Method for preparing poly(N-2-carboxyethyl pyrrole)-anodic aluminum oxide composite membrane

A technology of anodized aluminum and carboxyethylpyrrole, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve good electrical conductivity and biocompatibility, wide application, and simple preparation methods

Inactive Publication Date: 2011-06-15

XIAMEN UNIV

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these three affinity composite films all use natural polymers to modify the anodized aluminum film, and the method of using artificially synthesized polymer materials to modify the anodized aluminum film has not been reported yet.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

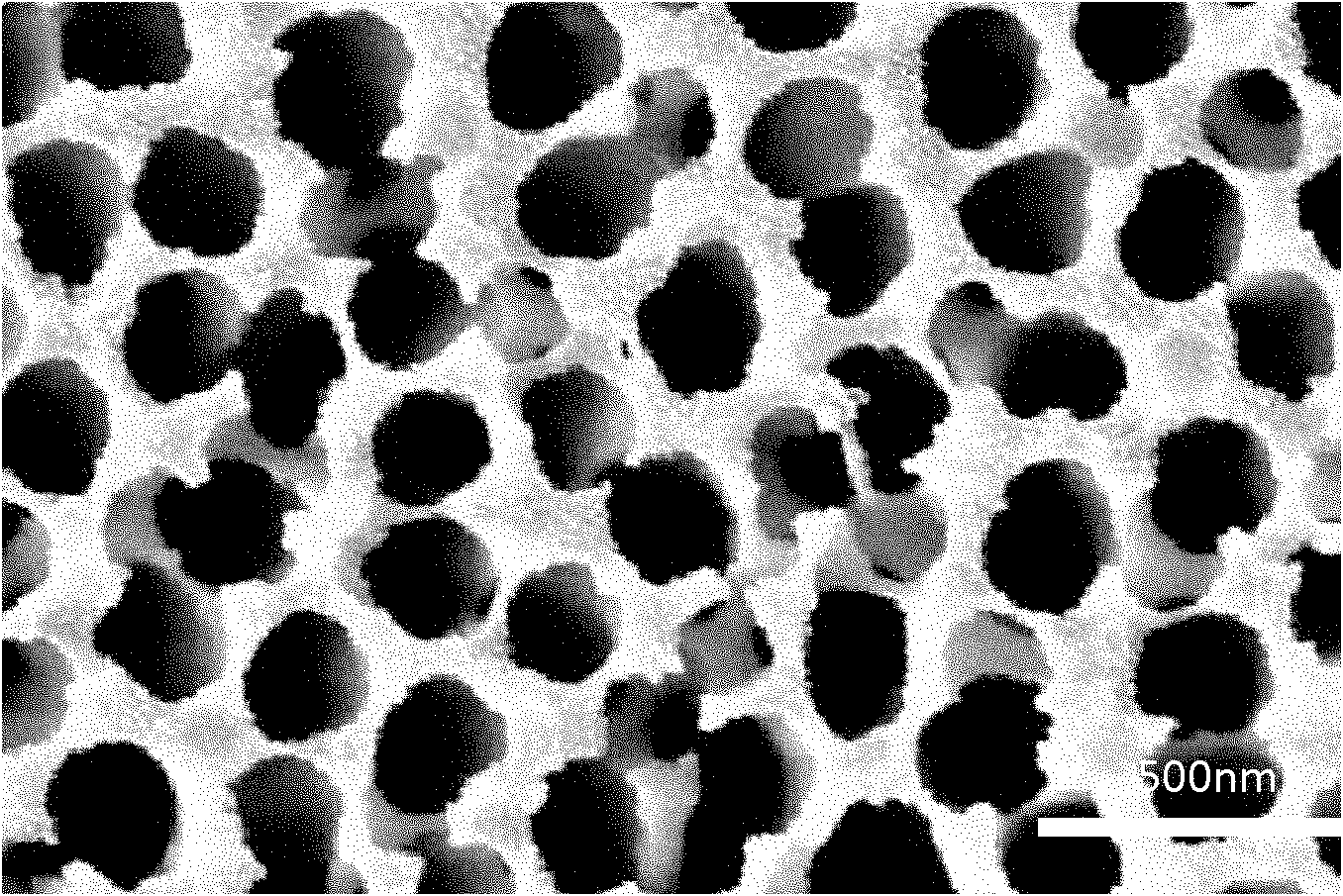

Login to View More Abstract

The invention discloses a method for preparing a poly(N-2-carboxyethyl pyrrole)-anodic aluminum oxide composite membrane, relates to a composite membrane preparation technique and provides a method for preparing a poly(N-2-carboxyethyl pyrrole)-anodic aluminum oxide composite membrane with high hydrophily and high biocompatibility. The method comprises the following steps: placing a pretreated anodic aluminum oxide membrane and a N-2-carboxyethyl pyrrole monomer in a vapor phase deposition polymerization device, vacuumizing the vapor phase deposition polymerization device and performing a vapor phase deposition polymerization reaction; and after the reaction is accomplished, cooling, and removing impurities to obtain the poly(N-2-carboxyethyl pyrrole)-anodic aluminum oxide composite membrane. The prepared poly(N-2-carboxyethyl pyrrole)-anodic aluminum oxide composite membrane covers the oxide layer on the anodic aluminum oxide membrane, and lowers the non-specific absorption of the anodic aluminum oxide membrane. The preparation method is simple, and can be widely used in affinity separation.

Description

Preparation method of poly N-2-carboxyethylpyrrole-anodized aluminum composite film technical field The invention relates to a composite membrane preparation technology, in particular to a preparation method of a poly N-2-carboxyethylpyrrole-anodized aluminum oxide composite membrane. Background technique Traditional separation methods, such as precipitation, crystallization, chromatography, etc., can improve the purity of the product, but there are problems such as cumbersome process and low activity recovery rate. Affinity membrane chromatography has the technical advantages of high selectivity, high yield, and high-purity products in one step, and has become one of the most effective technologies for protein purification. The separation efficiency of the affinity membrane mainly depends on the performance of the membrane material, and the commonly used affinity membrane material is mainly an organic membrane material. Natural polymer materials such as cellulose and pol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D69/12

Inventor 石巍涂晶姜海容葛东涛

Owner XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com