Steam-attemperation-based oxygen-enriched combustion and natural gas hydrate development co-production system and method

An oxygen-enriched combustion and natural gas technology, which is applied in the combustion method, steam generation, combustion air/fuel supply, etc., can solve the problems of poor fuel supply continuity, large natural gas transportation volume, and high separation energy consumption, so as to reduce renovation costs. , The effect of sufficient fuel combustion and protection of the atmospheric environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

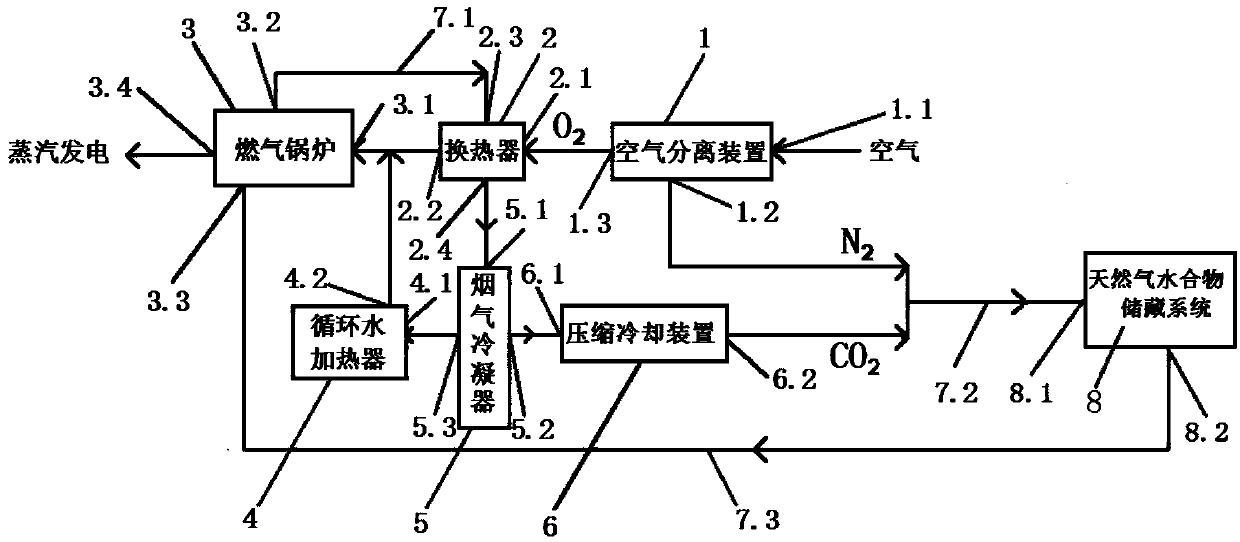

[0027] like figure 1 Shown in the present invention is an oxygen-enriched combustion and natural gas hydrate cogeneration system based on steam temperature regulation, including an air separation device 1, a heat exchanger 2, a gas boiler 3, a circulating water heater 4, and a flue gas condenser 5 , a compression cooling device 6, and a natural gas hydrate storage system 8; the air separation device 1 is provided with an air inlet 1.1, a nitrogen outlet 1.2, and an oxygen-enriched outlet 1.3; The oxygen inlet 2.1 is connected, and the high-temperature oxygen outlet 2.2 of the heat exchanger 2 is connected with the high-temperature oxygen inlet 3.1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com