Method for preparing amorphous carbon nano tube and SBA-15 mesoporous molecular sieve from attapulgite clay as template and raw material

A technology of attapulgite clay and mesoporous molecular sieve, which is applied in the directions of carbon nanotubes, molecular sieve compounds, chemical instruments and methods, etc., can solve the problems of HF toxicity, corrosiveness, environmental pollution, and the inability of silicon components to be effectively utilized, etc. Effective utilization and reduction of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

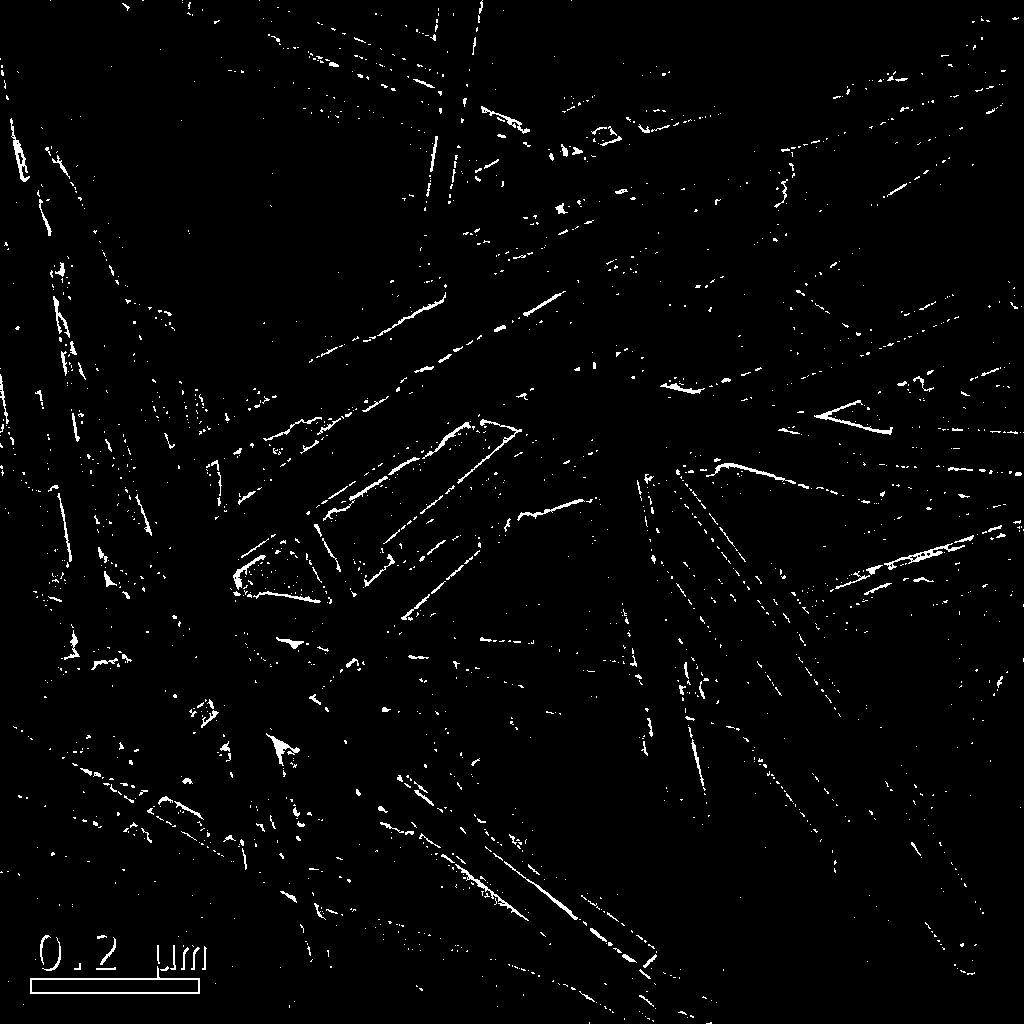

[0015] Embodiment 1: Prepare amorphous carbon nanotubes and SBA-15 mesoporous molecular sieves according to the following steps

[0016] (1) Add 10g of attapulgite clay to 50mL of 3mol / L hydrochloric acid solution, transfer it to a reaction kettle lined with polytetrafluoroethylene, treat at 180°C for 18h, suction filter, wash with water, and dry to obtain acidified attapulgite clay , then put 1.5g of acidified attapulgite clay on a polytetrafluoroethylene tray and place it in a reaction kettle, pre-add 1.5g of furfuryl alcohol into the kettle, seal it and treat it at 130°C for 6h, take it out and put it in a porcelain crucible, and put it in a protective N in the atmosphere furnace 2 Carbonization at 800°C for 2 hours under protection to obtain C-attapulgite clay composite material;

[0017] (2) Add the obtained C-attapulgite clay composite material into 24mL1.8mol / L NaOH solution, stir evenly, then transfer to a reaction kettle, seal and treat at 180°C for 18h, and filter w...

Embodiment 2

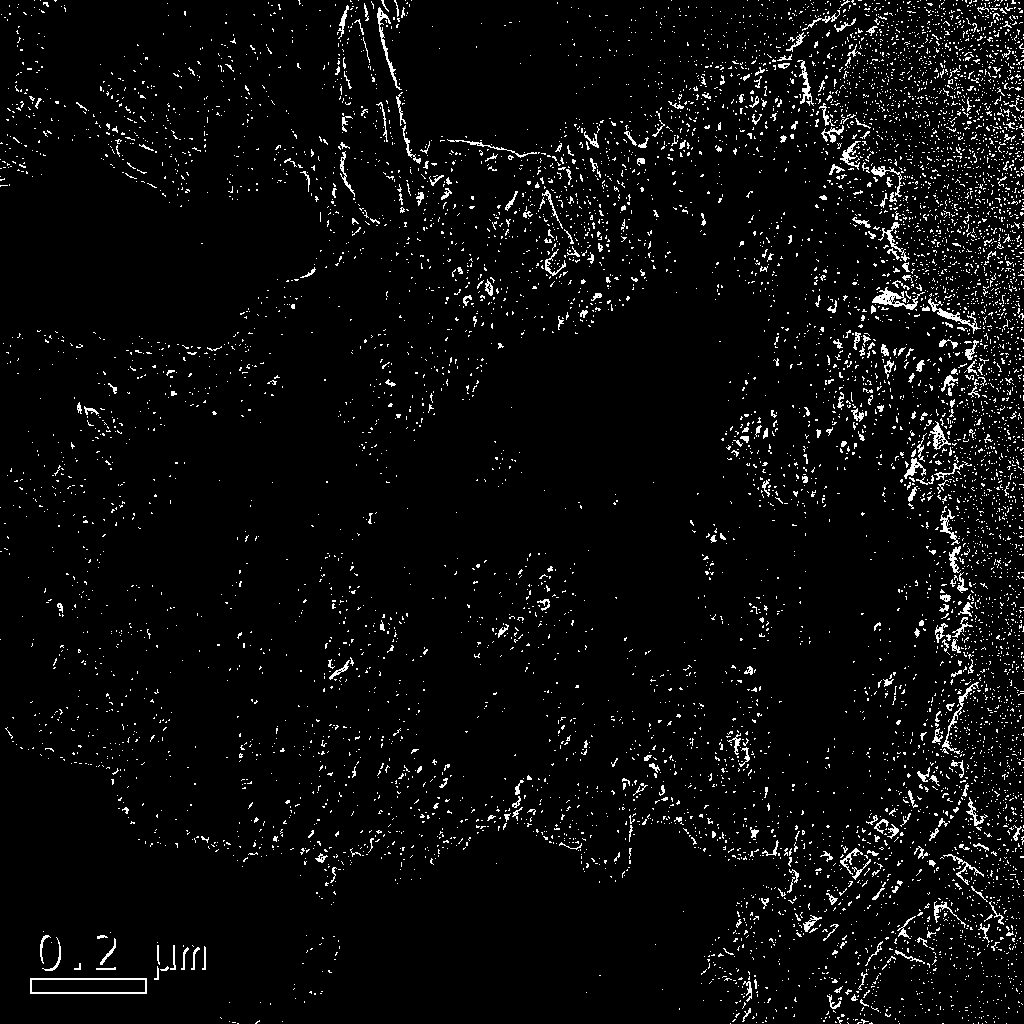

[0019] Embodiment 2: Prepare amorphous carbon nanotubes and SBA-15 mesoporous molecular sieves according to the following steps

[0020] (1) Add 10g of attapulgite clay to 40mL of 4mol / L hydrochloric acid solution, transfer it to a reaction kettle lined with polytetrafluoroethylene, treat at 180°C for 15h, filter with suction, wash with water, and dry to obtain acidified attapulgite clay , then put 1.5g of acidified attapulgite clay on a polytetrafluoroethylene tray and place it in a reaction kettle, add 1.5g of furfuryl alcohol to the kettle, treat it at 130°C for 4.5h after sealing, take it out and put it in a porcelain crucible, Protective atmosphere furnace N 2 Carbonization at 700°C for 3 hours under protection to obtain C-attapulgite clay composite material;

[0021] (2) Add the obtained C-attapulgite clay composite material into 24mL2mol / L NaOH solution, stir evenly, then transfer it to a reaction kettle, seal it and treat it at 180°C for 15h, and filter it with suctio...

Embodiment 3

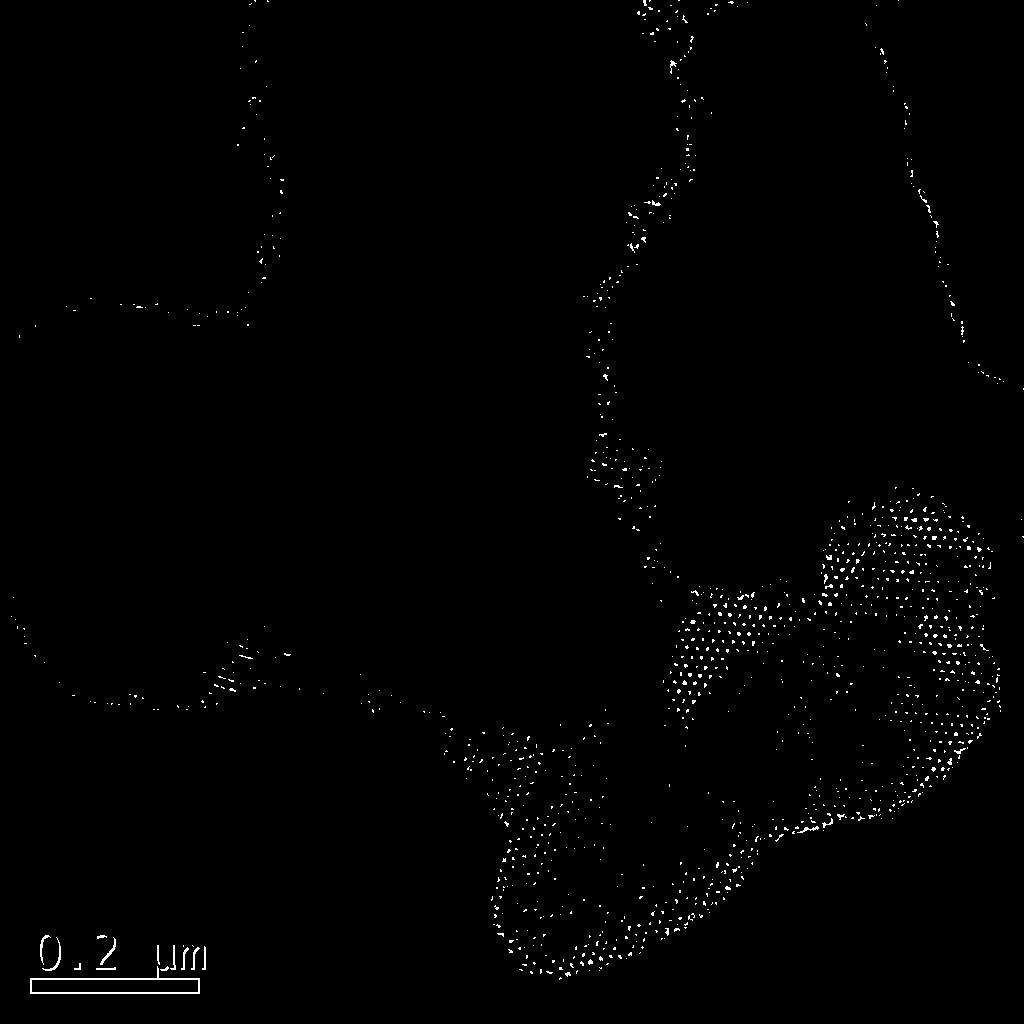

[0023] Embodiment 3: Prepare amorphous carbon nanotubes and SBA-15 mesoporous molecular sieves according to the following steps

[0024] (1) Add 10g of attapulgite clay to 30mL of 5mol / L hydrochloric acid solution, transfer it to a reaction kettle lined with polytetrafluoroethylene, treat at 180°C for 12h, suction filter, wash with water, and dry to obtain acidified attapulgite clay , then put 1.5g of acidified attapulgite clay on a polytetrafluoroethylene tray, place it in a reaction kettle, pre-add 1.5g of furfuryl alcohol into the kettle, seal it and treat it at 130°C for 3h, take it out and put it in a porcelain crucible, and put it in a protective N in the atmosphere furnace 2 Carbonization at 600°C for 4 hours under protection to obtain C-attapulgite clay composite material;

[0025] (2) Add the obtained C-attapulgite clay composite material into 24mL2.2mol / L NaOH solution, stir evenly, then transfer to the reaction kettle, seal and treat at 180°C for 12h, and filter wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com