Patents

Literature

71results about How to "Lower capture costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reversible solid adsorption method and system utilizing waste heat for on-board recovery and storage of co2 from motor vehicle internal combustion engine exhaust gases

ActiveUS20130298532A1Emission reductionModerate temperatureGas treatmentCarbon compoundsOn boardAtmospheric air

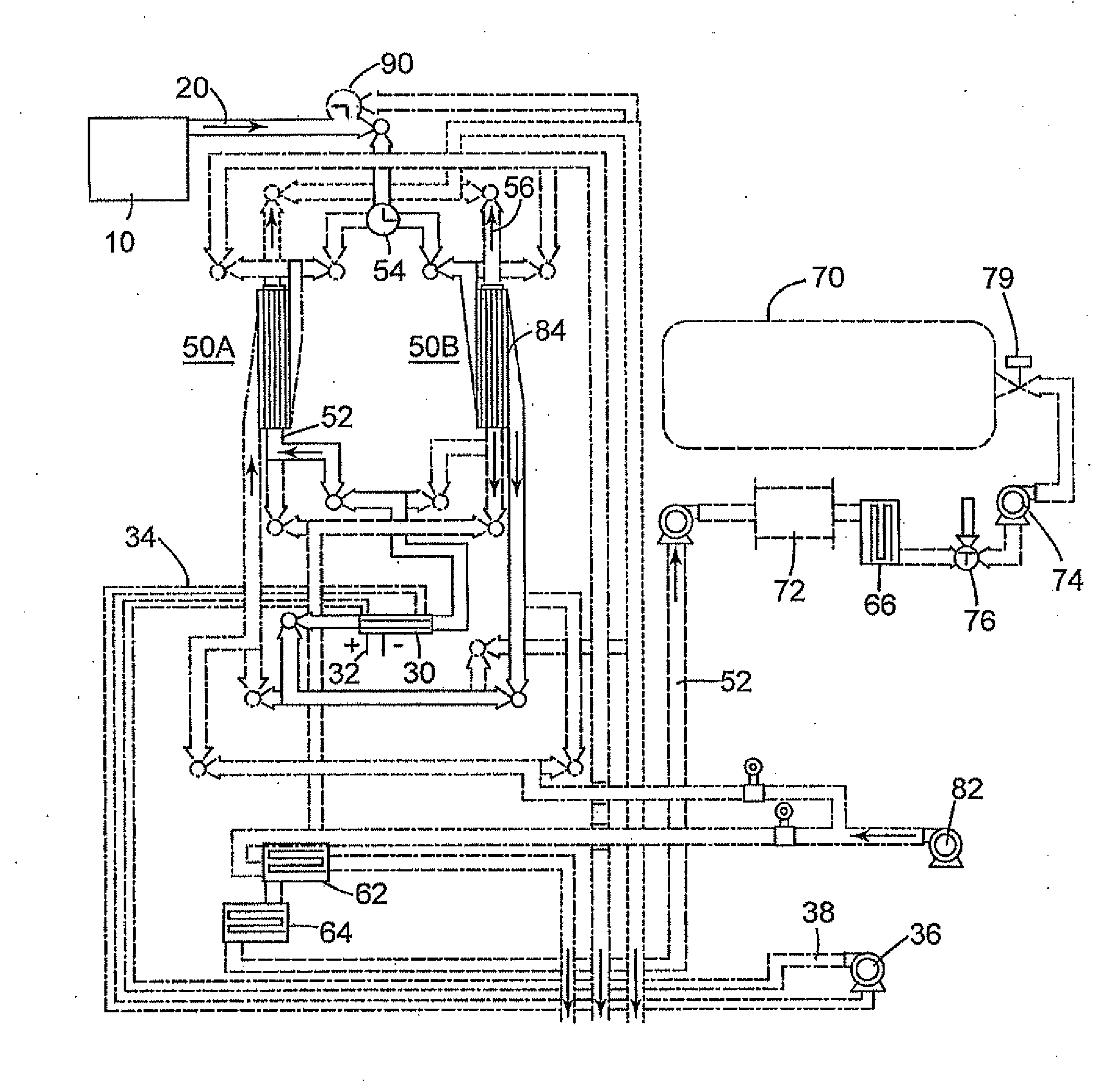

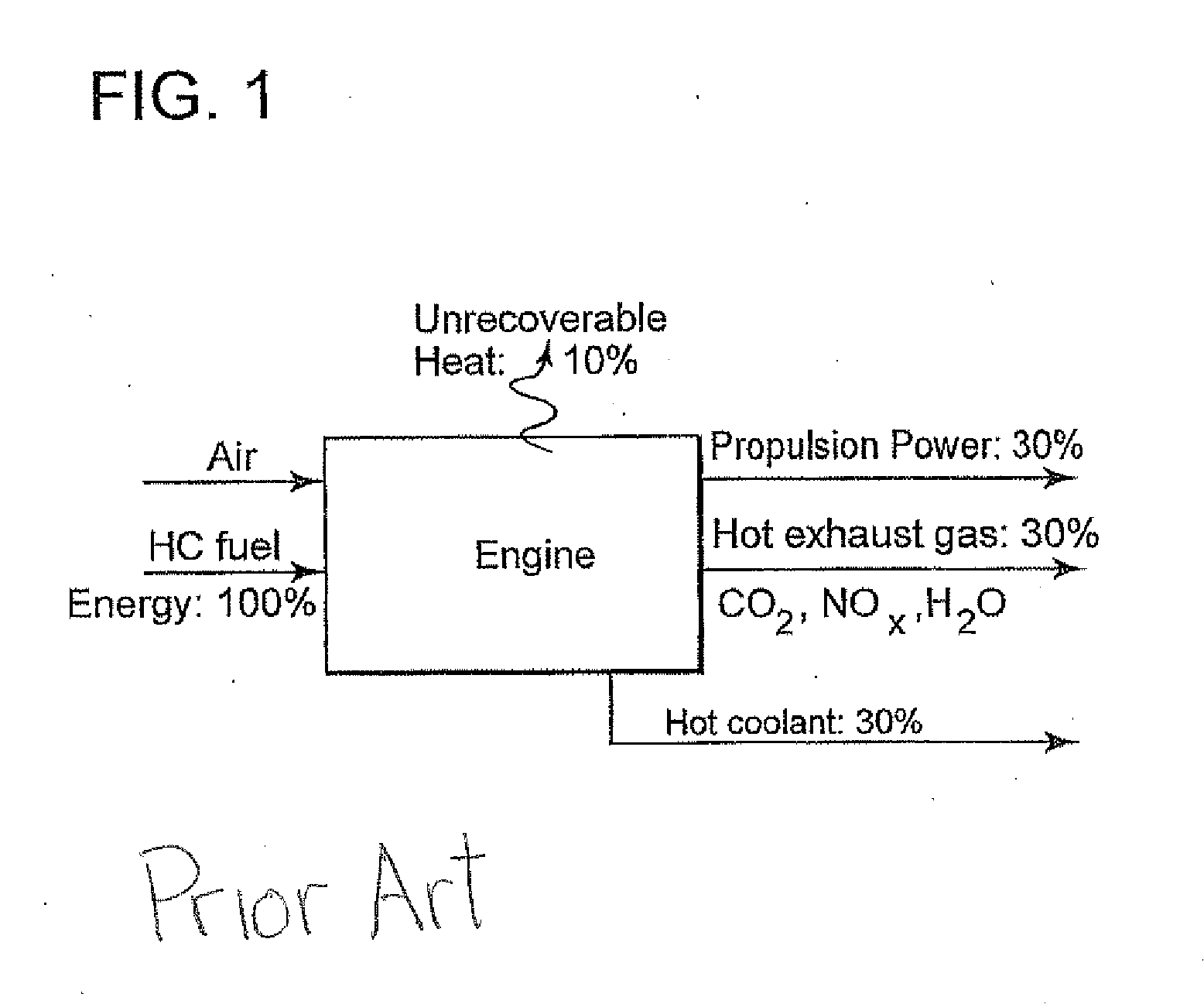

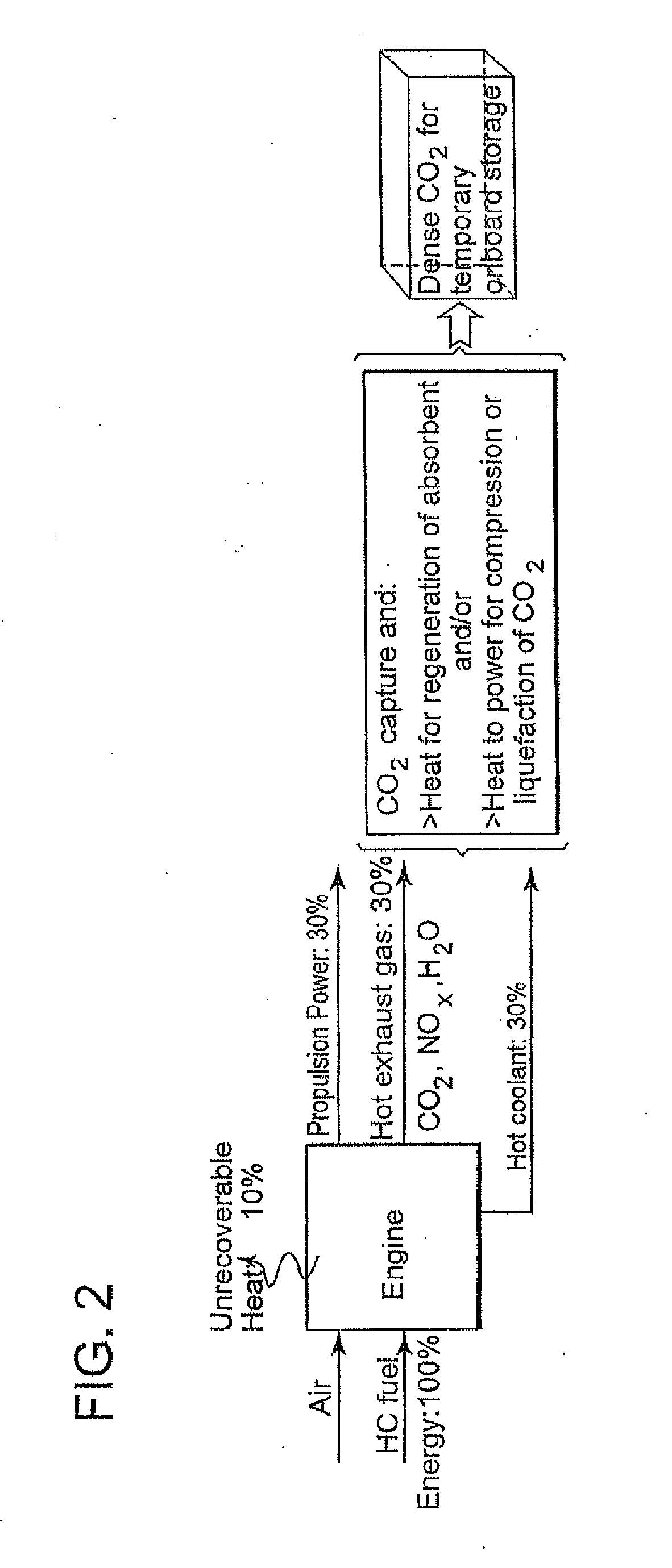

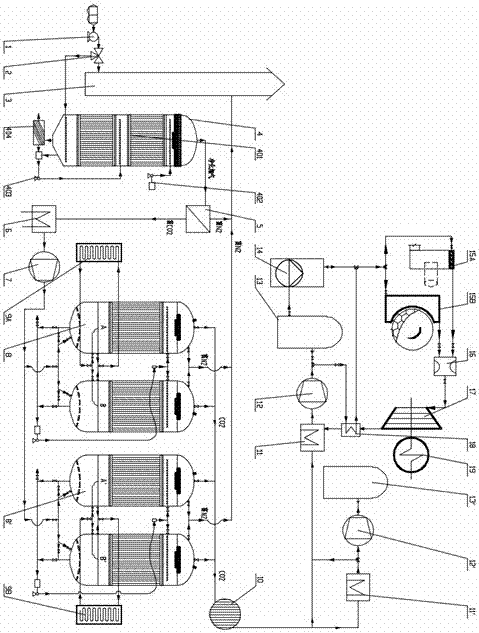

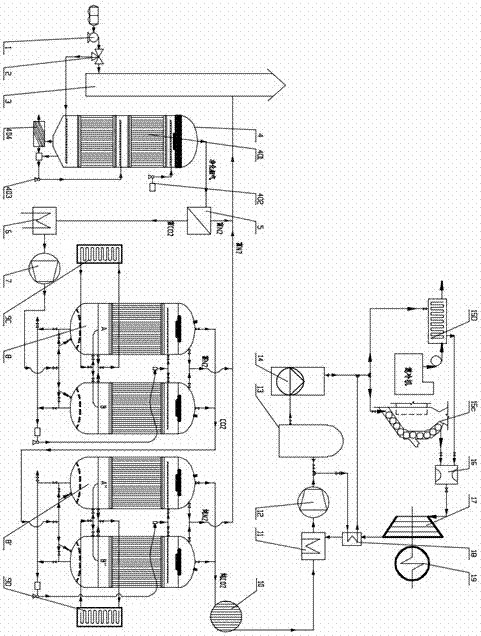

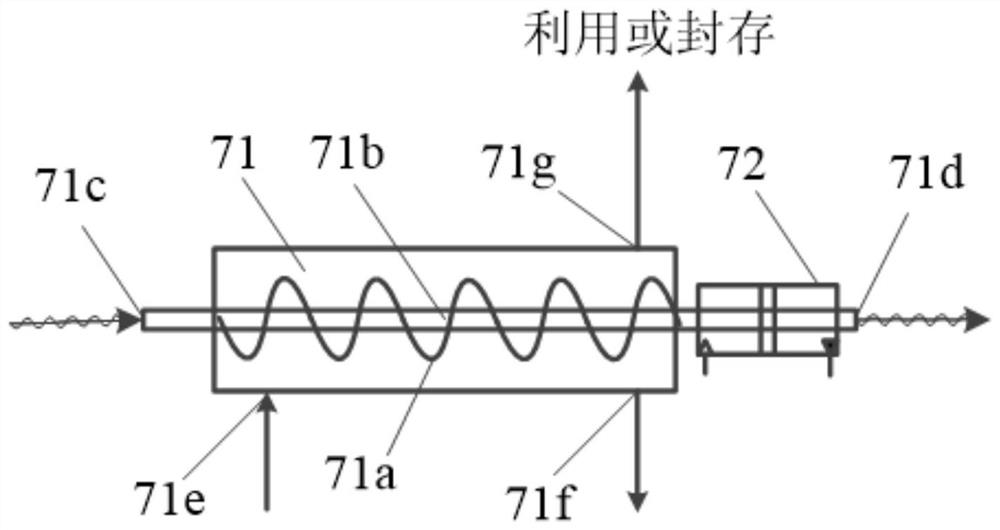

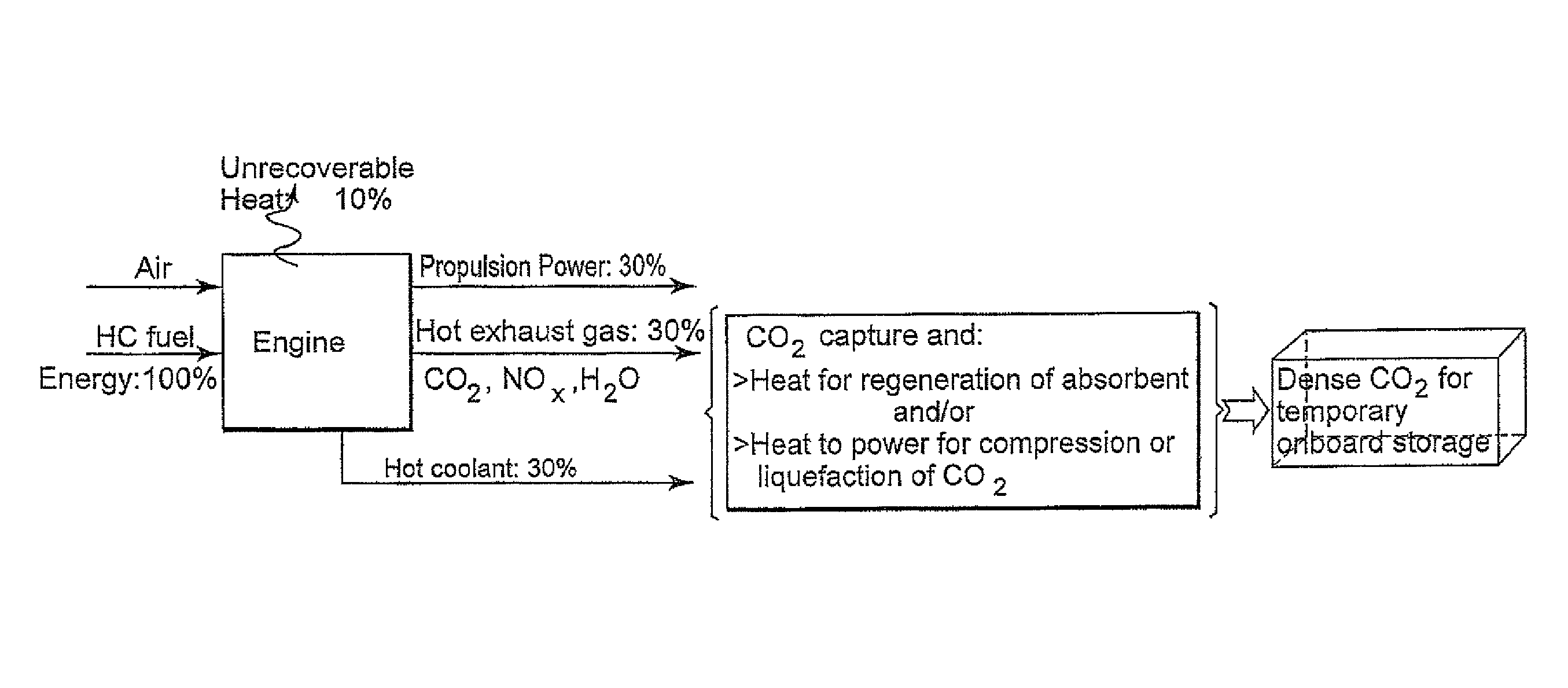

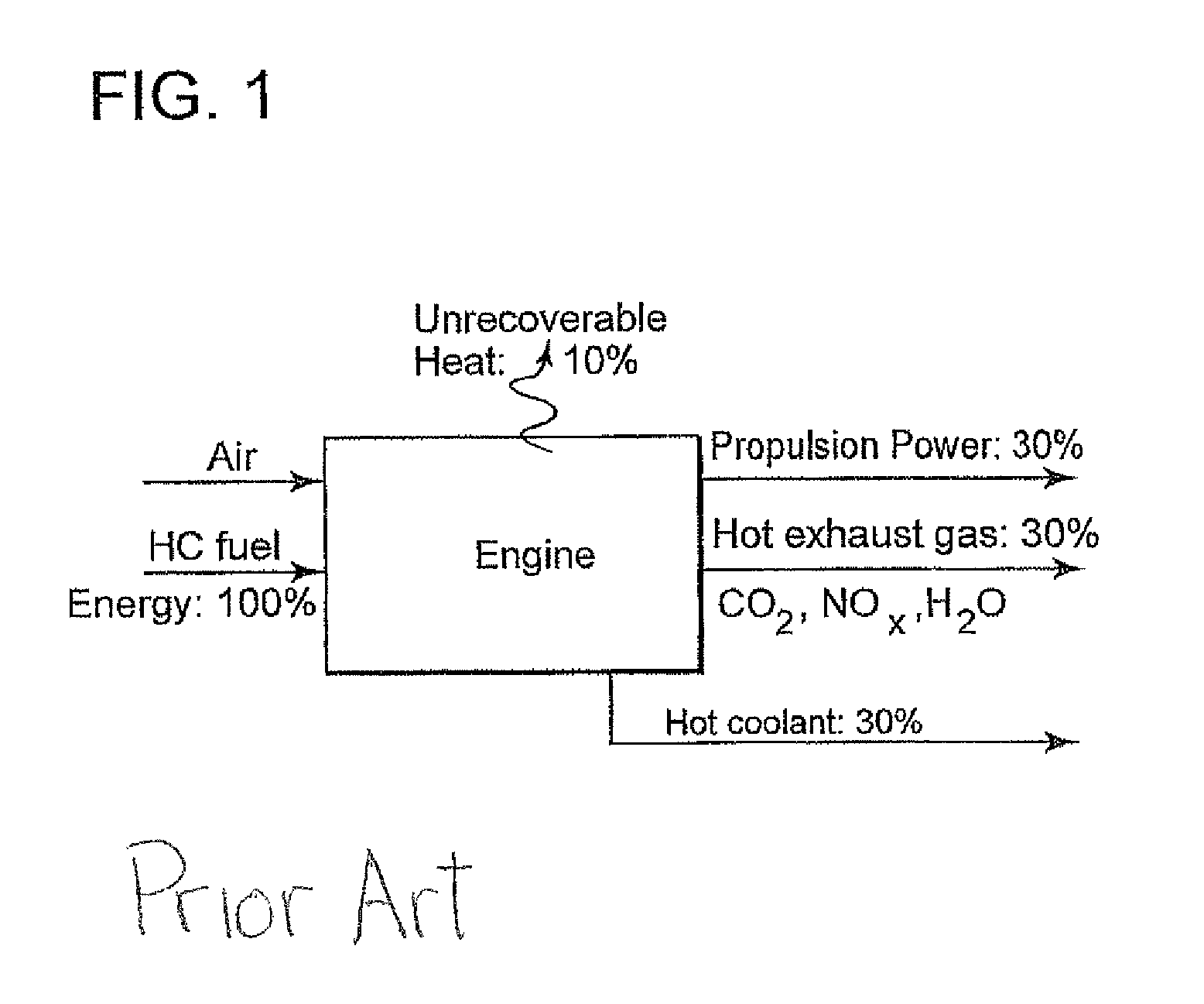

A method and system are described for on-board treatment of an exhaust stream containing CO2 emitted by a hydrocarbon-fueled internal combustion engine (ICE) used to power a vehicle in order to reduce the amount of CO2 discharged into the atmosphere which include:a. a treatment zone on board the vehicle containing a capture agent having a predetermined capacity for extracting CO2 from the exhaust stream,the treatment zone preferably operating in swing mode with at least two subsystems, each having an inlet for admitting the exhaust gas stream and an outlet for passage of a treated exhaust stream having a reduced CO2 content,the treatment zone preferably operating in swing mode with at least two subsystems, each including a heat exchanger with an inlet for receiving the hot exhaust gas stream from the ICE for passage in heat exchange relation with the capture agent to release CO2 and regenerate the capture agent, and an outlet for the cooled exhaust gas stream,the treatment zone having a CO2 discharge outlet for CO2 released from the regenerated capture agent;b. a compression zone in fluid communication with the CO2 discharge outlet from the treatment zone, the compression zone including one or more compressors for reducing the volume of the CO2;c. a storage zone for receiving the compressed CO2 for temporary storage on board the vehicle; andd. an exhaust gas conduit in fluid communication with the treated exhaust gas stream outlet from the treatment zone.

Owner:SAUDI ARABIAN OIL CO

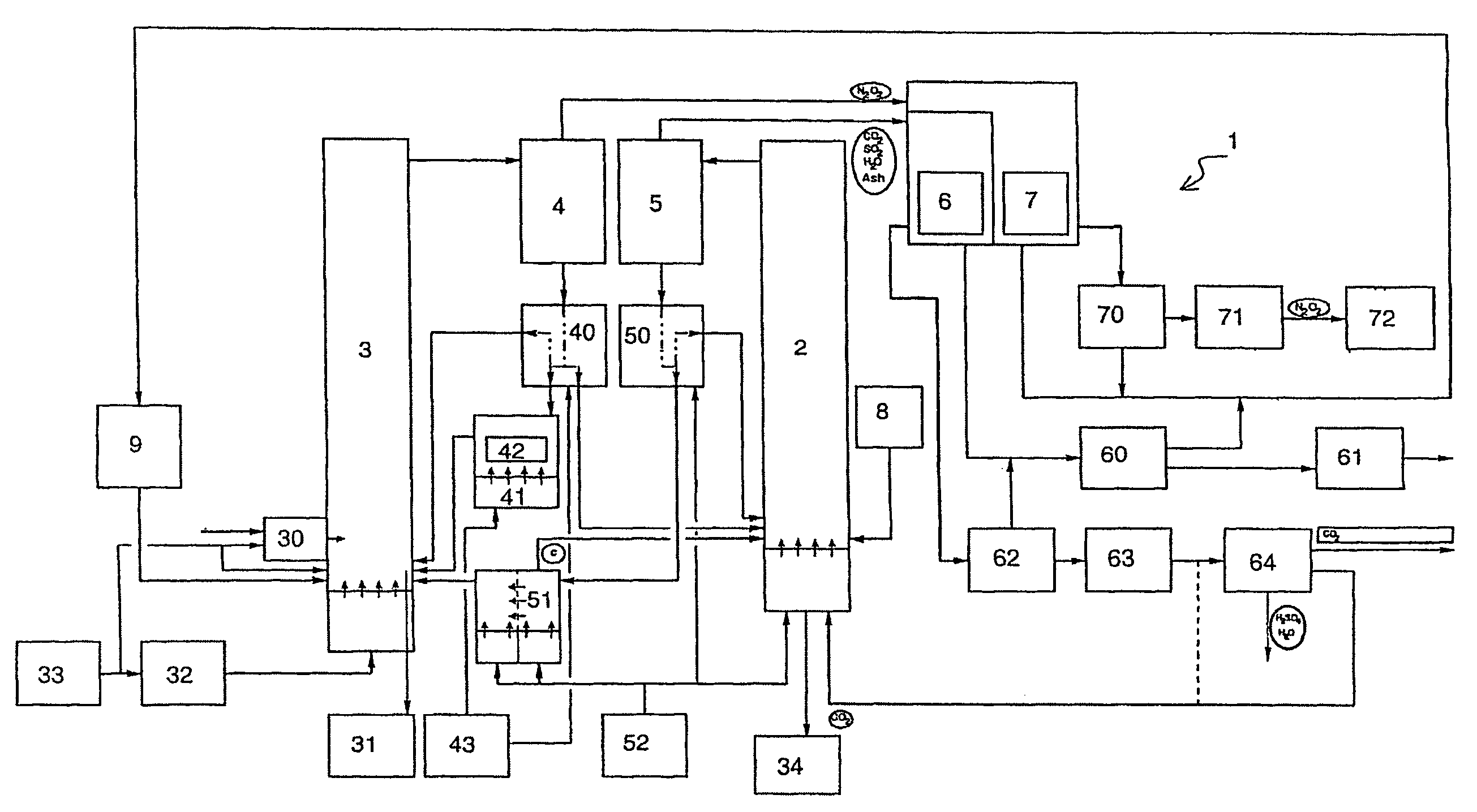

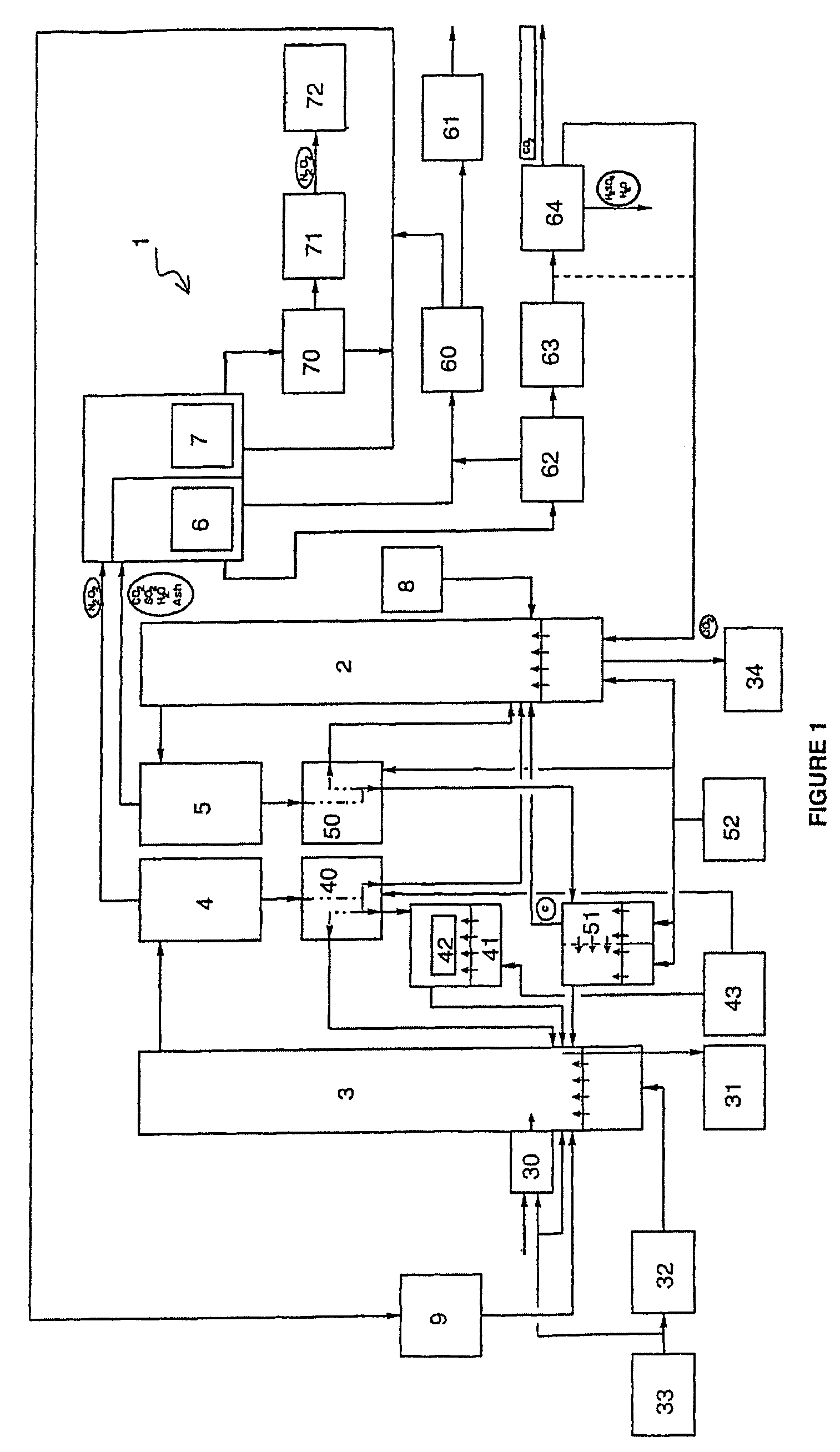

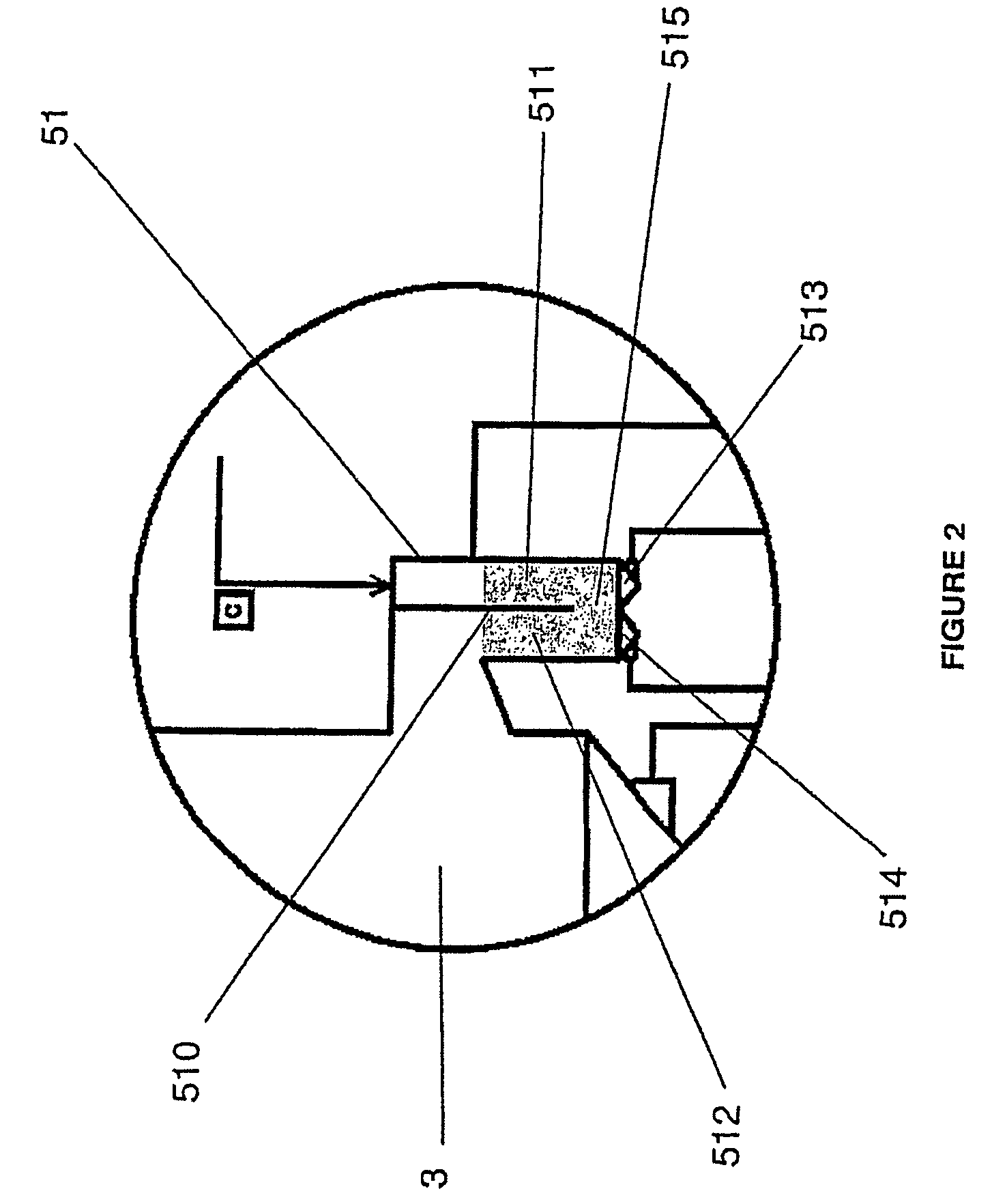

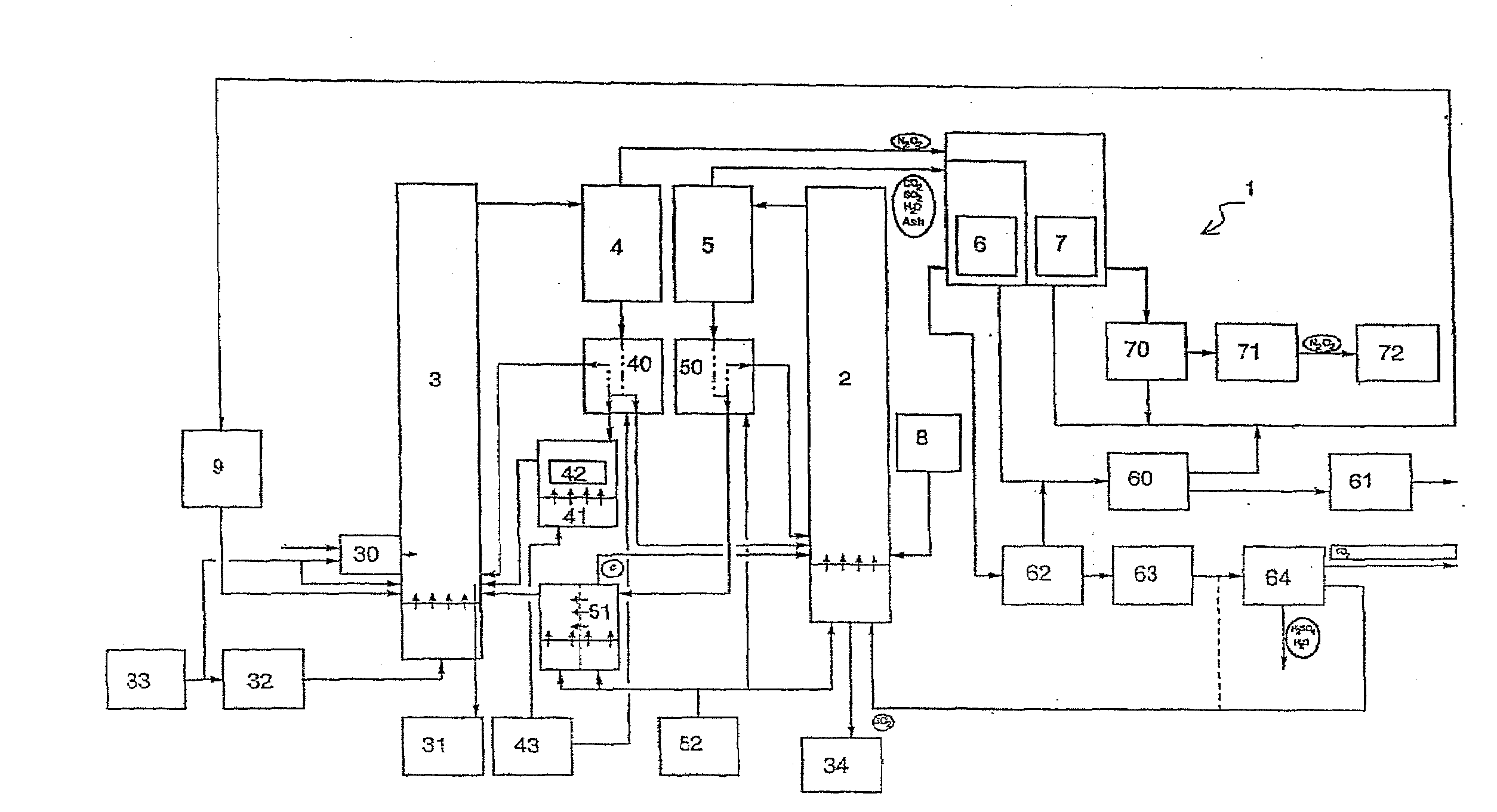

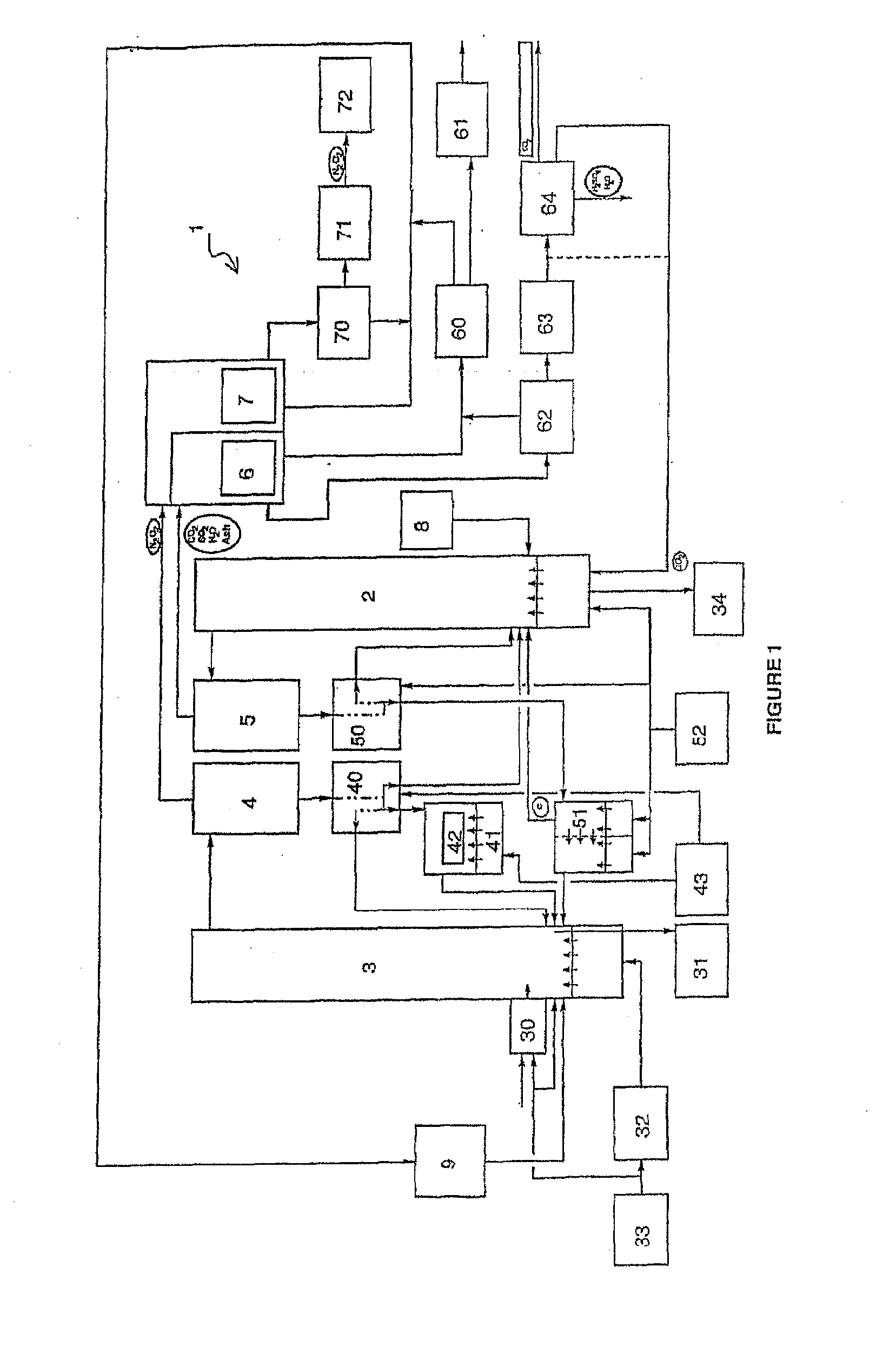

Combustion installation with CO2 recovery

ActiveUS7533620B2Reduces CO capture costRequired separationFluidized bed combustionSolid fuel combustionCycloneSolid fuel

An installation for combustion (1) of carbon-containing solids includes an oxide reducing reactor (2), a first cyclone (5), a recuperator (6), an oxidation reactor (3), a second cyclone (4), wherein flows an oxide which is reduced then oxidized in each of the two reactors (2 and 3). In the installation, the fuel is ground before being introduced into the reduction reactor (3). The reduced size of the solid fuel particles enables more complete and faster combustion and enables almost 100% production of fly ashes which are separated from the circulating oxides.

Owner:GENERAL ELECTRIC TECH GMBH

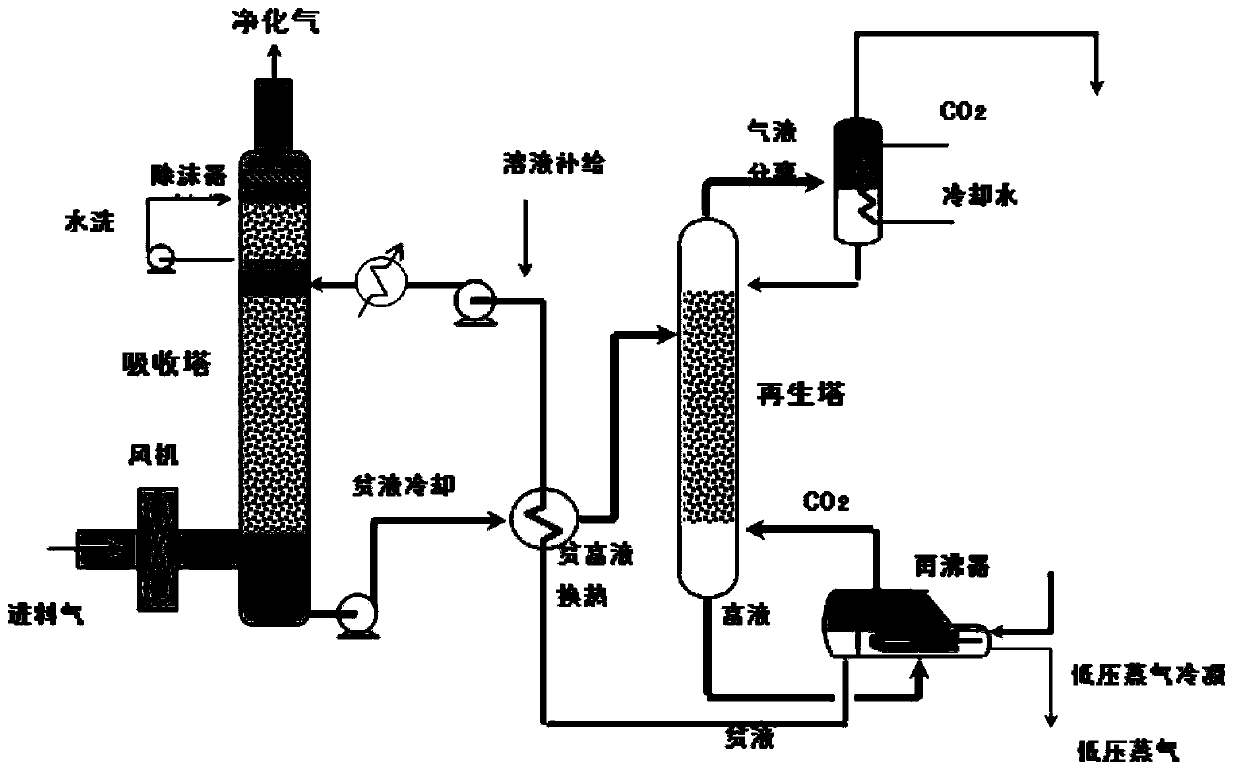

Method and integrated system for removing target gas component in source gas

ActiveCN103463934AIncrease usageHigh energy consumptionDispersed particle separationVapor–liquid separatorGas composition

The invention provides a method for removing a target gas component in source gas. The method comprises the following steps: a) allowing source gas containing the target gas component to pass through an absorption tower, carrying out gas absorption in the absorption tower and allowing absorbed poor gas to enter into a water scrubber; b) cyclically using cyclic excess water in the water scrubber; c) subjecting a rich liquid from the bottom of the absorption tower to heat exchange with a poor liquid flowing out from the bottom of a regeneration tower in a poor-rich liquid heat exchanger and then allowing the rich liquid to enter into the top of the regeneration tower; d) stripping the rich liquid with rising steam and allowing obtained poor liquid to flow out from the bottom of the regeneration tower and to be delivered to the absorption tower; e) allowing a stripped steam mixture containing target gas to depart from the top of the regeneration tower, condensing steam in a gas-liquid separator and allowing the target gas to depart from the gas-liquid separator and to be transferred to a storage part; and f) introducing a condensate of the gas-liquid separator into the top of the absorption tower and the water scrubber again. The invention further provides an integrated system for removing the target gas component in the source gas.

Owner:青岛海山减碳环保科技有限公司

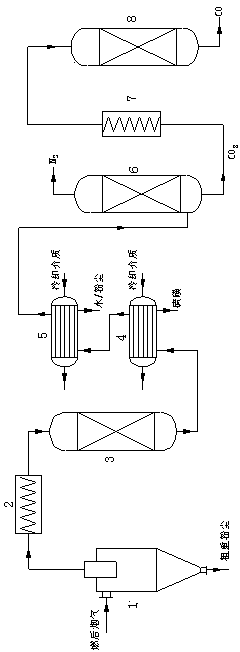

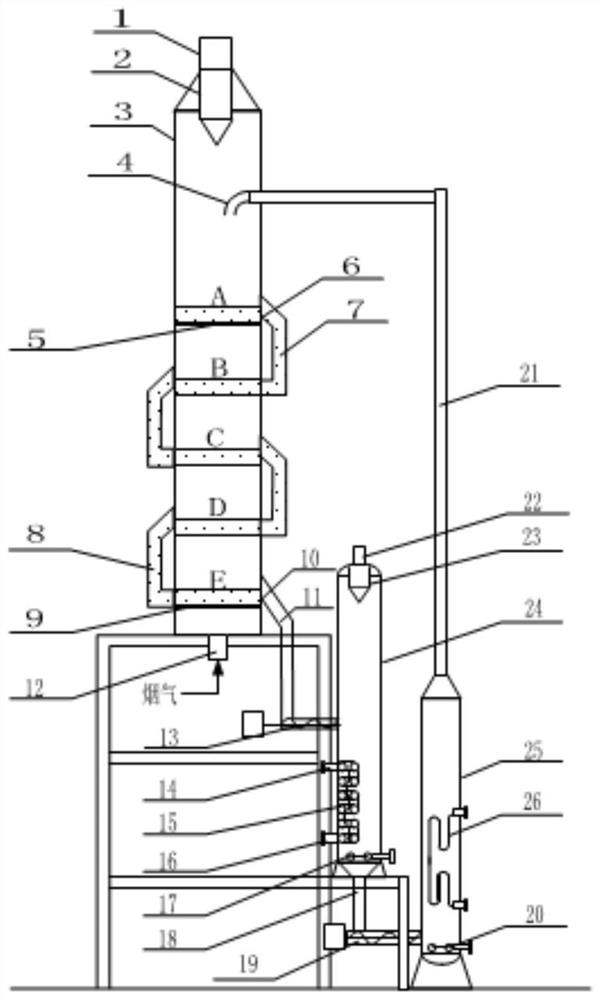

Method for synchronous desulphurization, denitration dedusting and emission reduction of carbon dioxide by fire coal and flue gas

InactiveCN104162358ALower capture costsIncrease concentrationCombination devicesProductsFlue gasEconomic benefits

The invention relates to a method for synchronous desulphurization, denitration dedusting and emission reduction of carbon dioxide by fire coal and flue gas, which comprises the following steps: cyclone dust collection, heating by flue gas, reduction by carbon for desulphurization and denitration, two-grade cooling for recovering sulphur, dedusting, collecting, heating of carbon dioxide and reduction. According to the invention, desulphurization and denitration treatment are simple and thoroughly, collection cost of carbon dioxide is reduced, and no secondary pollutant is generated, the byproduct has good market value, and zero discharge is realized. According to the invention, individual desulphurization and denitration treatment can be avoided, separating cost of carbon dioxide is reduced, cost and risk of transhipment and burying of carbon dioxide can be avoided, the produced CO is a C1 chemical important raw material, and the method has good economic benefit.

Owner:TIANJIN UNIV

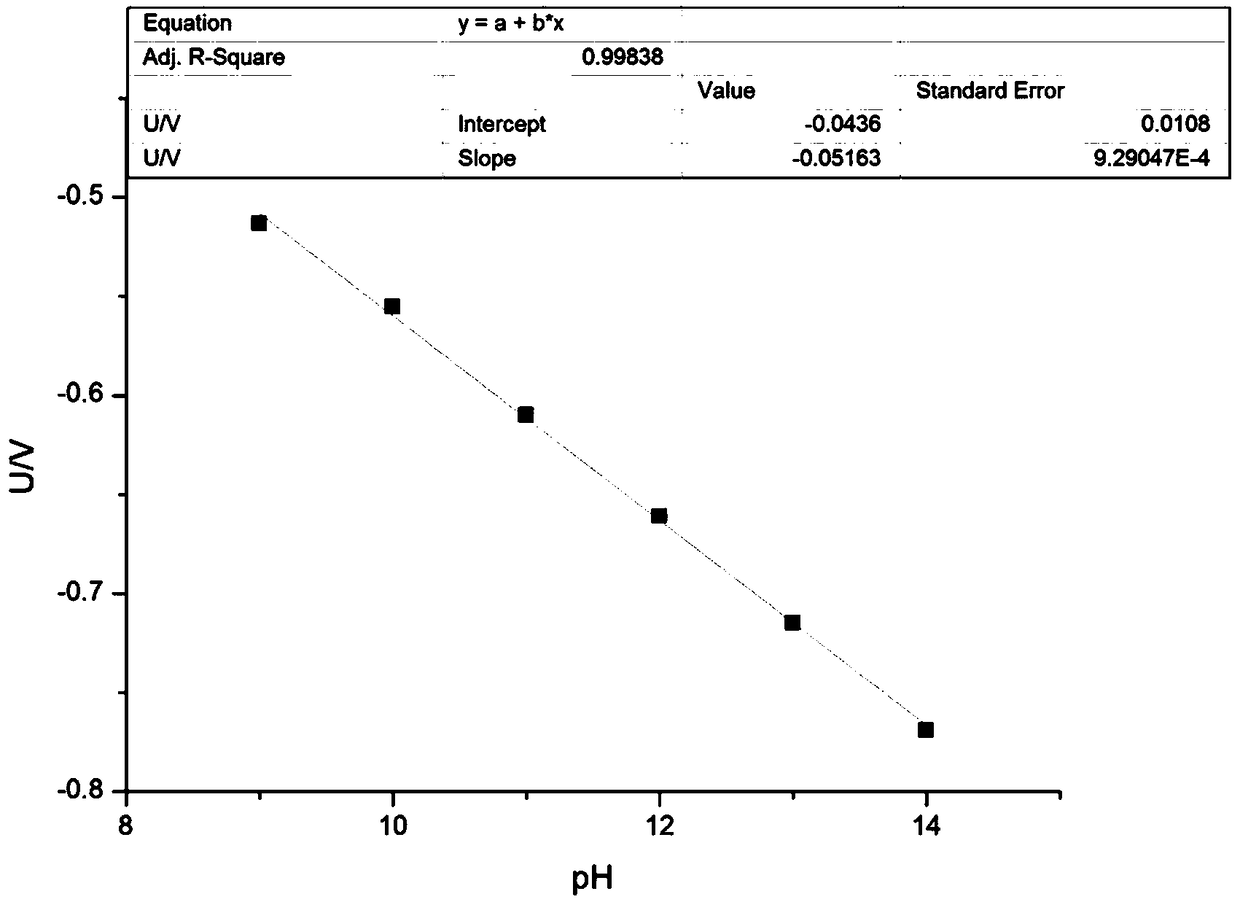

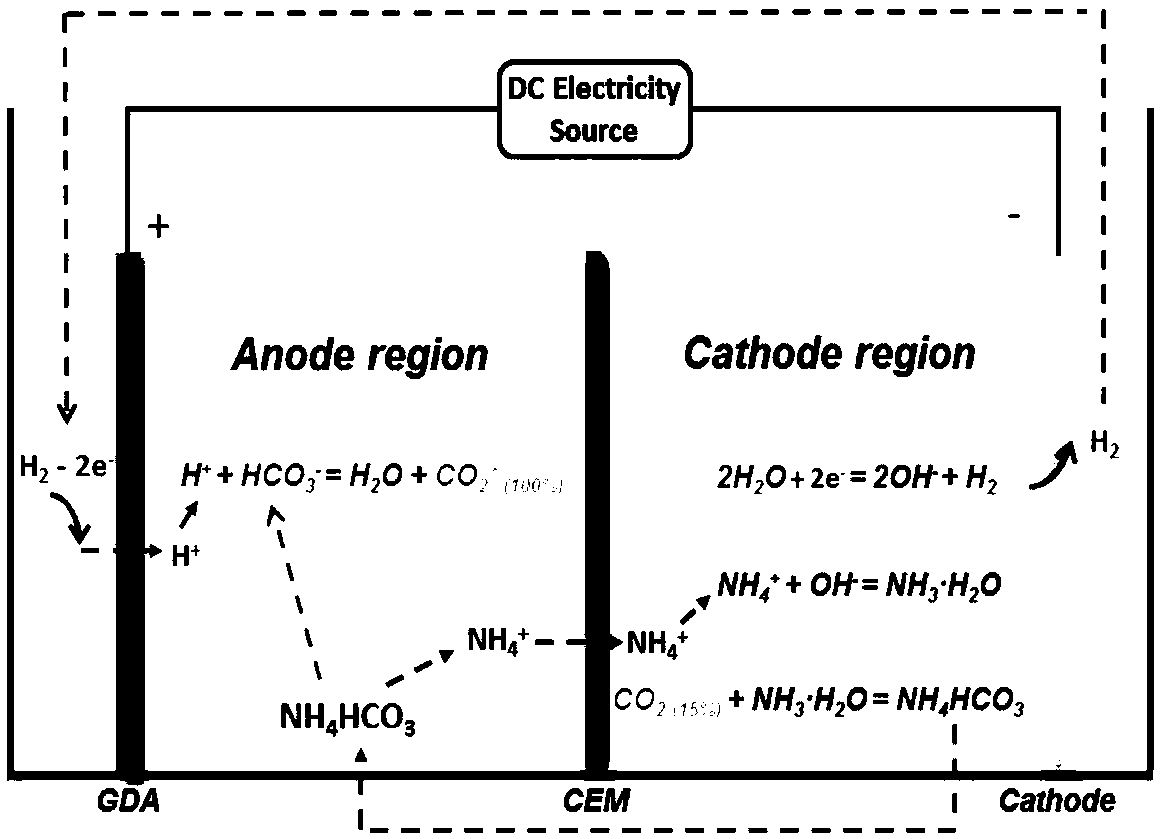

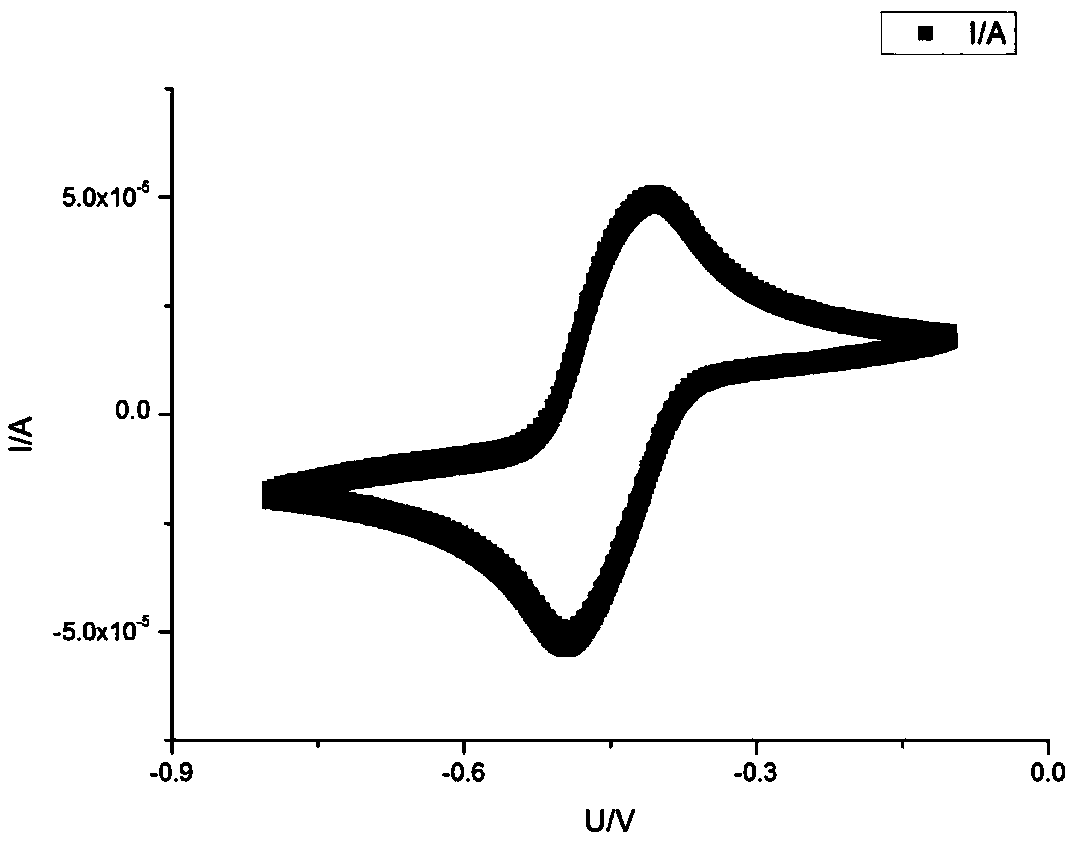

Riboflavin promoting low concentration CO2 electrochemical trapping method

ActiveCN108728860AReduce overpotentialReduce energy consumptionCellsCarbon compoundsHigh concentrationTrapping

The invention provides a riboflavin promoting low concentration CO2 electrochemical trapping method, and belongs to the technical field of CO2 electrochemical trapping. The method comprises the following steps that a cation-exchange membrane is placed in an electrolytic cell; a FMN solution and a potassium acid carbonate solution are added in acathode zone; a FMNH2 solution and a potassium acid carbonate solution are added in an anode zone; direct current is applied between the anode electrode and the cathode electrode; two electrons are obtained in the cathode electrode by the FMN; two protons are received in a KHCO3 solution to form the FMNH2 solution in the reduction state; generated CO32-enters the solution and is used for absorbing low concentration CO2; the FMNH2 releases electrons at the anode electrode and returns to a oxidized state FMN; and the protons leave the FMNH2 to react with KHCO3 in the solution to release high concentration CO2. Low concentration CO2 trapping is achieved; when electric current density is at 10mAcm-2, the average voltage for trapping the CO2 is 0.065V, energy consumption of trapping one ton of the CO2 is about 80KWh, while energy consumption of trapping one ton of the CO2 by an existing chemical absorption method of MES regeneration is 370-510 KWh, so that energy saving is more than 75%.

Owner:SICHUAN UNIV

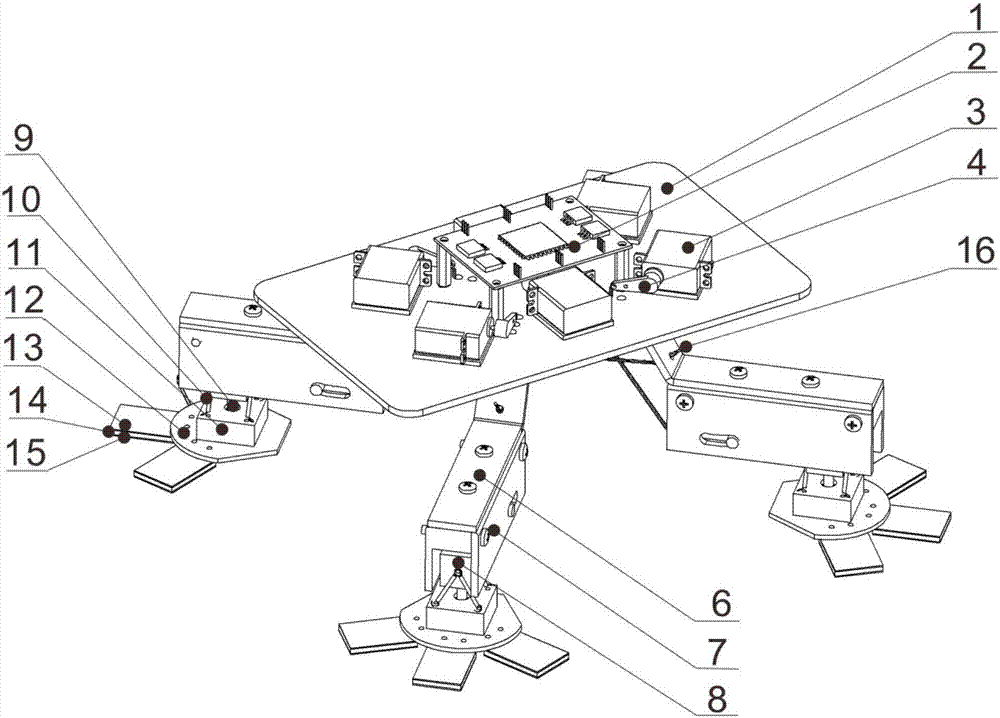

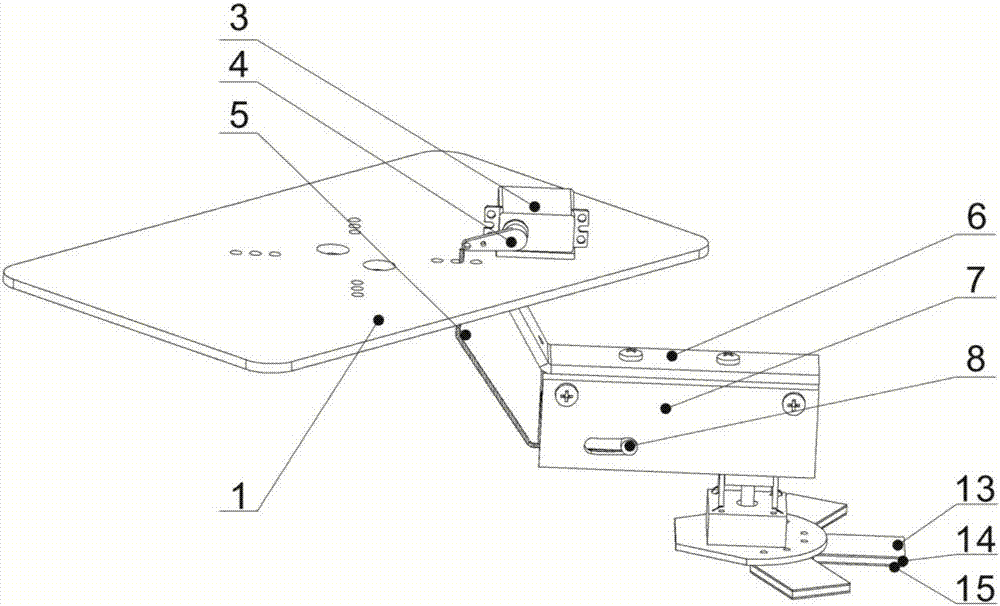

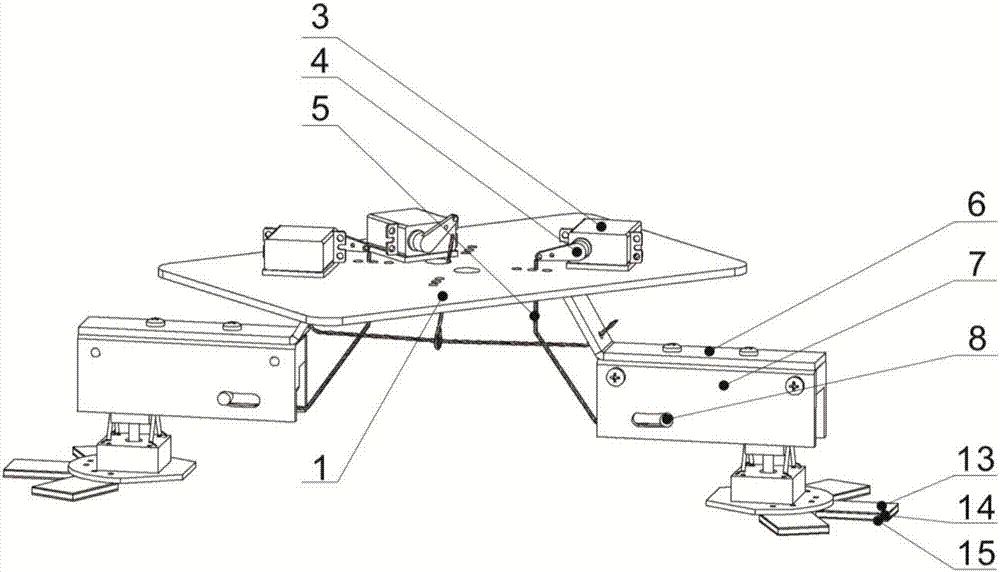

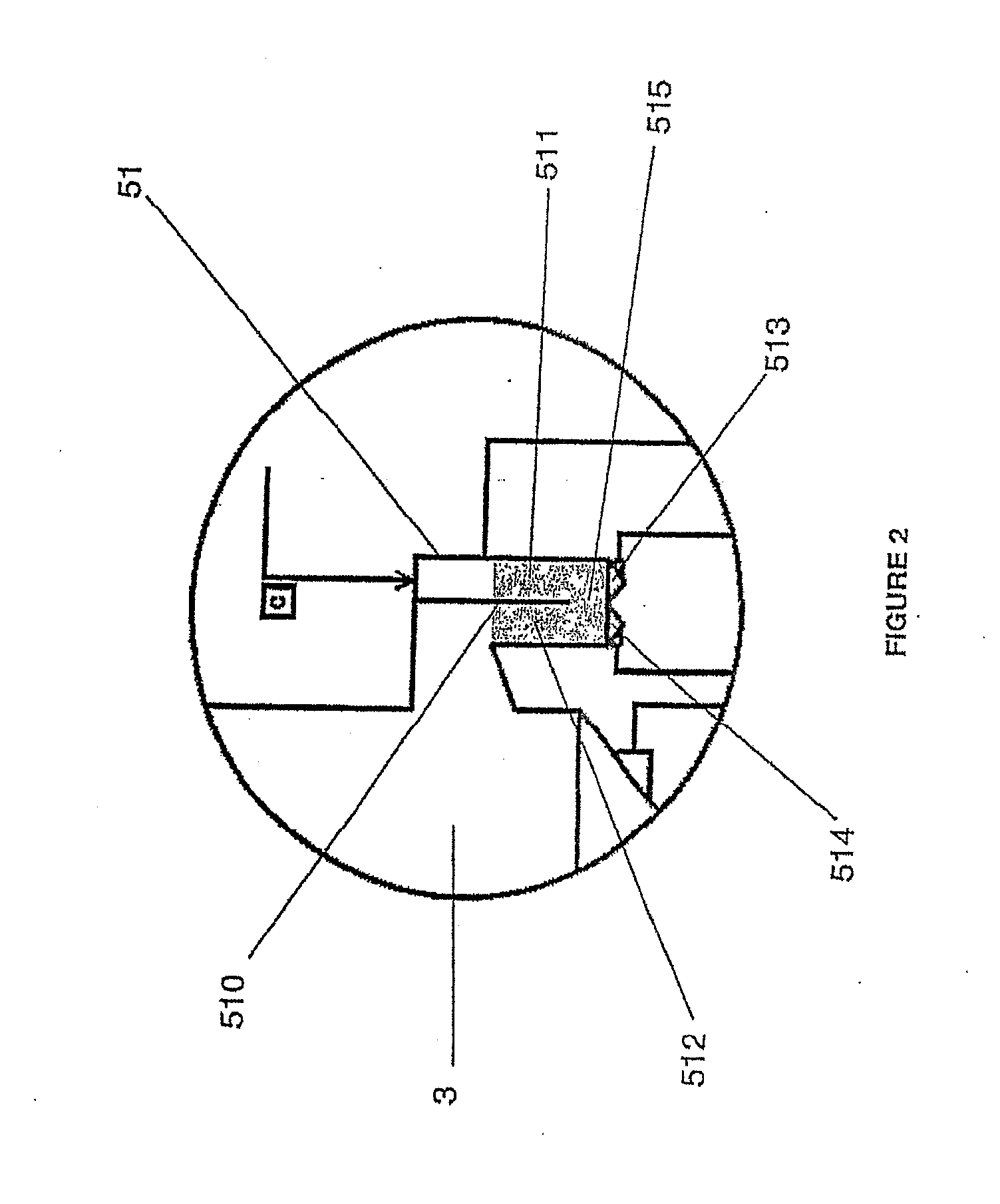

Bionic dry adhesion system for capturing non-cooperative targets in in-orbit manner

The invention discloses a bionic dry adhesion system for capturing non-cooperative targets in an in-orbit manner. The bionic dry adhesion system comprises a fuselage, flexible driving mechanisms, bionic paw mechanisms and bionic foot sole mechanisms. The flexible driving mechanisms and the bionic paw mechanisms are arranged on the fuselage, the bionic foot sole mechanisms are movably connected with the bionic paw mechanisms, adhesion units made of bionic adhesion materials are arranged at the tail ends of the bionic foot sole mechanisms, the bionic foot sole mechanisms can be driven by the flexible driving mechanisms to laterally move relative to the bionic paw mechanisms, and the bionic paw mechanisms can be driven by the flexible driving mechanisms to carry out adduction movement, so that the bionic adhesion units can tangentially move under the effect of normal pre-pressures to generate adhesion force. The bionic dry adhesion system has the advantages that the non-cooperative targets in spaces can be repeatedly adhered by the bionic dry adhesion system, and accordingly effects of capturing the non-cooperative targets can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

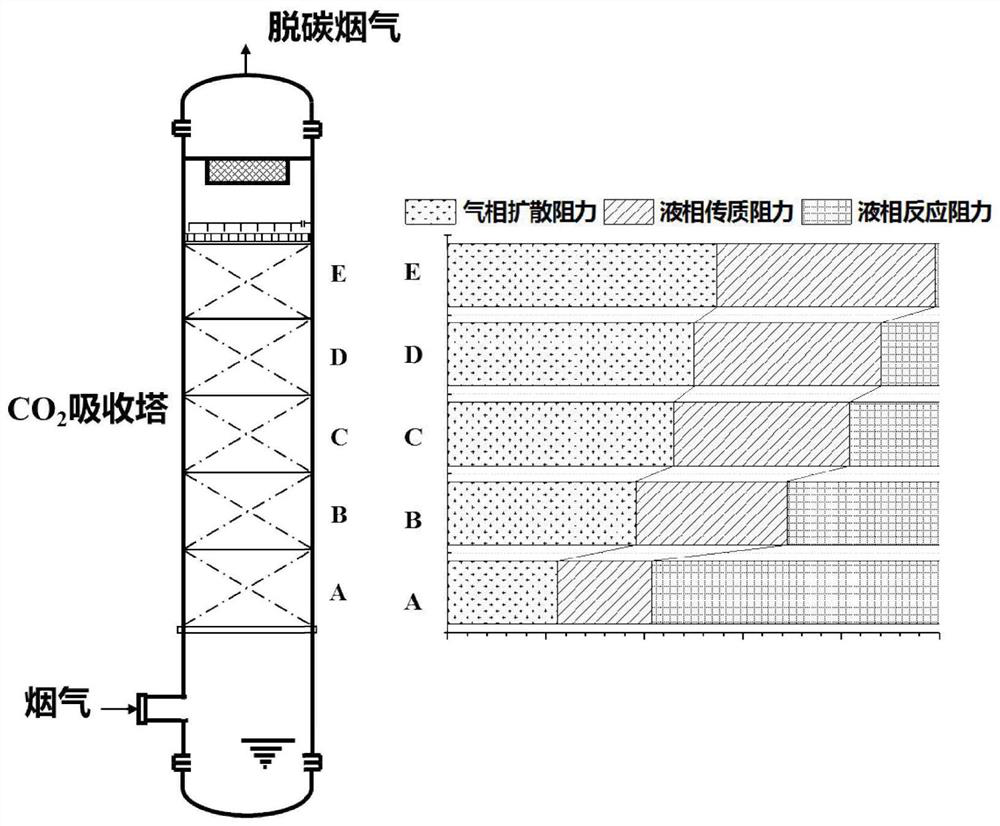

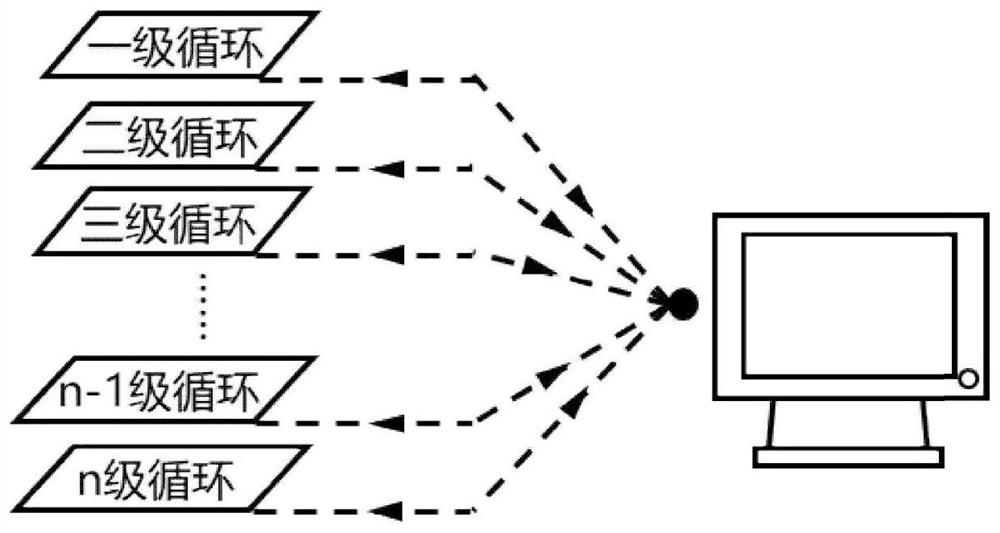

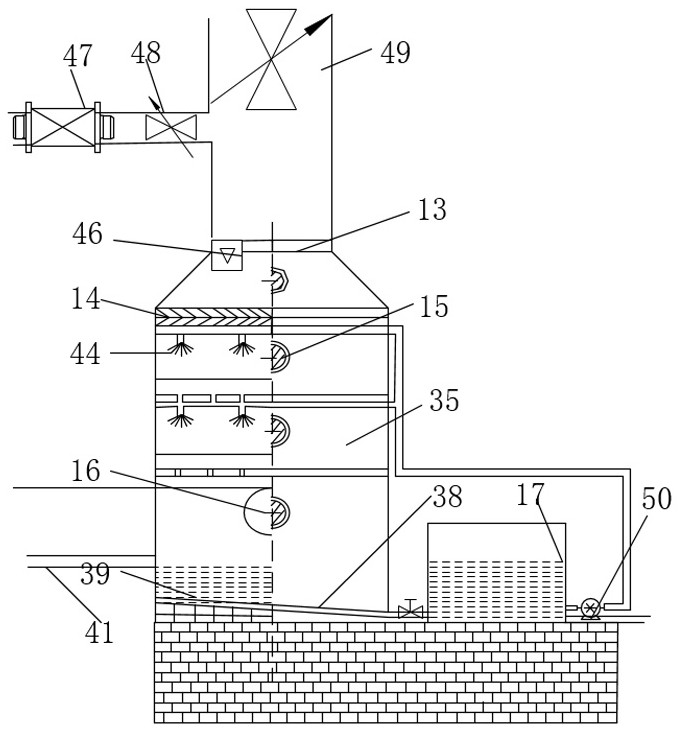

Partitioned multi-stage circulating CO2 trapping and concentrating method based on mass transfer-reaction regulation and control

PendingCN113521966AImprove capture efficiencyReduce desorption energy consumptionHuman health protectionProductsProcess engineeringSlurry

The invention relates to a partitioned multi-stage circulating CO2 trapping and concentrating method based on mass transfer-reaction regulation and control. The method adopts multi-element means such as multi-stage cycle absorption, intelligent multi-factor regulation, pre-washing cooling, inter-stage cooling, post-stage water washing, slurry cleaning, cooling water waste heat utilization, small-particle-size high-density spraying and the like. The method takes low cost, low energy consumption, stability and high efficiency as optimization targets, the generation of secondary pollutants is effectively inhibited while CO2 is efficiently trapped, and high-efficiency trapping, low-energy-consumption desorption and high-purity concentration of CO2 are realized. Aerosol removal is sequentially carried out from top to bottom through multi-stage circulation, the carbon capture efficiency is improved, the absorption rate and rich solution concentration are maintained, and the carbon emission reduction cost is reduced.

Owner:ZHEJIANG UNIV

Alcohol amine type ion liquor-containing compound absorbent capable of capturing carbon dioxide

InactiveCN103170216AIncrease absorption rateImprove stabilityDispersed particle separationAir quality improvementSteam pressureAbsorption capacity

The invention discloses an alcohol amine type ion liquor-containing compound absorbent capable of capturing carbon dioxide. The alcohol amine type ion liquor-containing compound absorbent is characterized by comprising an absorption component, a corrosion inhibitor, an antioxidant and solvent, wherein the absorption component consists of N-Methyldiethanolamine and ionic liquid (TETAH)<+>(BF4)<->. The invention provides a compound absorbent which is high-efficiency, good in stability, easy to desorb, and low in regeneration energy consumption and can capture carbon dioxide. Organic amine and ionic liquid are mixed, the organic alcamines has the characteristics of being high in absorption rate and large in absorption capacity and the ionic liquid has the properties of low steam pressure and good stability and the like, thus supplementing each other so as to improve the processing capacity of carbon dioxide.

Owner:SHANGHAI BOILER WORKS

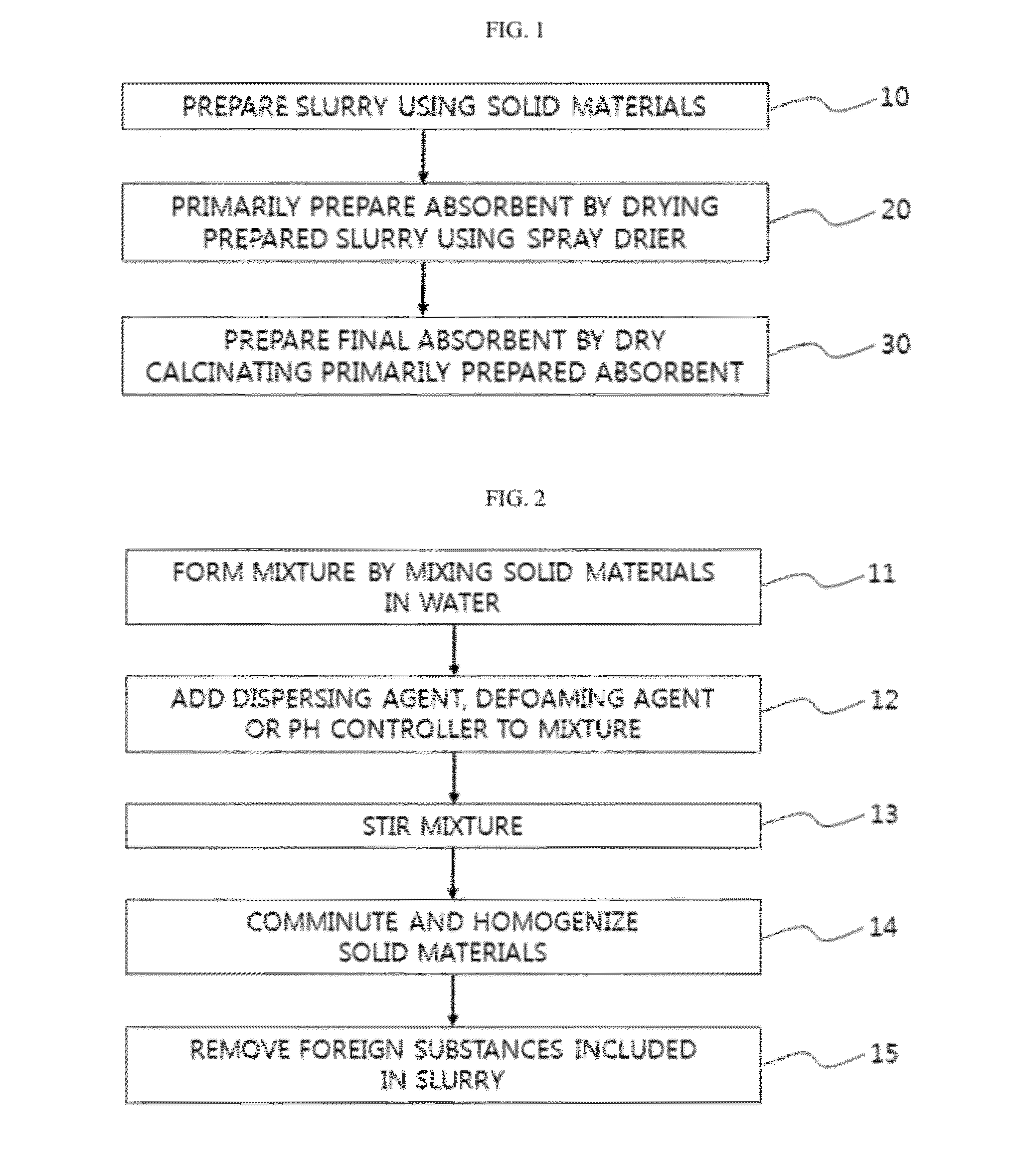

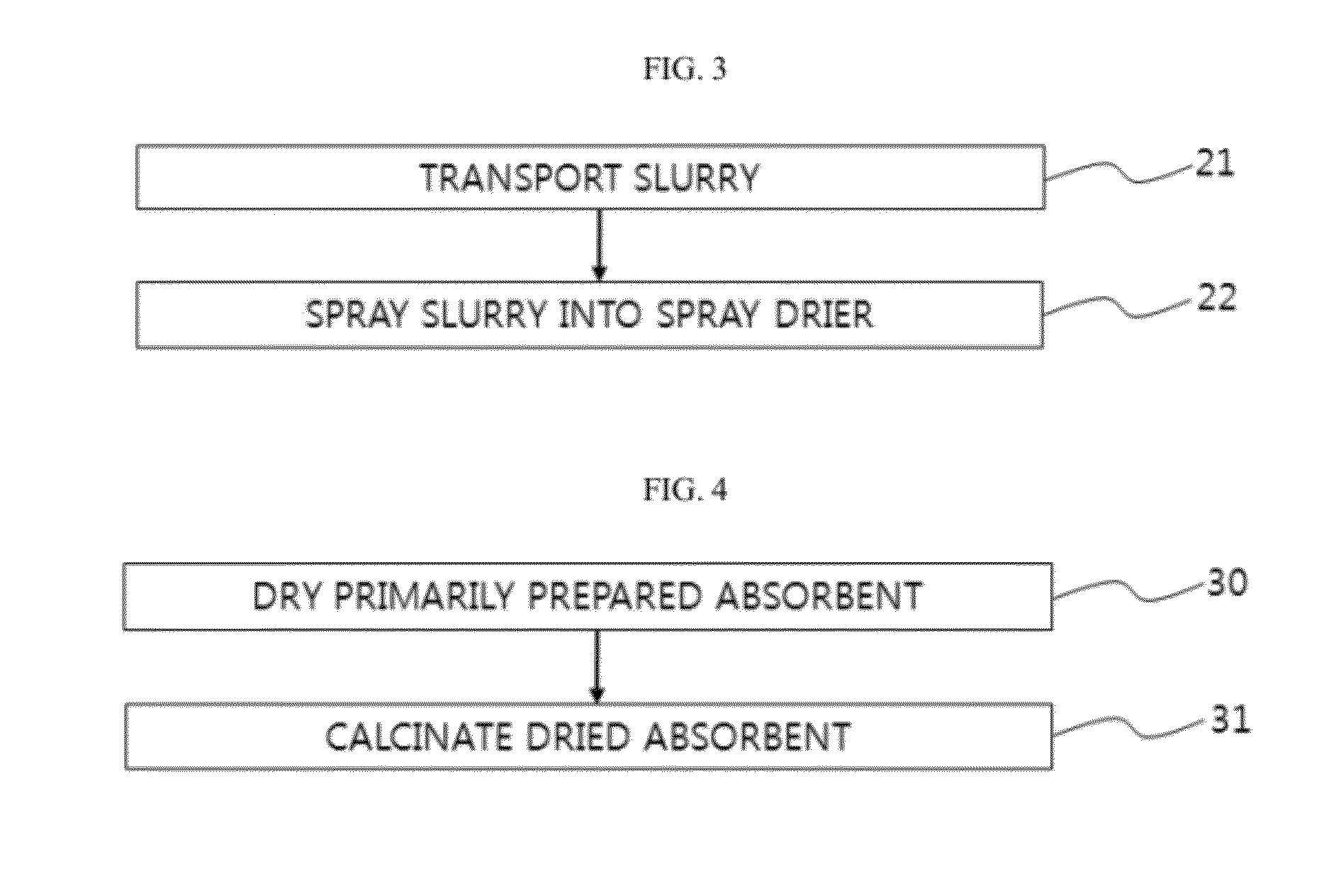

Carbon dioxide absorbent for exhaust gas, and preparation method thereof

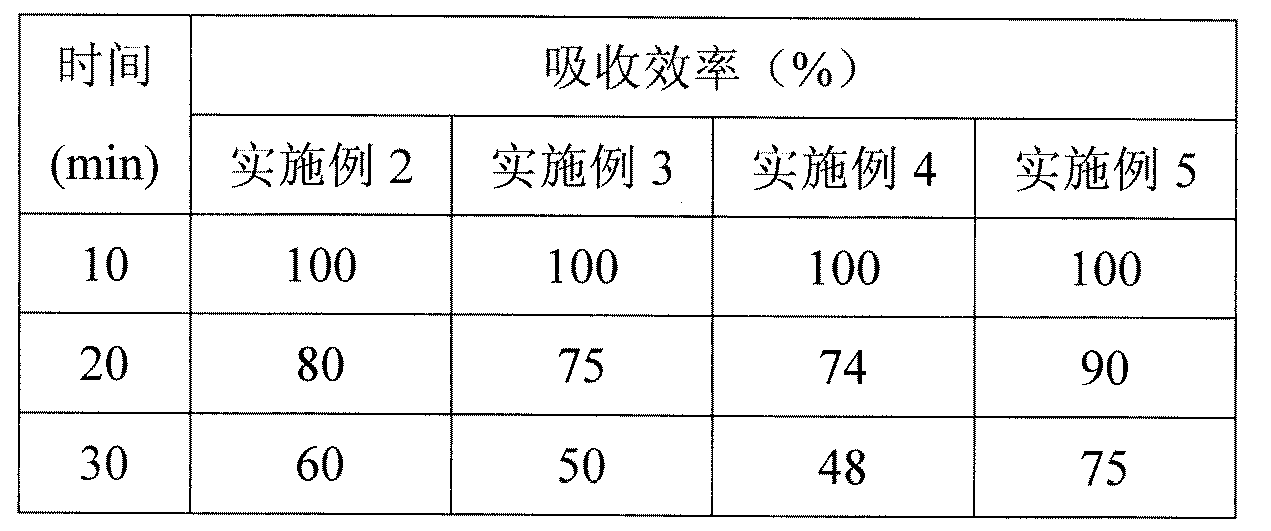

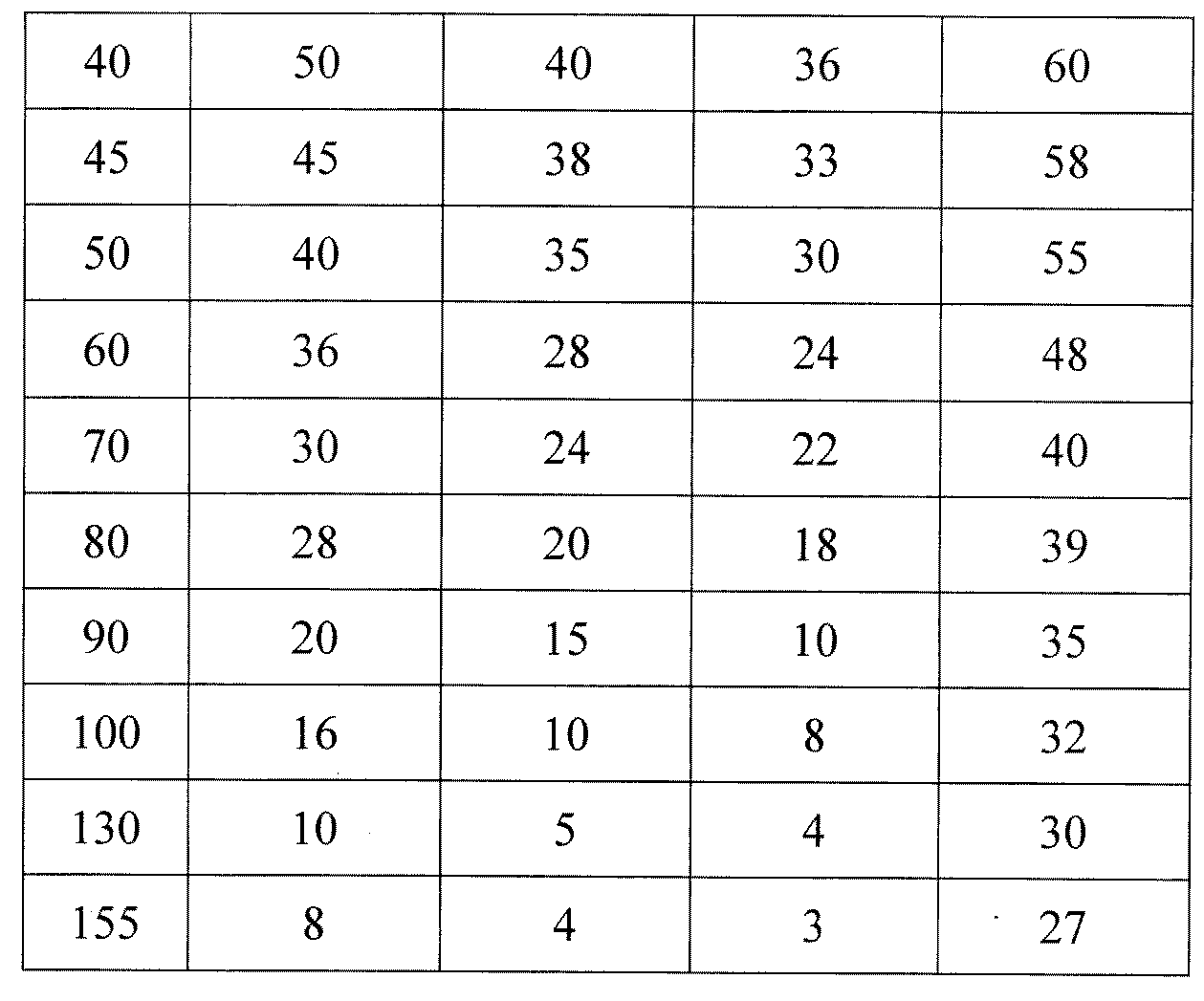

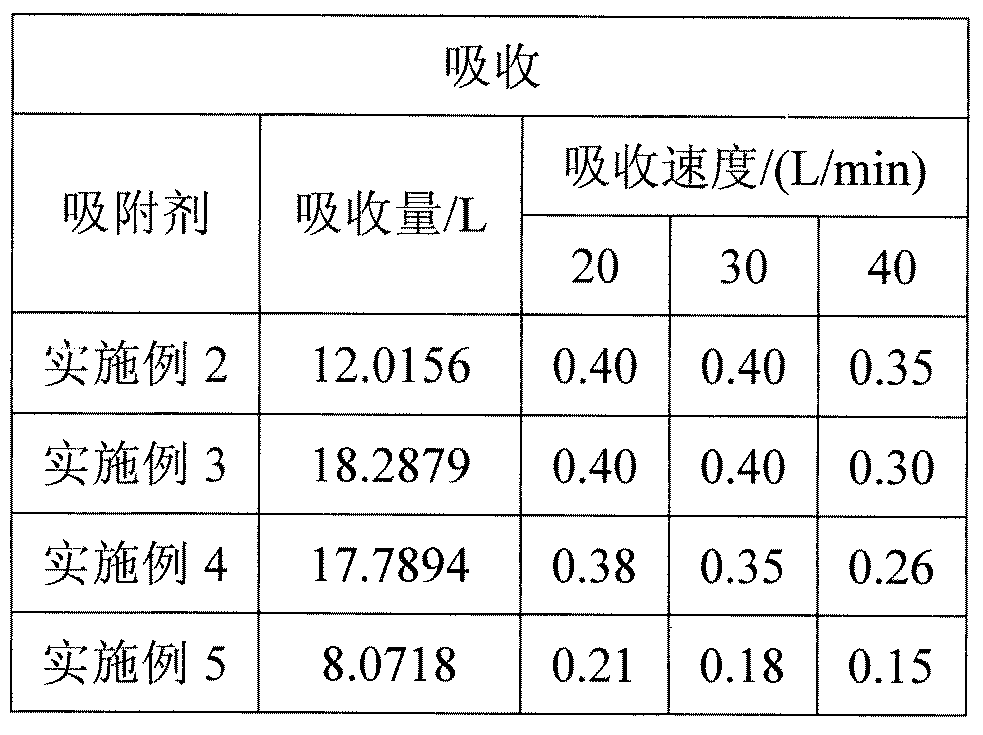

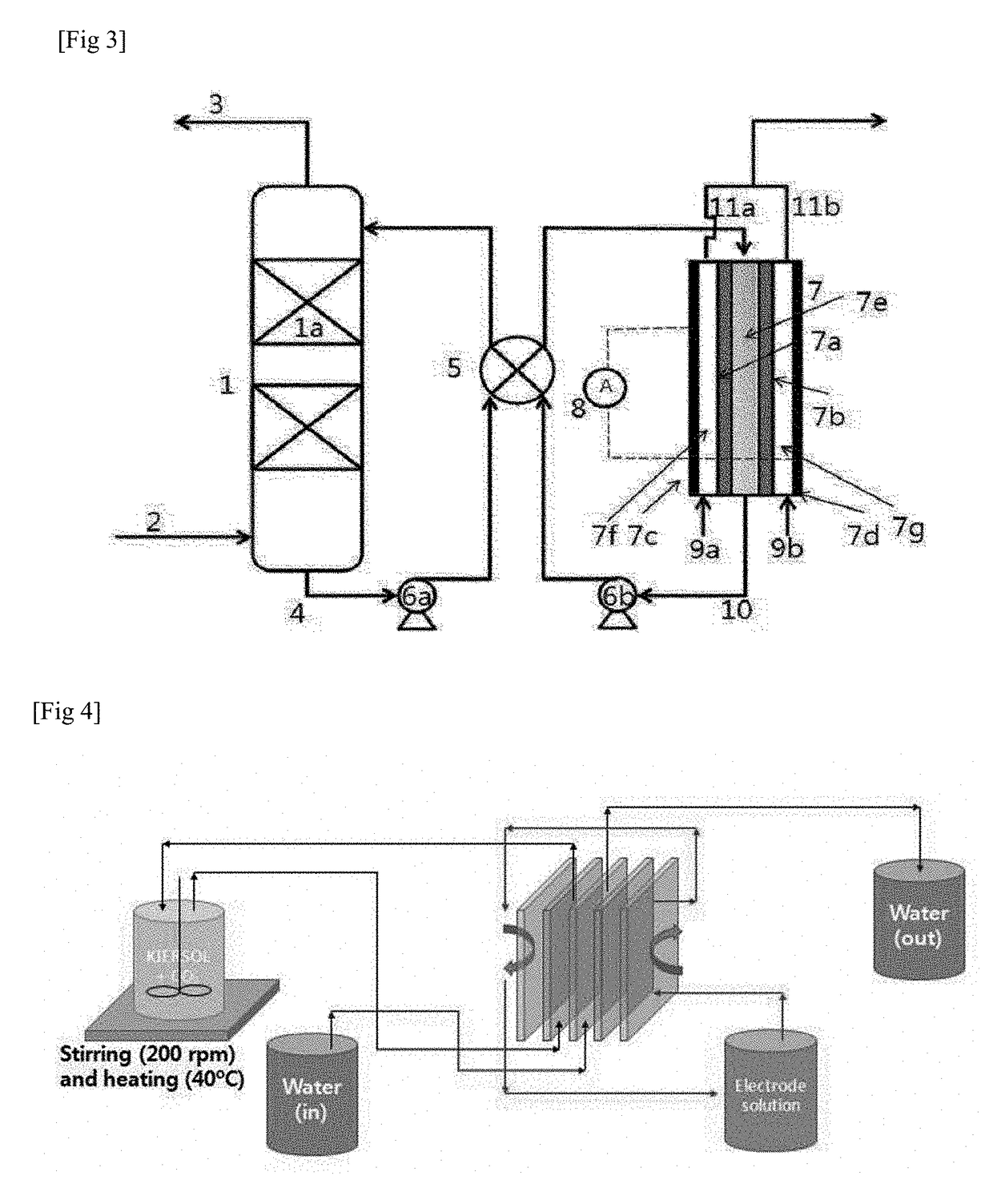

ActiveUS20120273720A1Easy to recycleLower capture costsGas treatmentOther chemical processesActive componentVolumetric Mass Density

A CO2 absorbent for exhaust gas capable of being repeatedly used in capturing and recycling of CO2 is provided. The CO2 absorbent for exhaust gas capturing CO2 included in exhaust gas is composed of solid materials including an active component at 5 to 70 wt %, a support at 5 to 70 wt %, an inorganic binder at 5 to 70 wt % and a recycling improver at 5 to 70 wt %. The CO2 absorbent for exhaust gas having such a composition meets the requirements for processes, including physical properties such as a spherical shape, an average particle size and size distribution, a tap density and attrition resistance, and has excellent CO2 absorbing capability and recycling capability.The carbon dioxide absorbent for exhaust gas satisfies physical characteristics such as spherical shape, average particle size and size distribution, tap density, attrition resistance and the like required for processes, and has excellent CO2 absorption and recycling capabilities.

Owner:KOREA ELECTRIC POWER CORP

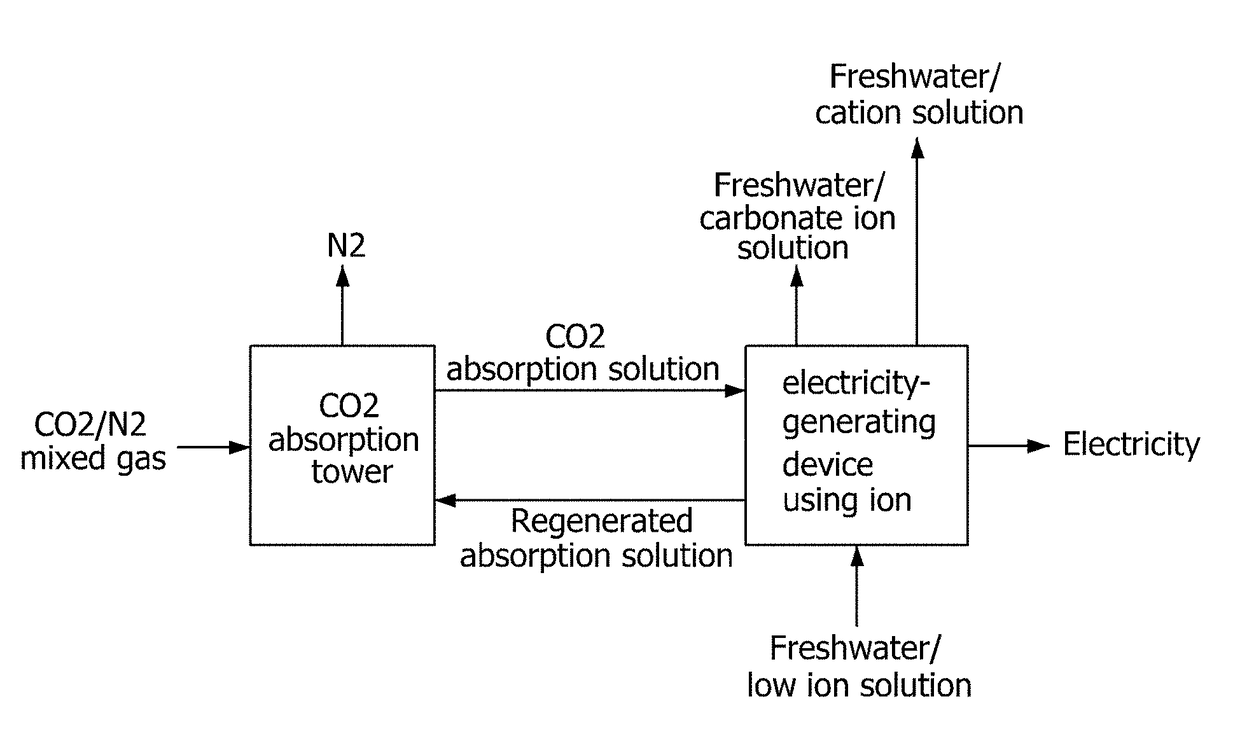

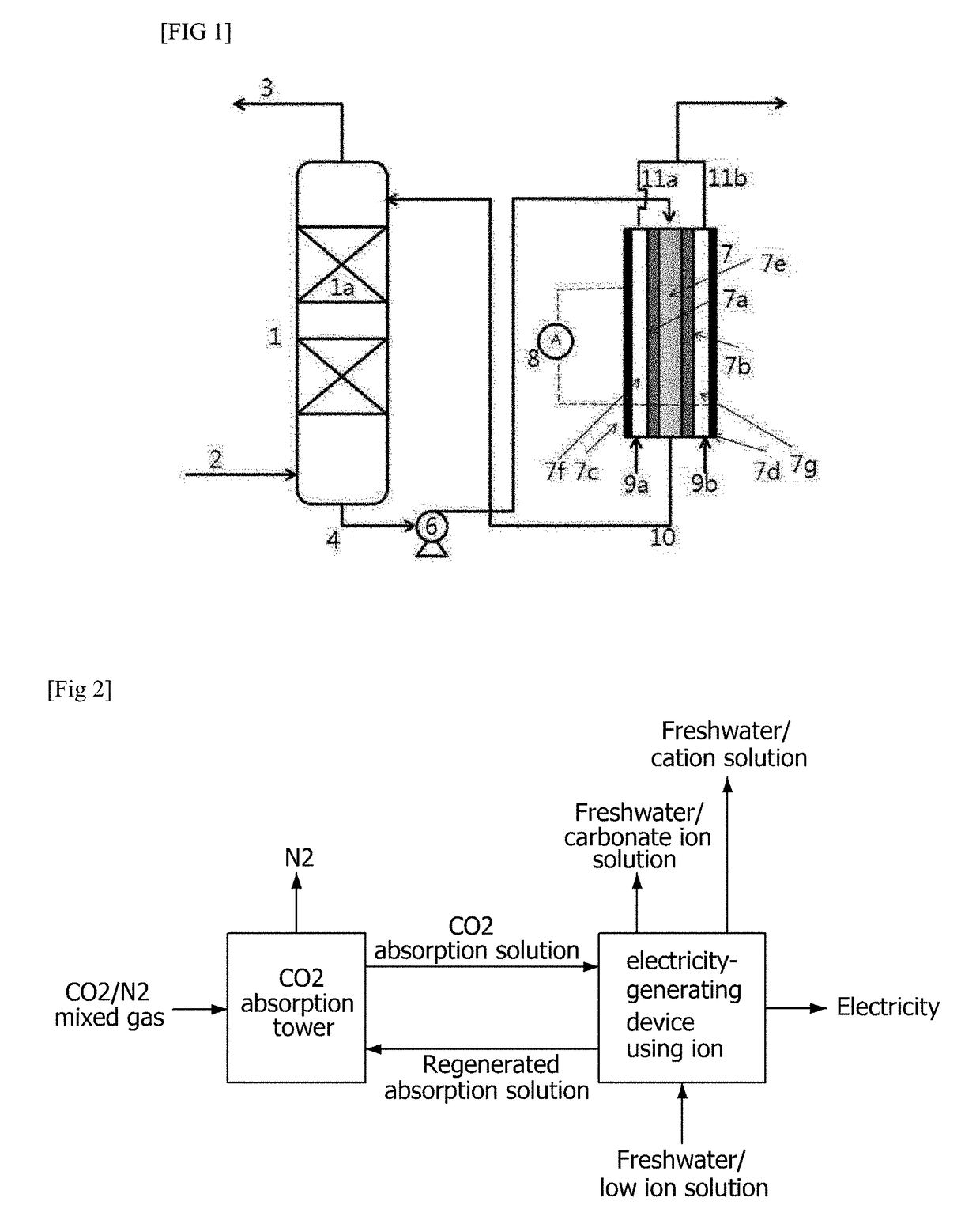

Carbon dioxide trapping device and method capable of producing electricity

ActiveUS20170256812A1Efficient captureContinuous operationGas treatmentFuel cell heat exchangeTrappingFresh water organism

An apparatus and process are provided for electricity production and high-efficiency trapping of carbon dioxide, using carbon dioxide within combustion exhaust gas and converging technologies associated with a carbon dioxide absorption tower and a generating device using ions which uses a difference in concentration of salinity between seawater and freshwater. It is expected that enhanced electrical energy production efficiency, an effect of reducing costs for the operation of a carbon dioxide trapping process, and electricity production from carbon dioxide, which is a greenhouse gas, can be simultaneously achieved by increasing the difference in concentration using an absorbent for absorbing carbon dioxide.

Owner:KOREA INST OF ENERGY RES

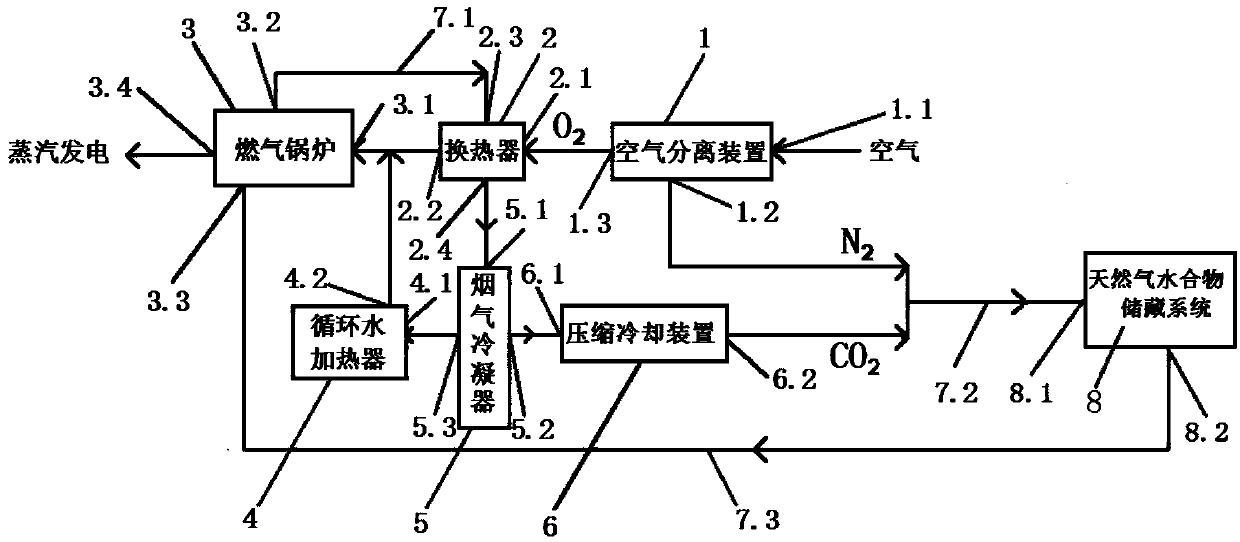

Steam-attemperation-based oxygen-enriched combustion and natural gas hydrate development co-production system and method

PendingCN107940432ALow retrofit costReduces carbon black and NOx formationSolidificationLiquefactionOxygen enrichmentFlue gas

The invention discloses a steam-attemperation-based oxygen-enriched combustion and natural gas hydrate development co-production system and method. The system comprises an air separator, a heat exchanger, a gas-fired boiler, a circulating water heater, a flue gas condenser, a compressing-cooling device and a natural gas hydrate storage system, wherein an oxygen-enriched outlet of the air separatoris connected with an oxygen-enriched inlet of the heat exchanger; a high-temperature oxygen outlet of the heat exchanger is connected with a high-temperature oxygen inlet of the gas-fired boiler; a flue gas outlet of the gas-fired boiler is connected with a high-temperature flue gas inlet of the heat exchanger; a low-temperature flue gas outlet of the heat exchanger is connected with a flue gas inlet of the flue gas condenser; and a gas outlet of the flue gas condenser is connected with a gas inlet of the compressing-cooling device. By adoption of the system disclosed by the invention, a power plant is self-sufficient in fuel, no any residue and exhaust gas are generated after combustion, the pollutant discharge, the quantity of follow-up gas processing equipment and the high CO2 capturing cost are reduced, and the double value of economy and environmental protection is achieved.

Owner:YANGTZE UNIVERSITY

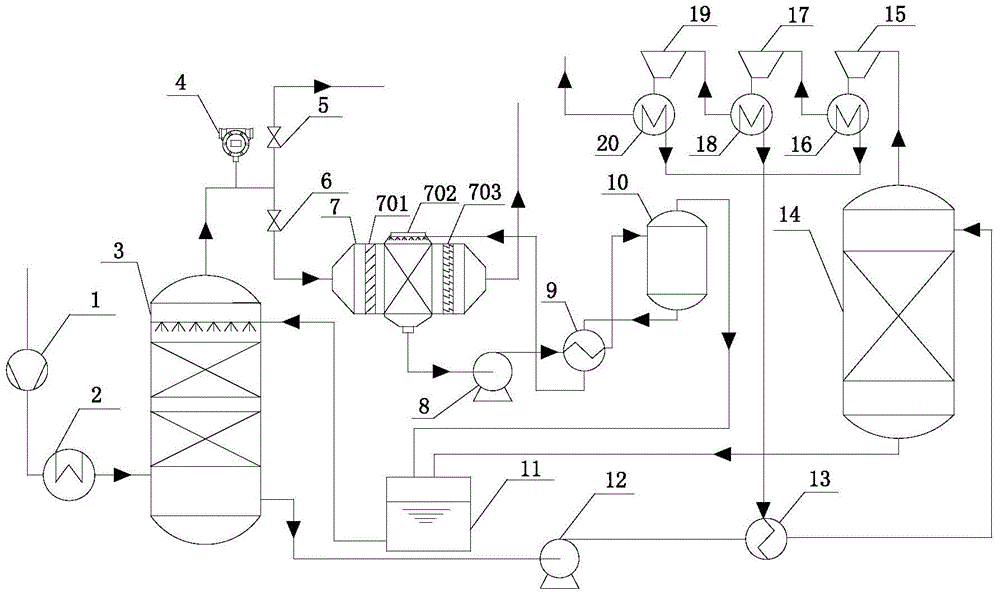

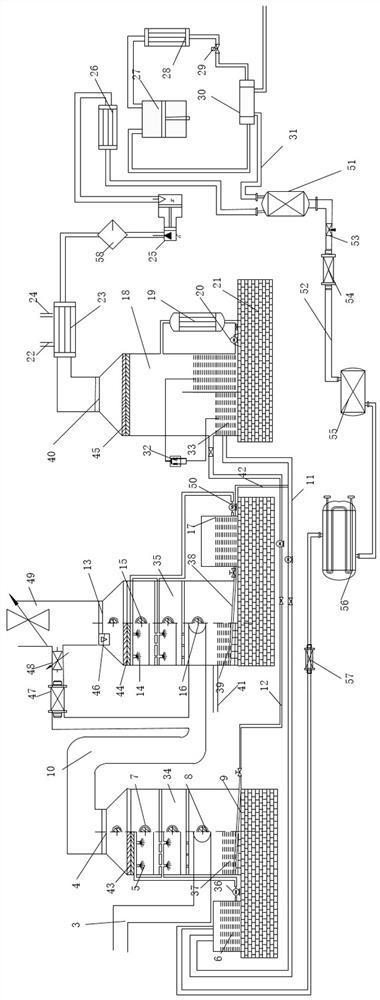

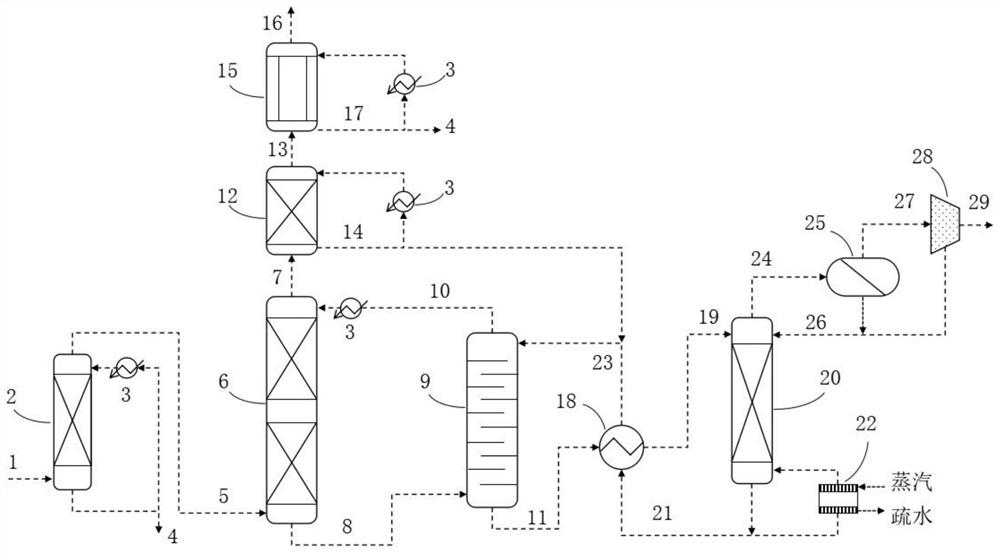

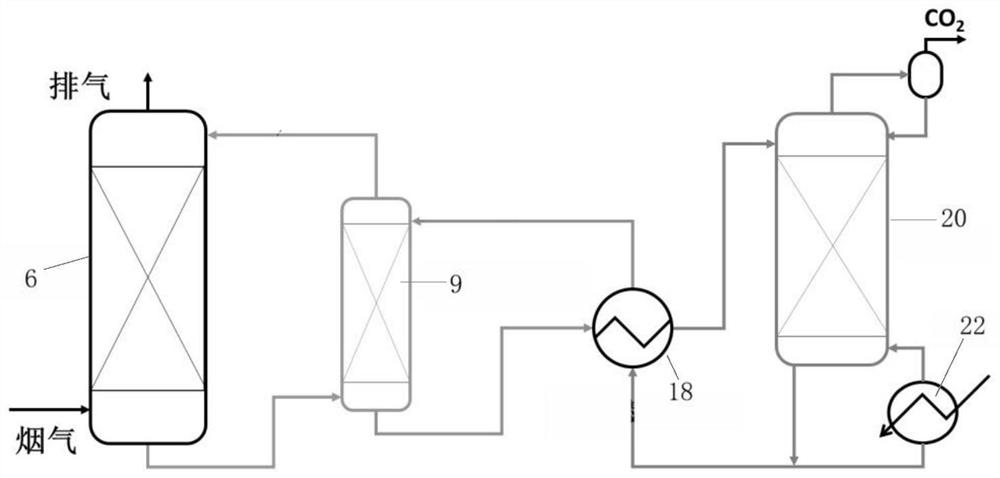

A flue gas carbon dioxide capture system and capture method

ActiveCN104107629BLower capture costsLow costProductsCarbon compoundsHigh concentrationCo2 absorption

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

Continuous trapping and generating apparatus for carbon dioxide in cement kiln flue gas

ActiveCN106914117AReduce the difficulty of capturingLower capture costsGas treatmentUsing liquid separation agentCarbon dioxideFlue gas

The invention relates to a continuous trapping and generating apparatus for carbon dioxide in cement kiln flue gas. The apparatus comprises a tail exhaust fan, an electric three-way air valve, a chimney, a flue gas oxidation purifier, a membrane separation apparatus, a cooler, a flue gas compressor, a CO2 cyclic capturing tower, a waste heat energy-storage apparatus, a dehydration drier, a CO2 cooler, a CO2 compressor, a liquefied CO2 storage tank, a CO2 high-pressure pump, a CO2 energy-storage apparatus, a current stabilizer, a turbine, a generator and a heat regenerator. The apparatus can realize the requirement of external zero power consumption to cement production, is benefit for realizing a circular economy target of four zeros with one negative for cement enterprises, can greatly reduce the exhaust gas, exhaust water, waste heat and dust pollution on environment during a cement production process, and can effectively realize the effective emission reduction and low carbon production for cement production.

Owner:长沙紫宸科技开发有限公司

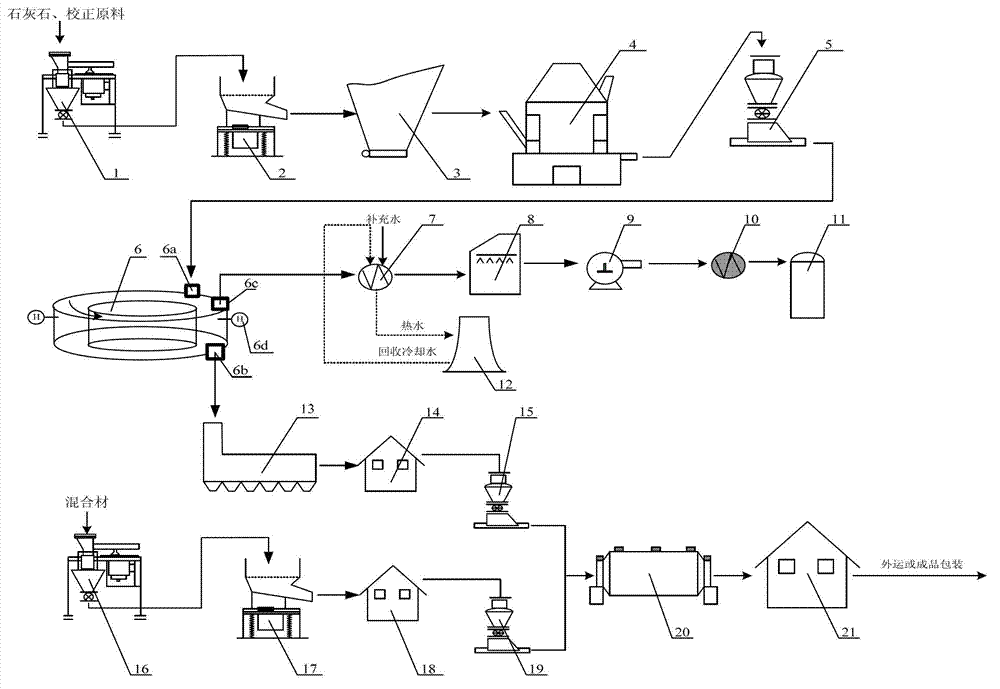

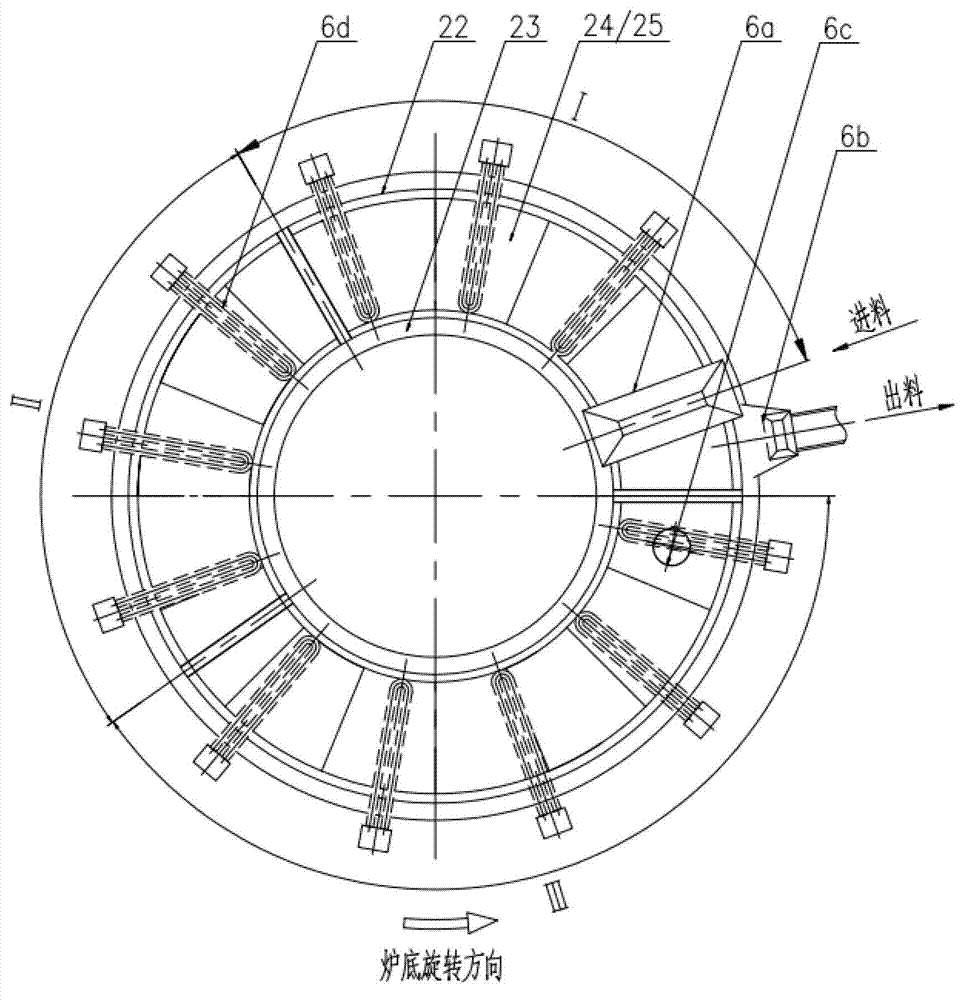

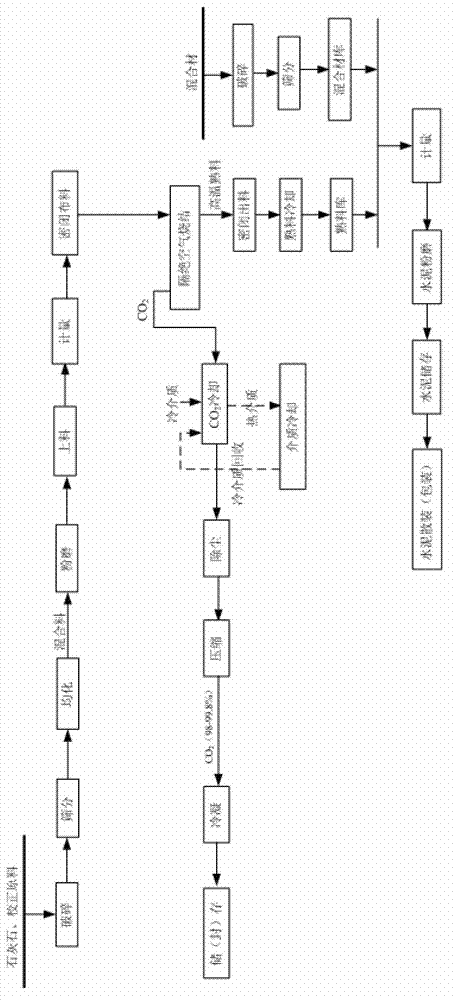

Method and equipment for producing cement and gathering CO2 by utilizing closed ring-shaped calcination furnace

InactiveCN103043930AFor subsequent useEasy to handleFurnace typesClinker productionMixed materialsCement grinding

The invention discloses a method and equipment for producing cement and gathering CO2 by utilizing a closed ring-shaped calcination furnace. The equipment comprises a raw material crusher, a material screening machine, a material homogenizing cabin, a material flour mill, a material metering device and a closed ring-shaped calcination furnace which are connected with one another sequentially, wherein the closed ring-shaped calcination furnace is connected with a CO2 gathering mechanism and a grate cooler respectively; the grate cooler is connected with a clinker storage warehouse and a clinker metering device respectively; the clinker metering device and a blending material preparing mechanism are connected with a cement grinding mill respectively; and the cement grinding mill is connected with a cement storage warehouse. The method comprises the following steps: raw material preprocessing, raw material preparing, clinker calcinating, discharging, carbon gathering, mixed material preparing and cement manufacturing process. The equipment provided by the invention has a compact structure, low investment intensity and a low operation cost, and is easy to maintain. The technological conditions for realizing the production of cement and the gathering of CO2 are mature, and the procedures are simple, so that CO2 generated in the cement producing process can be gathered effectively.

Owner:XIAN UNIV OF SCI & TECH

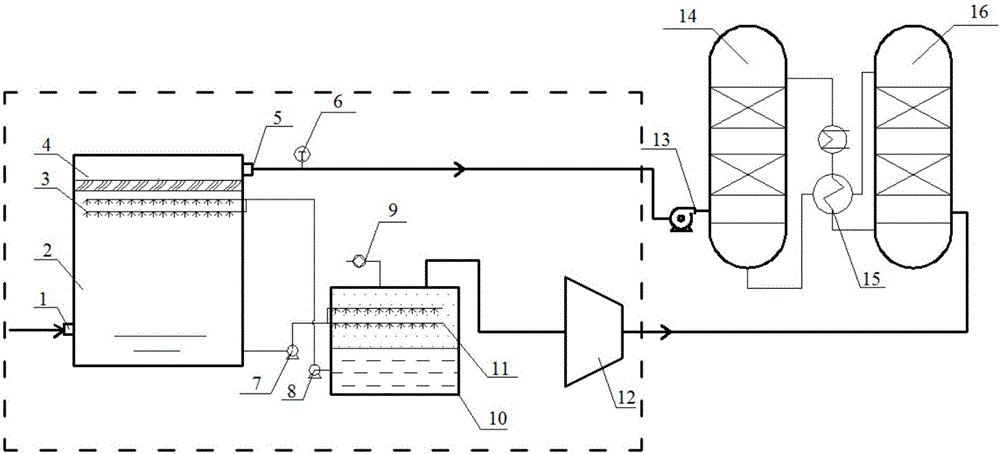

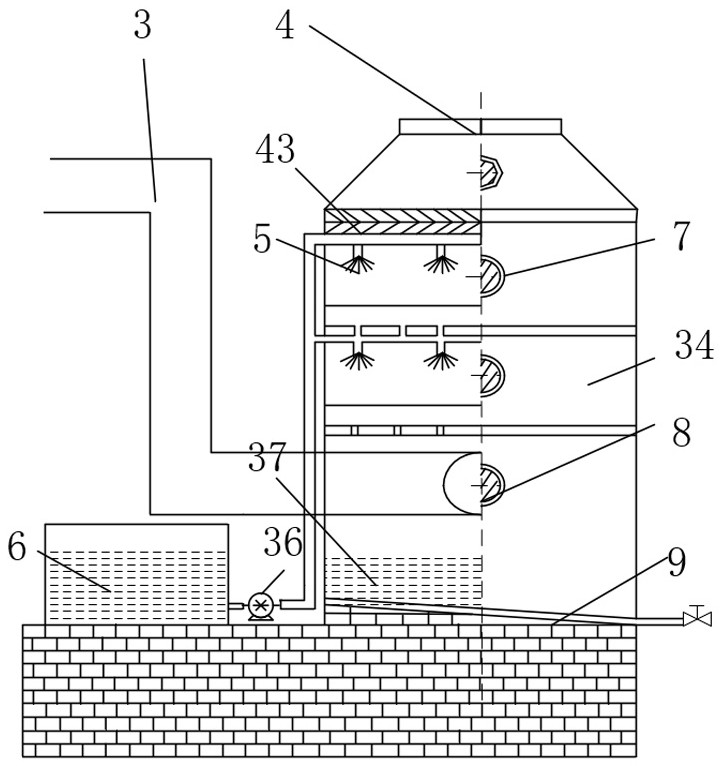

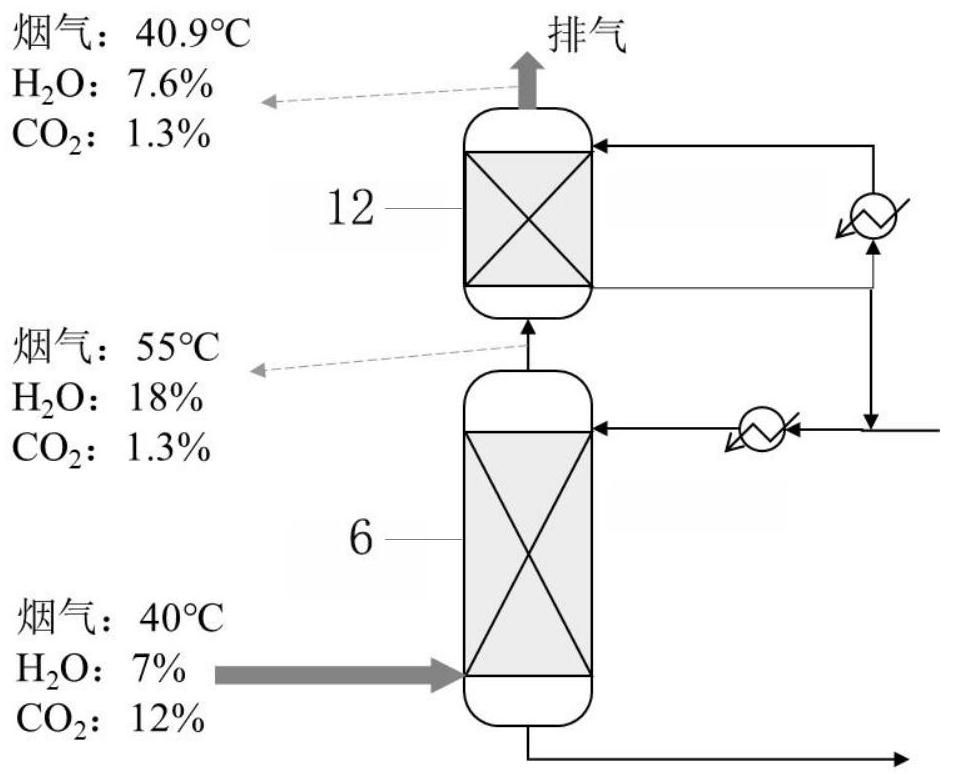

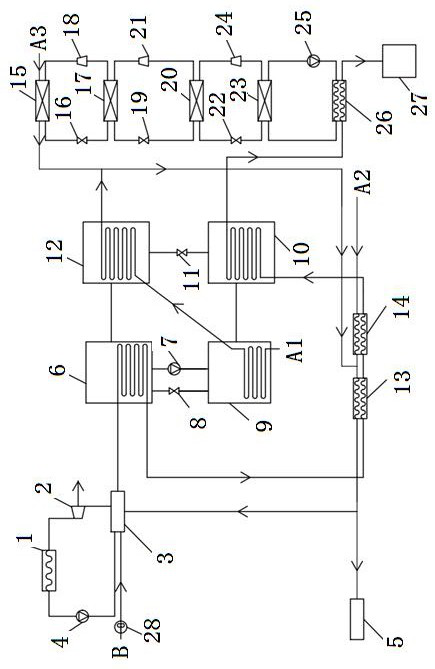

Flue gas pretreatment system for reducing coal-fired flue gas CO2 gathering energy consumption

InactiveCN106731443ARealize "low temperature" flue gasImprove desulfurization efficiencyGas treatmentLighting and heating apparatusFlue gasRecuperator

The invention relates to a flue gas pretreatment system for reducing coal-fired flue gas CO2 gathering energy consumption, and belongs to the field of correlation techniques for coal-fired flue gas CO2 gathering. The flue gas pretreatment system for reducing coal-fired flue gas CO2 gathering energy consumption mainly comprises a direct contact type heat exchanger, wherein the direct contact type heat exchanger is arranged on a flue of a flue gas outlet of a desulfurizing tower; a spraying layer and a demister are arranged in the heat exchanger; the upper part of the heat exchanger communicates with a CO2 gathering device through the flue; a vacuum flashing device and a steam compressing device are arranged on the outer side of the heat exchanger; the bottom of the heat exchanger successively communicates with the vacuum flashing device, the steam compressing device and the CO2 gathering device through pipelines; the bottom of the vacuum flashing device communicates with the spraying layer of the heat exchanger through a pipeline, so that high-temperature water in the heat exchanger is changed into low-temperature water after flowing through the vacuum flashing device, and then is sprayed again from the inside of the heat exchanger. By the design of the brand-new structure, after the flue gas is desulfurized, the temperature of the flue gas can be reduced, the moisture content is reduced, and the effect of reusing waste heat is achieved.

Owner:SHANDONG UNIV

Combustion installation with co2 recovery

InactiveUS20090199749A1Lower capture costsRequired separationFluidized bed combustionCapillary burnersCycloneReduced size

Owner:GENERAL ELECTRIC TECH GMBH

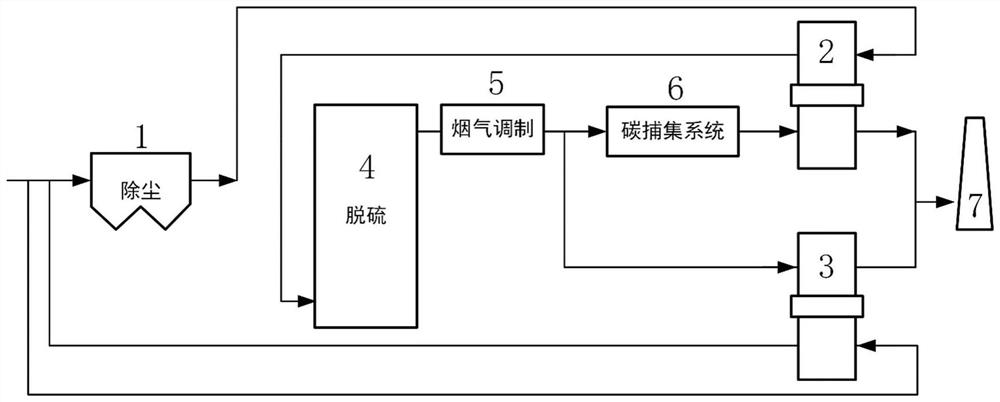

System and method for improving trapping economy of CO2 in flue gas of coal-fired boiler

ActiveCN113813744AImprove capture economicsReduce volumeLighting and heating apparatusDispersed particle separationThermodynamicsFlue gas

The invention discloses a system and a method for improving the trapping economy of CO2 in flue gas of a coal-fired boiler. The system is based on a rotary CO2 adsorption and desorption device, and mainly comprises a dust remover, a flue gas heater, the rotary CO2 adsorption and desorption device, a desulfurization tower, a flue gas conditioning device, a solution absorption method carbon capture device and a chimney. According to the invention, the CO2 concentration of the flue gas entering the solution absorption method carbon capture system is increased by using the rotary carbon dioxide adsorption and desorption device. According to the method, the initial concentration of the CO2 in the flue gas entering the solution absorption process carbon capture device can be increased under the condition of lower energy consumption, so that the energy consumption of a solution absorption method carbon capture system or the volume of the solution absorption method carbon capture system can be greatly reduced, and finally, the carbon dioxide capture cost of a coal-fired boiler is greatly reduced; the carbon capture economy of the system is effectively improved.

Owner:XI AN JIAOTONG UNIV

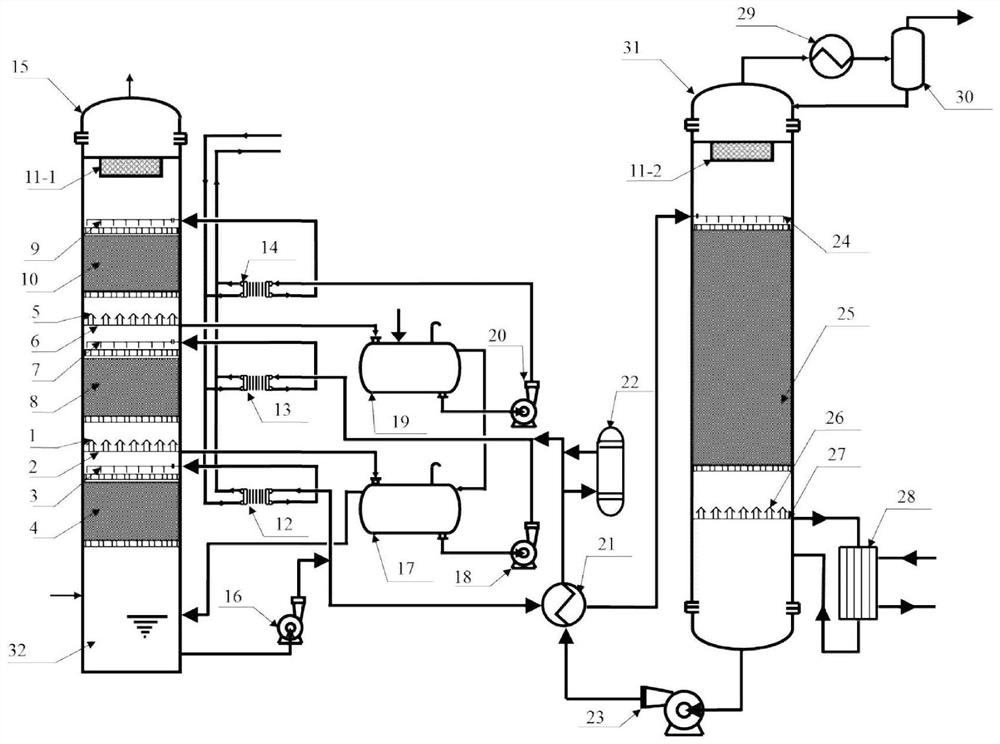

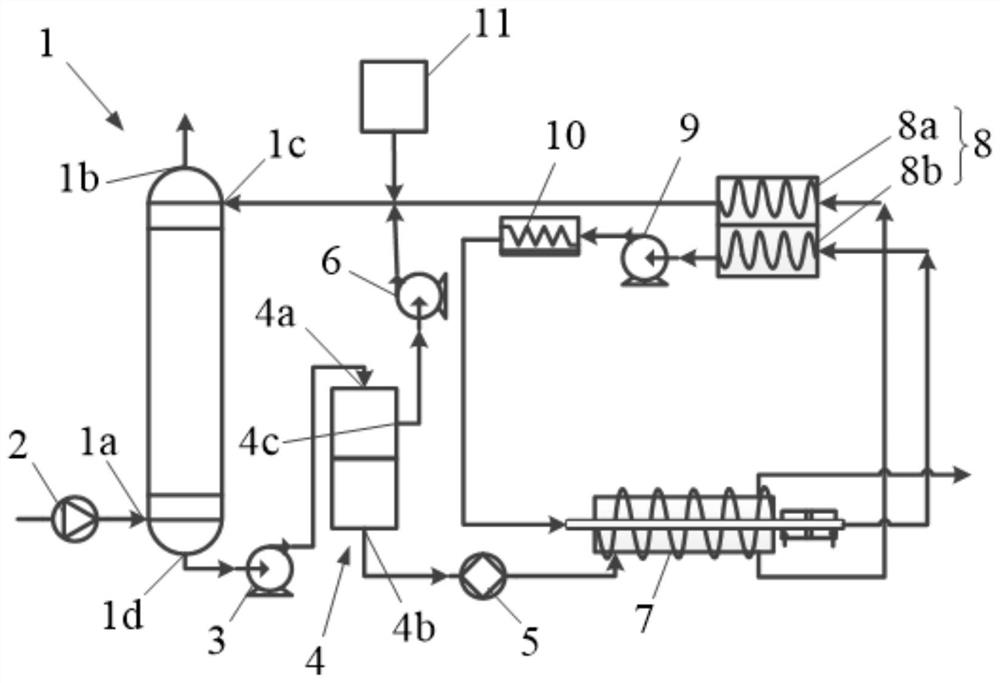

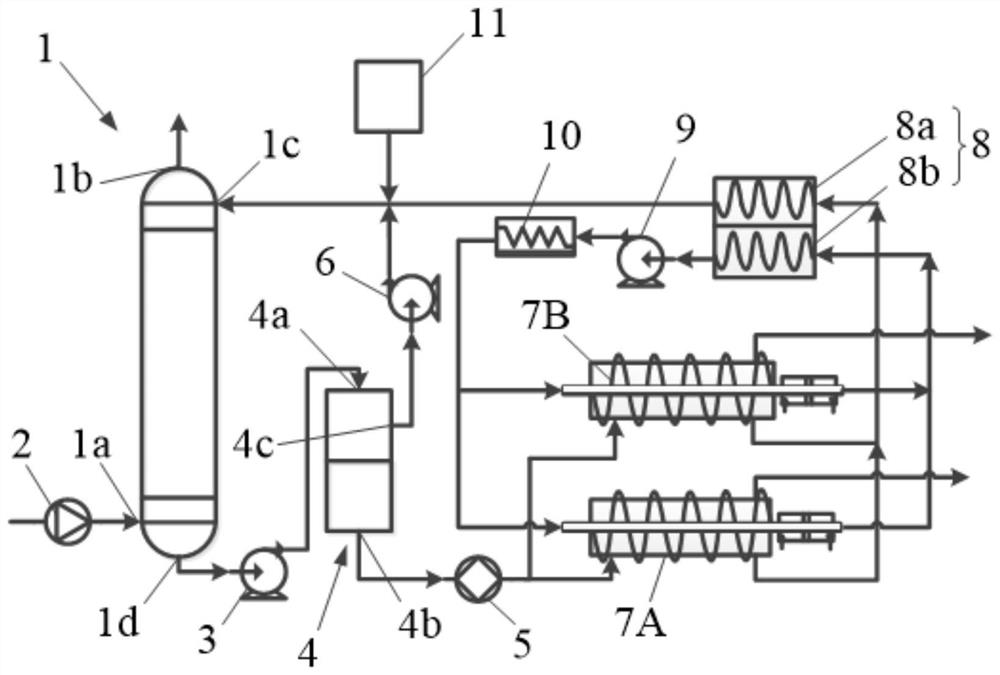

Carbon dioxide trapping system based on phase change absorbent

ActiveCN114452779ALower capture costsIncrease Absorbent LoadDispersed particle separationAir quality improvementEngineeringPower apparatus

The carbon dioxide trapping system based on the phase change absorbent comprises an absorption tower, a phase splitter, a first-class power device, a heat exchange regenerator, a heat pump and a plurality of second-class power devices, and a mixed absorbent outlet of the absorption tower is connected with an absorbent inlet of the phase splitter through one second-class power device. A lean-phase absorbent outlet of the phase splitter is connected with a mixed absorbent inlet of the absorption tower through a second-class power device, a rich-phase absorbent outlet of the phase splitter is connected with a rich-phase absorbent inlet of the heat exchange regenerator through a first-class power device, and a regenerated absorbent outlet of the heat exchange regenerator is connected with a first inlet of the heat pump; a first outlet of the heat pump is connected with a mixed absorbent inlet of the absorption tower, a heat exchange medium outlet of the heat exchange regenerator is connected with a second inlet of the heat pump, a second outlet of the heat pump is connected with a heat exchange medium inlet of the heat exchange regenerator through a second-class power device, and the heat exchange regenerator comprises a gas exhaust port. And the heat exchanger is used for discharging carbon dioxide desorbed from the heat exchange regenerator.

Owner:TSINGHUA UNIV

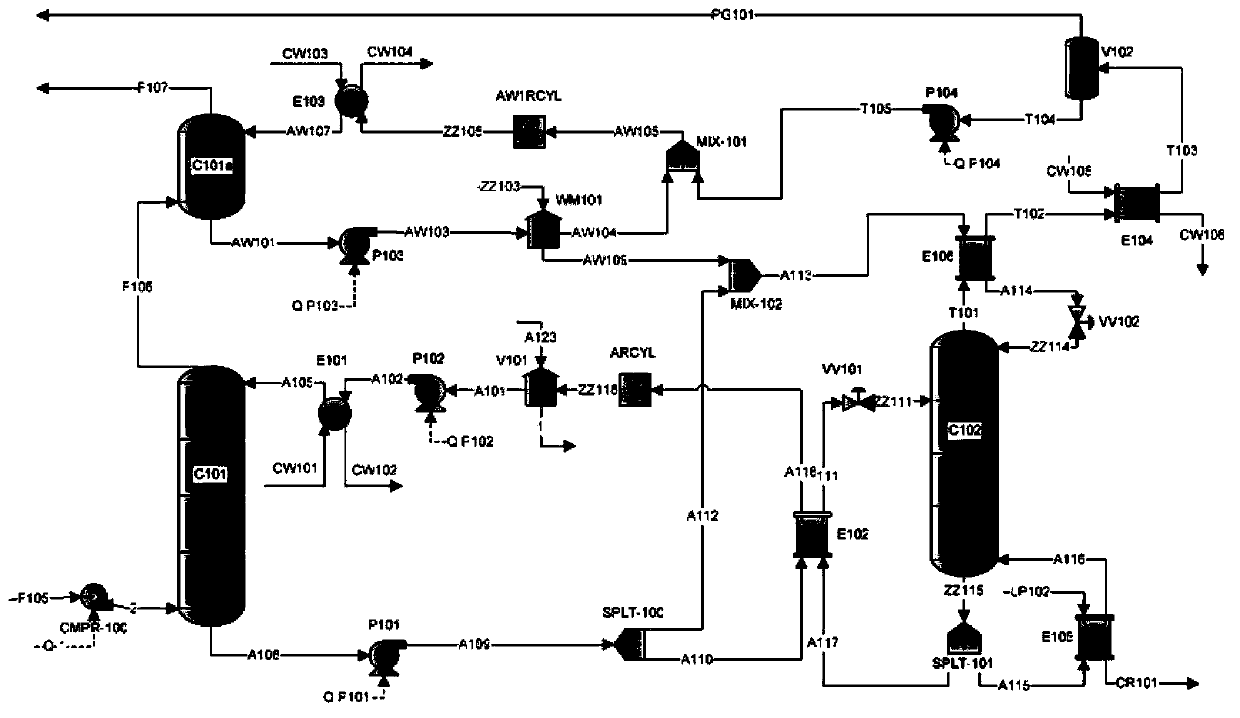

Reversible solid adsorption method and system utilizing waste heat for on-board recovery and storage of CO2 from motor vehicle internal combustion engine exhaust gases

ActiveUS9581062B2Lower the volumeLower capture costsGas treatmentCarbon compoundsOn boardInternal combustion engine

A method and system for on-board treatment of an exhaust stream containing CO2 emitted by an internal combustion engine in order to reduce the amount of CO2 discharged into the atmosphere which include:a. a treatment zone, preferably operating in swing mode with at least two subsystems, on board the vehicle containing a capture agent having a predetermined capacity for extracting CO2 from the exhaust stream, each subsystem having a heat exchanger with an inlet for admitting the hot exhaust gas stream for passage in heat relation with the capture agent to release CO2 and regenerate the capture agent, an outlet for passage of a treated, cooled exhaust stream having a reduced CO2 content, and an outlet for CO2 released from the regenerated capture agent;b. a compression zone for reducing the volume of the CO2; andc. a storage zone for the temporary storage of compressed CO2.

Owner:SAUDI ARABIAN OIL CO

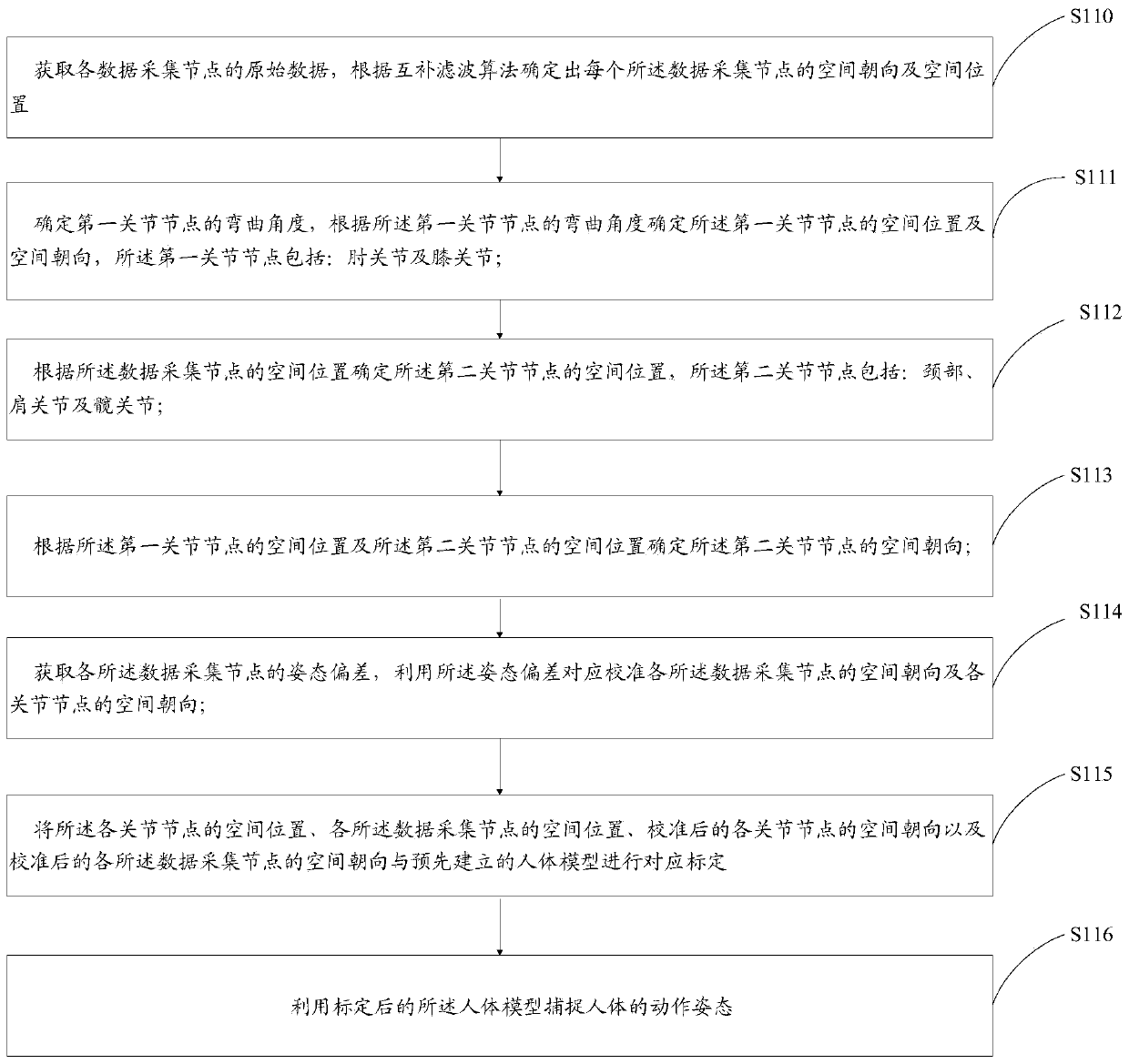

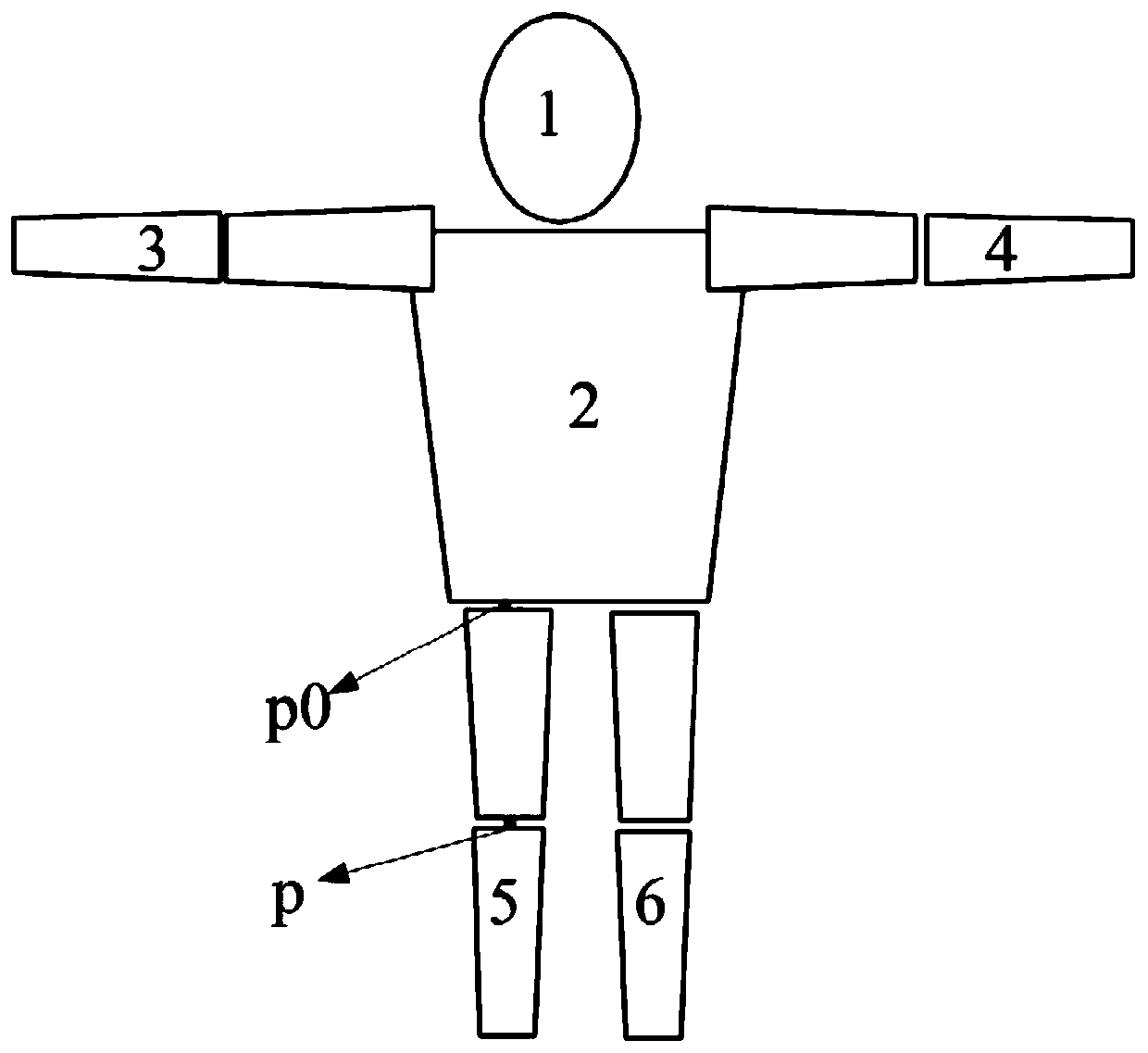

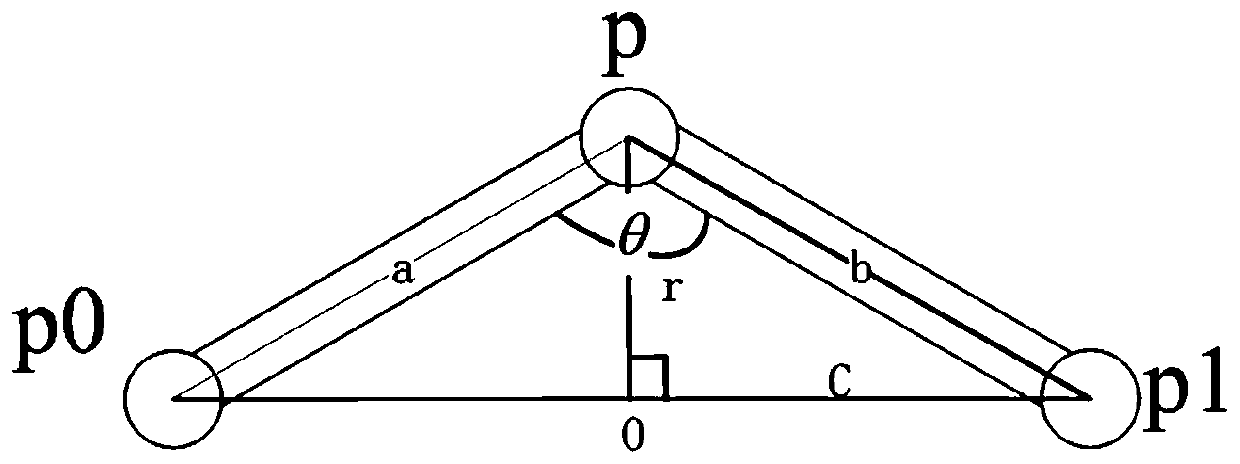

Human body motion posture capturing method and system

ActiveCN111158482AReduce usageLower capture costsInput/output for user-computer interactionGraph readingSpatial OrientationsHuman body

The invention provides a human body motion posture capturing method and system, and the method comprises the steps: determining the spatial orientation and spatial position of each data collection node based on the original data of each data collection node; determining spatial positions and spatial orientations of the joint nodes; calibrating the spatial orientation of each data acquisition nodeand the spatial orientation of each joint node; correspondingly calibrating the spatial position and the spatial orientation of each joint node, the spatial position and the spatial orientation of thedata acquisition node and the human body model; capturing action postures of a human body by utilizing the human body model; thus, calculating the posture of the first joint node of the human body, and then calculating the posture of the second joint node according to the posture of the first joint node, so the capture of the human body action posture can be realized only by setting six data acquisition points, the use number of sensors is effectively reduced, and the capture cost of the human body action posture is reduced.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

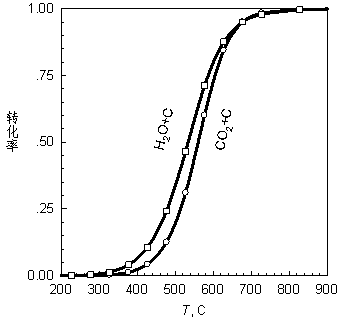

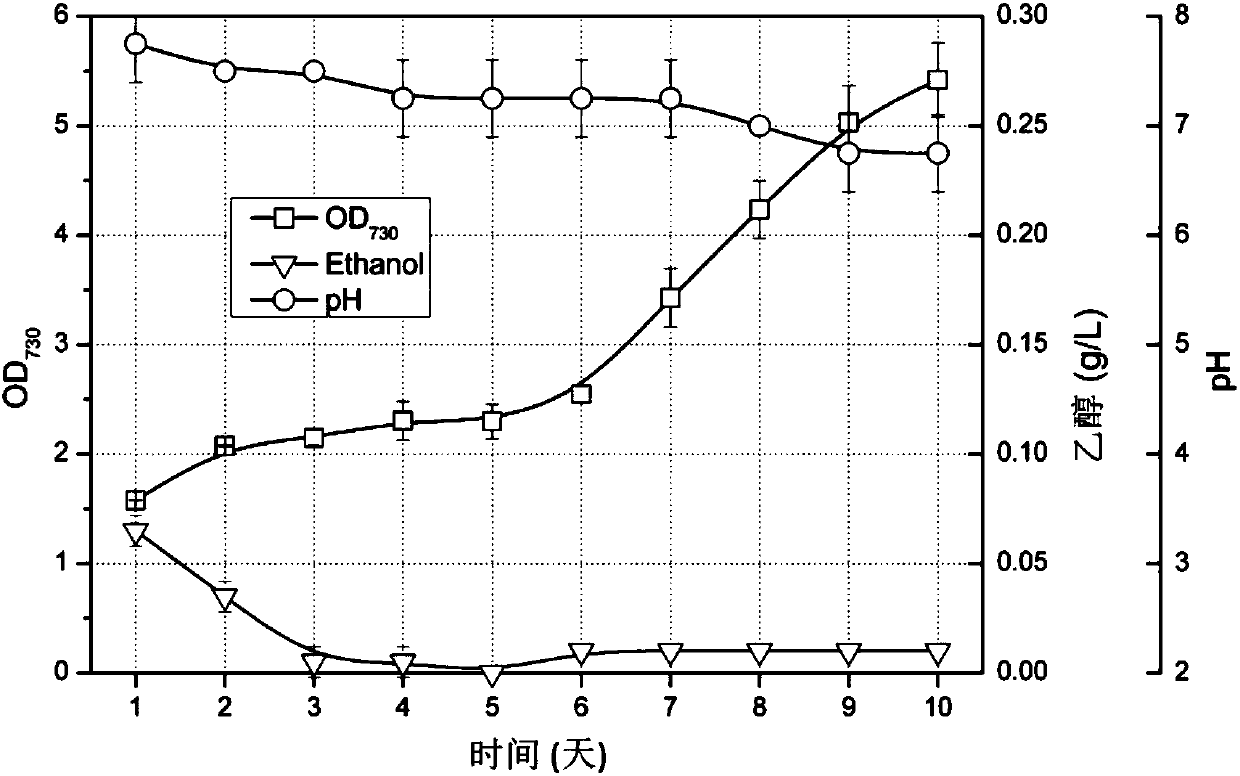

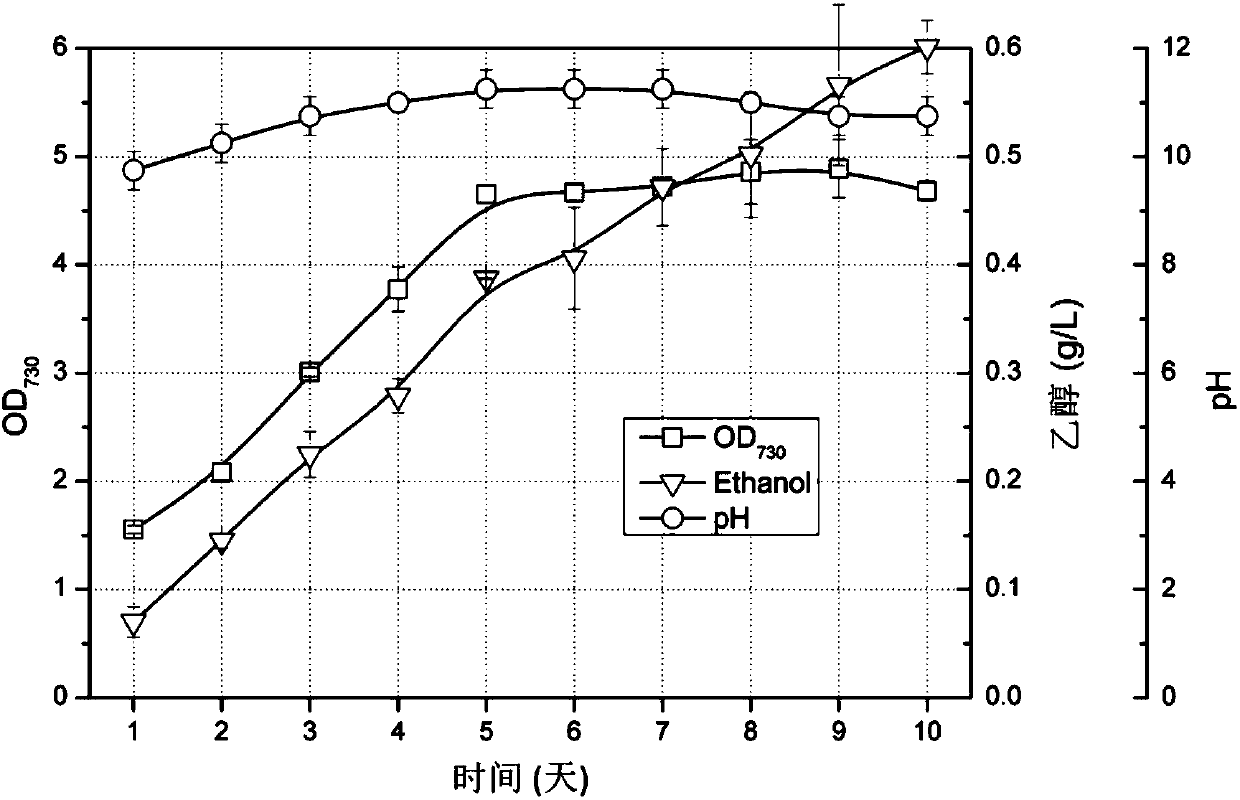

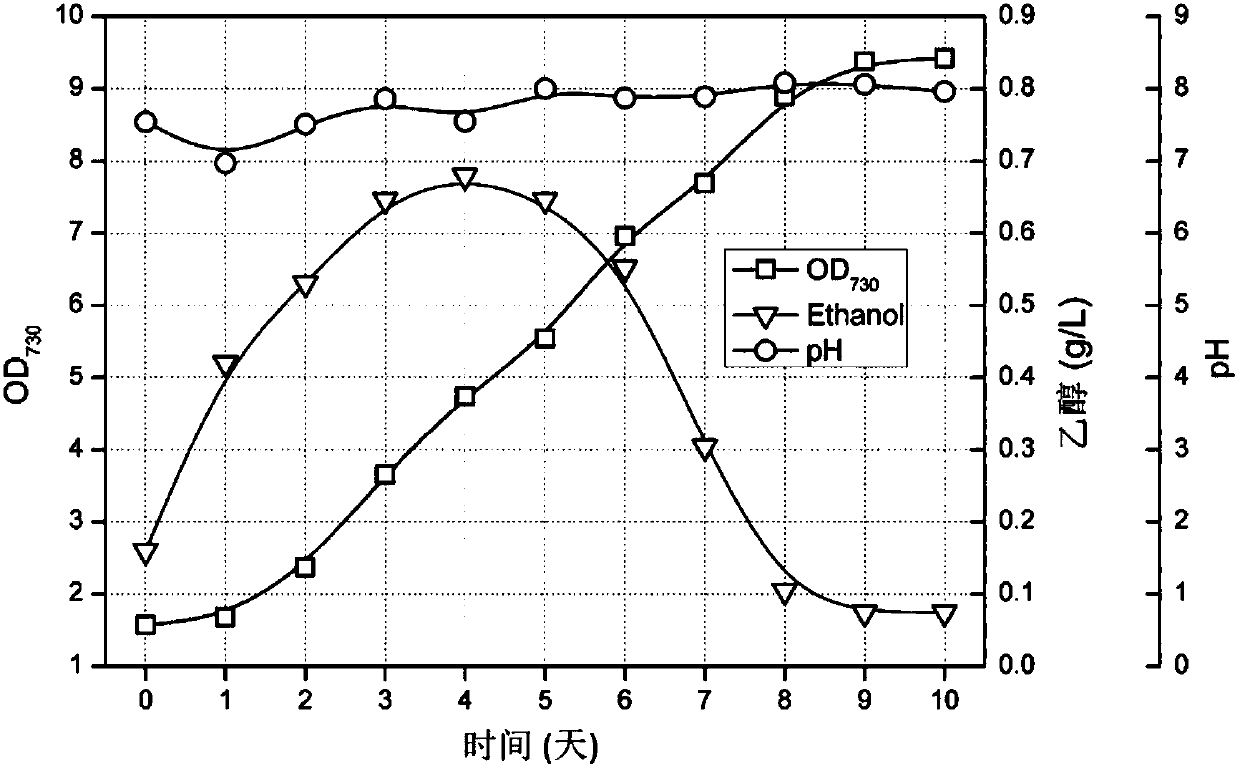

Pollution prevention and control method for ethanol consumption bacteria in ethanol producing genetic engineering cyanobacteria culture system

ActiveCN105950668ALower capture costsImprove capture efficiencyBiofuelsMicroorganism based processesSodium bicarbonateBiotechnology

The invention discloses a pollution prevention and control method for ethanol consumption bacteria in an ethanol producing genetic engineering cyanobacteria culture system and belongs to the technical field of biological energy and the technical field of algal culture. The method mainly solves the technical problem about biological pollution prevention and control over the ethanol consumption bacteria in the genetic engineering cyanobacteria ethanol production process. The method comprises the steps in the ethanol producing genetic engineering cyanobacteria culture process, through a high-pH strategy that the culture system is captured through a sodium bicarbonate carbon source, and the pH value is controlled to gradually rise to 11.0 and kept at 11.0+ / -0.5 in the culture process, breeding of the ethanol consumption bacteria and ethanol consumption in the culture process are inhibited. The method can provide reference for a large-scale cyanobacteria culture pollution control system, and has important significance on biology liquid fuel produced from genetic engineering cyanobacteria.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

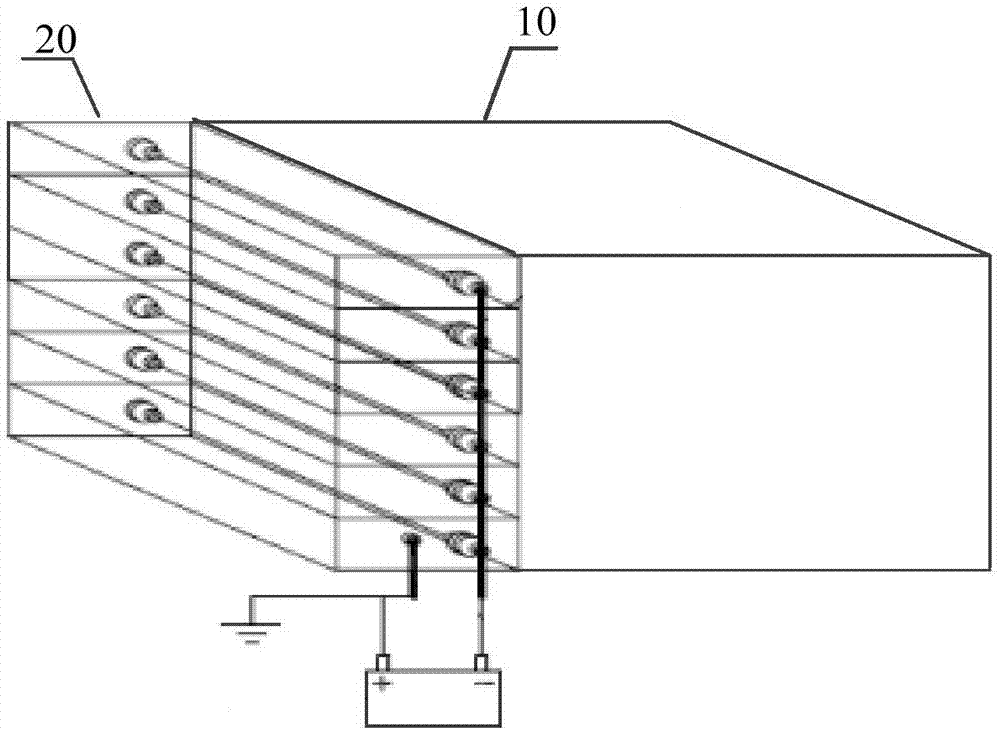

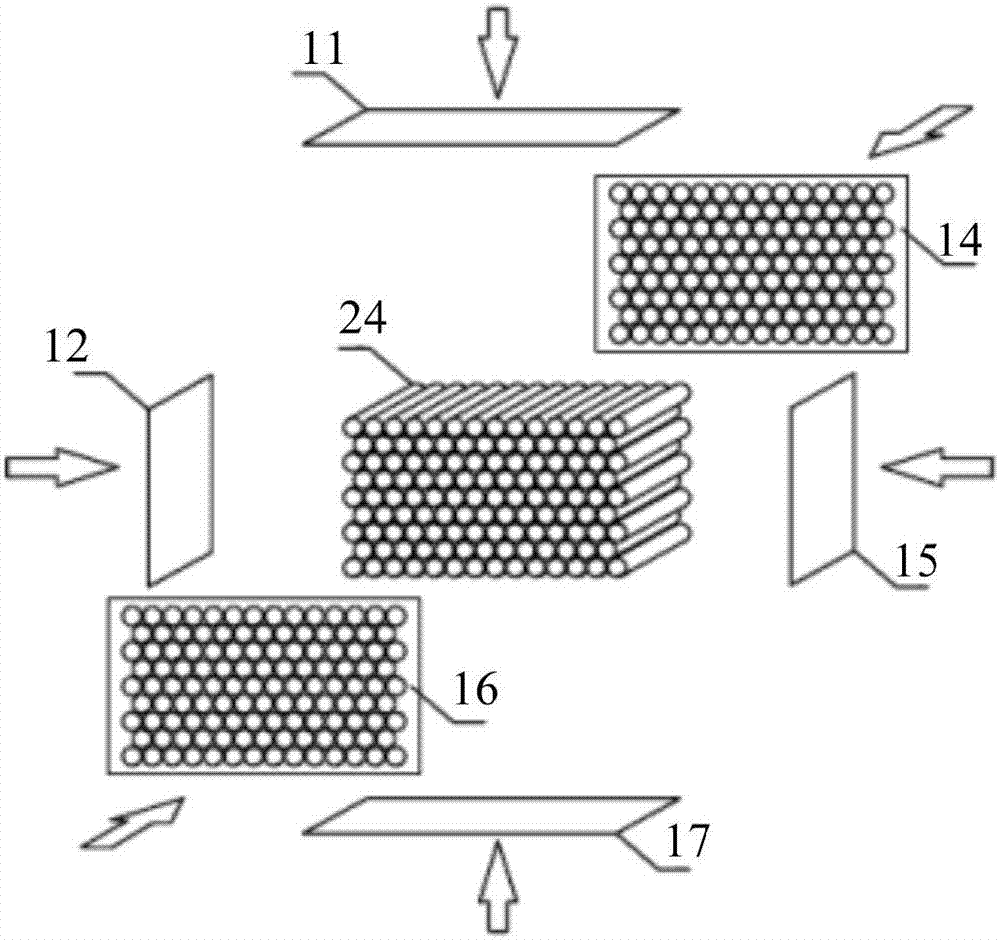

Particulate matter trapping device

ActiveCN107413527AReduce resistanceLarge circulationExternal electric electrostatic seperatorElectrostatic separation detailsElectricityParticulates

The invention discloses a particulate matter trapping device. The device comprises filter brushes, a shell and a gas ionization device, wherein a plurality of through holes penetrate from an air inlet face to an air outlet face of the shell, the filter brushes are inserted into the through holes in a one-to-one correspondence manner, the filter brushes are in contact with the side walls of the corresponding through holes, the shell is made of conductive metal, the filter brushes comprise piezoelectric materials, the gas ionization device is arranged on the air inlet surface of the shell, when the air flows through the gas ionization device, the gas ionization device charges the particulate matter in the air, then the air flows through the through holes, the filter brushes generate charge due to the pressure of the air on the filter brushes, the charge is transmitted to the side walls of the corresponding through holes, and the particulate matter in the air is trapped. The device has the advantages that the gas resistance is low, secondary pollution is greatly reduced, the trapped particulate matter can be removed by cleaning the shell, and therefore repeated use of the shell can be realized, and the cost can be reduced.

Owner:JIANGSU ZHONGKE RUISAI POLLUTION CONTROL ENG

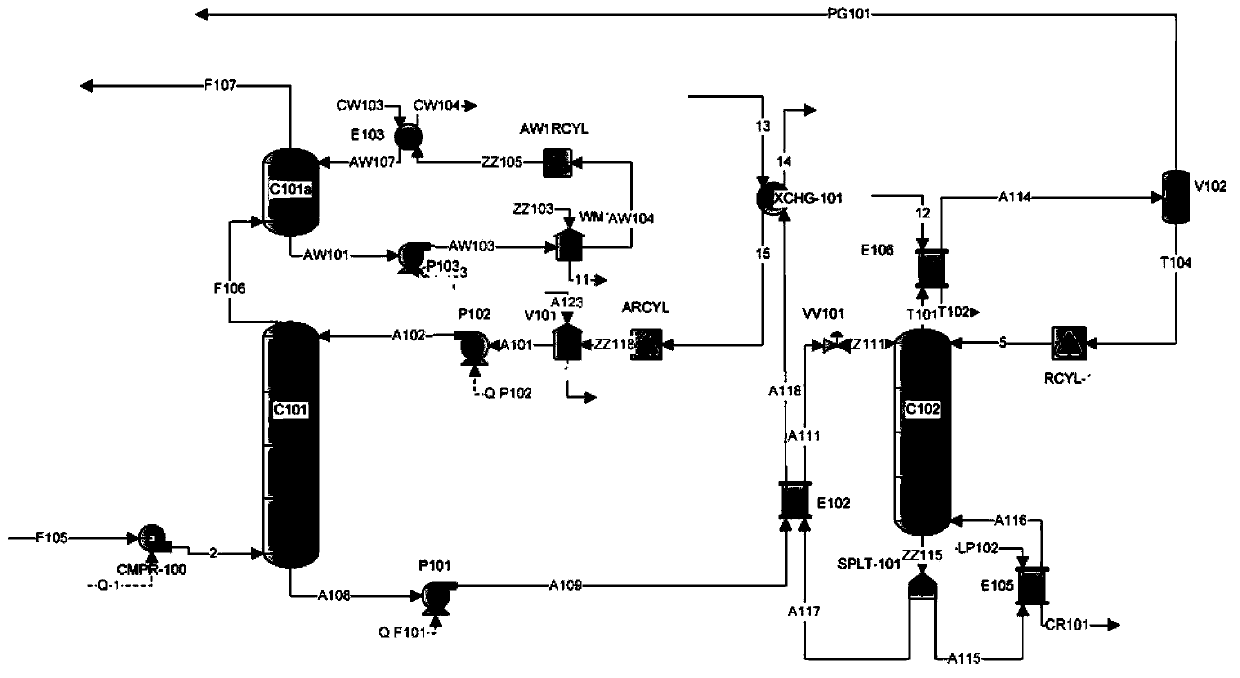

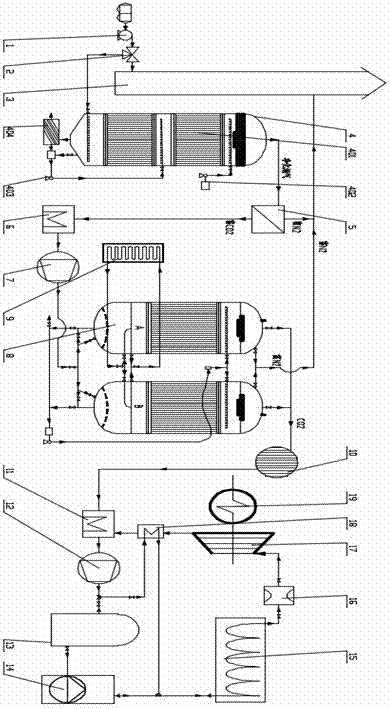

Coal-fired power plant carbon dioxide ammonia process trapping and low-temperature liquefaction system and method

InactiveCN112221327AEfficient recyclingAvoid wastingProductsGas treatmentVapor–liquid separatorCo2 absorption

The invention provides a coal-fired power plant carbon dioxide ammonia process trapping and low-temperature liquefaction system and method. The system comprises a carbon dioxide chemical process trapping system, a low-temperature liquefaction system and an absorbent recycling system, and the carbon dioxide chemical process trapping system comprises a carbon dioxide absorption tower, an ammonia gasabsorption tower and a carbon dioxide desorption tower; the low-temperature liquefaction system comprises a pneumatic dryer, a gas supercharger, a screw compressor, a condenser and an evaporator; andthe absorbent recycling part comprises a gas-liquid separator, a throttle valve, a liquid one-way valve, a gas one-way valve, a liquid ammonia storage tank and a liquid ammonia evaporator. The coal-fired power plant carbon dioxide ammonia process trapping and low-temperature liquefaction system has the characteristics of efficiently capturing carbon dioxide, reducing the greenhouse effect and protecting the environment, and can be widely applied to various coal-fired power plants and related coal-fired industry industries.

Owner:HENAN POLYTECHNIC UNIV

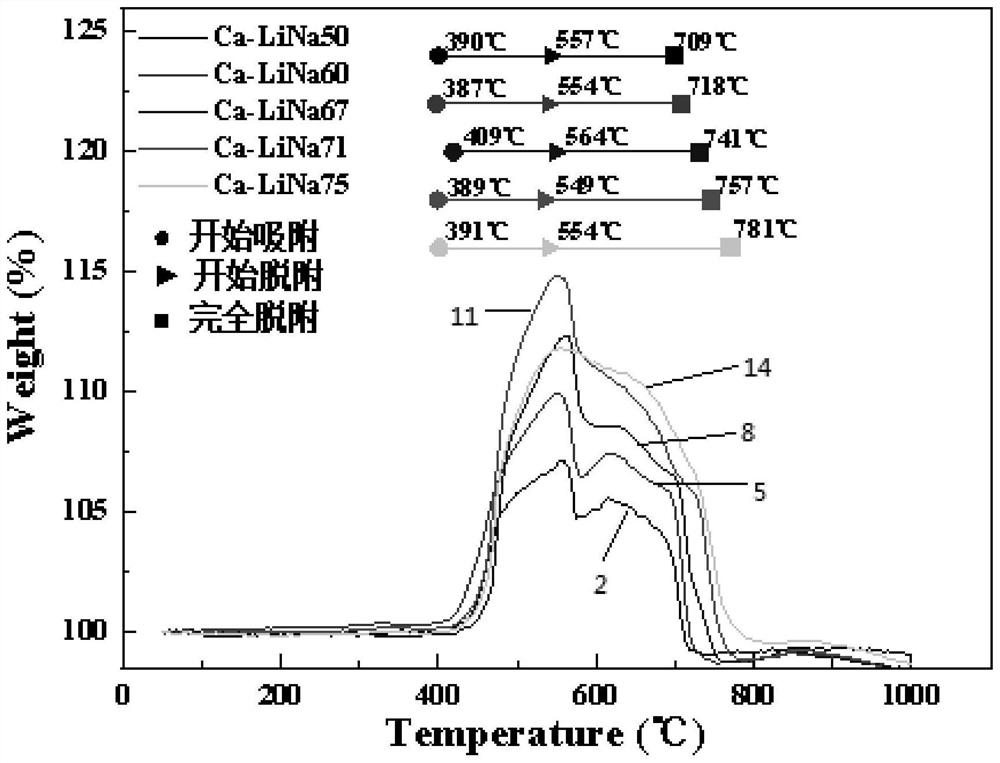

Carbon dioxide trapping agent and preparation method thereof

InactiveCN111974344AAchieve reuseShort capture timeProductsGas treatmentCalcium silicateEnvironmental engineering

The invention provides a carbon dioxide trapping agent and a preparation method thereof, and relates to the technical field of energy conservation and emission reduction. The carbon dioxide trapping agent comprises the following raw materials: calcium orthosilicate and an alkali metal carbonate, wherein the molar quantity of the alkali metal carbonate accounts for 60% or more of the total molar quantity of the calcium orthosilicate and the alkali metal carbonate. The method has the advantages that the carbon dioxide trapping agent is wide in raw material source, low in preparation cost, low intrapping temperature and capable of achieving rapid regeneration, and no pollutant is generated in the whole process.

Owner:SHANGHAI UNIV

Spherical solid amine multistage thin-layer bubbling bed carbon dioxide trapping and desorbing system and spherical solid amine multistage thin-layer bubbling bed carbon dioxide trapping and desorbing method

PendingCN113856411AAchieving Countercurrent ContactIncrease capture rateGas treatmentDispersed particle separationFlue gasSorbent

The invention provides a spherical solid amine multi-stage thin-layer bubbling bed carbon dioxide trapping and desorbing system and a spherical solid amine multi-stage thin-layer bubbling bed carbon dioxide trapping and desorbing method. In the system, at least two groups of thin-layer bubbling bed components are laminated in an adsorption device from top to bottom, and a main body of each group of thin-layer bubbling bed components is a gas distribution pore plate. One end of each gas distribution hole plate is a feeding end, the other end of each gas distribution hole plate is a discharging end, a discharging pipe is arranged at the discharging end of each gas distribution hole plate, and the lower end of each discharging pipe is open and is communicated with the feeding end of the next group of gas distribution hole plates. A gas outlet is formed in the top of the adsorption device, and a flue gas inlet and an adsorbent discharge pipe are arranged at the lower part of the adsorption device; and the top of the desorption device is sequentially provided with a filter and a desorbed gas outlet, the lower part is provided with a heating coil and a distributor, and the bottom is provided with a material outlet; a cooling pipe and a distribution pipe are arranged in the cooling device, and the top of the cooling device is connected with a lifting pipe; and the upper end of the lifting pipe extends into the adsorption device. The system is used for industrial flue gas CO2 capture, the CO2 capture rate is high, and a high-purity CO2 product can be produced.

Owner:BEIJING DERUNCHEN ENVIRONMENTAL PROTECTION TECH CO LTD

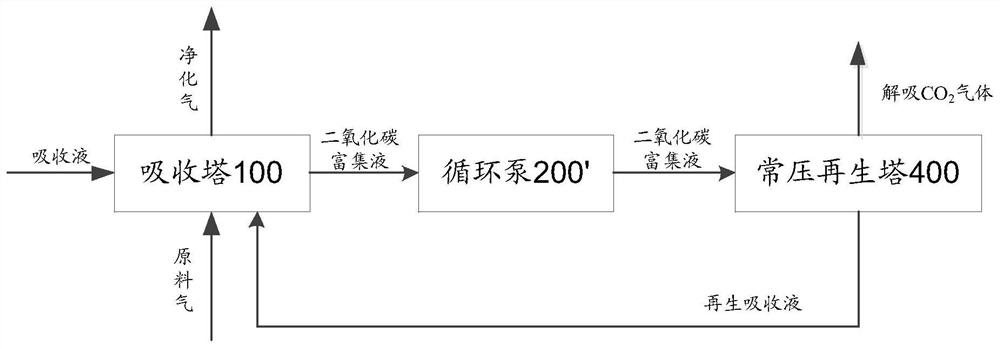

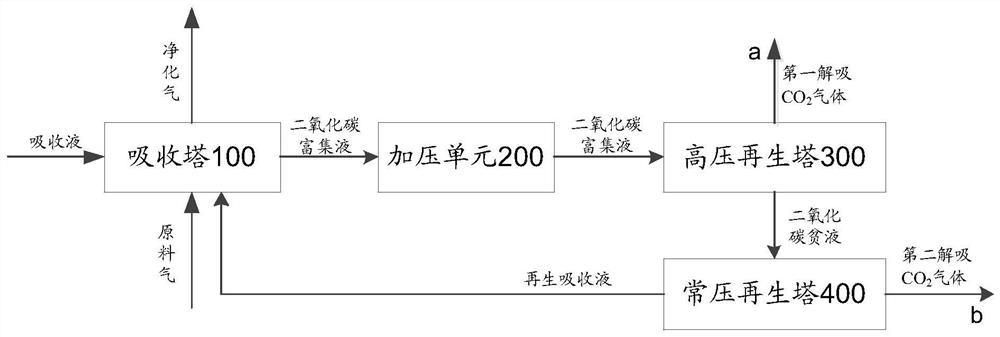

CO2 trapping device and method

InactiveCN111715033AReduce compression costsLow heat of vaporizationDispersed particle separationThermodynamicsTrapping

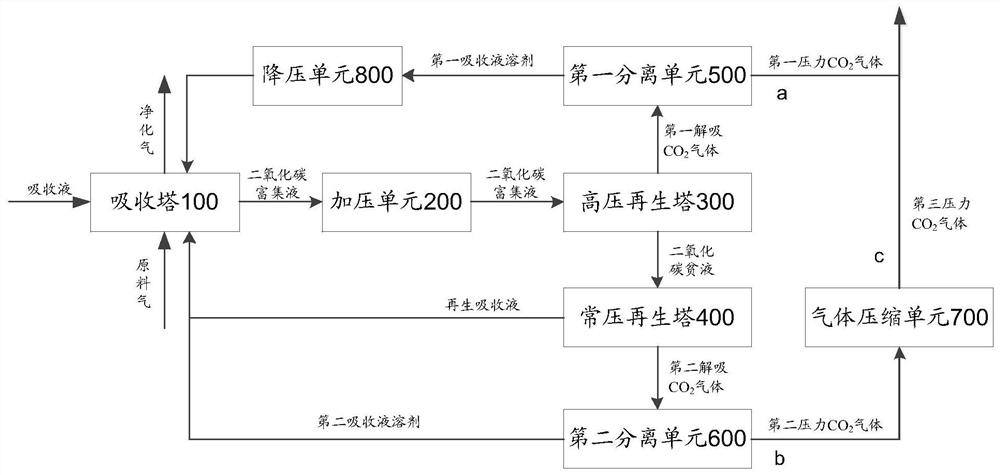

The invention discloses a CO2 trapping device and method, relates to the technical field of gas purification, and aims to improve the carbon dioxide desorption speed and reduce the carbon dioxide trapping energy consumption at the same time. The CO2 trapping device comprises an absorption tower, a high-pressure regeneration tower and a normal-pressure regeneration tower; the liquid outlet of the absorption tower is connected with the liquid inlet of the high-pressure regeneration tower; the liquid outlet of the high-pressure regeneration tower is connected with the liquid inlet of the normal-pressure regeneration tower, the liquid outlet of the normal-pressure regeneration tower is connected with the liquid inlet of the absorption tower, the gas outlet of the normal-pressure regeneration tower is connected with a second carbon dioxide branch, and the pressure of the high-pressure regeneration tower is equal to a preset carbon dioxide pressure. The CO2 trapping method is applied to theCO2 trapping device. The provided CO2 trapping device and method are used for gas purification.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

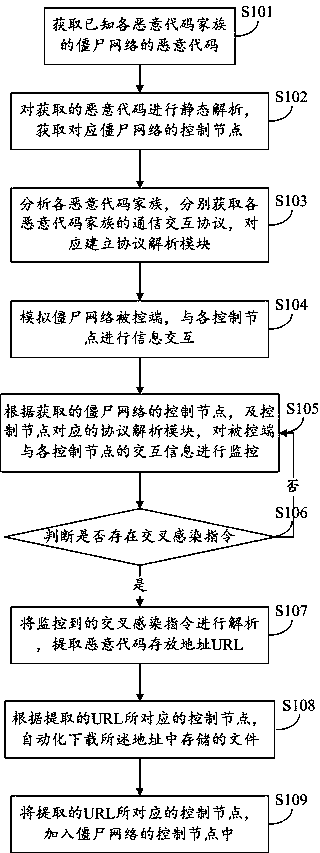

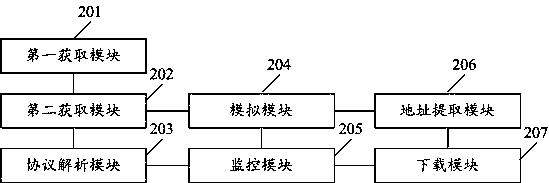

Method and system for monitoring and capturing file server site for online storage of malicious codes based on cluster botnet

The invention provides a method and a system for monitoring and capturing a file server site for online storage of malicious codes based on a cluster botnet. The method comprises the following steps of acquiring malicious codes of a botnet of each known malicious code family, analyzing a control node, acquiring a protocol of each malicious code family, and establishing a protocol analysis module;and simulating a controlled end and carrying out information interaction and monitoring with a control end in order to acquire a cross infection instruction, analyzing a malicious code storage address, namely the newly found file server site for online storage of the malicious codes, according to the cross infection instruction, and carrying out package downloading on files in the address. According to the technical scheme, the cluster botnet can be monitored, the situation of cross infection of the malicious codes can be found in time, and the new file server site for online storage of the malicious codes can be found. Meanwhile, the monitoring of the new file server site for online storage of the malicious codes is monitored, the monitoring of the control end in the past is combined, andinteractive monitoring between the botnets can be realized.

Owner:BEIJING ANTIY NETWORK SAFETY TECH CO LTD

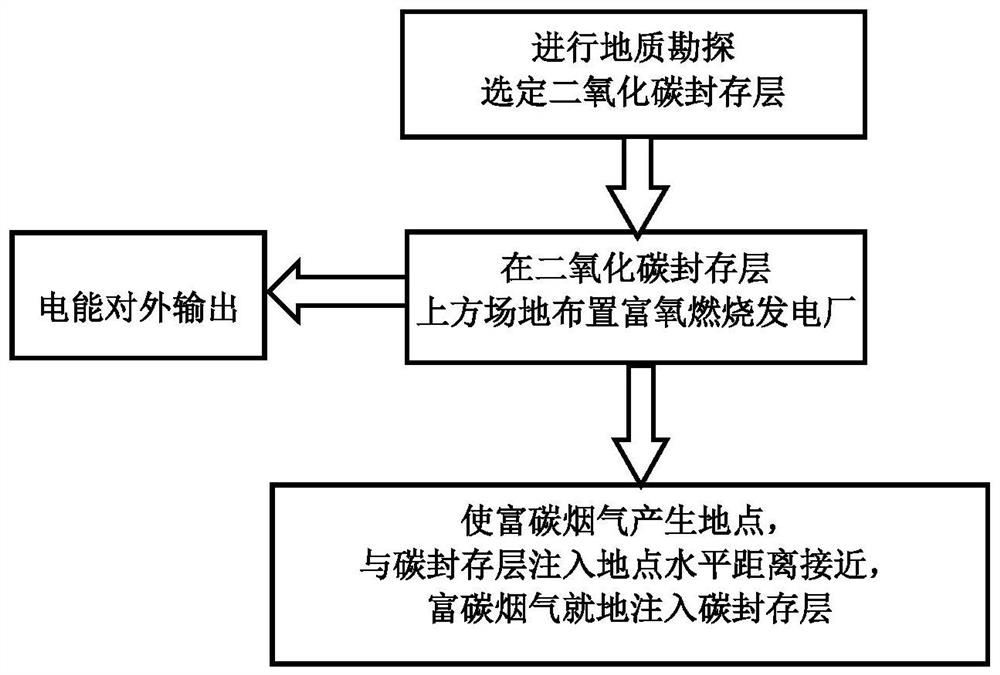

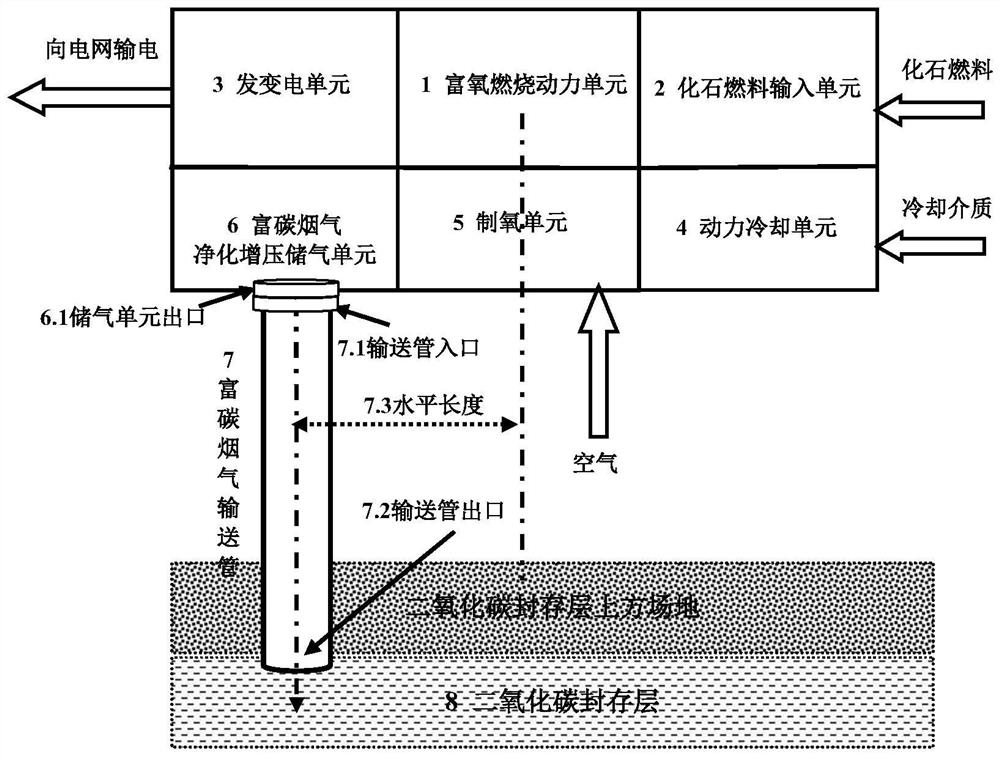

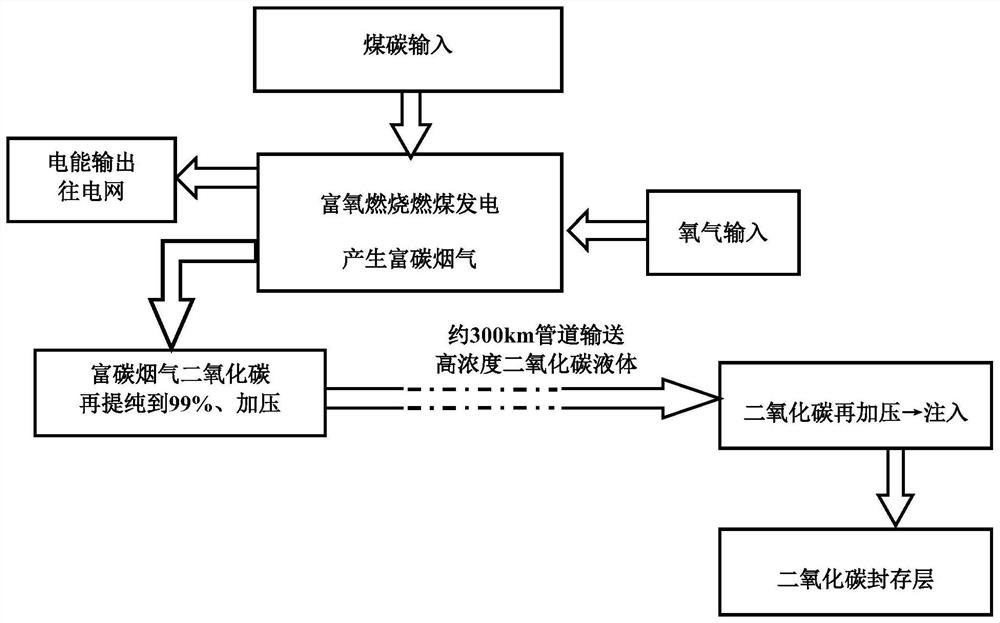

Zero-carbon-emission fossil fuel power generation method and device system

PendingCN113871653AOmit long-distance transportationLower capture costsCarbon compoundsOther gas emission reduction technologiesFlue gasEnvironmental engineering

The invention discloses a zero-carbon-emission fossil fuel power generation method and device system, and the method comprises the steps: carrying out the geological exploration, selecting a carbon dioxide storage layer, building a fossil fuel power plant at a site above the selected carbon dioxide storage layer, carrying out the oxygen-enriched combustion power generation of oxygen blowing in fossil fuel in the power plant, and transmitting the generated electric energy to the outside. Generated flue gas rich in carbon dioxide is injected into a carbon dioxide storage layer in situ; according to the invention, the horizontal distance between the generation place of the carbon dioxide-rich flue gas and the injection place of the carbon dioxide sequestration layer is close, and the carbon-rich flue gas containing 50%-95% of carbon dioxide is directly injected into the carbon sequestration layer, so that a long-distance transportation link between a carbon capture link and a carbon sequestration link is omitted; and the carbon capture cost and the whole-process CCS cost can be greatly reduced, so that zero-carbon-emission fossil fuel power generation can be economically and feasibly realized.

Owner:彭斯干

Flue gas carbon dioxide trapping system and method based on organic solvent absorption-extraction regeneration cycle

ActiveCN113101786ASmall sizeReduce heat consumptionGas treatmentDispersed particle separationFlue gasOrganic solvent

The invention relates to a flue gas carbon dioxide trapping system based on organic solvent absorption-extraction regeneration cycle. The flue gas carbon dioxide trapping system comprises a flue gas pretreatment tower, an absorption tower, an extraction regeneration tower, a desorption tower, a water balance tower and a solvent recovery tower; a flue gas outlet in the top of the flue gas pretreatment tower is connected to a flue gas inlet in the lower part of the absorption tower; a flue gas outlet in the top of the absorption tower is connected to a flue gas inlet in the bottom of the water balance tower; a flue gas outlet in the top of the water balance tower is connected to a flue gas inlet in the bottom of the solvent recovery tower through a flue gas pipeline; and a rich liquid outlet of the absorption tower is connected to a rich liquid inlet in the bottom of the extraction regeneration tower; an organic phase outlet in the top of the extraction regeneration tower is connected to an organic solvent inlet in the upper part of the absorption tower. The system disclosed by the invention has the beneficial effects that the advantages that the CO2 absorption rate of an organic solvent in the absorption tower is relatively high and the CO2 circulation capacity of a rich solution in the regeneration tower is large are fully exerted, so that the size of the absorption tower is reduced, the heat consumption of the desorption tower is reduced, and the carbon capture cost is reduced.

Owner:ZHEJIANG ZHENENG TECHN RES INST

Flue gas waste heat utilization and carbon dioxide capture and recovery process

PendingCN114279254AImprove heat utilizationDouble benefits of energy saving and environmental protectionDispersed particle separationIndirect heat exchangersWater recoveryCarbon dioxide

The invention discloses a flue gas waste heat utilization and carbon dioxide capture and recovery process, an adopted system comprises a steam power generation system, an absorption type unit, a cascade refrigeration system and the like, high-temperature flue gas transfers heat to the steam power generation system through heat exchange, and the temperature of water in a waste heat boiler of the steam power generation system is increased. Flue gas serves as a heating medium to provide heat for the absorption unit, the flue gas exchanges heat with an evaporator of the absorption unit, the evaporation temperature of the absorption unit is increased, and the circulation efficiency is improved. And heat is transferred to a boiler or a power generation system through a condenser of the absorption type unit to supply water, and flue gas heat is recycled. And the cascade refrigeration system performs low-temperature liquefaction, so that the flue gas is liquefied under the condition of extremely low temperature, and the purpose of removing carbon dioxide is achieved. Flue gas heat is recycled repeatedly, the flue gas heat utilization rate is greatly increased, and energy-saving and environment-friendly double benefits are achieved.

Owner:YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com