Partitioned multi-stage circulating CO2 trapping and concentrating method based on mass transfer-reaction regulation and control

A technology of CO2 and reaction, which is applied in the field of CO2 capture and concentration based on mass transfer-reaction control, and can solve the problems of difficulty in improving capture efficiency, small adjustable range of system operating parameters, and low desorption energy consumption. , achieve the effects of high-efficiency suppression of secondary pollutants, reasonable temperature distribution in the tower, and reduced desorption energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

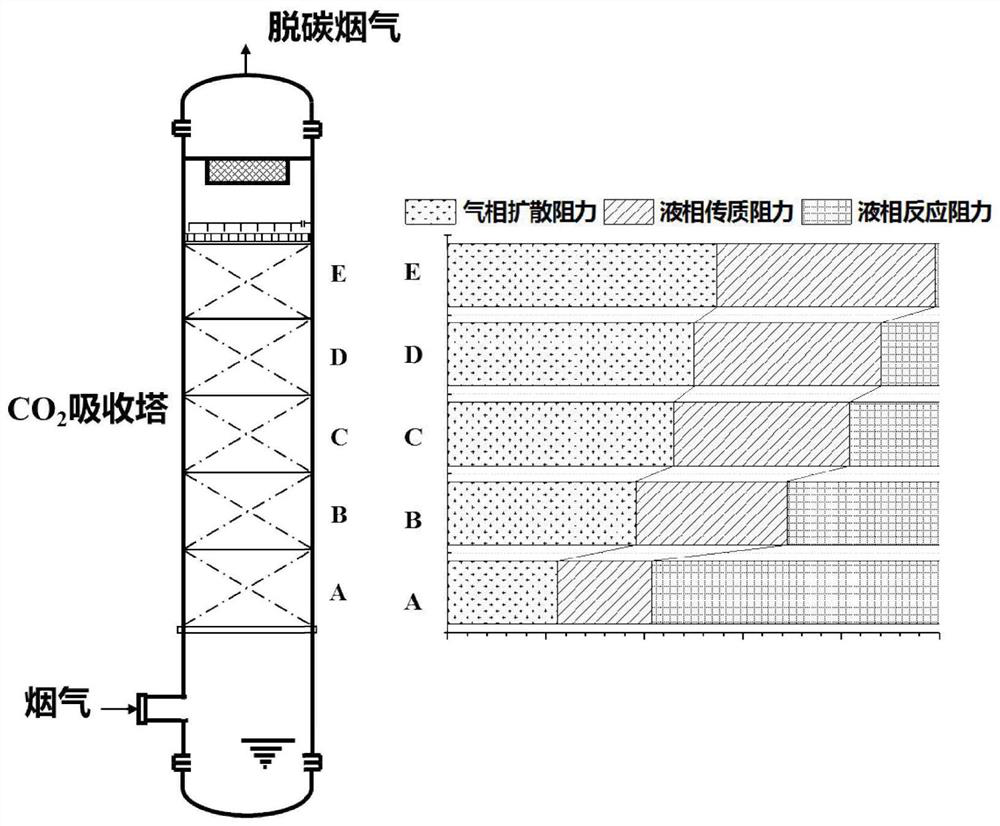

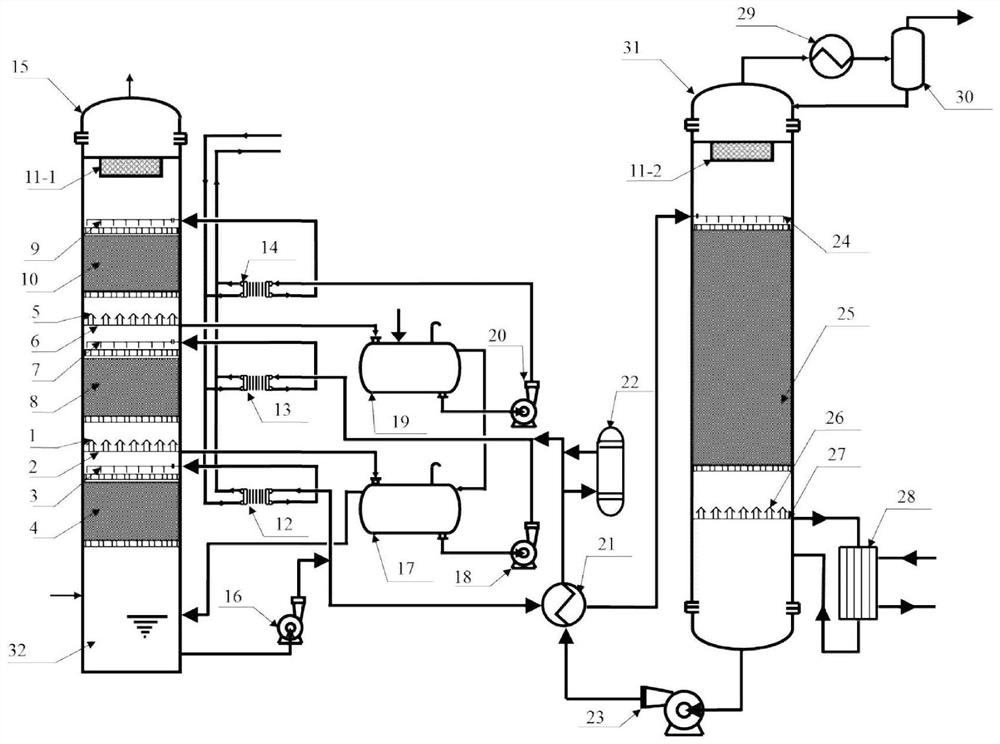

[0081] refer to figure 2 , a partitioned multistage cycle CO based on mass transfer-reaction regulation 2 Capture concentration method, using CO 2 capture concentration system, the CO 2 The capture and concentration system includes a multi-stage circulation absorption tower 15, a lean-rich liquid heat exchanger 21, a slurry cleaning device 22, a CO 2 Desorber 31 and CO 2 Concentration device.

[0082] The multi-stage circulation absorption tower 15 includes a CO 2 Absorption system, secondary CO 2 Absorption system and three-stage water washing system; primary CO 2 Absorption system, secondary CO 2 The absorption system and the three-stage water washing system are connected in series from bottom to top, and the first mist eliminator 11-1 is installed at the top of the multi-stage circulation absorption tower 15 .

[0083] Flue gas enters primary CO 2 The absorption system passes through a section of packing layer 4, a section of nozzle 3, the first separator 2 and th...

Embodiment 2

[0106] refer to Figure 5 , a partitioned multistage cycle CO based on mass transfer-reaction regulation 2 Capture concentration method, using CO 2 capture concentration system, the CO 2 The capture and concentration system includes a multi-stage circulation absorption tower 15, a lean-rich liquid heat exchanger 21, a slurry cleaning device 22, a CO 2 Desorber 31 and CO 2 Concentration device.

[0107] The multi-stage circulating absorption tower 15 includes a Venturi type pre-washing section 33, a primary CO 2 Absorption system, secondary CO 2 Absorption system and three-stage water washing system. Level 1 CO 2 Absorption system, secondary CO 2 The absorption system and the three-stage water washing system are connected in series from bottom to top, and the first mist eliminator 11 is arranged on the top of the multi-stage circulation absorption tower 15 .

[0108] The Venturi type pre-washing section 33 is arranged at the front of the multi-stage circulation absorpt...

Embodiment 3

[0119] refer to Figure 6 , a partitioned multistage cycle CO based on mass transfer-reaction regulation 2 Capture concentration method, using CO 2 capture concentration system, the CO 2 The capture and concentration system includes a multi-stage circulation absorption tower 15, a lean-rich liquid heat exchanger 21, a slurry cleaning device 22, a CO 2 Desorber 31 and CO 2 Concentration device.

[0120] The multi-stage circulating absorption tower 15 includes a Venturi type pre-washing section 33, a primary CO 2 Absorption system, secondary CO 2 Absorption system, tertiary CO 2 Absorption system and four-stage water washing system. Level 1 CO 2 Absorption system, secondary CO 2 Absorption system, tertiary CO 2 The absorption system and the four-stage water washing system are connected in series from bottom to top, and the first mist eliminator 11-1 is installed on the top of the multi-stage circulation absorption tower 15 .

[0121] The Venturi type pre-washing secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com