Film of polyimide containing color base group, and preparation method

A technology of polyimide film and chromophore, which is applied in the field of polyimide film containing chromophore and its preparation, can solve the problems of pores, difficulties in obtaining high-quality polyimide materials, and difficult volatilization And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The raw materials used are as follows:

[0024] Pyromellitic dianhydride (PMDA), a commercially available product.

[0025] 2,4-Diamino-4'-nitroazobenzene (DAB) was synthesized according to references (Balcerzak E.S., Sapich B., Stumpe J., Polymer, 2005, 46:49).

[0026] The ratio of raw materials used is as follows:

[0027] 1.1 parts of pyromellitic dianhydride (PMDA) (number of moles)

[0028] 1 part of 2,4'-diamino 4'-nitroazobenzene (DAB) (moles)

[0029] Preparation of PMDA-DAB type PI membrane:

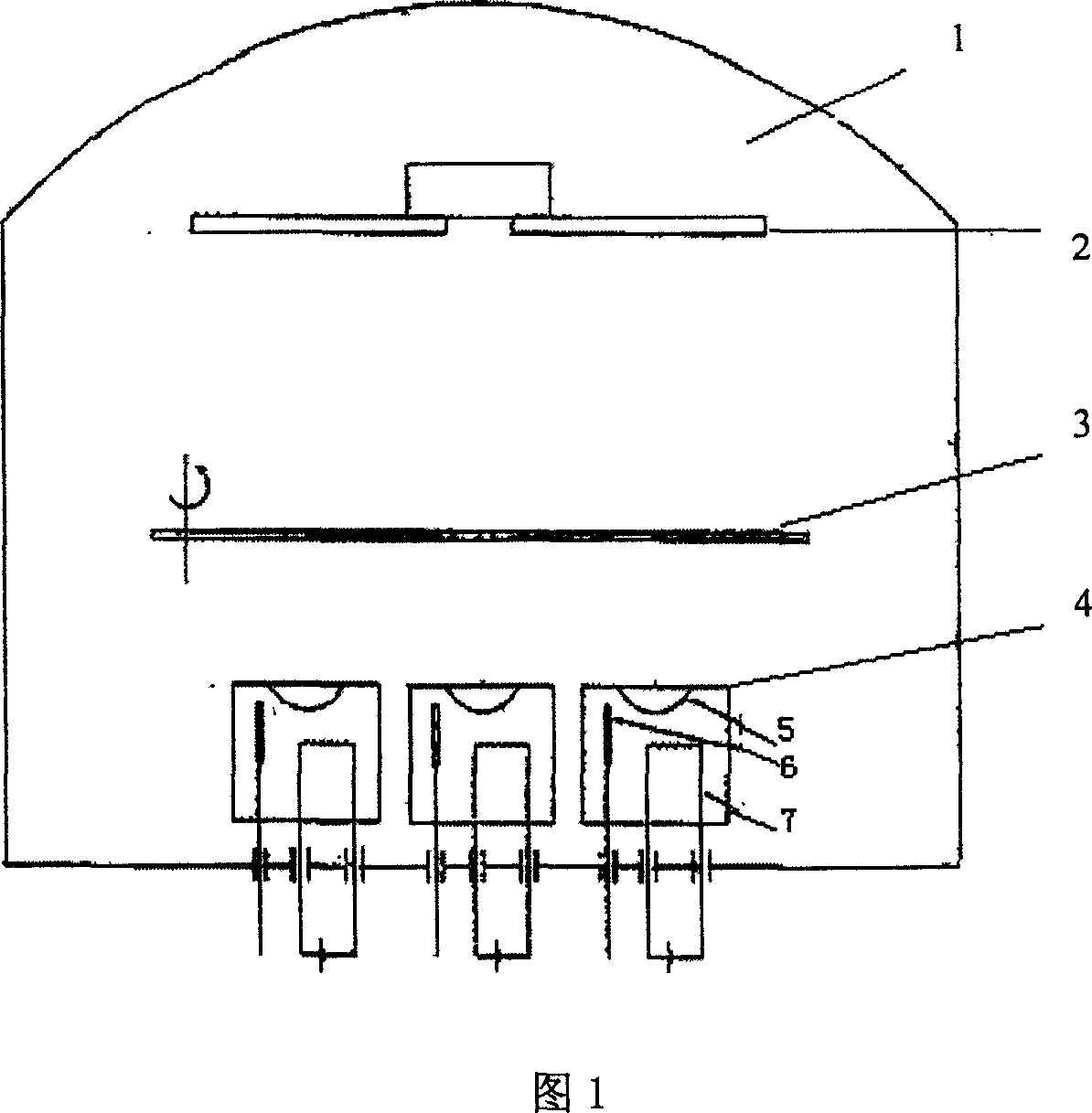

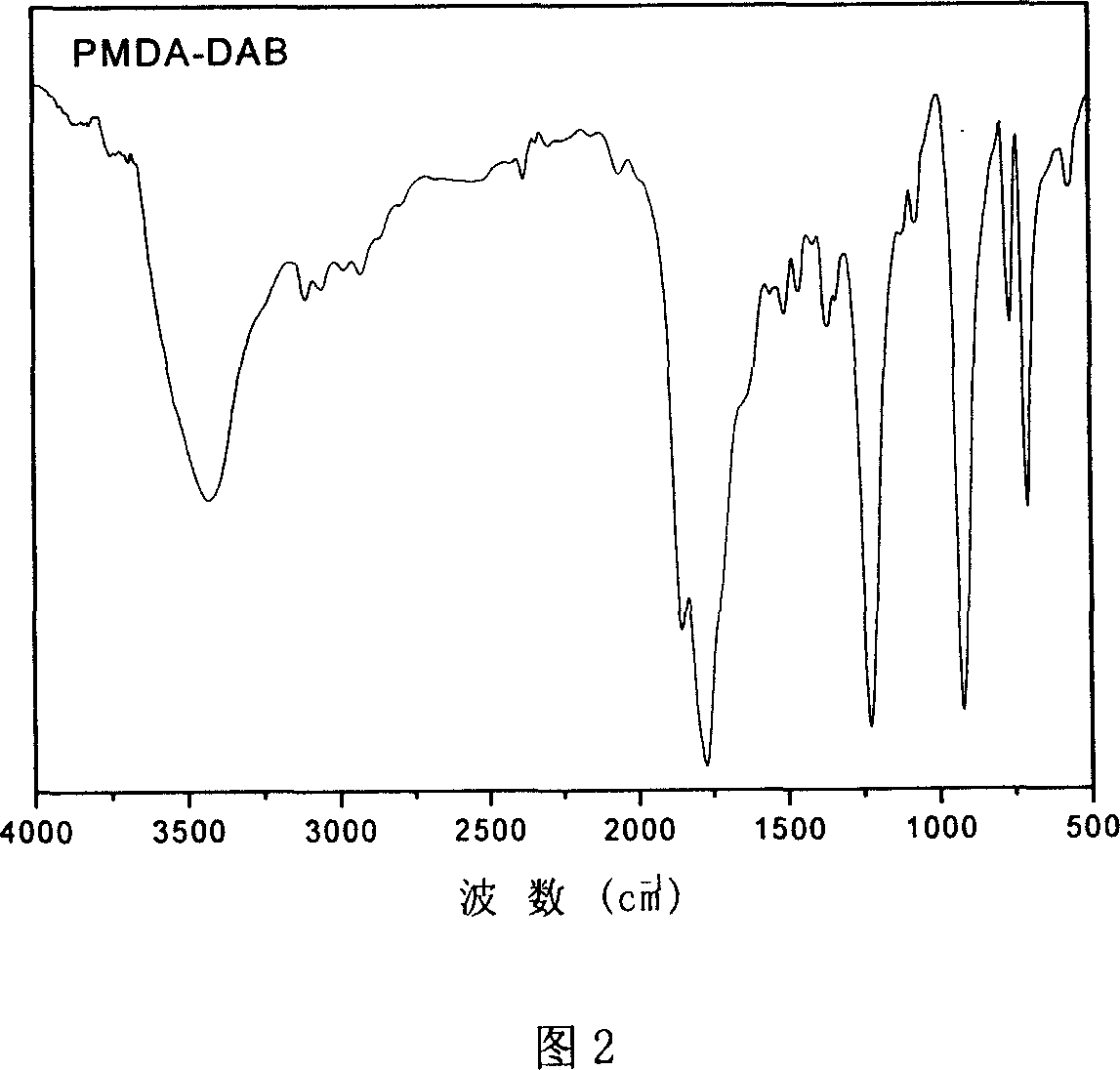

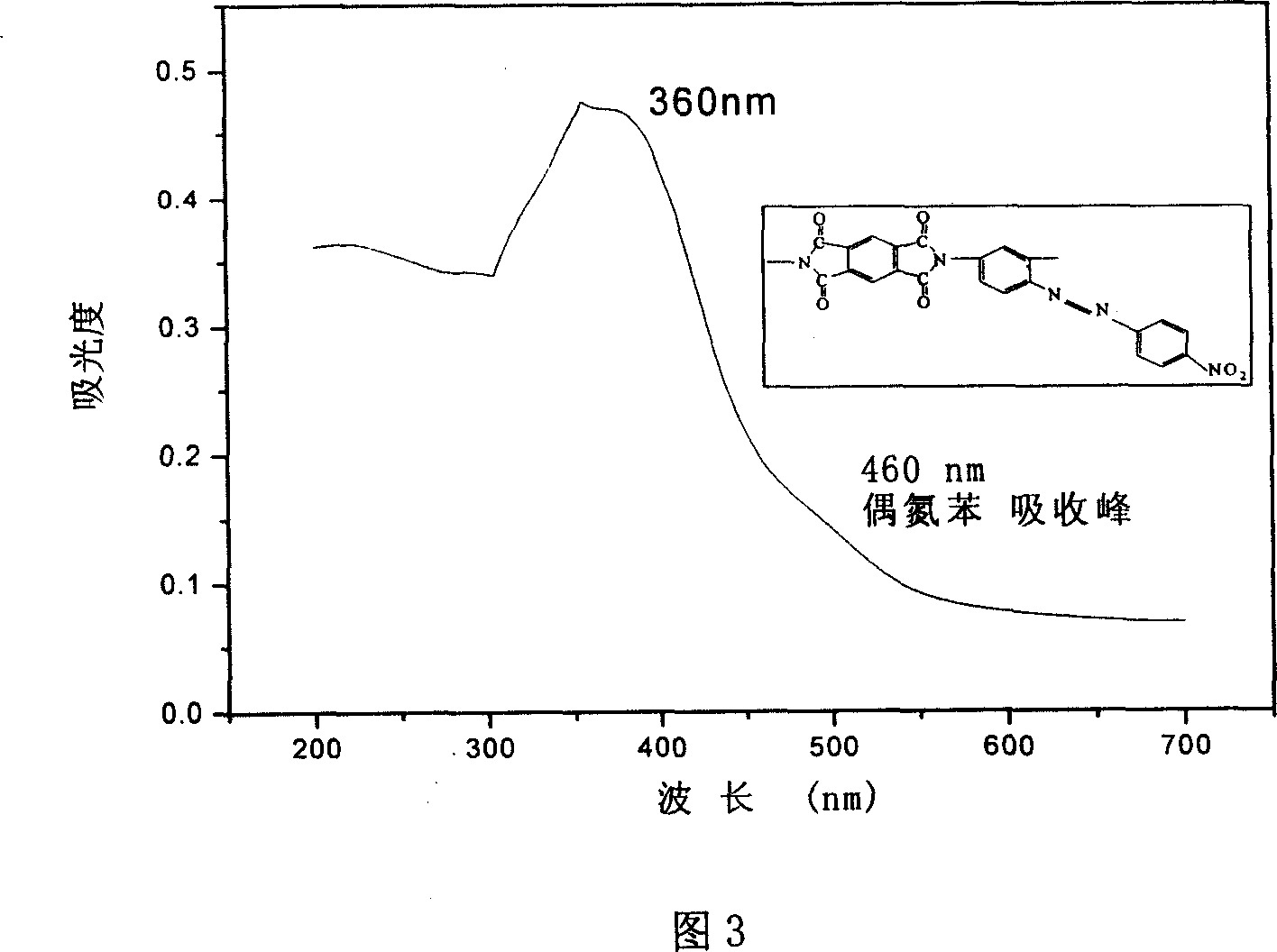

[0030] Put PMDA and DAB on two copper heating boats respectively, and control the temperature of the two to 170°C and 150°C (at the same time) respectively through the transformer. The system vacuum is higher than 1×10 -3 Pa, while evaporating for 20-30 minutes, the prepolymer polyamic acid film of polyimide is polymerized and deposited on the substrate. Then put the polyamic acid film deposited on the substrate into a vacuum oven for heat treatment, the temperatur...

Embodiment 2

[0037] The raw materials used are as follows:

[0038] 2,2'-bis(4-dicarboxyphenoxyphenyl)propane dianhydride (BSAA), a commercial product.

[0039] 2,4-Diamino-4'-nitroazobenzene (DAB), prepared as described in Example 1.

[0040] The ratio of raw materials used is as follows:

[0041] 2,2'-bis(4-dicarboxyphenoxyphenyl)propane dianhydride (BSAA) 1.1 parts (number of moles)

[0042] 2,4-diamino-4'-nitroazobenzene (DAB) 0.9 parts (moles)

[0043] Preparation of BSAA-DAB-PI membrane:

[0044] Put BSAA and DAB on two copper heating boats respectively, and control the temperature of the two to 255°C and 150°C (at the same time) respectively through a transformer. The system vacuum is higher than 1×10 -3Pa, while evaporating for 20-30 minutes, the prepolymer polyamic acid film of polyimide is polymerized and deposited on the substrate. Then put the polyamic acid film deposited on the substrate into a vacuum oven for heat treatment, the temperature is 250° C., the heat treatmen...

Embodiment 3

[0047] The raw materials used are as follows:

[0048] 3,3',4,4'-Biphenyltetracarboxylic dianhydride (BPDA), a commercially available product.

[0049] 2,4-Diamino-4'-nitroazobenzene (DAB), prepared as described in Example 1.

[0050] The ratio of raw materials used is as follows:

[0051] 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) 1.1 parts (moles)

[0052] 2,4-diamino-4'-nitroazobenzene (DAB) 0.8 parts (moles)

[0053] Preparation of BPDA-DAB type PI membrane:

[0054] Put BPDA and DAB on two copper heating boats respectively, and control the temperature of the two to 260°C and 150°C (at the same time) respectively through the transformer. The system vacuum is higher than 1×10 -3 Pa, while evaporating for 20-30 minutes, the prepolymer polyamic acid film of polyimide is polymerized and deposited on the substrate. Then put the polyamic acid film deposited on the substrate into a vacuum oven for heat treatment, the temperature is 200°C, the heat treatment time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com