Bisphenol A-type polyimide material and method for making same

A polyimide and aromatic diamine technology, applied in the field of bisphenol A type polyimide film, can solve the problems of complex process, solvent residue, film gap and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] All the raw materials used were purchased from Shanghai Synthetic Resin Research Institute and were chemically pure.

[0025] The ratio of raw materials used is as follows:

[0026] 2,2'-bis(4-dicarboxyphenoxyphenyl)propane dianhydride (BSAA) 1.1 parts (number of moles)

[0027] 4,4'-(isopropylidene) bis(4-phenoxyaniline) (BAPP) 1 part (number of moles)

[0028] Preparation of BSAA / BAPP type PI membrane:

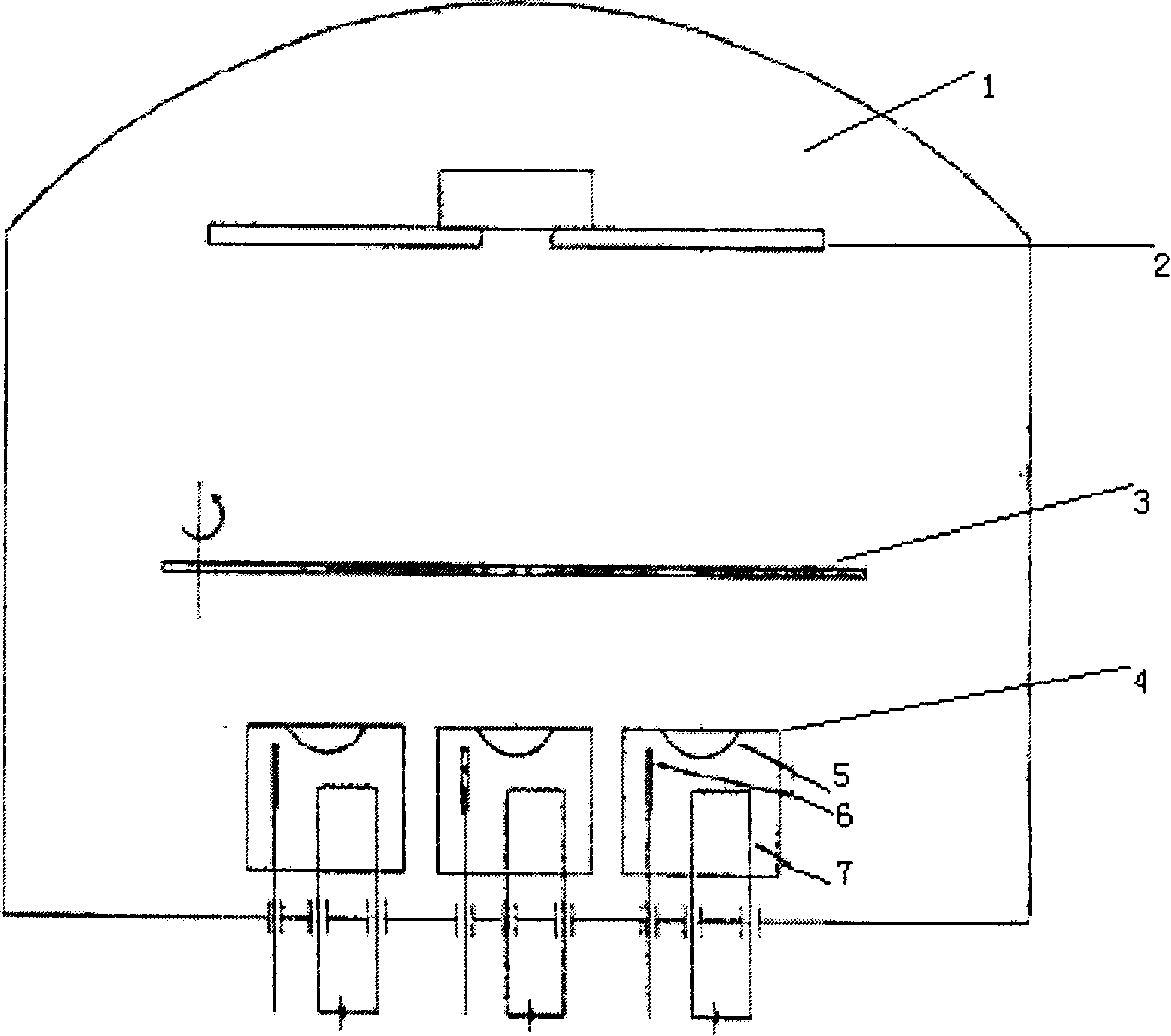

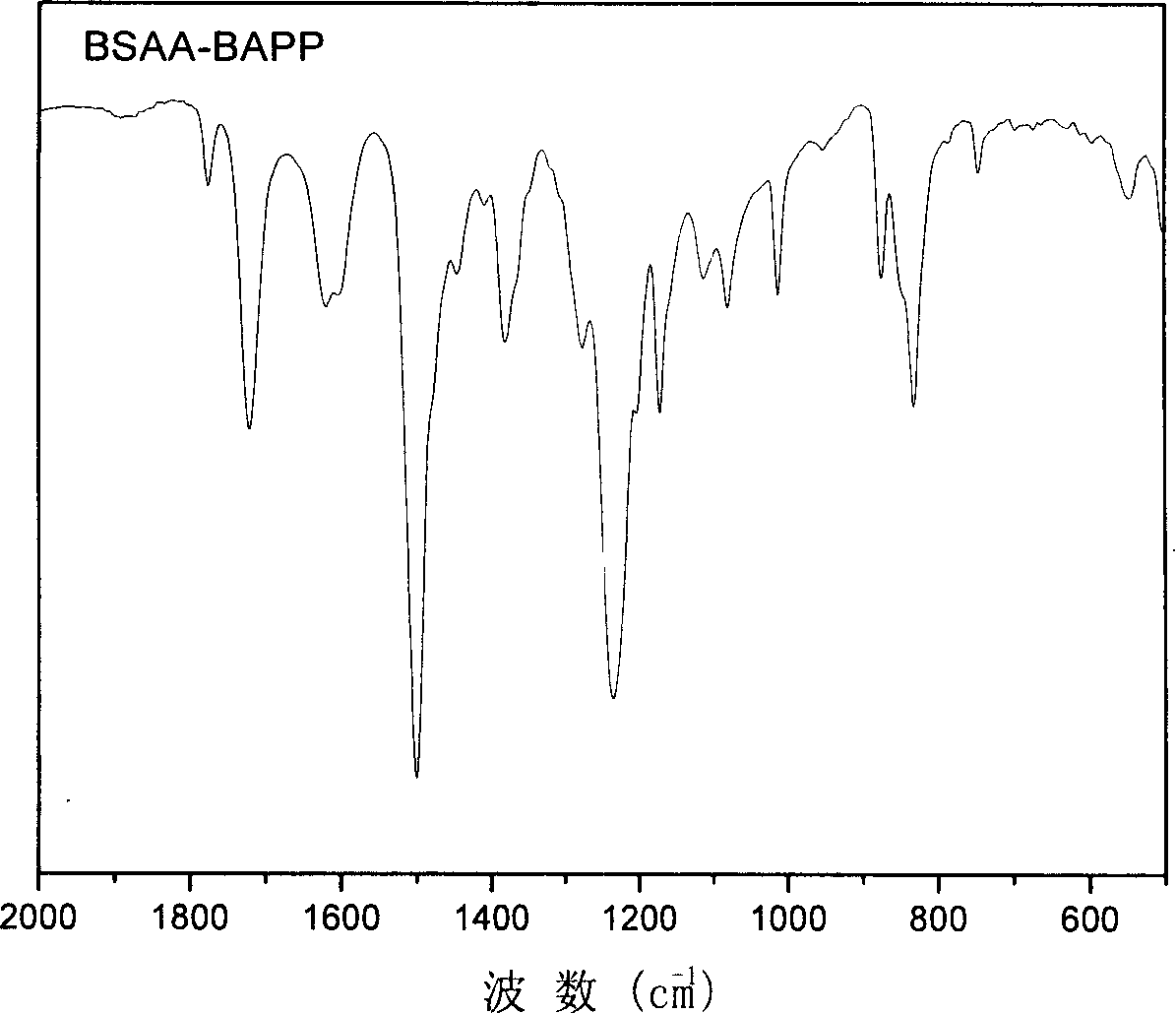

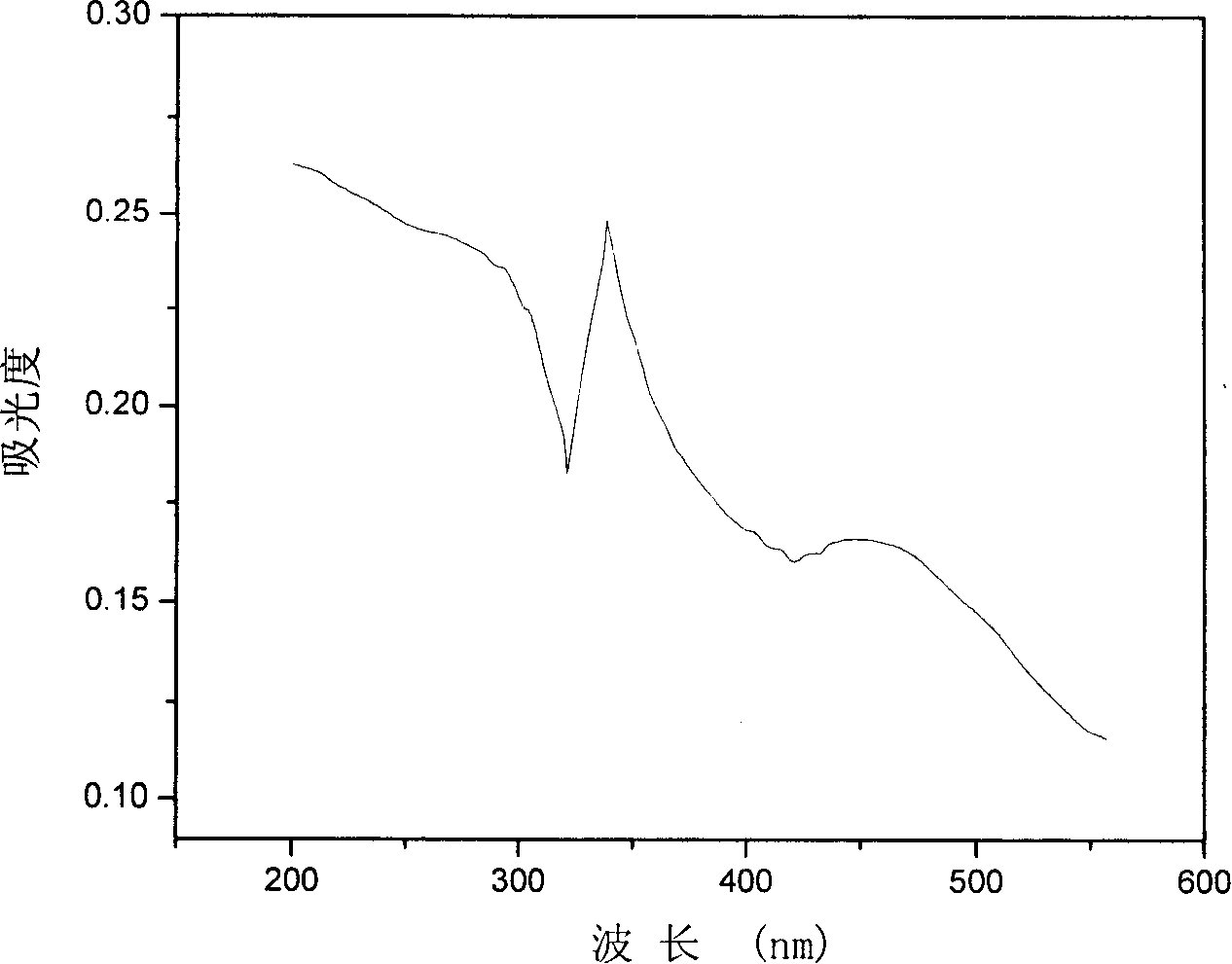

[0029] Put BSAA and BAPP on two copper heating boats respectively, and control the temperature of the two to 255°C and 225°C (at the same time) respectively through a transformer. The system vacuum is higher than 1×10 -3 Pa, while evaporating for 20-30 minutes, the prepolymer polyamic acid film of polyimide is polymerized and deposited on the substrate. Then put the polyamic acid film deposited on the substrate into a vacuum oven for heat treatment, the temperature is 250° C., the heat treatment time is 2 hours, and the vacuum degree is about 4 Pa. After heat tre...

Embodiment 2

[0040] The ratio of raw materials used is as follows:

[0041] 2,2'-bis(4-dicarboxyphenoxyphenyl)propane dianhydride (BSAA) 1.1 parts (number of moles)

[0042] 1 part of 4,4'-diaminodiphenyl ether (ODA) (number of moles)

[0043] Preparation of BSAA / ODA type PI membrane:

[0044] Put BSAA and ODA on two copper heating boats respectively, and control the temperature of both to 255°C and 160°C (at the same time) respectively through a transformer. The system vacuum is higher than 1×10 -3 Pa, while evaporating for 20-30 minutes, the prepolymer polyamic acid film of polyimide is polymerized and deposited on the substrate. Then put the polyamic acid film deposited on the substrate into a vacuum oven for heat treatment, the temperature is 250° C., the heat treatment time is 2 hours, and the vacuum degree is about 4 Pa. After heat treatment, a dehydration-cyclized BSAA / ODA polyimide film is obtained.

[0045] The performance measurement method and results of BSAA / ODA type PI fi...

Embodiment 3

[0047] The ratio of raw materials used is as follows:

[0048] 2,2'-bis(4-dicarboxyphenoxyphenyl)propane dianhydride (BSAA) 1.1 parts (number of moles)

[0049] 1 part of p-diaminodiphenylmethane (MDA) (number of moles)

[0050] Preparation of BSAA / MDA type PI membrane:

[0051] Put BSAA and MDA on two copper heating boats respectively, and control the temperature of the two to 255°C and 170°C (at the same time) respectively through a transformer. The system vacuum is higher than 1×10 -3 Pa, while evaporating for 20-30 minutes, the prepolymer polyamic acid film of polyimide is polymerized and deposited on the substrate. Then put the polyamic acid film deposited on the substrate into a vacuum oven for heat treatment, the temperature is 250° C., the heat treatment time is 2 hours, and the vacuum degree is about 4 Pa. After heat treatment, a dehydration-cyclized BSAA / MDA type polyimide film is obtained.

[0052] The performance measurement method and results of BSAA / MDA type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com