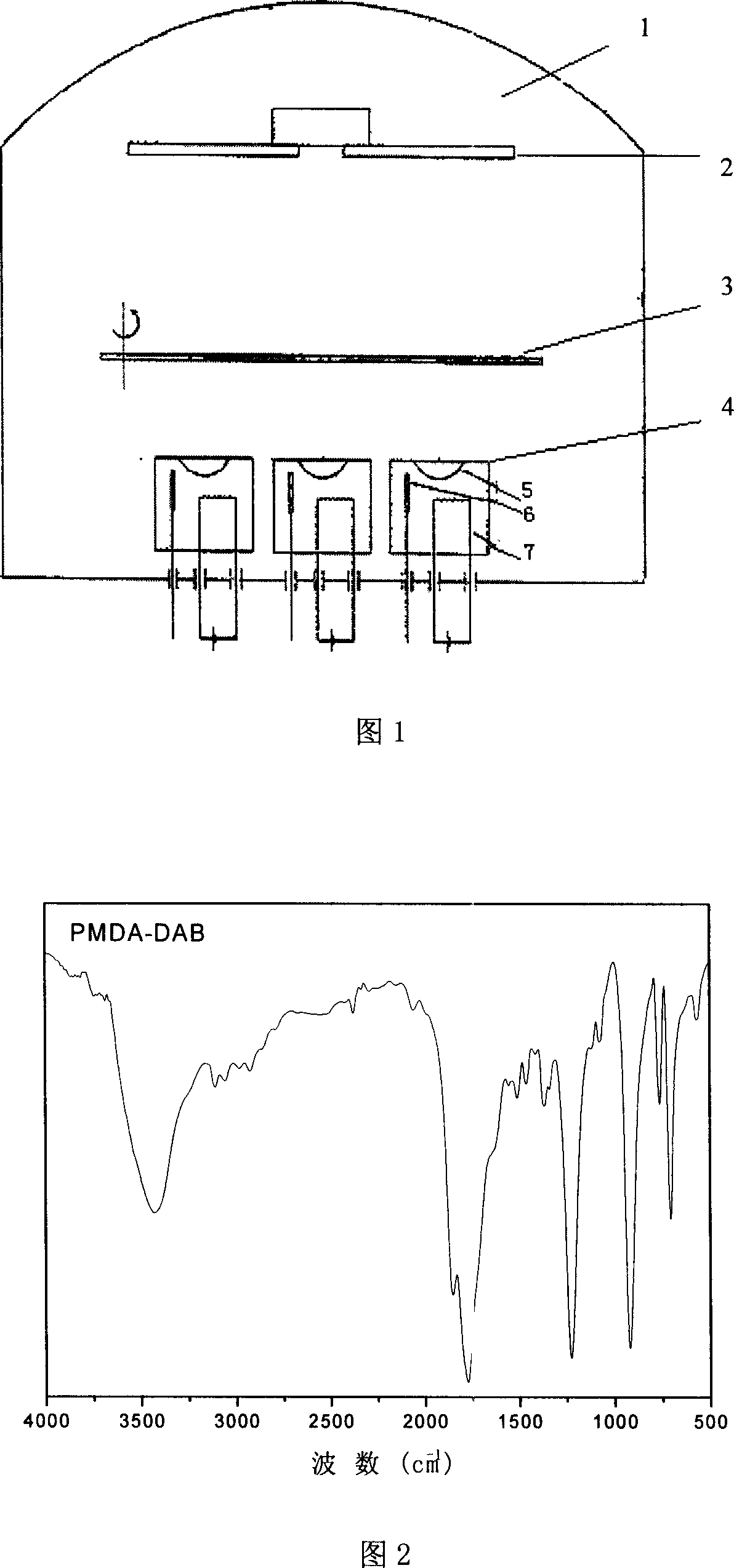

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

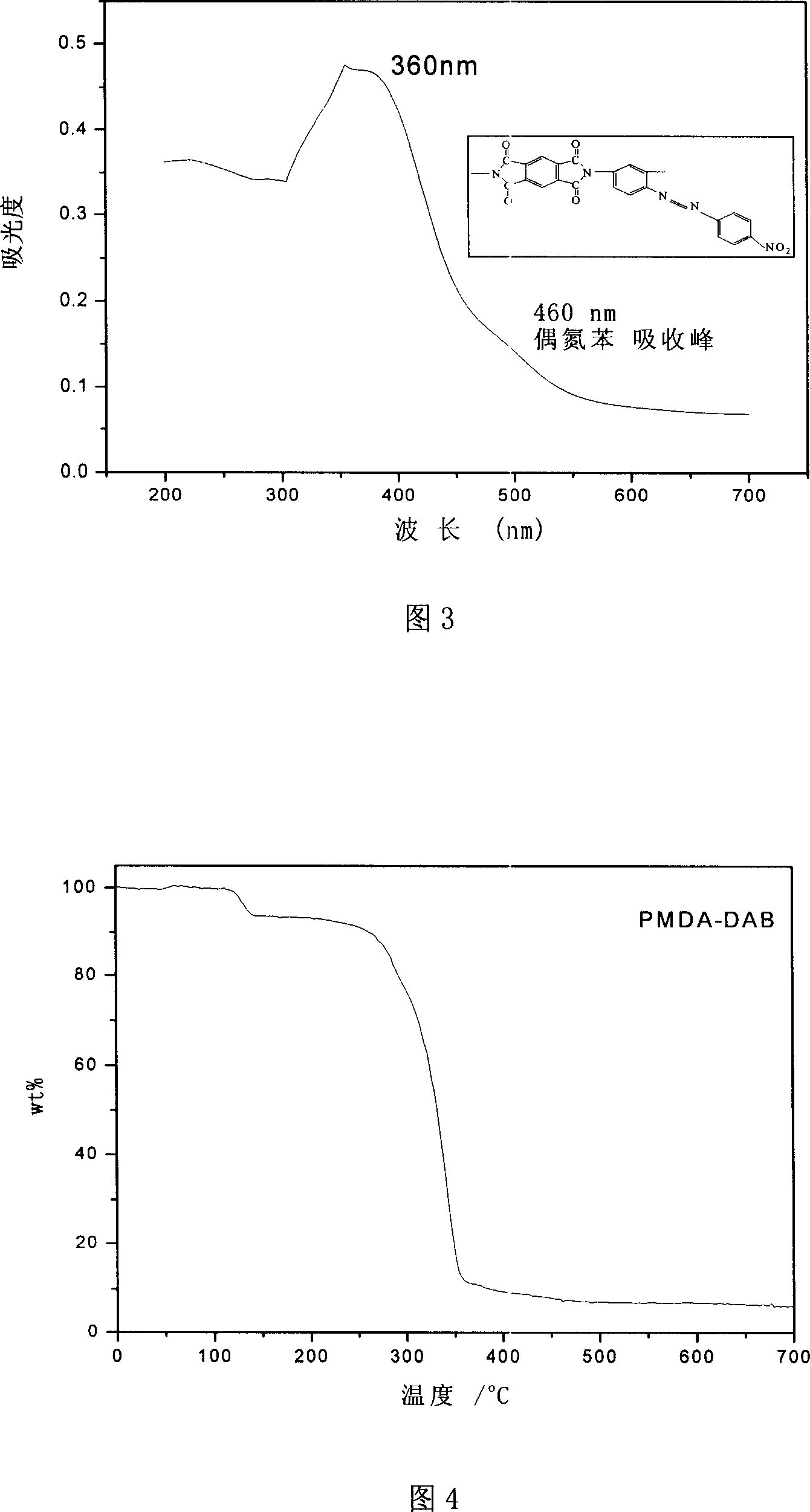

Abstract

This invention relates to a method for preparing polyimide thin film containing chromophore. The polyimide thin film, prepared by vapor deposition polymerization, can retain good thermal stability and chemical stability as that prepared by traditional method, and has such advantages as high uniformity, high compactness, no pin holes, no need for catalyst, no residual solvent, high purity and simple process. The polyimide thin film is suitable for fabricating photoelectrical devices such as optical switch.

Description

A kind of polyimide film containing chromophore and preparation method thereof technical field The invention belongs to the technical field of functional macromolecular materials, and in particular relates to a new polyimide film containing chromogenic groups and a preparation method thereof. Background technique Polyimide (PI) as a functional polymer material, due to its good thermal properties (the decomposition temperature of fully aromatic polyimide is generally around 500 ° C), excellent mechanical properties, stable chemical properties and Good dielectric properties, widely used in aerospace, microelectronics, nano, liquid crystal, separation membrane and other fields. There are many kinds of polyimides, and there are also multiple approaches in the synthesis. The most commonly used method at present is the solution method (StrunskusT., GrunzeM., Polyimides, Dekker, NewYork, 1996: 187), but there are also some defects in the solution method. The synthesis reaction o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08J5/18C08L79/08C08G73/10

Inventor 浦鸿汀李媛媛万德成

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com