Corrosion preventing method

An anti-corrosion, metal-based technology, applied in the direction of dilators, catheters, brackets, etc., can solve problems that are difficult to prevent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Embodiments of the present invention will be described below.

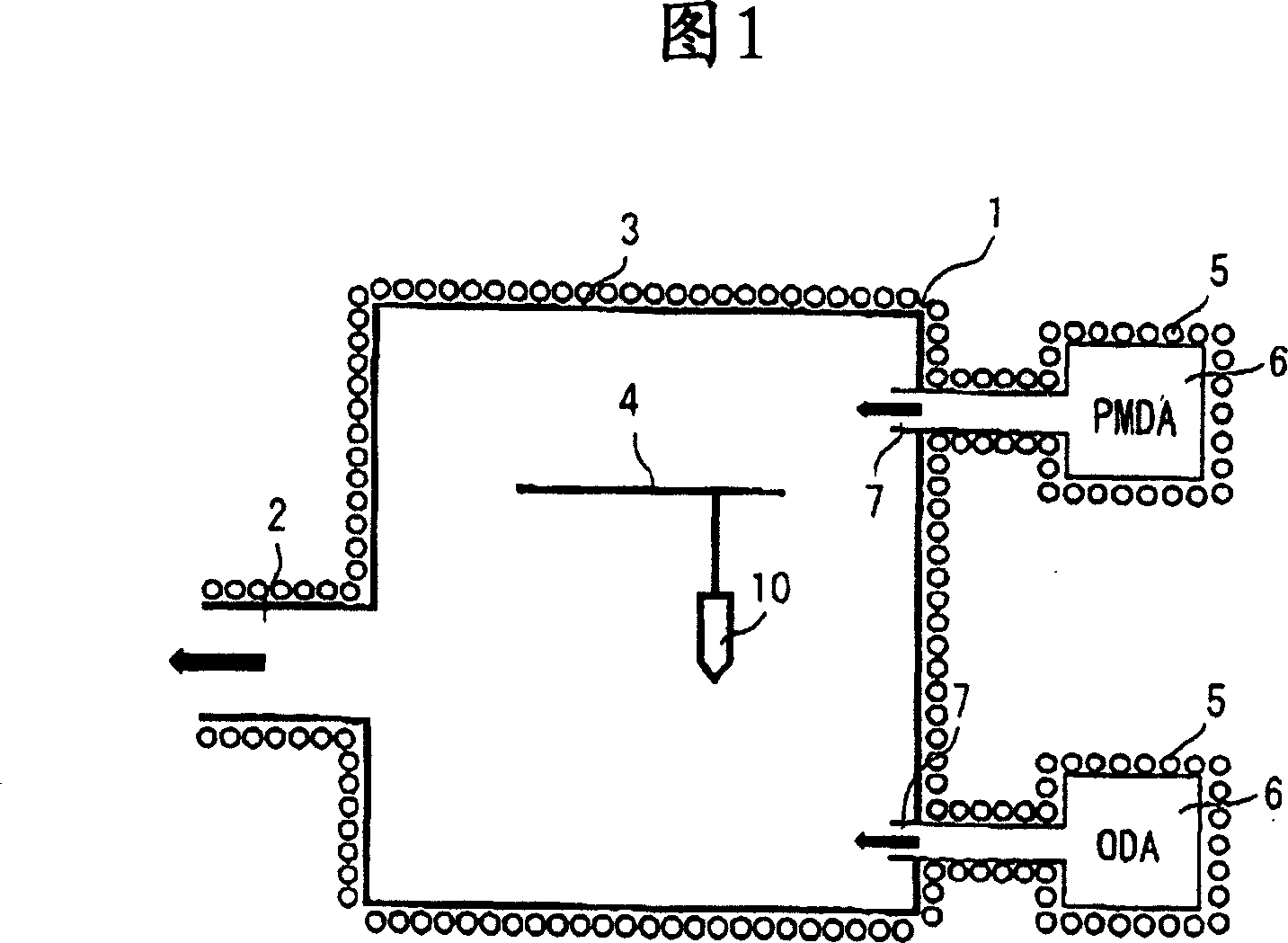

[0044] Fig. 1 shows the vapor deposition polymerization apparatus used in this example. In the vapor deposition polymerization device represented by 1 in this figure, the metal substrate 10 to be treated for corrosion protection is fixed in the treatment chamber 3 connected with the vacuum system 2 by the fixing fixture 4, and the monomers of the two heating containers 6 The gas introduction port 7 communicates with the processing chamber 3, and heats each heating container to a predetermined temperature by the heater 5 located at the periphery. Pyromellitic anhydride (PMDA) is contained in one heating vessel 6, and 4,4'-oxidized diphenylamine (ODA) is contained in another heating vessel 6, and pyromellitic anhydride (PMDA) vapor gas is mixed with 4, 4'-Oxidized diphenylamine (ODA) vapor gas is introduced into the processing chamber 3 so that a polyimide coating can be formed on the surface of the metal su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com