Flue gas pretreatment system for reducing coal-fired flue gas CO2 gathering energy consumption

A pretreatment, flue gas technology, applied in gas treatment, greenhouse gas reduction, combustion technology mitigation, etc., can solve problems such as increasing capture energy consumption, wasting energy, reducing absorbent capacity, etc., to reduce capture cost, improve the capture efficiency, and reduce the energy consumption of CO2 capture and regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

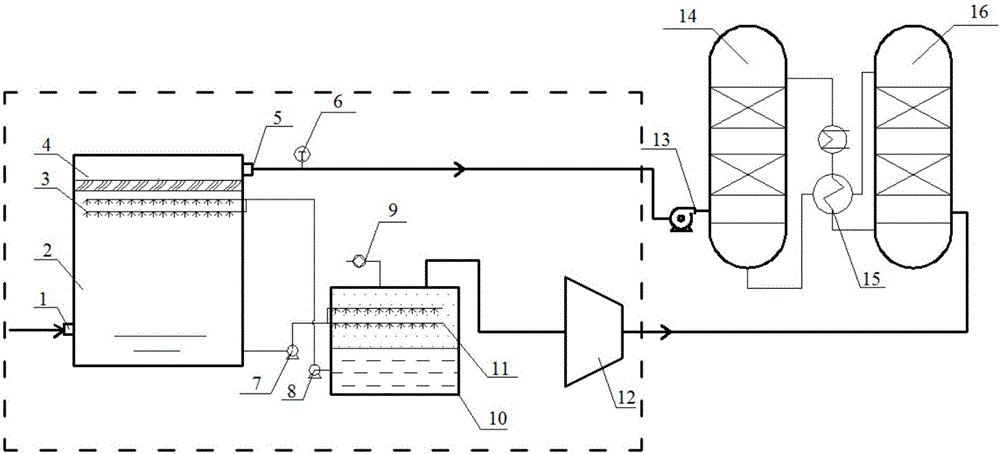

[0023] Embodiment: A method for reducing coal-fired flue gas CO 2 The flue gas pretreatment system that captures energy consumption, its structure is as follows figure 1 shown, including:

[0024] Direct contact heat exchanger 2, the lower left side of the heat exchanger 2 is the smoke inlet 1, the heat exchanger is equipped with a heat exchanger spray layer 3 and a demister 4, and the upper right side of the heat exchanger 2 has a smoke outlet 5 , the smoke outlet 5 passes through the flue and CO 2 The absorption tower 14 of the trapping device is connected, and a thermocouple 6 and a booster fan 13 are arranged on the flue behind the smoke outlet.

[0025] A vacuum flash device 10 and a vapor compression device 12 are arranged outside the heat exchanger 2 , and the bottom of the heat exchanger 2 communicates with the vacuum flash device 10 , vapor compression device 12 , and regeneration tower 16 sequentially through pipelines and a circulation pump 7 .

[0026] The vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com