Method for preparing poly-p-xylylene nano fibers through chemical vapor deposition

A chemical vapor deposition, parylene technology, applied in the field of materials, achieves the effects of simple reaction conditions, avoidance of by-products, and controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

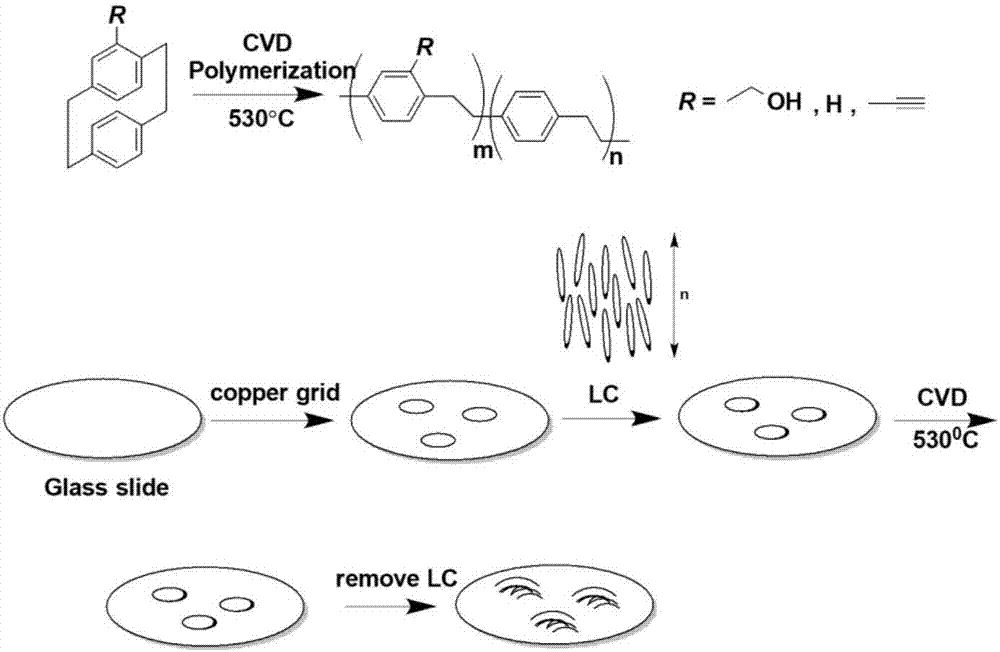

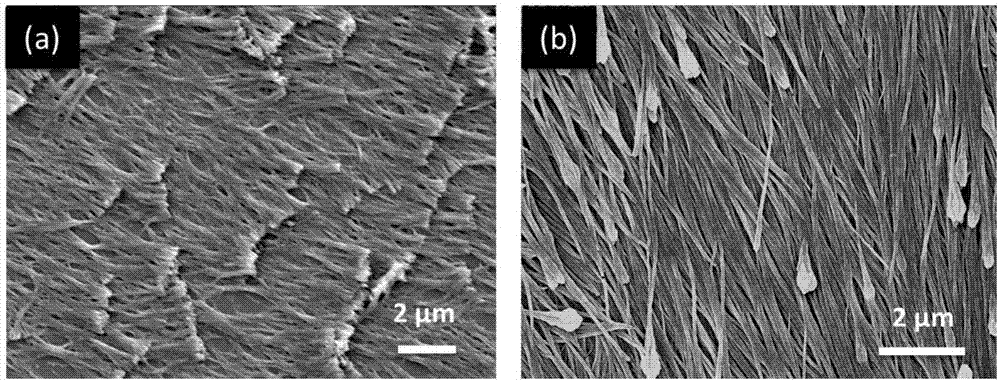

[0027] Preparation of parylene nanofibers: The glass sheet and copper mesh were ultrasonically treated with absolute ethanol to remove surface impurities. Then, the cleaned glass sheet is treated with a silane coupling reagent for a period of time and then used for later use. Place the nematic liquid crystal on a glass plate with a copper grid, and use a 10 μl micro-syringe to take 7 μl of liquid crystal on the copper grid. Place the prepared glass slide on the sample stage of the deposition chamber. The precursor of CVD reaction is 10g p-xylene dimer. Raise the temperature of the cracking chamber to the target temperature of 530°C, while keeping the system at a relatively low vacuum. After the temperature of the deposition area reaches the set temperature, increase the vacuum. When it reaches 0.08 Torr, at a certain deposition rate Perform CVD polymerization. The active free radicals cracked by CVD grow along the gaps between liquid crystal molecules. After the CVD, the C...

Embodiment 2

[0029] Preparation of parylene nanofibers (other steps are the same as in Example 1): 10g of p-xylene dimer is placed in the CVD sublimation zone, the cracking temperature is 550°C, and the deposition rate is The sample stage temperature was 0 °C. CVD polymerization was performed on nematic liquid crystal E7. After soaking with absolute ethanol, the nanofibers were obtained after drying.

Embodiment 3

[0031] Preparation of parylene nanofibers (other steps are the same as in Example 1): 10 g of 4-hydroxymethyl-p-xylylene dimer is placed in the CVD sublimation zone, the cracking temperature is 500 ° C, and the deposition rate is The sample stage temperature was -10°C. CVD polymerization was performed on nematic liquid crystal E7. After soaking with hexane, the nanofibers were obtained after drying.

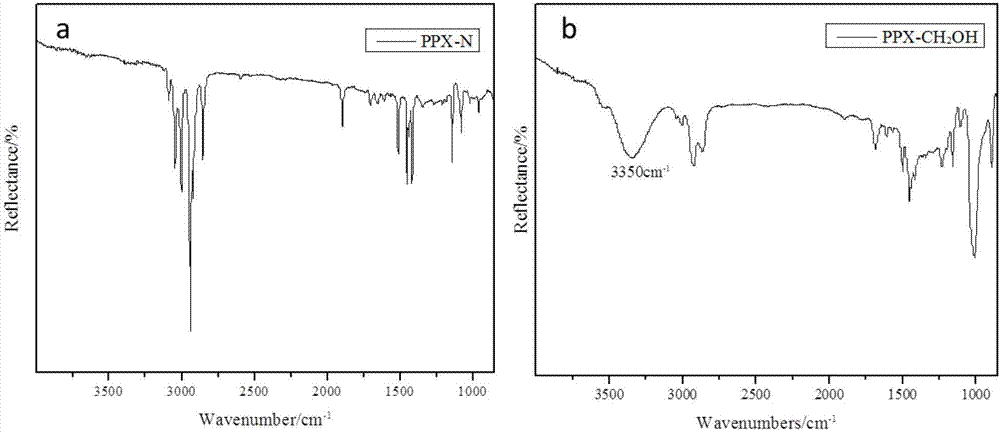

[0032] like figure 2 As shown, a and b represent PPX-N nanofibers and PPX-CH 2 OH nanofibers. It can be seen from the figure that the PPX-N nanofibers at 3100cm -1 Left and right and 1650~1450cm -1 This is the characteristic absorption peak of PPX benzene ring. 2922cm -1 and 2855cm -1 is the stretching vibration absorption peak of methylene, and PPX-CH 2 In addition to the characteristic peaks of PPX-N in the infrared characteristic peaks of OH nanofibers, at 3350cm -1 The -OH characteristic absorption peak appeared at , which indicated that parylene nanofibers could ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com