Anhydrous carbon dioxide absorbent and method for absorbing/desorbing carbon dioxide

A carbon dioxide and absorbent technology, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problem that solid materials are difficult to recycle in continuous flow, inconvenient for large-scale, continuous operation, and heat integration systems cannot be efficient Land use and other issues, to achieve the effect of good carbon dioxide selectivity, high carbon dioxide absorption, and low regeneration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

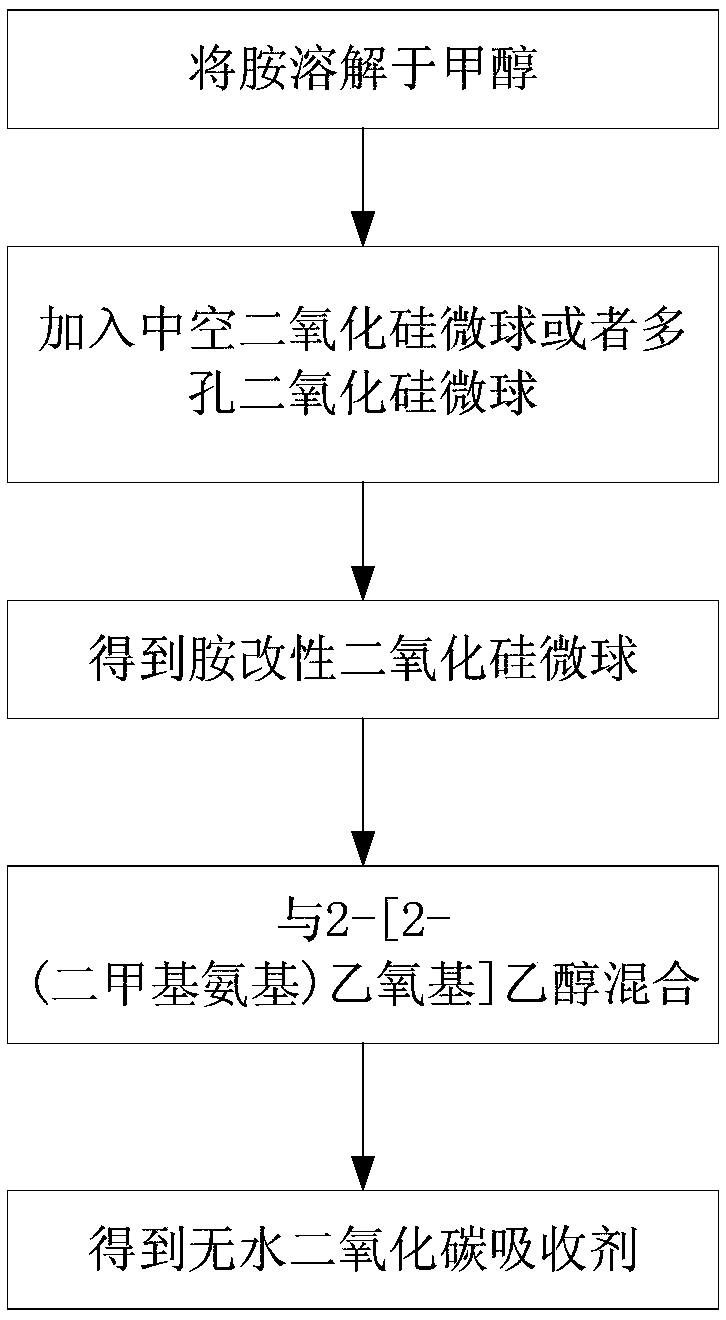

[0029] A preparation method of anhydrous carbon dioxide absorbent, comprising the following steps:

[0030] A. Dissolve the amine in methanol and stir until completely dissolved to obtain a mixed solution;

[0031] B. Add hollow silica microspheres or porous silica microspheres to the mixed solution obtained in step A, continue to stir and react for 2 to 8 hours, and vacuum dry after the reaction to obtain amine-modified silica microspheres ;

[0032] C, mixing amine-modified silica microspheres with 2-[2-(dimethylamino)ethoxyl]ethanol to obtain amine-modified silica microsphere emulsion-like anhydrous carbon dioxide absorbent; amine-modified The mass fraction range of the silicon dioxide microspheres in the absorbent is 5wt%-40wt%.

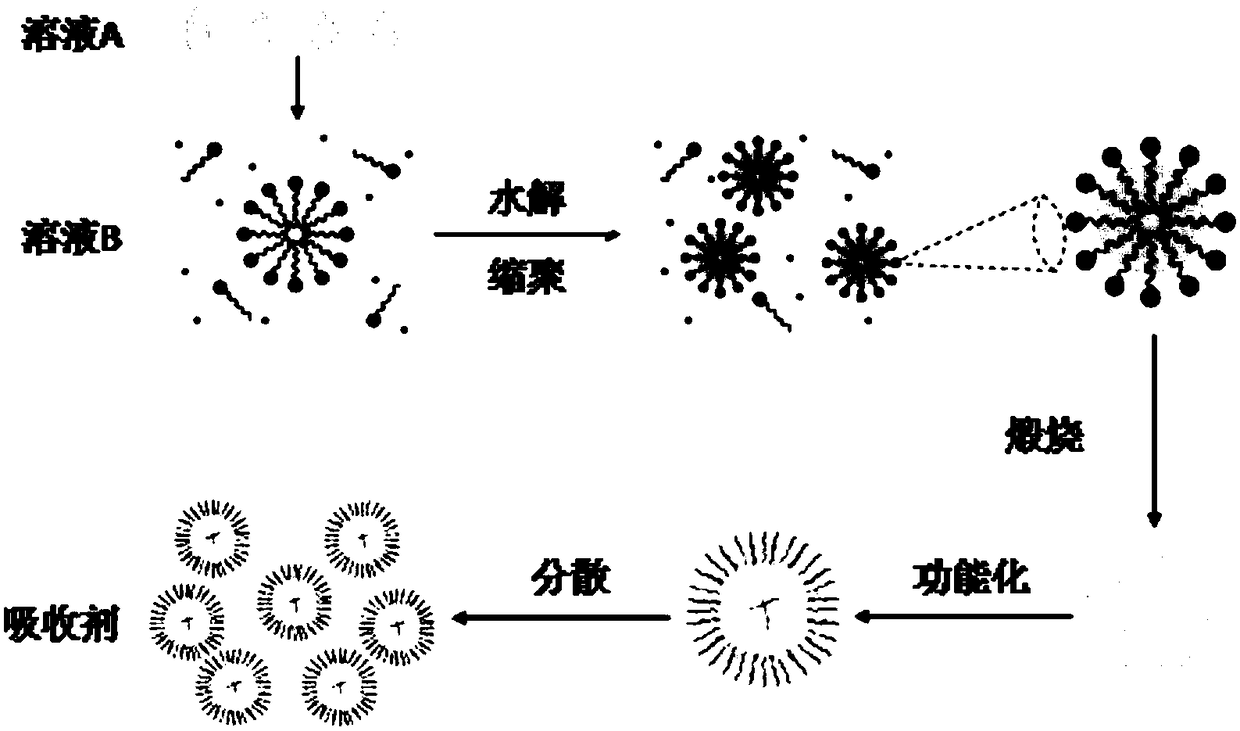

[0033] In a specific embodiment, the hollow silica microspheres are prepared according to the following steps: adding polystyrene (PS) powder to a mixed solution of ethanol and water and ultrasonically dispersing for 0.5-1.5 hours, and then dis...

Embodiment 1

[0042] A. As a comparison, weigh about 10 mg of amine-modified porous silica microspheres and put them in a physical absorption instrument to measure the absorption of polyethyleneimine-modified porous silica microspheres.

[0043] B. As a comparison, weigh about 5g of pure liquid phase absorbent 2-[2-(dimethylamino)ethoxy]ethanol and place it in the absorption kettle, turn on the vacuum pump to evacuate the system, and when the absorption system remains in a vacuum state , close the absorption system, pass carbon dioxide into the absorption tank for absorption, and obtain the carbon dioxide of the absorbent by measuring the pressure of the absorption system at different times, and the absorption reaches equilibrium when the pressure of the absorption system remains unchanged within 30 minutes.

[0044] C. Take by weighing about 5g of the absorbent of the present invention and place it in the absorption kettle. The absorbent of the invention adopts amine-modified porous silica ...

Embodiment 2

[0048] Weigh about 5 g of polyethyleneimine modified absorbent PEI (600), diethylenetriamine modified absorbent DETA and ionic liquid modified absorbent respectively for carbon dioxide absorption. The carbon dioxide absorption capacity of sexual absorbent, diethylenetriamine modified absorbent and ionic liquid modified absorbent is 0.5067mmol / g, 0.8875mmol / g and 0.4534mmol / g respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com